Omnidirectional mobile electric jack

A technology of omnidirectional movement and jack, applied in the direction of lifting device, etc., can solve the problems of low efficiency, long operation time, inconvenience, etc., and achieve the effect of stable structure, convenient movement and improved speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

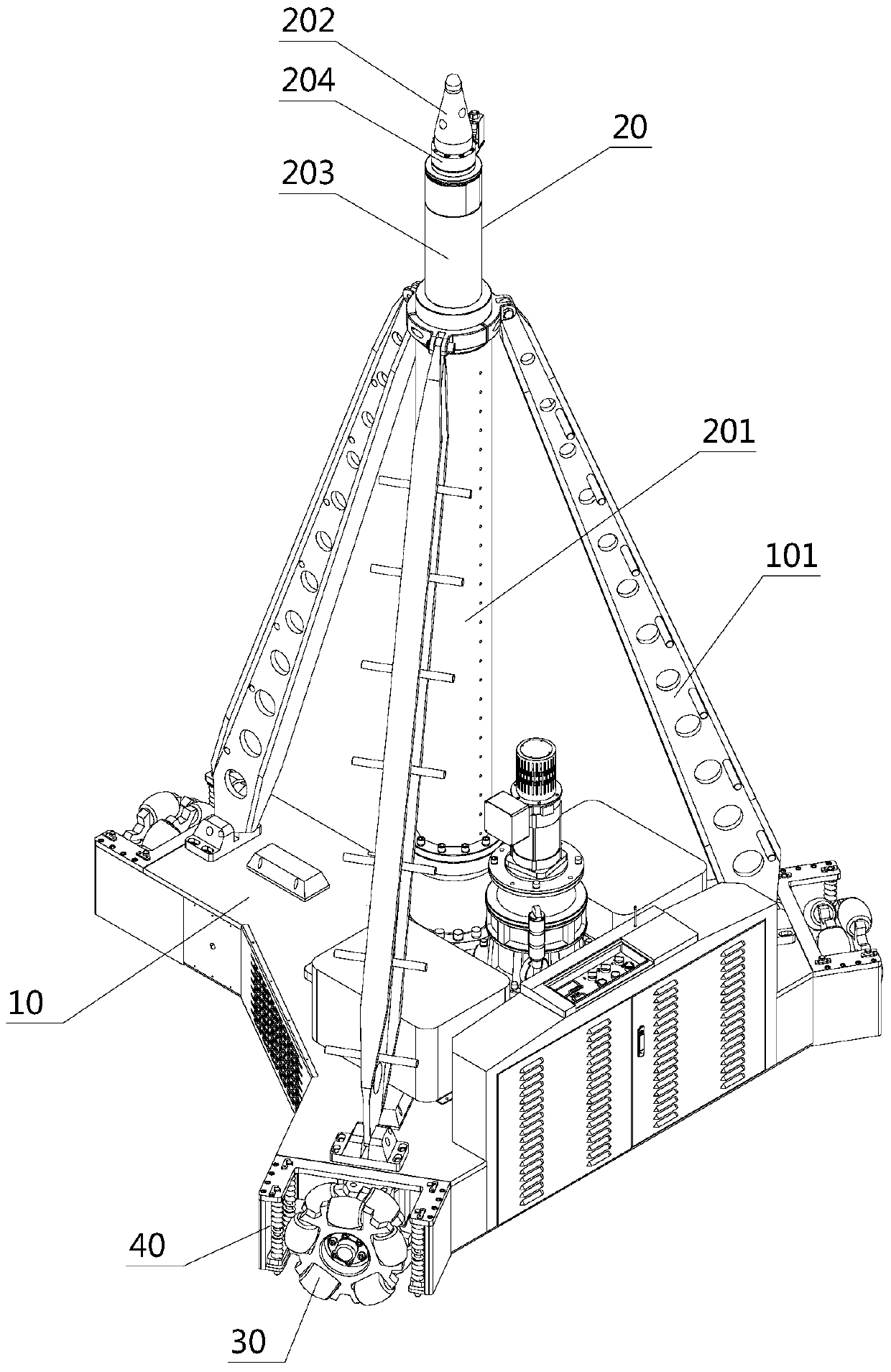

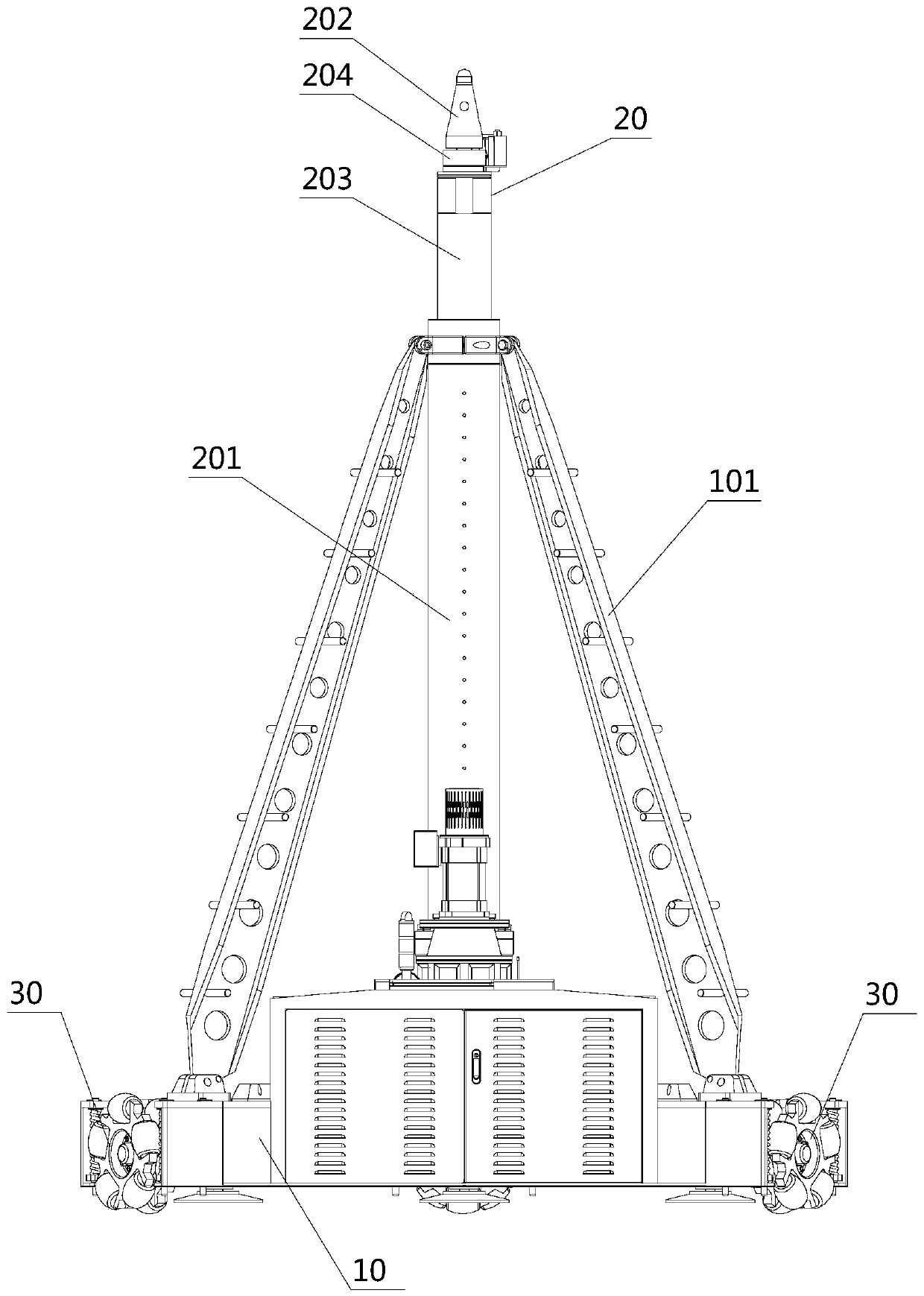

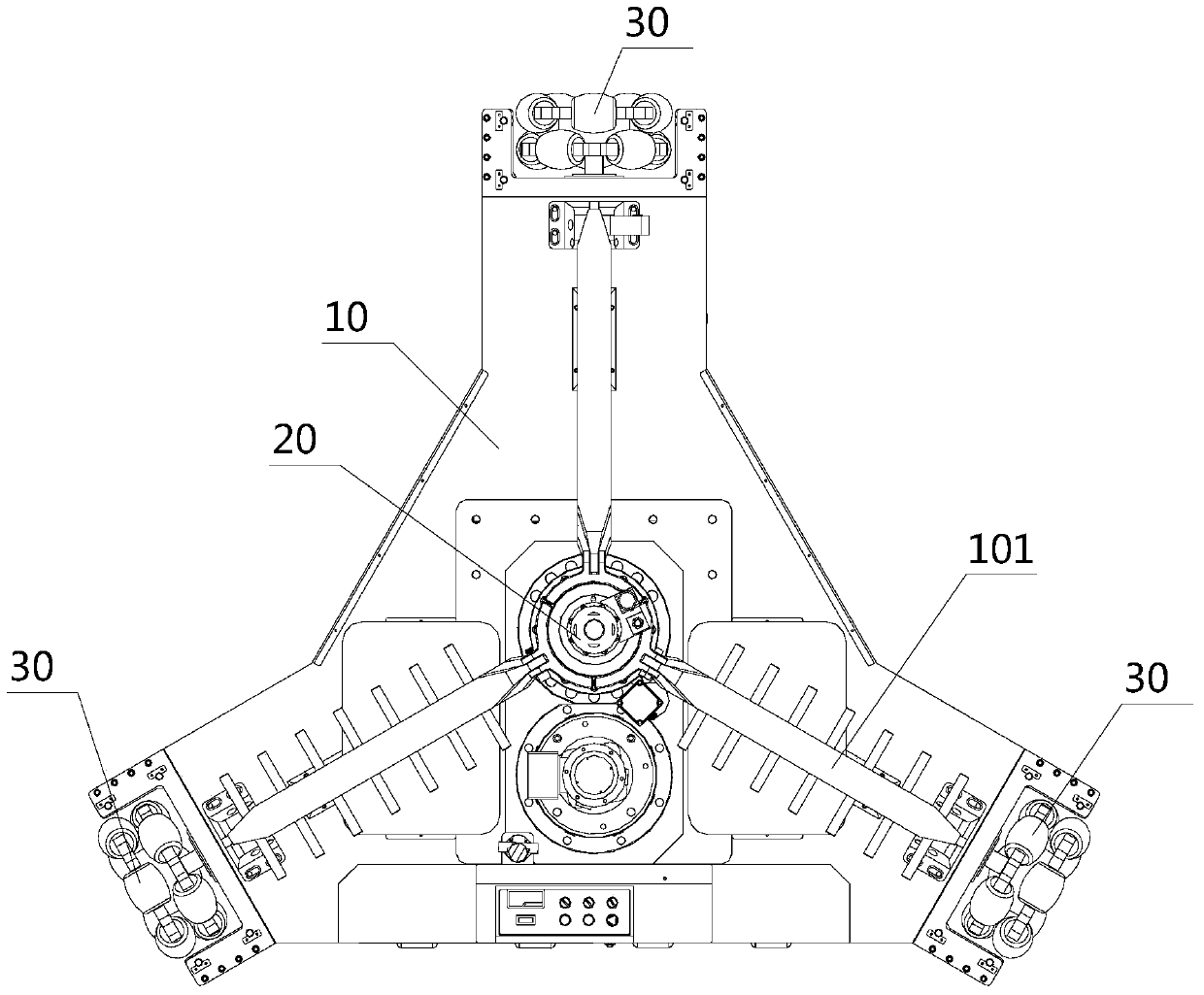

[0042] This embodiment provides an omnidirectional mobile electric jack, which belongs to the special jack for large aircraft, and is a large jack that can not only move omnidirectionally on the ground, but also electrically lift the aircraft.

[0043] see Figure 1 to Figure 6 , the omnidirectional mobile electric jack includes a foundation bearing platform 10, an electric jack assembly 20 and an automatic suspension device, the electric jack assembly 20 is installed on the foundation bearing platform 10, and the automatic suspension installation includes a mobile wheel assembly 30 and a suspension device 40, the mobile wheel The assembly 30 is connected with the basic bearing platform 10 , and the suspension device 40 is connected with the moving wheel assembly 30 .

[0044]In this embodiment, the basic carrying platform 10 is a three-wheel omnidirectional robot mobile platform, that is to say, there are three mobile wheel assemblies 30 . The electric jack assembly 20 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com