Automatic microweighing system and method

A micro-weighing and automatic technology, which is applied in the direction of weighing, measuring devices, and weighing equipment with special properties/forms, etc., can solve problems that are difficult to achieve, difficult to promote, and expensive, and achieve convenient operation, The effect of reducing manpower input and improving weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and embodiments. The technical features of the various implementations in the present invention can be combined accordingly on the premise that there is no conflict with each other.

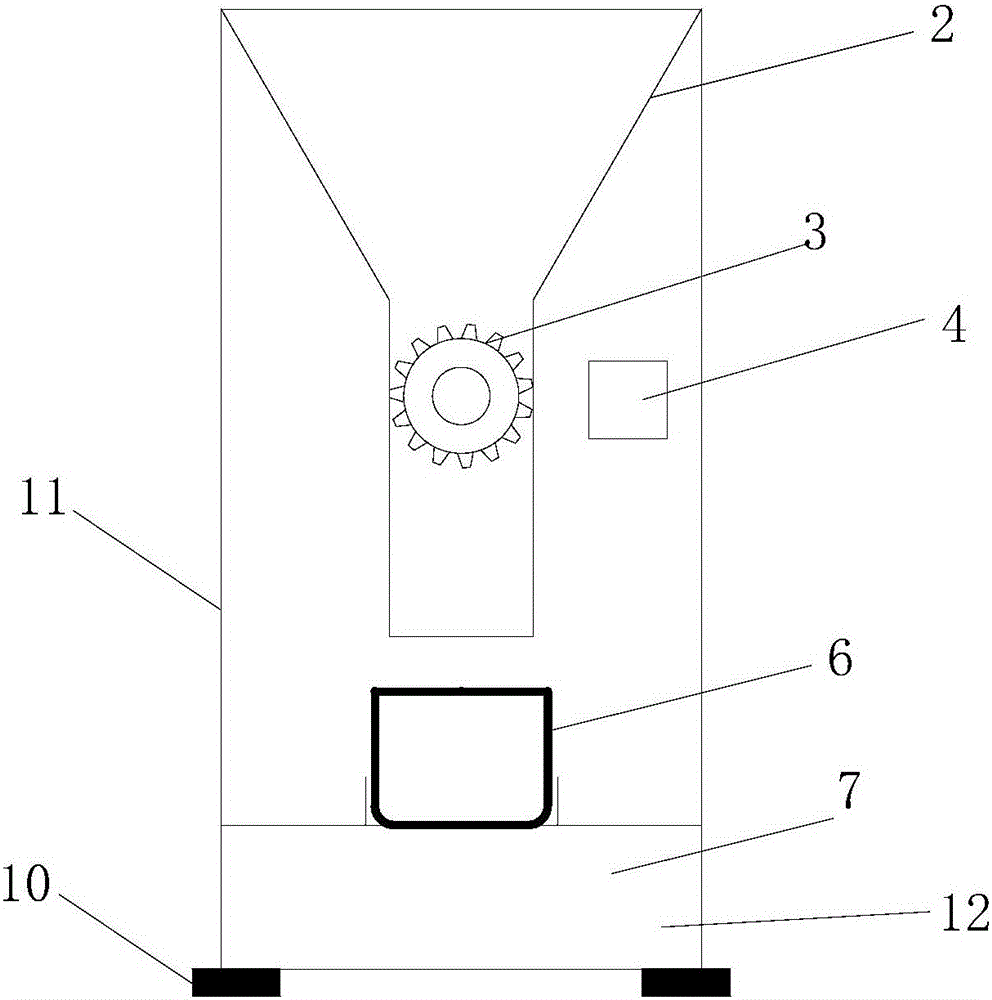

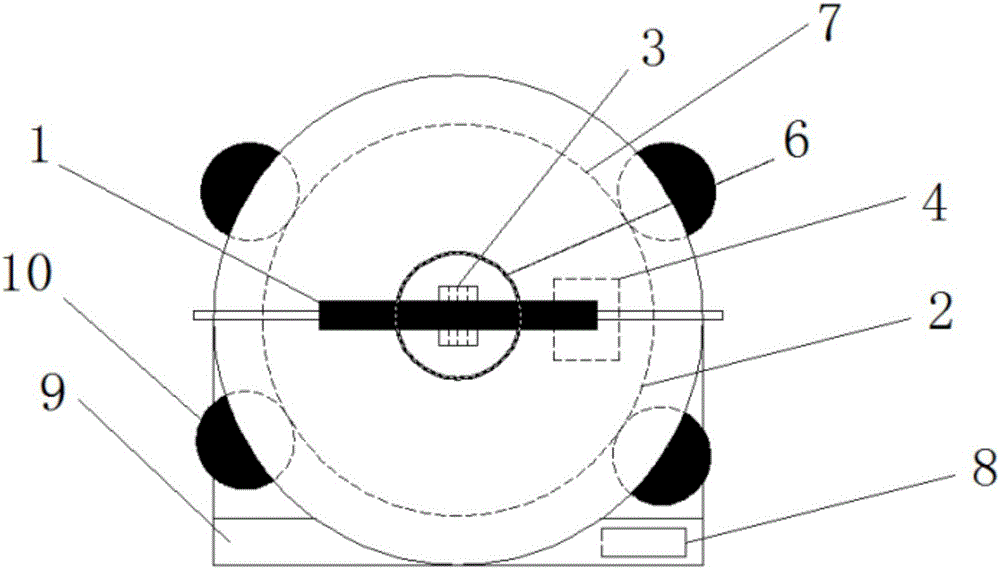

