Method for compound magnetic powder flaw detection

A magnetic particle flaw detection and composite technology, applied in the direction of material magnetic variables, can solve the problems of uneven magnetic field distribution, burnt workpiece, spark phenomenon, etc., to avoid burn workpiece, reduce labor intensity, and avoid spark phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical characteristics of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

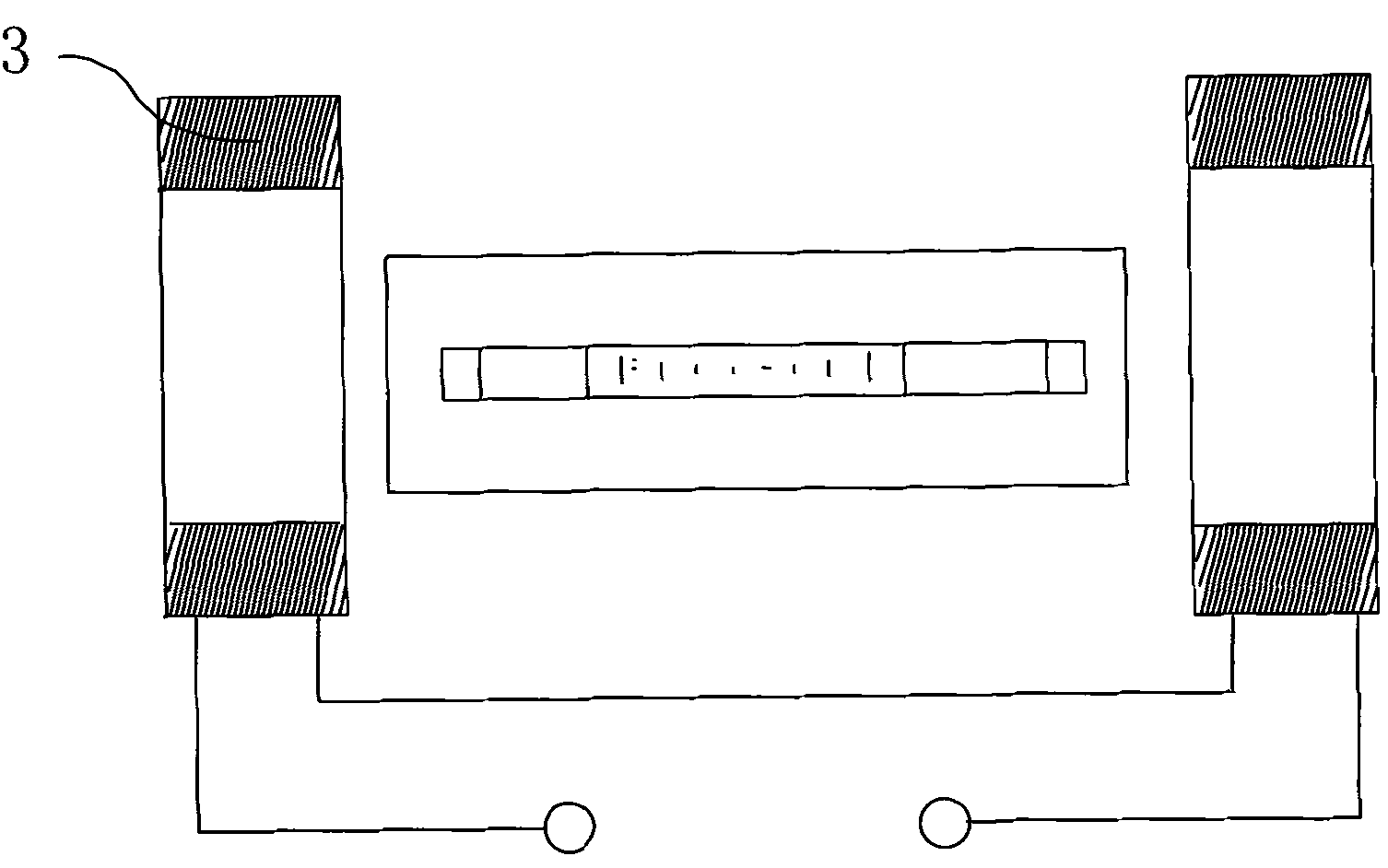

[0018] A composite magnetic particle flaw detection method, comprising the following steps: (1) pretreatment; (2) magnetization; (3) applying magnetic powder or magnetic suspension; (4) observation and recording of magnetic marks; (5) defect rating; 6) demagnetization; (7) post-processing; the magnetization method in the step (2) is the full induction type of the circumferential closed yoke magnetization and the longitudinal coil magnetization.

