Preparation of graphene/manganese oxide flexible electrode for super capacitor by employing laser one-step method

A supercapacitor, manganese oxide flexible technology, applied in the field of electrochemistry, can solve problems such as waste of raw materials, complicated process, and environmental pollution by waste materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

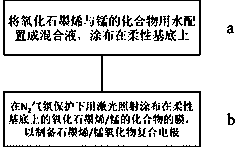

Method used

Image

Examples

Embodiment 1

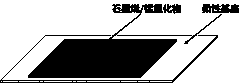

[0039] Graphene oxide (GO) was prepared by the improved Hummer method, taking 0.1g of GO, MnSO 40.2g, add distilled water, mix and stir to obtain a mixed solution;

[0040] Apply the obtained mixed solution evenly on the PET film, and dry it to obtain the electrode precursor;

[0041] N at a flow rate of 1 l / min 2 In the atmosphere, use a laser with a power of 300mW and a scan rate of 8 cm / s for irradiation reduction. The laser irradiation route can be set according to the needs. When GO is reduced by laser irradiation, MnSO 4 It is decomposed into manganese oxide to obtain graphene / manganese oxide flexible electrode;

Embodiment 2

[0043] GO was prepared by the improved Hummer method, GO 0.1g, MnCO 3 0.3g, added into distilled water, mixed and stirred to obtain a mixed solution;

[0044] Apply the obtained mixed solution evenly on the polyimide (PI) film, and dry it to obtain the electrode precursor;

[0045] N at a flow rate of 0.5 l / min 2 Under the atmosphere, use a laser with a power of 200mW and a scan rate of 6 cm / s for irradiation reduction. The laser irradiation route can be set according to the needs. When GO is reduced by laser irradiation, MnCO 3 It is decomposed into manganese oxide to obtain graphene / manganese oxide flexible electrode;

Embodiment 3

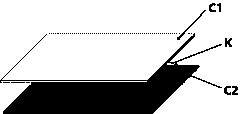

[0047] Positive and negative electrodes all adopt the graphene / manganese oxide flexible electrode that obtains in embodiment 1, use Na 2 SO 4 / Smoked silica gel is used as the electrolyte and packaged to obtain a symmetrical supercapacitor. Such as image 3 As shown, the graphene / manganese oxide supercapacitor includes: graphene / manganese oxide C1 and C2 (ie, the graphene / manganese oxide electrode obtained in Example 1); package K, and electrolyte solution (not shown).

[0048] Among them, the graphene / manganese oxide electrodes C1 and C2 are the graphene / manganese oxide electrodes obtained in Example 1, filled with Na2SO4 / smoked silica gel electrolyte (not shown) in the middle, and the electrolyte naturally isolates the electrodes in space, thereby omitting Diaphragm part of a conventional supercapacitor.

[0049] image 3 The K packaging material (light-curing glue) shown in , cures and encapsulates the graphene / manganese oxide electrodes C1 and C2, thereby forming a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com