Method for preparing super hydrophobic magnetic wood surface and wood

A technology for superhydrophobic surface and magnetic wood, which is applied to the preparation of superhydrophobic magnetotropic wood surface, method and wood field, can solve problems such as restricting application, and achieve the effects of easy operation and control, improving use value, and preventing weather resistance deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

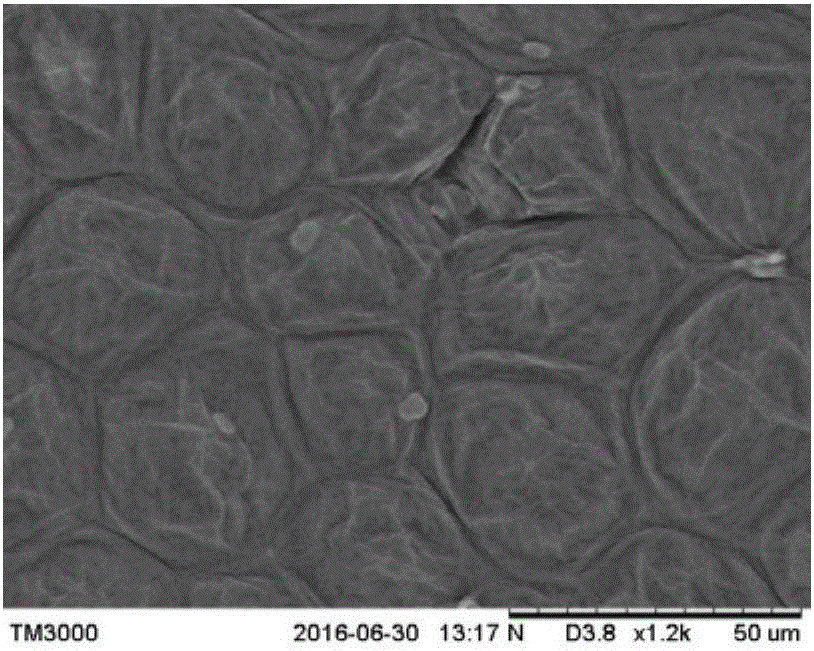

Image

Examples

Embodiment 1

[0044] The invention provides a kind of method for preparing superhydrophobic magnetotropic wood surface, comprises the following steps:

[0045] S101: Mix polydimethylsiloxane and Sylgard 184 uniformly at a weight ratio of 10:1 to form the first mixture; polydimethylsiloxane and Fe with a particle size of 30nm-60nm 3 o 4 Mix at a weight ratio of 10:10, and stir at -100° C. for 50 h to form a second mixture.

[0046] S102: intercepting the surface of the lotus leaf of 5 cm×5 cm, cleaning the surface with ethanol and drying it, fixing the dried lotus leaf on a glass slide, and then coating the first mixture on the surface of the lotus leaf fixed on the glass slide, Form the first mixture layer of 3 mm on the lotus leaf surface after drying.

[0047] S103: Curing the product obtained in S102 at 25°C for 5 hours, then infiltrating the cured product with heptadecafluorodecyltriethoxysilane at 100°C for 5 hours, and then peeling and removing the lotus leaves to obtain the first m...

Embodiment 2

[0052] The invention provides a kind of method for preparing superhydrophobic magnetotropic wood surface, comprises the following steps:

[0053] S101: Mix polydimethylsiloxane and Sylgard 184 uniformly in a weight ratio of 8:1 to form the first mixture; polydimethylsiloxane and CoFe with a particle size of 1nm-100nm 2 o 4 Mix at a weight ratio of 10:0.5, and stir at 0° C. for 30 h to form a second mixture.

[0054] S102: intercept taro leaves of 3cm×3cm, wash the surface with ethanol and then dry them, fix the dried taro leaves on a glass slide, and then coat the first mixture on the surface of the taro leaves fixed on the glass slides, Form the first mixture layer of 2mm on the taro leaf surface after drying.

[0055] S103: curing the product obtained in S102 at 100°C for 3 hours, then infiltrating the cured product with heptadecafluorodecyltriethoxysilane at 130°C for 3 hours, and then peeling and removing the taro leaves to obtain the first mixture layer; , the face tha...

Embodiment 3

[0059] The invention provides a kind of method for preparing superhydrophobic magnetotropic wood surface, comprises the following steps:

[0060] S101: Mix polydimethylsiloxane and Sylgard 184 uniformly in a weight ratio of 15:1 to form the first mixture; polydimethylsiloxane and MnFe with a particle size of 20nm-80nm 2 o 4 Mix at a weight ratio of 10:5, and stir at 100° C. for 0.01 h to form a second mixture.

[0061] S102: Cut rose petals of 3cm×3cm, wash the surface with ethanol and dry them, fix the dried rose petals on a glass slide, and then coat the surface of the rose petals fixed on the glass slide with the first The mixture forms a first mixture layer of 5 mm on the surface of the dried rose petals.

[0062] S103: curing the product obtained in S102 at 150° C. for 1 hour, then infiltrating the cured product with heptadecafluorodecyltriethoxysilane at 60° C. for 7 hours, and then peeling and removing rose petals to obtain a first mixture layer; Wherein, the surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com