Semi-worsted cashmere piece-making machine

A sliver-making and semi-worsted technology, applied in textiles and papermaking, deburring devices, fiber processing, etc., can solve the problem that the quality of subsequent products cannot meet the technical requirements of textile technology and market needs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

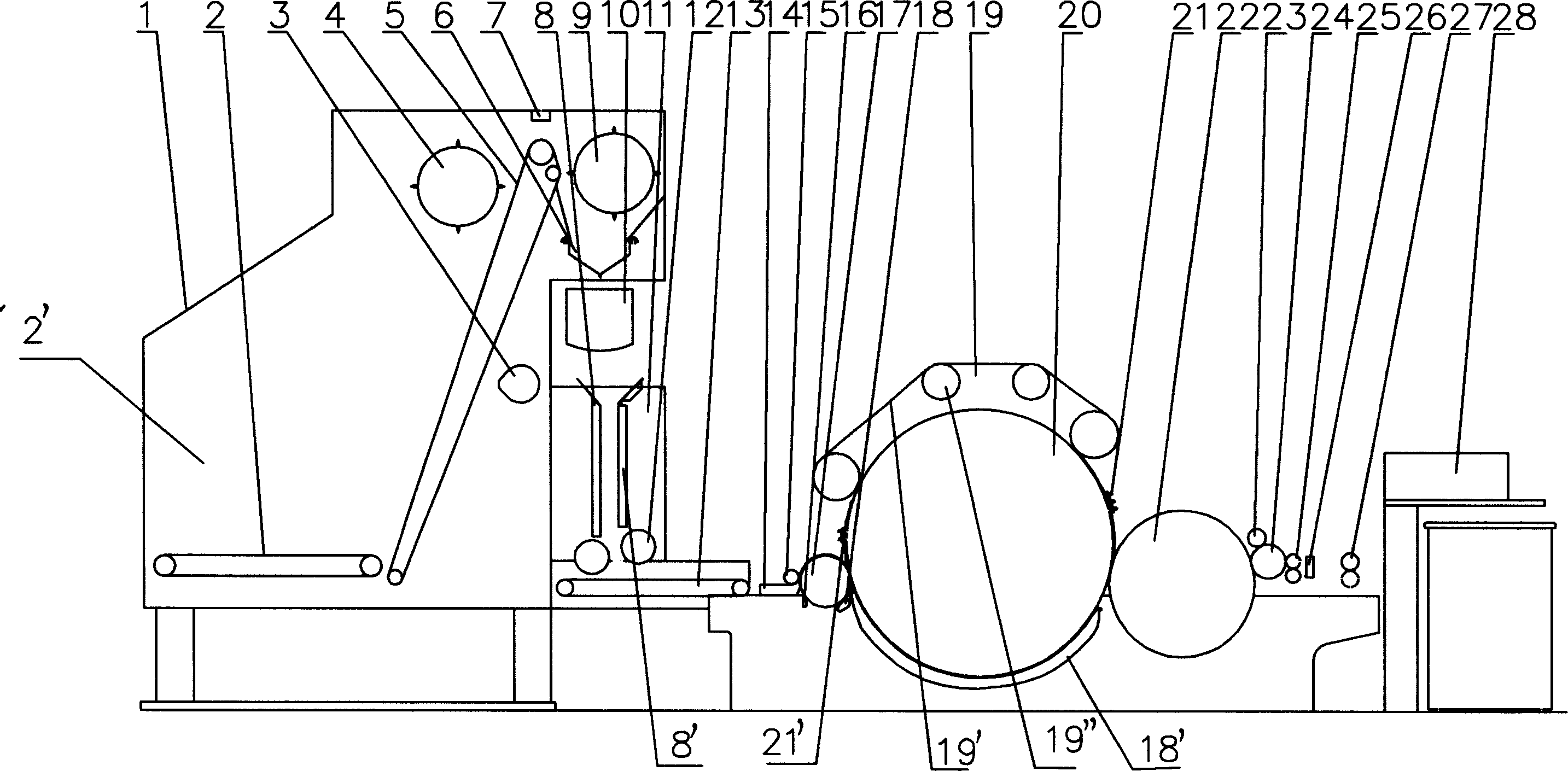

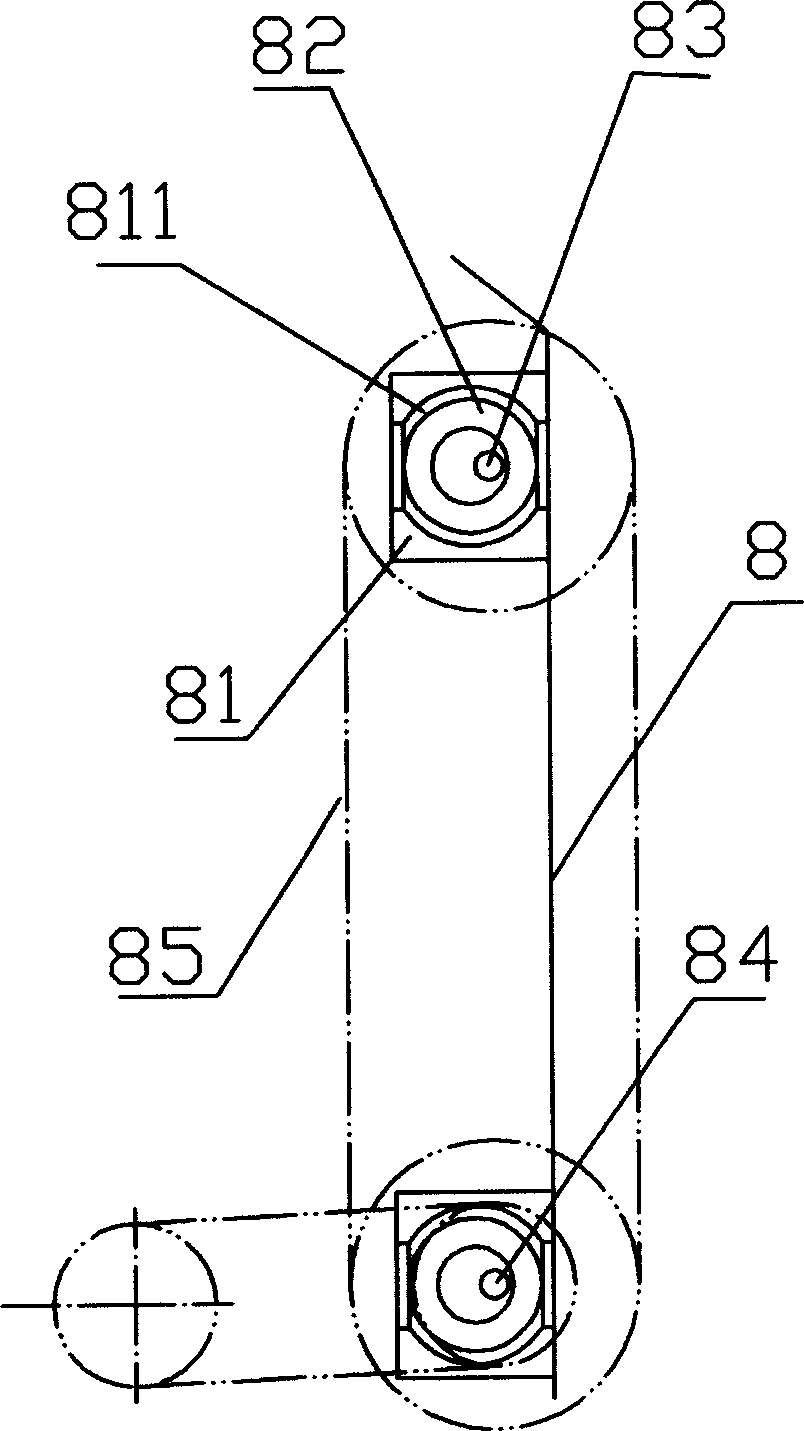

[0016] Referring to the accompanying drawings, the semi-worsted cashmere sliver making machine of the present invention, its feeding unit can adopt the following technical methods, the casing 1 of the feeding unit mainly contains raw material wool fiber storage chamber 2 ', volume chamber 11, in the storage A bottom flat curtain 2 and an oblique nail curtain 5 are arranged between the chamber 2' and the volume chamber 11, and the upper front side of the oblique nail curtain and the upper part of the oblique nail curtain are respectively provided with a hair equalizing roller 4 and a magnetic steel 7, and the upper rear side of the oblique nail curtain 5 is arranged Hair stripping roller 9, a vertical fixed plate 8 ' and a vertical vibrating plate 8 are set in the volume chamber 11, between the vertical vibrating plate 8 and the fixed plate 8 ' is the passage cavity for wool fiber, the fixed plate 8 ' and the vibrating plate 8. Either or all of them are provided with ventilation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com