Grinder shell cover casting method

A technology of end caps and mills, which is applied in the direction of casting molding equipment, casting molds, and casting mold components, and can solve the problems of not very strong cooling iron effect and small wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

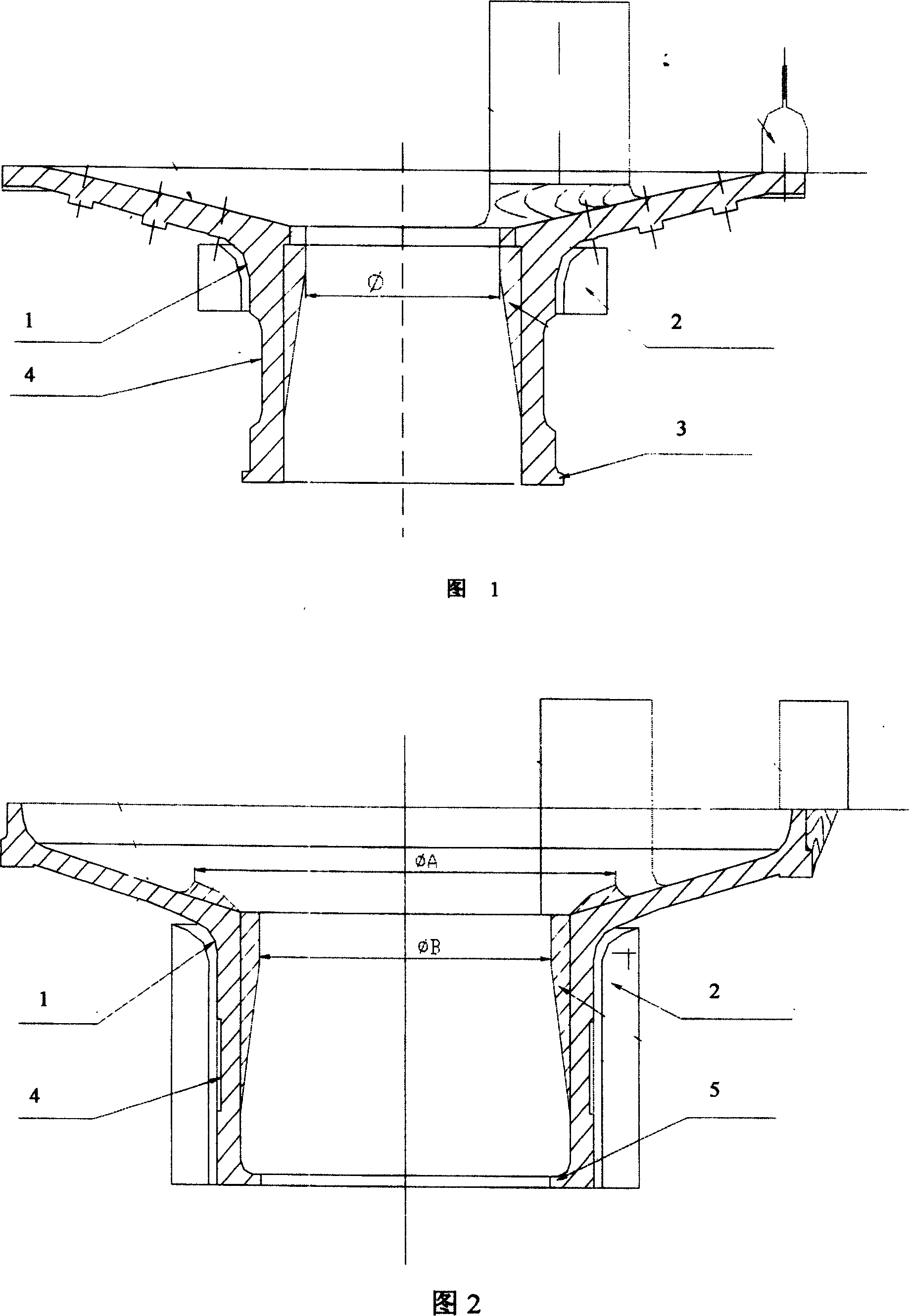

[0021] As shown in Figures 1 and 2, the casting method of the mill end cover described above is as follows: when the small end of the end cover (4) has an outer flange (3), the rounded corners of the end cover are indirectly cooled The iron (2) adopts block structure; when the small end of the end cover (4) has an inner flange (5), the rounded corners of the end cover indirect external chill iron (2) and the journal chill iron adopt an integral structure. The design method of the rounded indirect external chiller of the end cover is as follows: the width of the chiller exceeds the lower end of the fillet arc by more than 50mm to ensure the quality of the casting. Since the diameter of the hot node circle in the fillet area generally exceeds 280mm, the indirect external chiller is adopted. Cold iron, the thickness of the cold iron hanging sand layer is 10mm-20mm; the thickness of the cold iron in the fillet area of the end cover is 0.6-0.8 times the diameter of the hot joint...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com