Synchrotron radiation in-situ imaging fatigue testing machine comprising temperature control mechanism and testing method of synchrotron radiation in-situ imaging fatigue testing machine

A technology of fatigue testing machine and temperature control mechanism, applied in the field of fatigue testing machine, can solve the problems of structural collapse, unpredictable and controllable cold brittle failure of components, and high hazard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

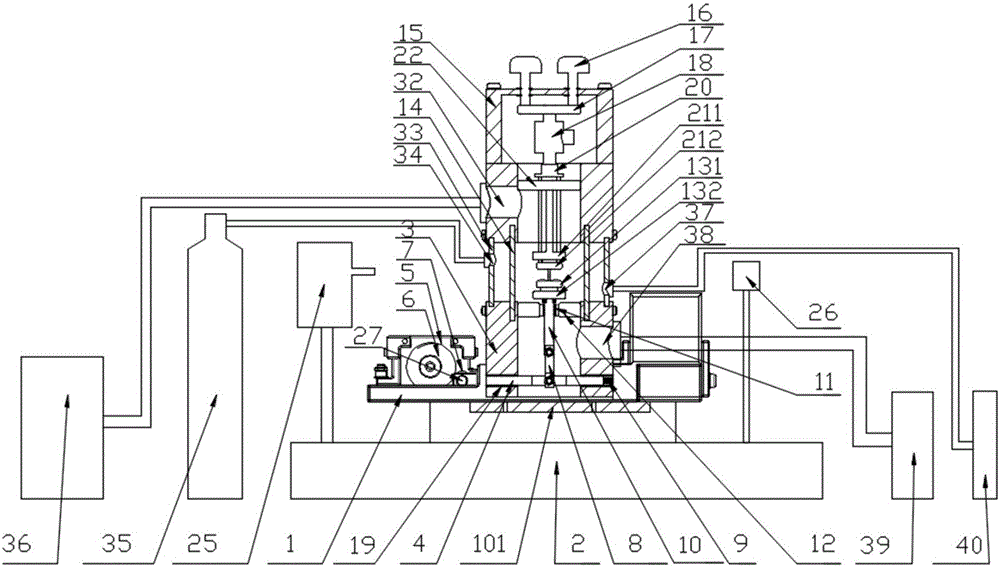

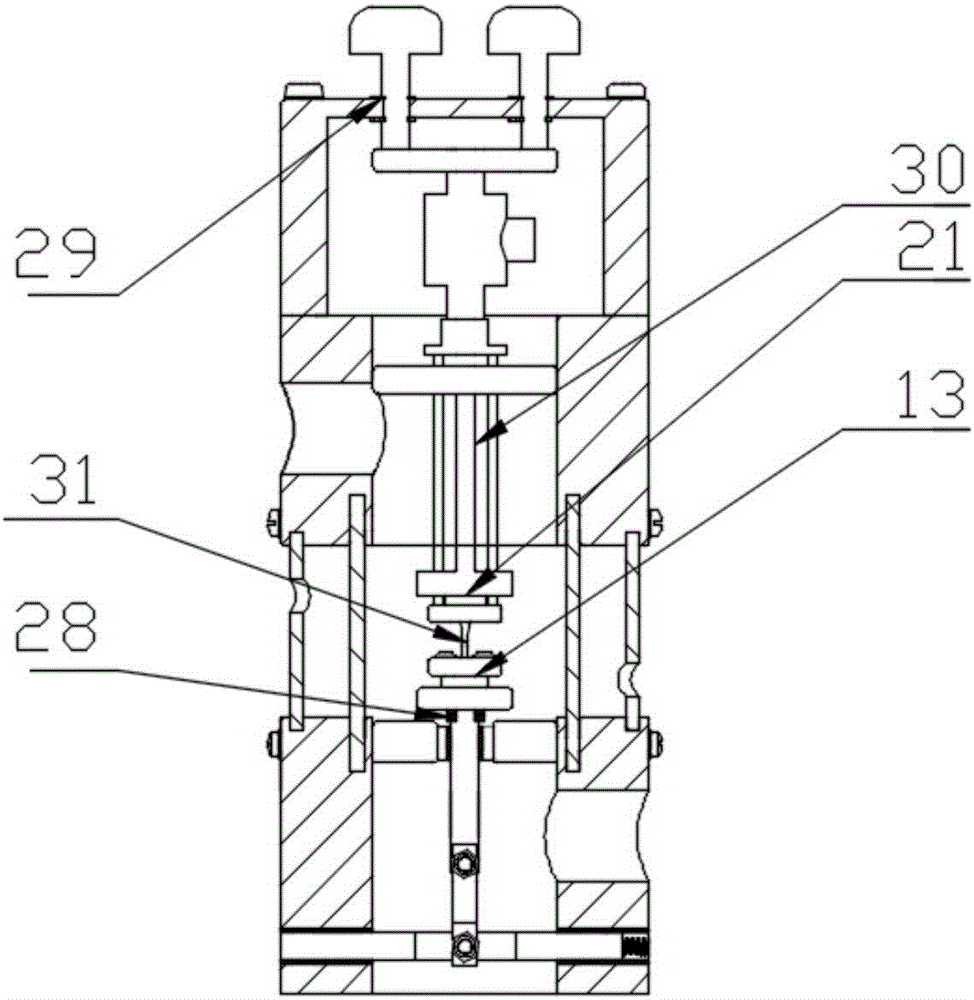

[0022] A synchrotron radiation in-situ imaging fatigue testing machine with a temperature control mechanism, comprising a bottom plate 1, the bottom plate cross 101 of the bottom plate 1 is fitted on the synchrotron radiation light source platform 2, and the middle part of the upper surface of the bottom plate 1 is fixed with a barrel-shaped base 3 , the push rod 4 is installed on the left wall and the right wall of the base 3 through the second horizontal linear bearing 19 . A servo motor 5 is installed on the left side of the upper surface of the base plate 1, and a cam 6 is installed on the shaft of the servo motor 5. The left end of the push rod 4 stretches out from the base 3 and contacts the right edge of the cam 6. The lower end is hinged, and the right end of the push rod 4 is connected to the right wall of the base 3 by a spring 9 .

[0023] It also includes a clamping mechanism and a temperature control mechanism.

[0024] The clamping mechanism includes a sample cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com