Qualitative detection method for cold roller surface micro linear defect

A linear defect, cold roll technology, used in optical testing flaws/defects, preparation of samples for testing, analysis of solids using sonic/ultrasonic/infrasonic waves, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The qualitative detection method of the micro linear defect on the cold roll surface of the present invention comprises the following steps:

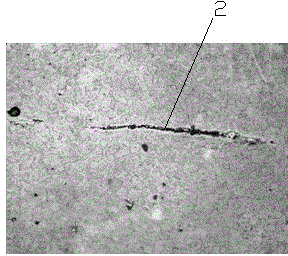

[0017] Step 1. Conduct ultrasonic surface wave detection on the surface of the cold roll, conduct magnetic particle inspection on the abnormal parts detected by ultrasonic surface wave, perform macroscopic observation on the microscopic parts of the small magnetic marks after magnetic particle inspection, and observe the microscopic parts of the small magnetic marks. Macroscopic morphology of tiny linear defects;

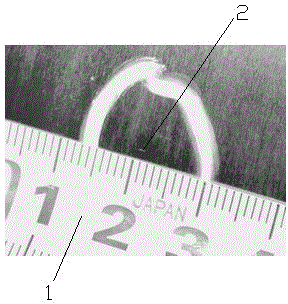

[0018] Step 2. For small linear defects of 0.2-2mm, use the metallographic defect positioning scale to locate the defect parts displayed by the magnetic particle flaw detection;

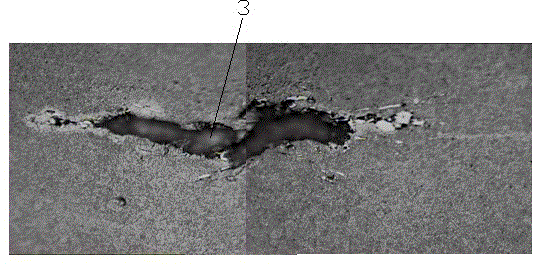

[0019] Step 3: Carry out on-site metallographic sample preparation on the linear defects of the cold roll, use sandpaper for rough grinding, fine grinding, polishing and corrosion, then copy the linear defects and the morphology of the tissue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com