Automatic-bolt-feeding magnetic powder flaw detecting line

A technology of magnetic particle flaw detection and automatic feeding, which is applied in the direction of material magnetic variables, etc., can solve the problems of unsatisfactory batch production of bolts, time-consuming and labor-intensive work, and high labor intensity of workers, achieving fast speed, high efficiency, and good reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

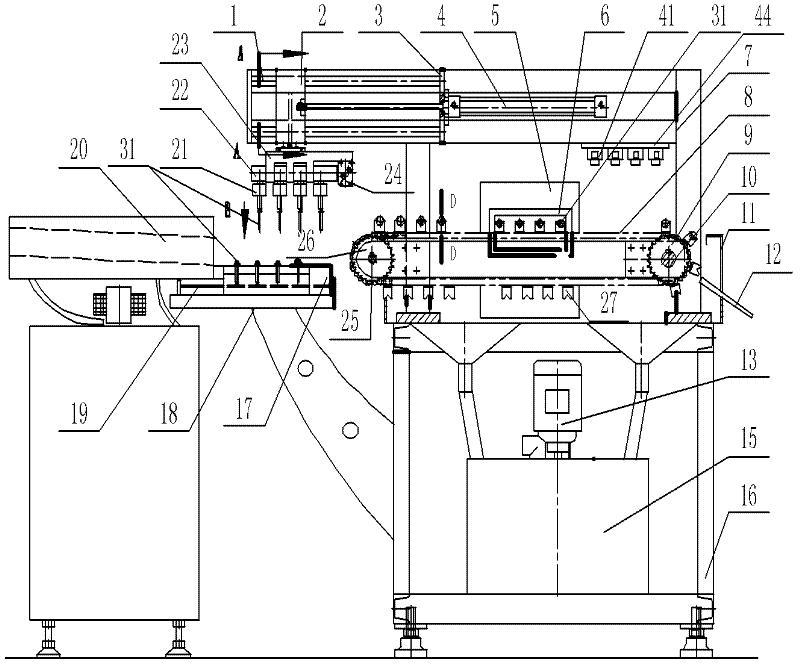

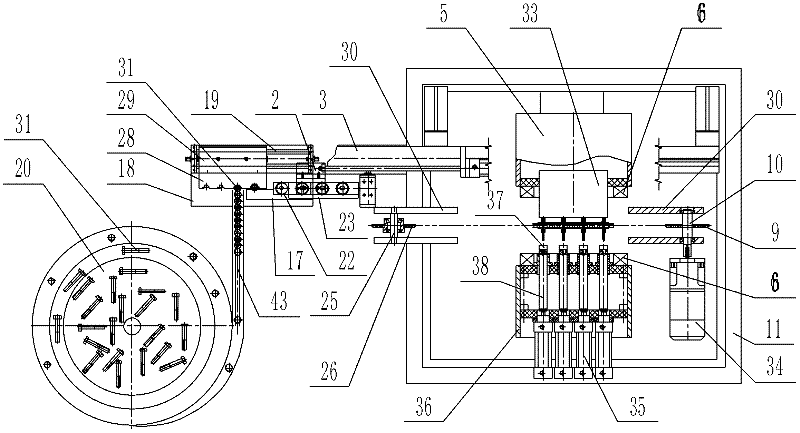

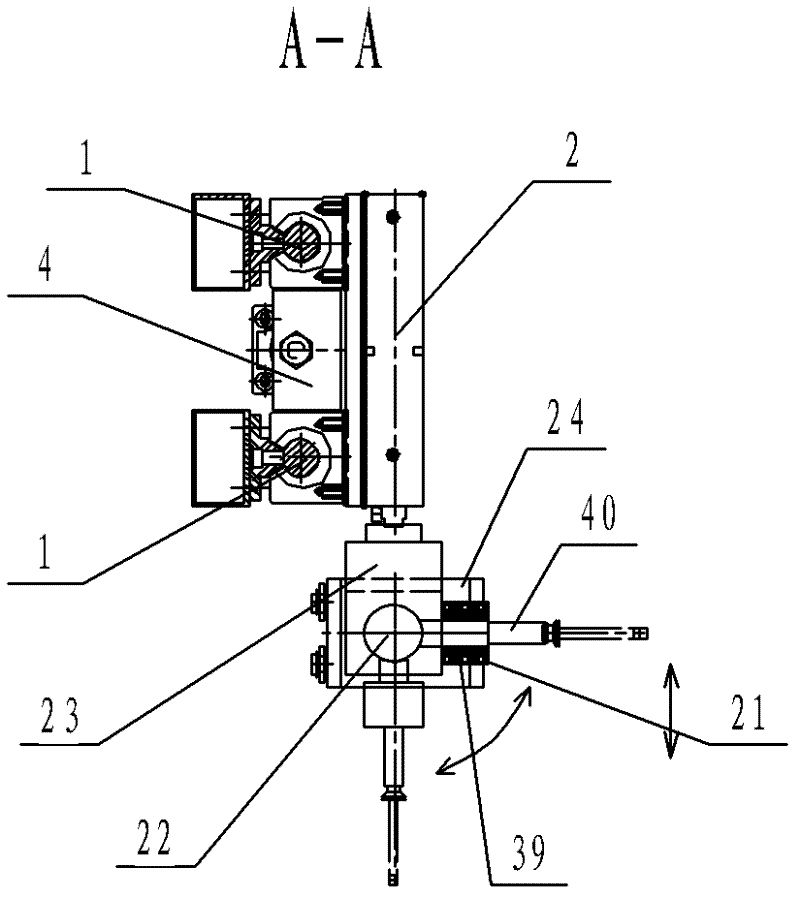

[0024] Describe the present invention in detail below in conjunction with accompanying drawing:

[0025] Such as Figure 1-4 As shown, the bolt automatic feeding magnetic particle flaw detection line includes electrical control system, spraying system, circumferential magnetization power supply, longitudinal magnetization power supply, lighting device, demagnetization device; , liquid storage tank 15, be provided with magnetic suspension nozzle at the place of magnetization device, and the liquid sump 11 that fixes on frame base 16 forms; As Figure 1-2 As shown, a sprocket conveying device is provided on the fixed liquid sump 11 above the frame seat 16, and the sprocket conveying device is to match a pair of sprocket shaft brackets 30 to the liquid sump 11 through the frame seat 16. Above, the drive shaft 10 and the drive sprocket 9, the driven shaft 25 and the driven sprocket 26 are respectively arranged on a pair of sprocket shaft frames 30, and one end of the drive shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com