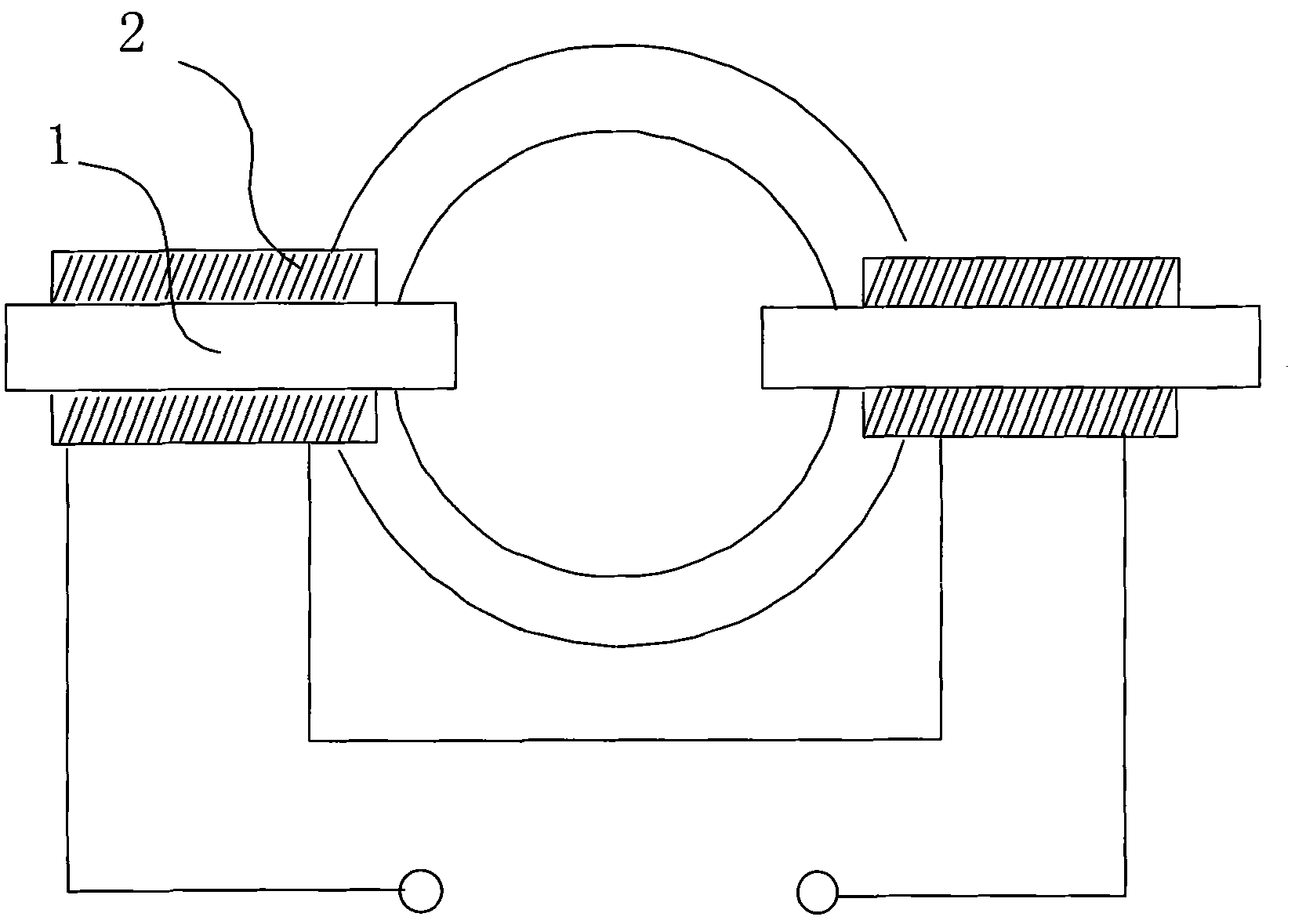

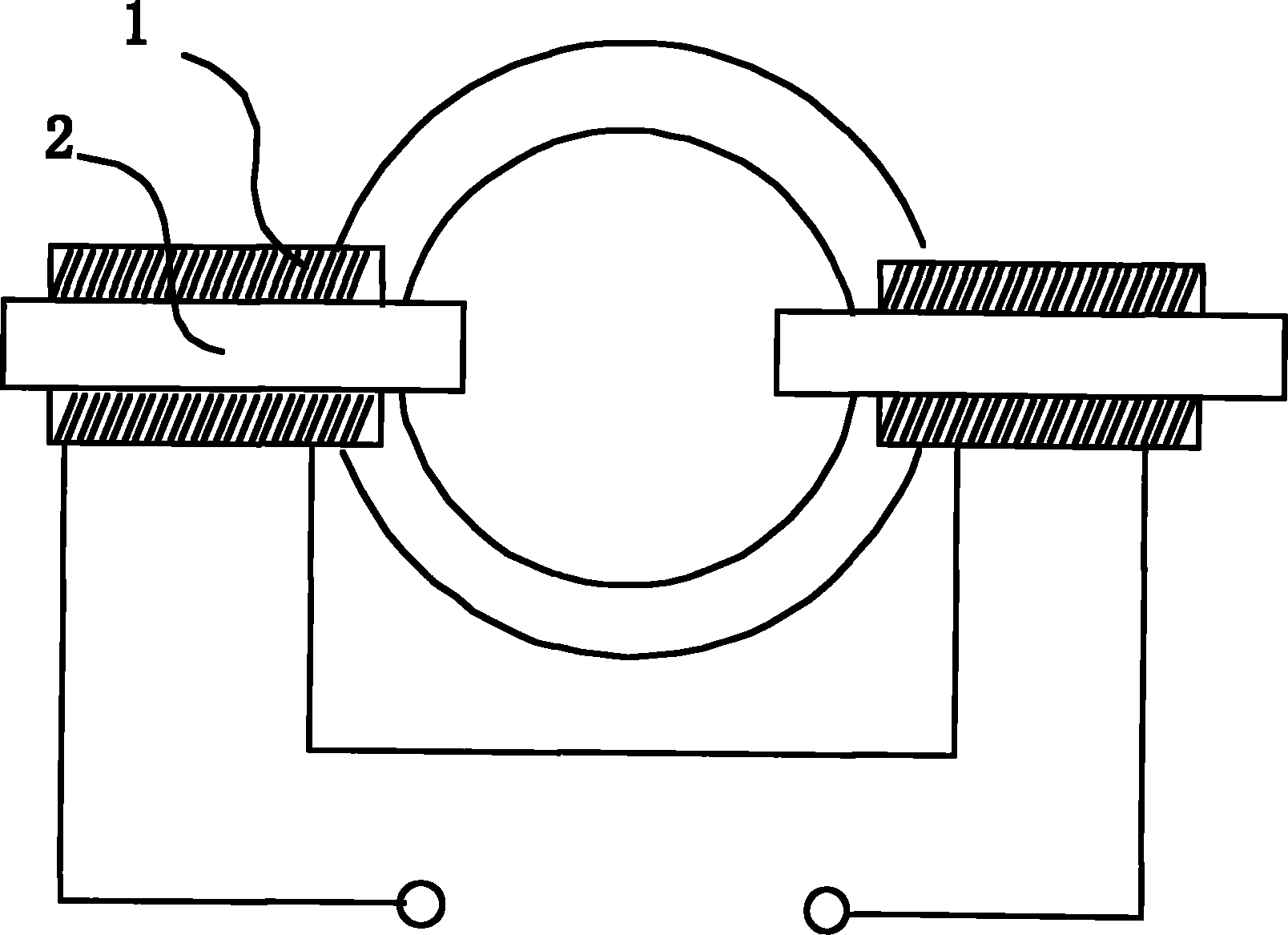

[0019] Such as figure 1 The schematic diagram of the closed yoke is shown, and it can be seen from the figure that the magnetization detection method adopts the method of applying a magnetic field to the broadband closed yoke 1, and the workpiece is used as a conductor to generate a closed magnetic circuit, and the workpiece is magnetized in the circumferential directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com