Production method of portable fried flour

A production method and technology of camellia oleifera, which is applied in the field of food processing, can solve the problems of complex production process of camellia oleifera, poor sensory effect, long brewing time, etc., and achieve the effect of avoiding the failure of active ingredients, improving the aroma score, and enhancing the aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

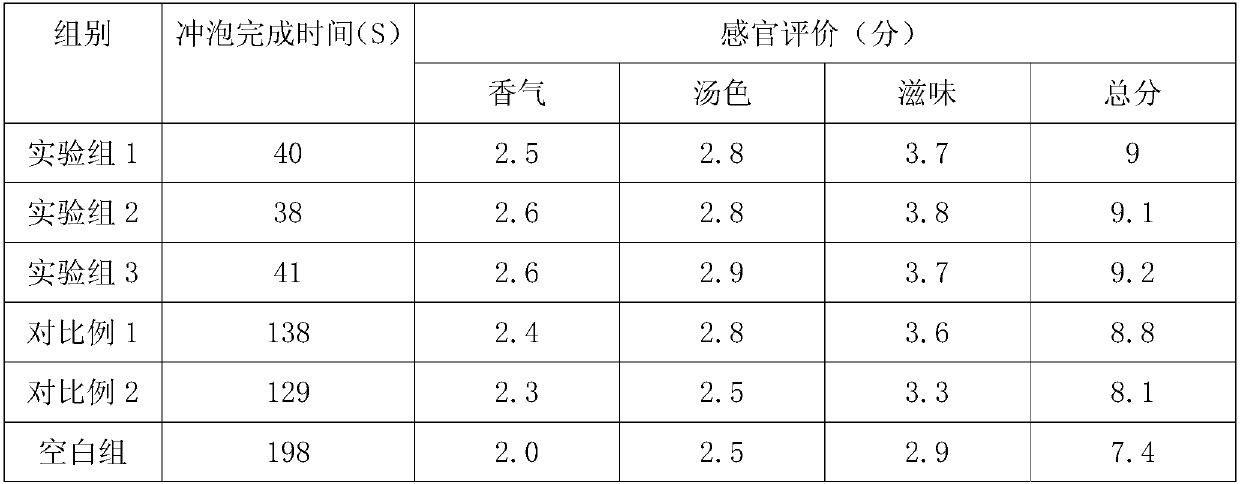

Examples

Embodiment 1

[0025] A method for making portable camellia oleifera, comprising the following steps:

[0026] (1) Weighing raw materials: by weight, weigh 20 parts of tea leaves, 20 parts of ginger, 5 parts of garlic, 3 parts of gardenia, 2 parts of lemon verbena, 8 parts of table salt and 2 parts of edible oil;

[0027] (2) Raw material processing: the tea leaves, ginger, garlic, gardenia and lemon verbena that have been weighed are mixed uniformly after being roughly pulverized respectively to obtain a mixed raw material with a particle size of 20 mesh;

[0028] (3) kneading: the above-mentioned mixed raw materials are put into a kneading machine and kneaded for 30 minutes to obtain a kneaded raw material with a cell destruction rate of more than 87%;

[0029] (4) Fermentation: After evenly mixing into the above-mentioned kneading raw materials a fermentation aid with a weight of 0.35% of the mixture mass, ferment at a temperature of 23°C and a humidity of 92% until the raw materials are ...

Embodiment 2

[0037] A method for making portable camellia oleifera, comprising the following steps:

[0038] (1) Weighing raw materials: in parts by weight, weigh 23 parts of tea leaves, 24 parts of ginger, 7 parts of garlic, 5 parts of gardenia, 5 parts of lemon verbena, 10 parts of table salt and 3 parts of edible oil;

[0039] (2) Raw material processing: the tea leaves, ginger, garlic, gardenia and lemon verbena that have been weighed are mixed uniformly after being roughly pulverized respectively to obtain a mixed raw material with a particle size of 20 mesh;

[0040] (3) kneading: the above-mentioned mixed raw materials are put into a kneading machine and kneaded for 33 minutes to obtain a kneaded raw material with a cell destruction rate of more than 87%;

[0041] (4) Fermentation: After evenly mixing into the above-mentioned kneading raw materials a fermentation aid with a weight of 0.4% of the mixture mass, ferment at a temperature of 24° C. and a humidity of 93% until the raw mat...

Embodiment 3

[0049] A method for making portable camellia oleifera, comprising the following steps:

[0050] (1) Weighing raw materials: by weight, take 25 parts of tea leaves, 28 parts of ginger, 8 parts of garlic, 8 parts of gardenia, 6 parts of lemon verbena, 13 parts of salt and 4 parts of edible oil;

[0051](2) Raw material processing: the tea leaves, ginger, garlic, gardenia and lemon verbena that have been weighed are mixed uniformly after being roughly pulverized respectively to obtain a mixed raw material with a particle size of 20 mesh;

[0052] (3) kneading: the above-mentioned mixed raw materials are put into a kneading machine and kneaded for 35 minutes to obtain a kneaded raw material with a cell destruction rate of more than 87%;

[0053] (4) Fermentation: After evenly mixing into the above-mentioned kneading raw materials a fermentation aid with a weight of 0.45% of the mixture mass, ferment at a temperature of 25° C. and a humidity of 94% until the raw materials are free ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com