[0022] The working principle of the automatic control micro-weighing system and method of the present invention is: the diameter of the gear is tangent to the lower part of the funnel, when the gear is stationary, the sample will be stored in the funnel; when the gear starts to rotate, the sample will pass through the gear The gap between the gears enters the sample cup, and by controlling the rotation state and static state of the gear, the precision requirement of sample micro-weighing is realized; the rotation state or static state of the gear is controlled by the controller to realize the micro control and precision control. automation.

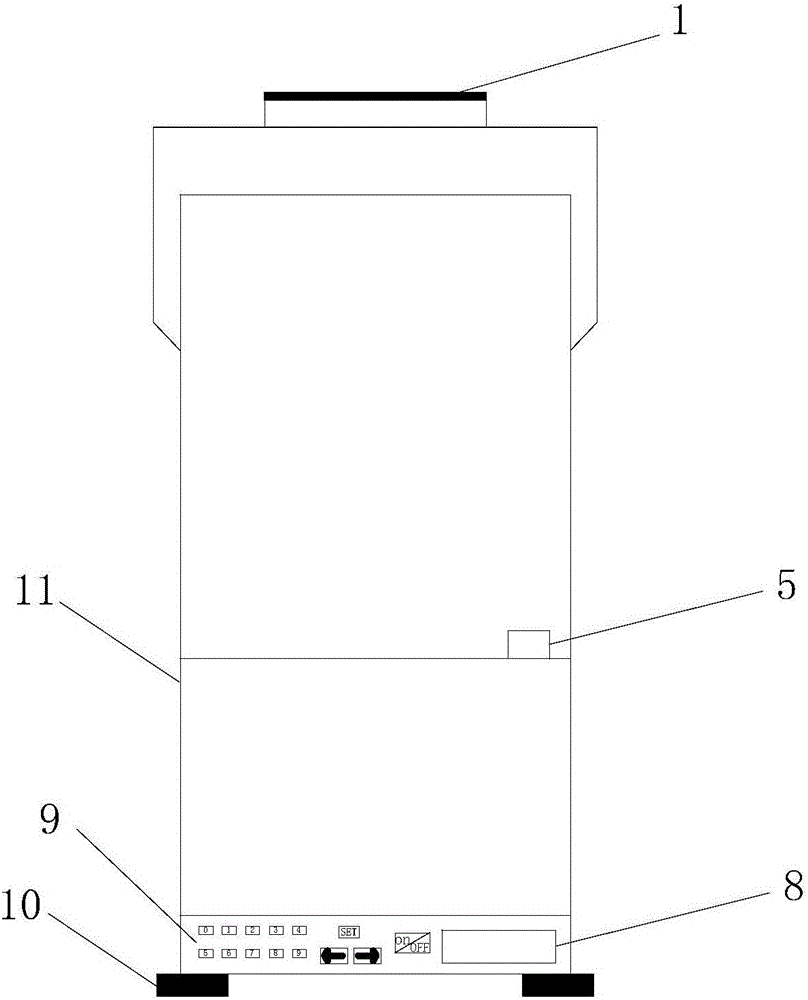

[0023] Such as figure 1 and 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com