Manufacturing method of axle for low-floor vehicle

A manufacturing method and low-floor technology, which is applied in the field of rail transit, can solve the problems of low yield rate, difficult axle and bridge casting process, and short service life, and achieve the effects of high yield rate of production, superior performance of finished products, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Taking the DZ1990 axle axle for low-floor vehicles as a specific example, the manufacturing method of the axle axle for low-floor vehicles of the present invention will be further described in detail.

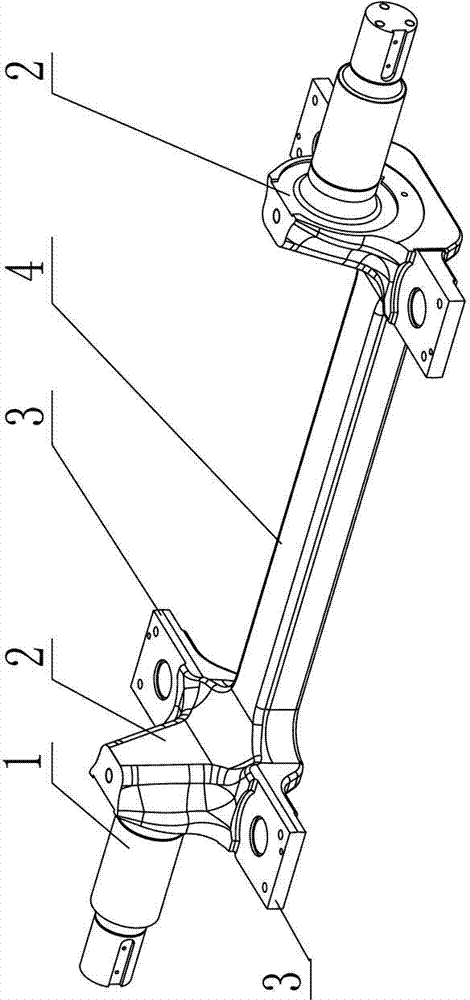

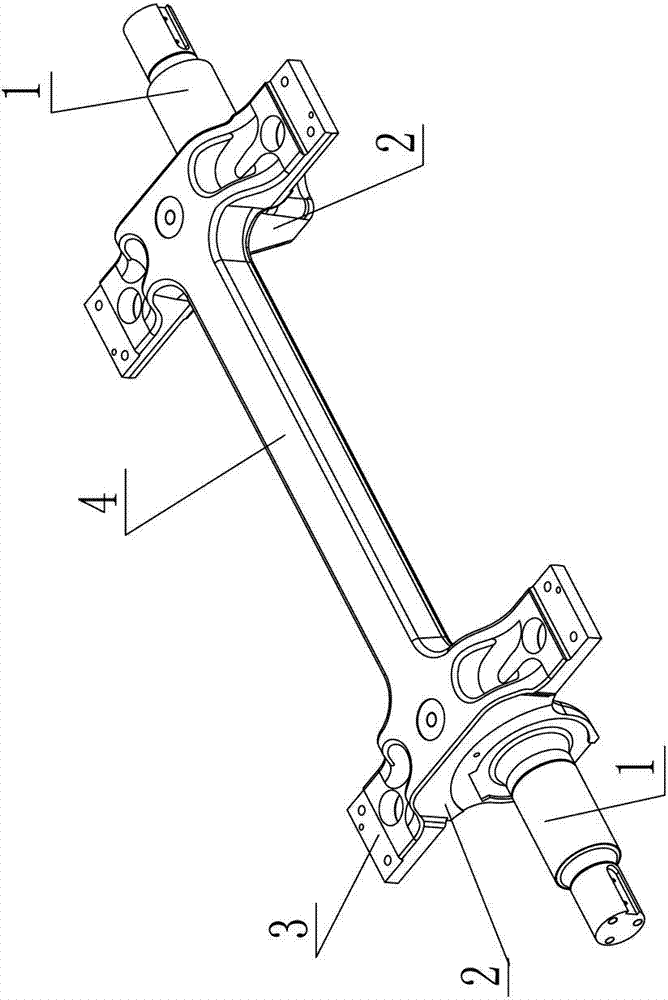

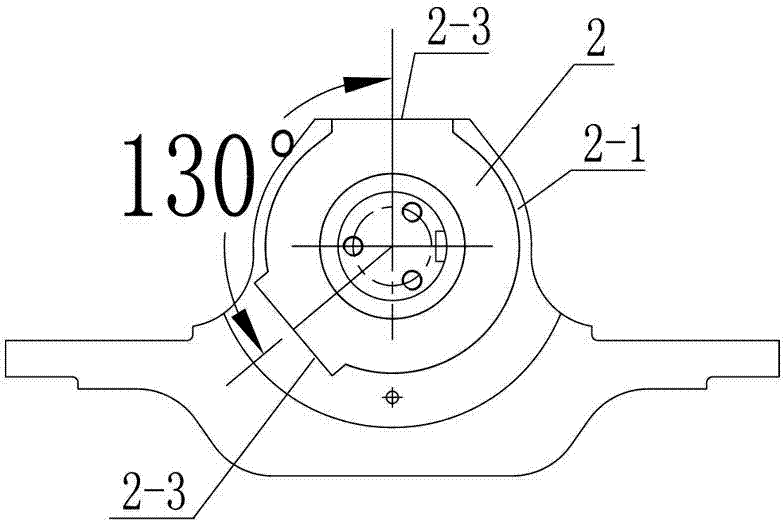

[0031] Such as figure 1 , 2 As shown, an axle bridge for a low-floor vehicle includes a journal 1, an axle head 2, a mounting seat 3 and an axle body 4. There are two axle heads 2 and they are respectively arranged at both ends of the axle body 4. Each axle head 2 A journal 1 and a mounting seat 3 are provided, the journal 1, the shaft head 2, the mounting seat 3 and the shaft body 4 are an integral single part, and the axle bridge is integrally forged, and its manufacturing method includes the following steps in sequence:

[0032] (1) Select 50CrMo4 alloy steel bar as the raw material of the integral forged axle bridge, and perform performance testing. The performance testing includes raw material chemical composition testing, low-magnification microstructure testing, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com