Preparation device for thermometal radial direction thrust sliding bearing blank and preparation method thereof

A technology for sliding bearings and bimetals, which is applied in the field of preparation devices for bimetallic bearing blanks, can solve the problems of poor bonding strength between the sprayed layer and the steel back, inconvenient step-by-step manufacturing methods, and unsatisfactory bonding strength, etc. Achieve the effect of simple structure, long service life and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

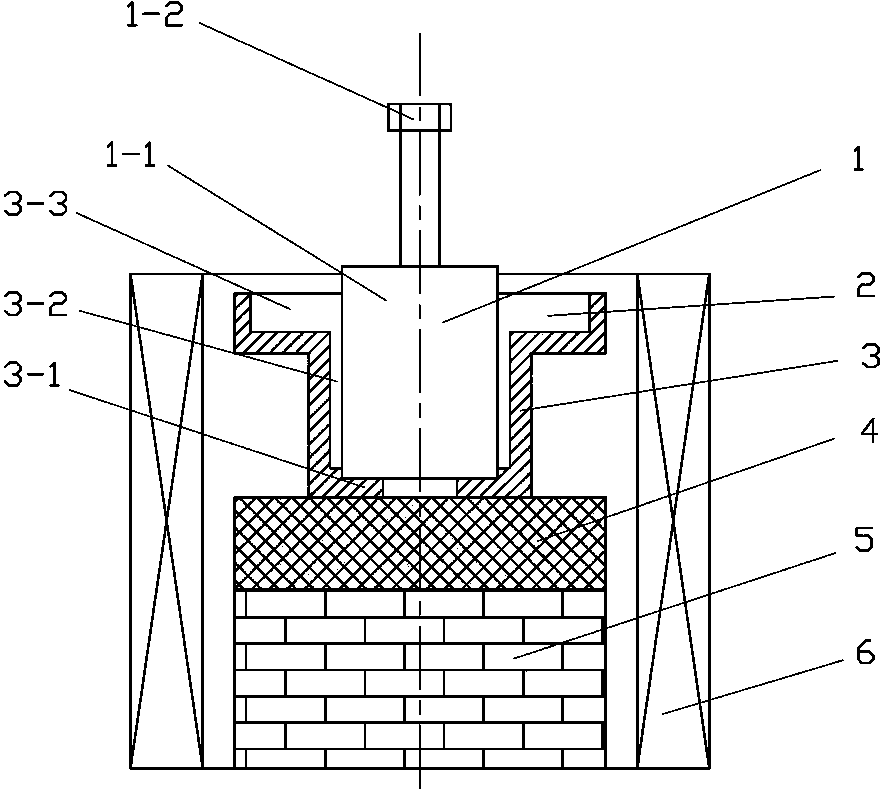

[0024] like figure 1 As shown, a device for preparing a bimetallic radial thrust sliding bearing blank of the present invention includes a mandrel 1, a billet 3, a graphite brick 4, a refractory brick 5 and an induction heater 6, and the billet 3 has a bottom plate 3- 1. The upper inner cavity 3-3 with a larger diameter and the lower inner cavity 3-2 with a smaller diameter, the mandrel 1 is inserted into the upper inner cavity 3-3 with a larger diameter and the lower inner cavity 3 with a smaller diameter -2 and fixed on the bottom plate 3-1 of the billet 3, an annular gap 2 is formed between the outer periphery of the mandrel 1 and the inner wall of the billet 3, the graphite brick 4 is placed at the bottom of the billet 3, and the refractory brick 5 is placed At the bottom of the graphite brick 4, the induction heater 6 surrounds the outer circumference of the billet 3, the graphite brick 4 and the refractory brick 5.

[0025] like figure 1 As shown, the mandrel 1 include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com