Batching system of concrete mixing plant

A technology of batching system and batching plant, applied in the field of batching system of concrete batching station, can solve problems such as trouble, affect production efficiency, inability to distinguish weighing, etc., and achieve the effects of improving weighing accuracy, promoting production efficiency and shortening weighing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

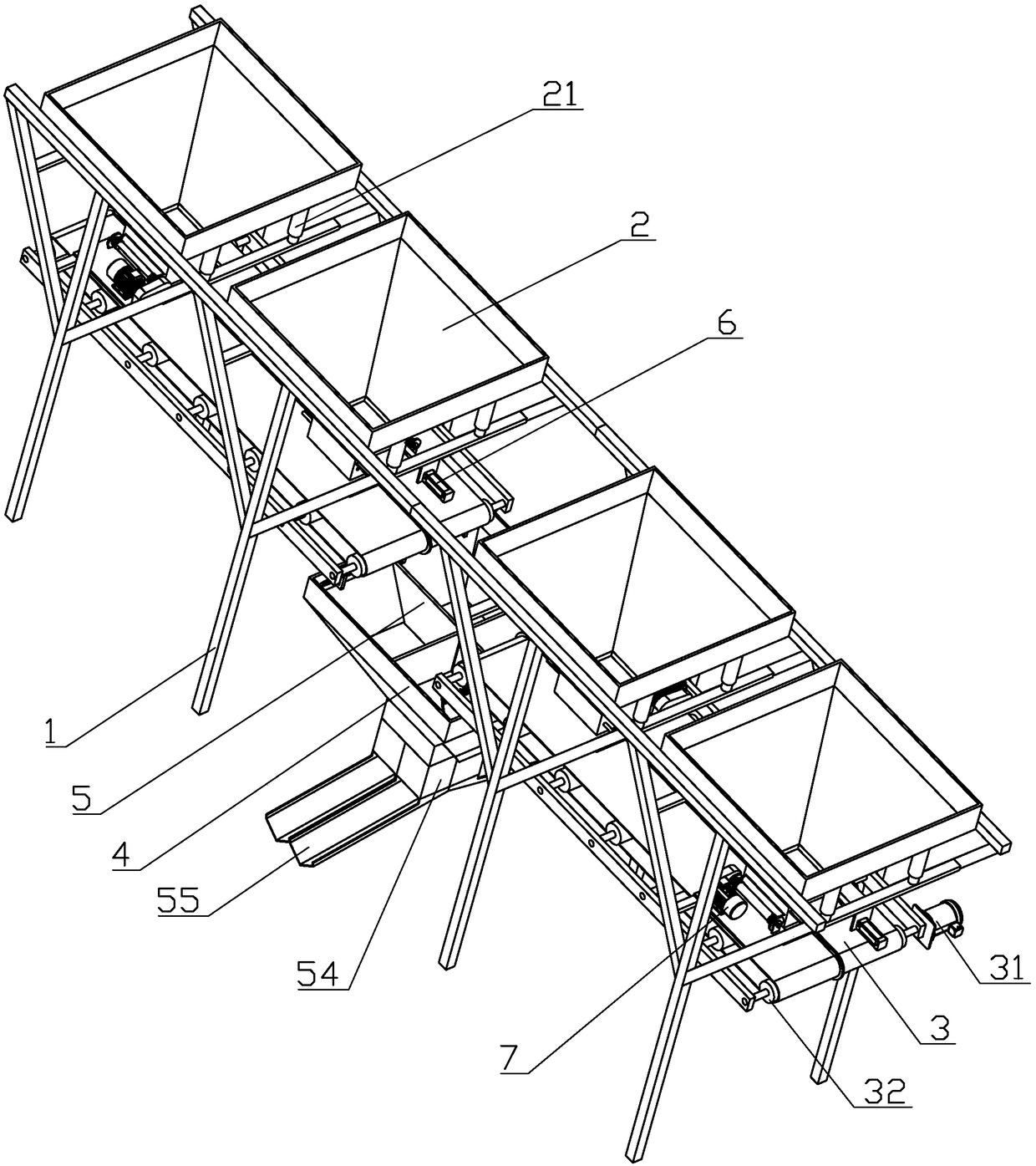

