Large bearing testing machine

A bearing test, large-scale technology, applied in the direction of mechanical bearing test, power measurement, measuring device, etc., can solve the problems of single function, large volume, high cost, and achieve the effect of good structure rigidity, reasonable structure layout and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

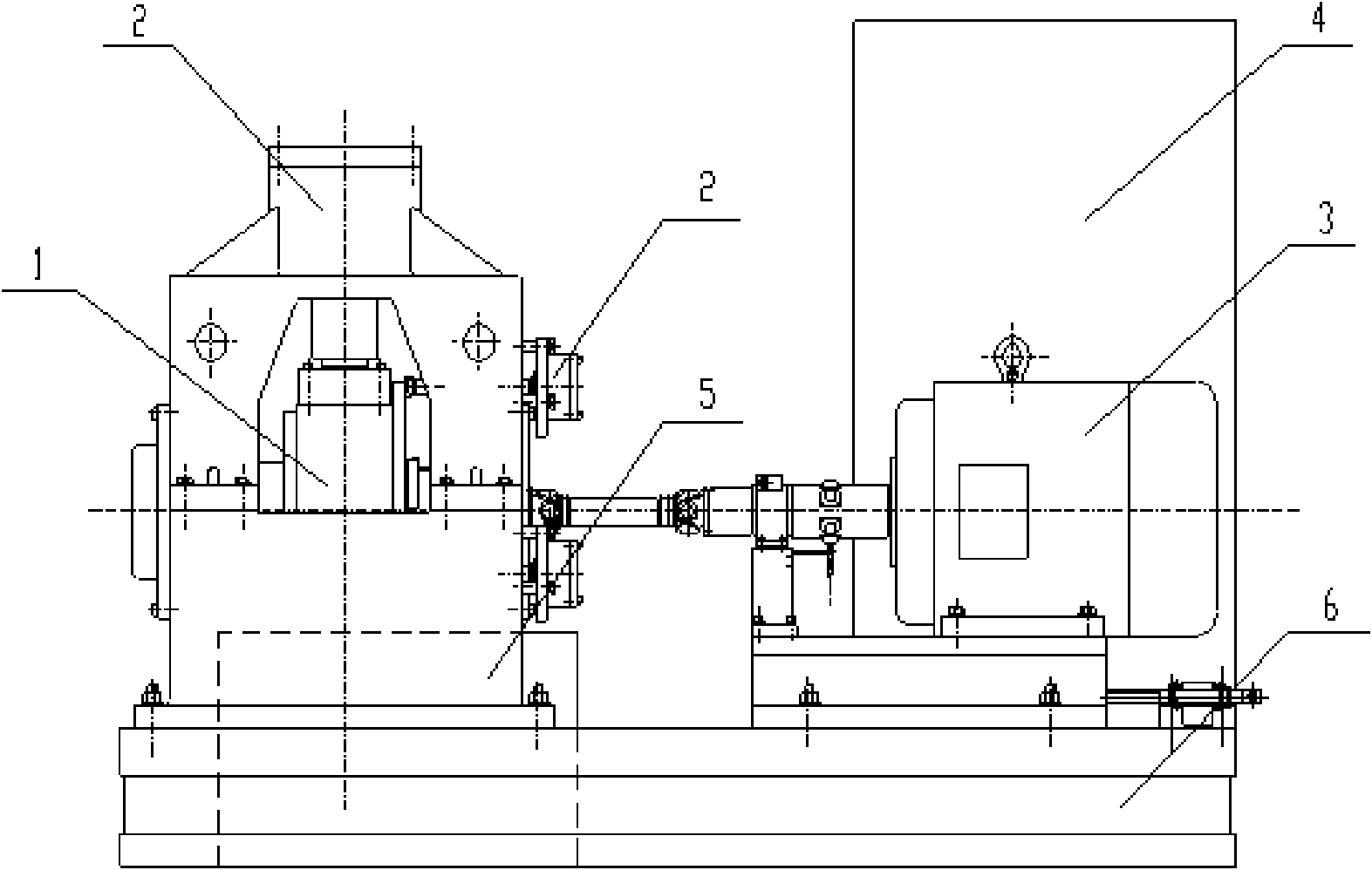

[0032] Such as figure 1 As shown, the large-scale bearing multifunctional testing machine is composed of a test unit 1, a loading unit 2, a drive unit 3, a control unit 4, a hydraulic power unit 5 and a workbench 6. The test unit 1 , the loading unit 2 , the driving unit 3 and the control unit 4 are installed on the workbench 6 , and the hydraulic power unit 5 is placed behind the workbench 6 and connected to the loading unit 2 . The test unit 1 installs the large bearing for the test, the loading unit 2 applies radial load, axial load and overturning moment to the test bearing, the drive unit 3 drives the test bearing to rotate at a specified speed and torque, and the control unit 4 controls the electrical operation and protection , Monito...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com