Corrosive agent for Nb - Si material microstructure specimens and an electrolyte corrosion technique

A technology of microstructure and corrosive agent, which is applied in the field of metallographic analysis in physical metallurgy, can solve the problems of waste of manpower and material resources, inability to distinguish alloys well, restrictions, etc., and achieve the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Prepare the Nb-Si series material microstructure sample according to the following steps:

[0023] 1) Corrosive agent configuration: measure 1ml H with graduated cylinder 3 PO4 and 99ml H 2 O, first the measured H 2 O was placed in a glass beaker, and then the measured H 3 Pour PO4 into the beaker and stir with a glass rod for about 30s;

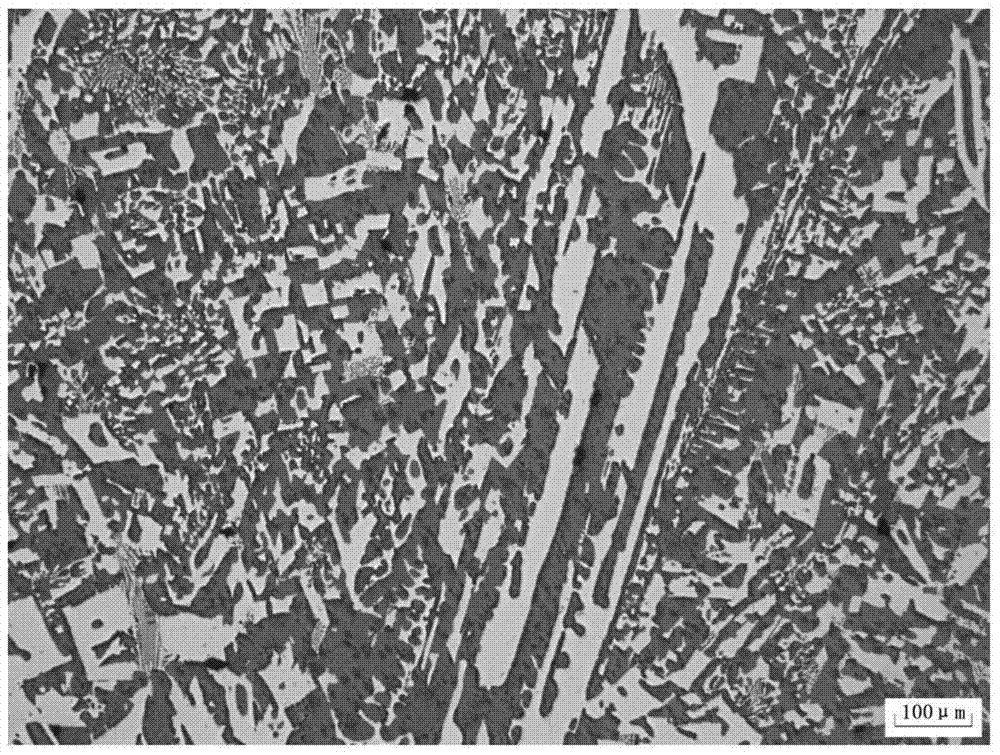

[0024] 2) Polish the Nb-22Ti-16Si-3Cr-3Al-2Hf material sample prepared by vacuum non-consumable arc melting, and connect it to a DC power supply XD173A-120 with a rated working voltage of 120V and a rated working current of 3A through a wire The anode of the stainless steel plate is connected to the cathode of the power supply through a wire, and the polished surface of the Nb-22Ti-16Si-3Cr-3Al-2Hf sample is kept opposite to the stainless steel plate, but cannot be contacted;

[0025] 3) Turn on the switch of the DC power supply, quickly adjust the voltage to 80V, observe the change of the current, and turn off the DC power switch...

Embodiment 2

[0029] Prepare the Nb-Si series material microstructure sample according to the following steps:

[0030] 1) Corrosive agent configuration: measure 1ml H with graduated cylinder 3 PO4 and 99ml H 2 O, first the measured H 2 O was placed in a glass beaker, and then the measured H 3 Pour PO4 into the beaker and stir with a glass rod for about 30s;

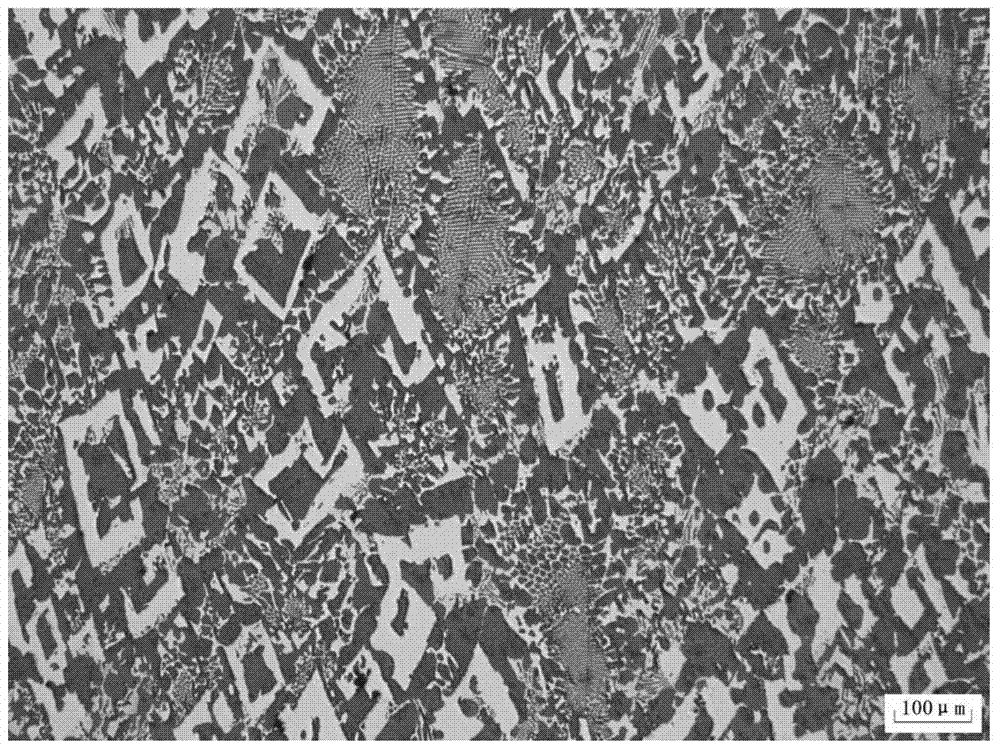

[0031] 2) Polish the crystallization front sample of Nb-20Ti-16Si-3Cr-3Al-2Hf material directional solidified in an electromagnetic cold crucible, and connect it to the DC power supply XD173A-120 with a rated working voltage of 120V and a rated working current of 3A through a wire Anode, the stainless steel plate is connected to the cathode of the power supply through a wire, and the polished surface of the Nb-22Ti-16Si-3Cr-3Al-2Hf sample is kept opposite to the stainless steel plate, but cannot be contacted;

[0032] 3) Turn on the switch of the DC power supply, quickly adjust the voltage to 70V, observe the change of the current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com