Preparation method and application of water-soluble natural pigment microcapsule

A natural pigment, water-soluble technology, applied in natural dyes, chemical instruments and methods, azo dyes, etc., can solve the problems of losing color rendering ability, affecting color fastness, etc., and achieve energy saving, environmental protection, color fastness, and bright colors. , good weather resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

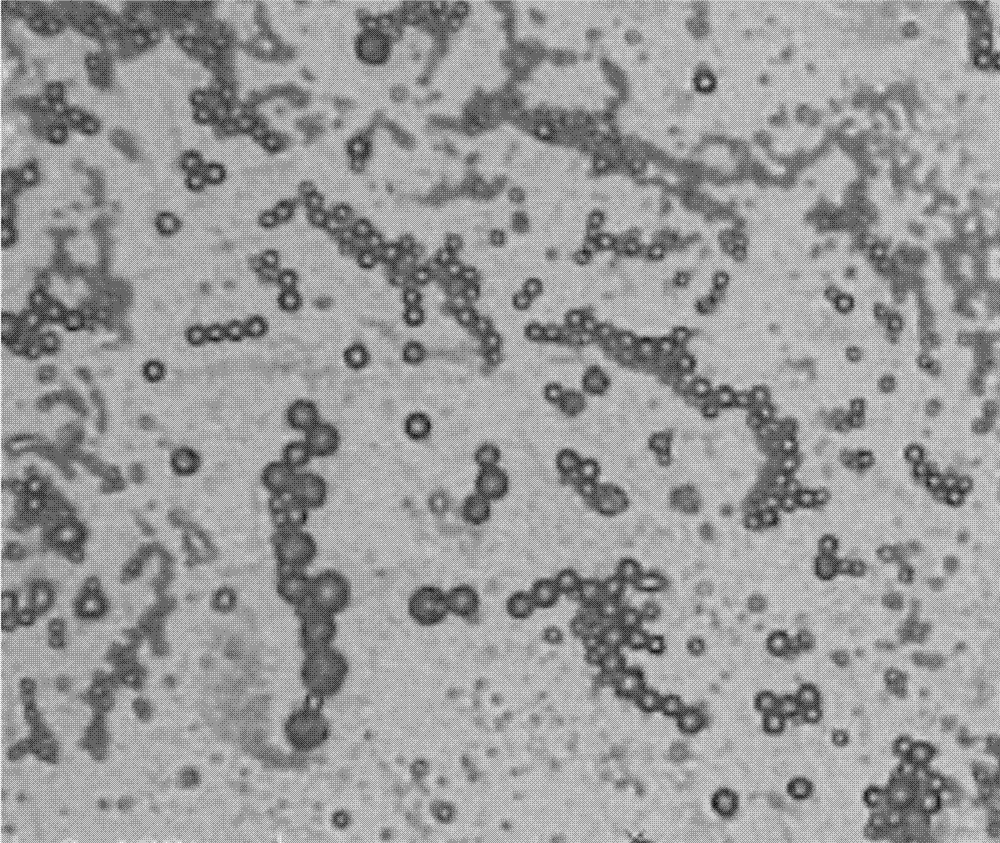

Image

Examples

Embodiment 1

[0025] A method for preparing water-soluble natural pigment microcapsules, comprising the following steps: adding 90mL of water, 1g of gardenia blue pigment, 0.6g of Span60, and 0.4g of Tween80 into a three-necked flask with a capacity of 250mL, heating up to 65°C at 400r / min Stir for 20 minutes to obtain a gardenia blue pigment microemulsion, add dropwise 4 g of methyl methacrylate, add 0.05 g of benzoyl peroxide, and react at a constant temperature of 80 ° C for 2 h. Then 1 g of acrylamide was added dropwise and reacted at a constant temperature of 80° C. for 3 hours to obtain gardenia blue pigment microcapsules with an average particle size of 6.331 μm.

Embodiment 2

[0027] A preparation method of water-soluble natural pigment microcapsules, comprising the following steps: adding 60mL of water, 2g of Suaeda sweet red pigment, 0.3g of Span60, 0.2g of Tween80 into a three-necked flask with a capacity of 250mL, heating up to 70°C at 500r / m Stir for 20 min to obtain Suaeda sweet red pigment microemulsion, add dropwise 4 g of methyl methacrylate, add 0.08 g of azobisisobutyronitrile, and react at a constant temperature of 85 ° C for 3 h. Add 2 g of acrylic acid dropwise, and react at a constant temperature of 85° C. for 3 hours to obtain Suaeda sweet red pigment microcapsules with an average particle size of 2.562 μm.

Embodiment 3

[0029] A method for preparing water-soluble natural pigment microcapsules, comprising the following steps: adding 80mL of water, 1.5g of chrysanthemum yellow, 0.6 span80 and 0.4 tween60 to a three-necked flask with a capacity of 250mL, heating up to 60°C and stirring at 600r / min for 10min To obtain a chrysanthemum yellow pigment microemulsion, add 4 g of methyl methacrylate dropwise, add 0.07 g of benzoyl peroxide, and react at a constant temperature of 80° C. for 2 h. Add 2 g of acrylic acid dropwise and react at a constant temperature of 80°C for 2 hours to obtain chrysanthemum yellow pigment microcapsules with an average particle size of 1.164 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com