Weighing method applied to non-sensor pulsator washing machine

A pulsator washing machine, washing machine technology, applied in the control device of washing machine, other washing machines, applications, etc., can solve the problems of inaccurate setting of washing machine water level, waste of water resources, wear and tear of clothes, etc., to shorten the time required for weighing, The effect of saving material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to easily understand the technical means, creative features, goals and effects of the present invention, the present invention will be further described below in conjunction with specific illustrations.

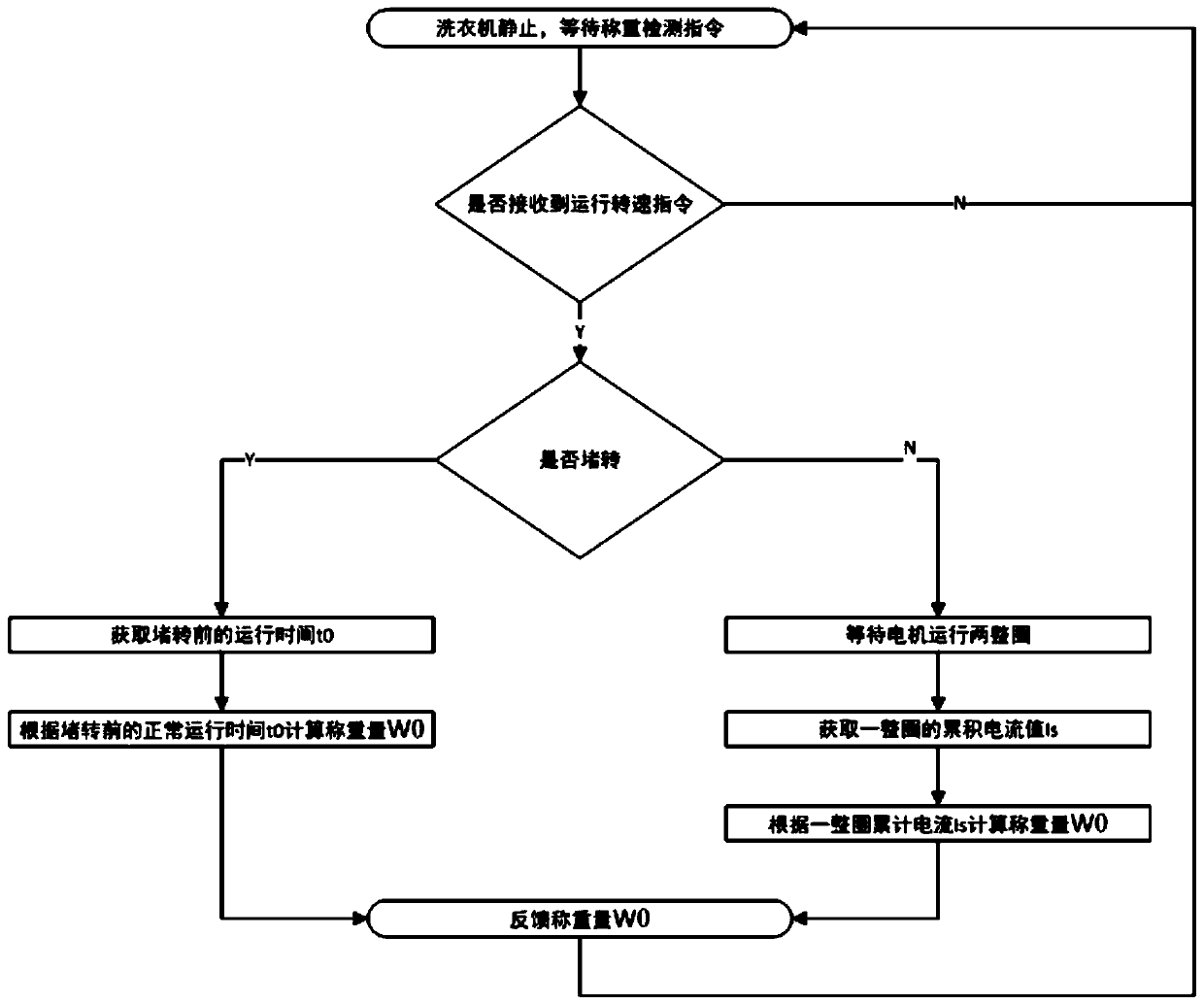

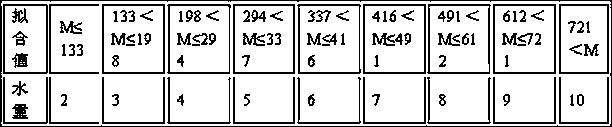

[0028] Such as figure 1 As shown, a weighing method applied to a sensorless pulsator washing machine. The pulsator washing machine includes a motor for driving the inner cylinder to rotate and an upper computer MCU electrically connected to the motor. The pulsator washing machine rotates without water before washing For two full circles, use the upper computer MCU to obtain the magnitude of the motor phase current, and calculate the cumulative current value Is of the motor for one full circle. The cumulative current value Is of the motor is calculated by a fitting formula. The upper computer MCU stores The corresponding relationship between each fitting value and the corresponding weighing weight. The pulsator washing machine determines the weighing weight of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com