Method for improving quality of perovskite thin film through solvent bath assisted heat treatment

A perovskite and thin-film technology, applied in coatings, photovoltaic power generation, electrical components, etc., can solve problems that restrict the promotion and application of heat treatment methods, difficult control of steam concentration, decomposition of perovskite materials, etc., and achieve heat treatment process optimization, Effect of improving crystal quality, reducing surface defects and component segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0031]The concentrations of cesium iodide, formamidine iodide, methylamine bromide, lead bromide and lead iodide were respectively 0.07mol / L, 1.19mol / L, 0.21mol / L, 0.21mol / L and 1.29mol / L It is dissolved in a mixed solvent of dimethylformamide and dimethyl sulfoxide, and the volume ratio of the two solvents is 4:1. After stirring and dissolving, take 50 μL of perovskite solution and drop it evenly on the pre-deposited SnO 2 The transparent conductive glass surface of the electron transport layer was spin-coated at a speed of 5000 rpm for 30 seconds, and 100 μL of chlorobenzene was rapidly added 15 seconds before the end of the final spin-coating. After spin-coating, the glass sheet was placed on a heating table at 100°C for 30 minutes to obtain a perovskite film.

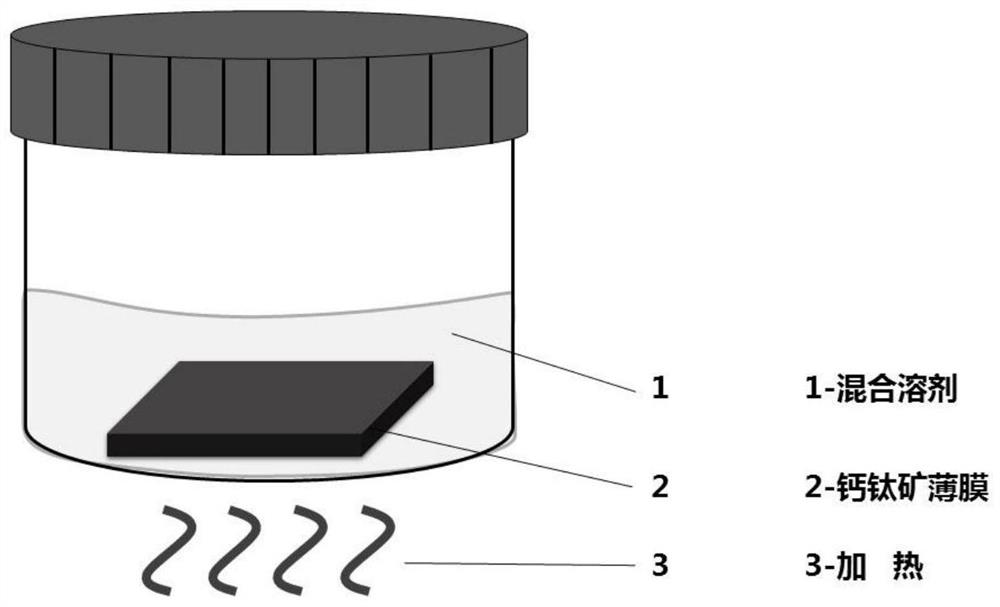

[0032] A mixed solvent of chlorobenzene and dimethylformamide was prepared, wherein the volume content of dimethylformamide was 1%, and it was stored in an open container with a lid. The perovskite film prepared b...

Embodiment 2

[0036] Both methylamine iodide and lead iodide were dissolved in a mixed solvent of dimethyl sulfoxide and γ-butyrolactone at a concentration of 1.3 mol / L, and the volume ratio of the two solvents was 3:7. After stirring and dissolving, take 40uL perovskite solution and drop it evenly on the pre-deposited SnO 2 The transparent conductive glass surface of the electron transport layer was spin-coated at a speed of 5000 rpm for 30 seconds, and 200 uL of toluene was rapidly added 15 seconds before the end of the final spin-coating. After spin coating, place the glass slide on a heating table at 100 °C for 40 min to obtain MAPbI 3 Perovskite thin films.

[0037] A mixed solvent of toluene and acetonitrile was prepared, wherein the volume content of acetonitrile was 2%, and it was stored in an open container with a lid. The perovskite film prepared by the above method is immersed in the prepared mixed solvent, so that the mixed solvent completely immerses the surface of the perovs...

Embodiment 3

[0039] The cesium iodide, lead bromide and lead iodide were dissolved into the dimethyl sulfoxide solution at the concentrations of 0.6 mol / L, 0.6 mol / L and 1.2 mol / L, respectively. After stirring and dissolving at 60 °C, 40uL of perovskite solution was taken and dropped evenly on the pre-deposited SnO. 2 The transparent conductive glass surface of the electron transport layer was spin-coated at 500 rpm and 2500 rpm for 3 s and 30 s, respectively. After spin-coating, heating at 42 °C for 4 min and 160 °C for 30 min was continuously performed to obtain CsPbI. 2 Br perovskite thin films.

[0040] A mixed solvent of diethyl ether and dimethyl sulfoxide is prepared, wherein the volume content of dimethyl sulfoxide is 0.5%, and it is stored in an open container with a lid. The perovskite film prepared by the above method is immersed in the prepared mixed solvent, so that the mixed solvent completely immerses the surface of the perovskite film, and then the open container is tight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com