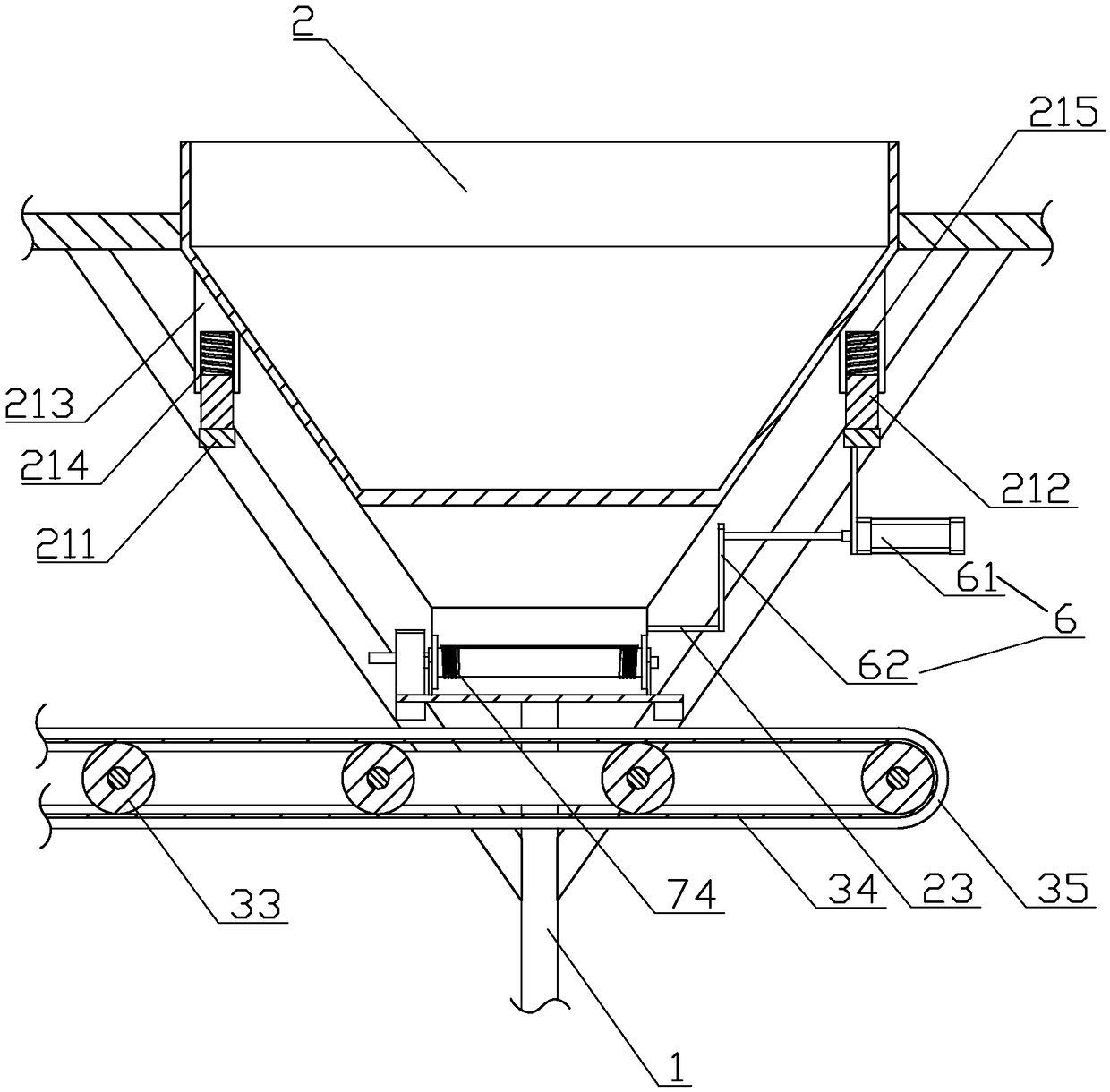

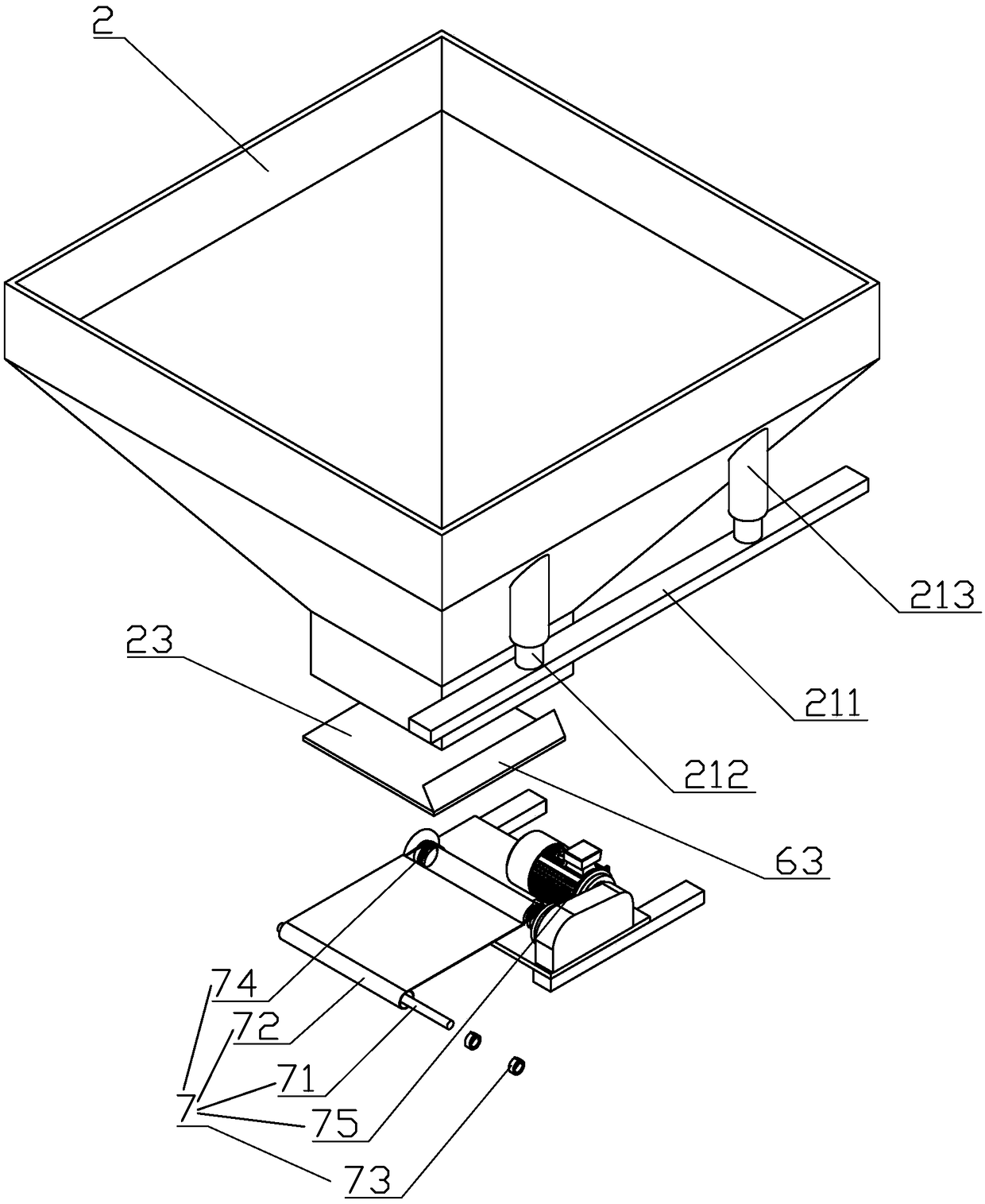

[0038] Such as figure 1 As shown, a batching system for a concrete mixing plant includes a frame 1 on which four feed hoppers 2 and a weighing hopper 4 are installed. The feed hopper 2 is funnel-shaped, and is installed on the top of the frame 1 through a support assembly 21 , and four feed hoppers 2 are distributed on both sides of the frame 1 in pairs. combine figure 2 As shown, the support assembly 21 includes a cross bar 211, a support rod 212, a connecting seat 213 and a buffer spring 215. The cross bar 211 is a cylindrical rod-shaped structure, and the two ends of the cross bar 211 are respectively connected to the frame 1 on both sides of the feed hopper 2. fixed. The support rods 212 are fixed on the cross bars 211 , and two support rods 212 are fixed on each cross bar 211 . The connection seat 213 is fixed on the outer wall of the feed hopper 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com