Inspection and repair line and method for bumper of coupler of motor train unit

A technology for buffers and maintenance lines, applied in the field of maintenance of close-connected coupler buffers, can solve the problems of low maintenance efficiency and poor versatility, and achieve the effects of saving labor costs, comprehensive functions, and improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

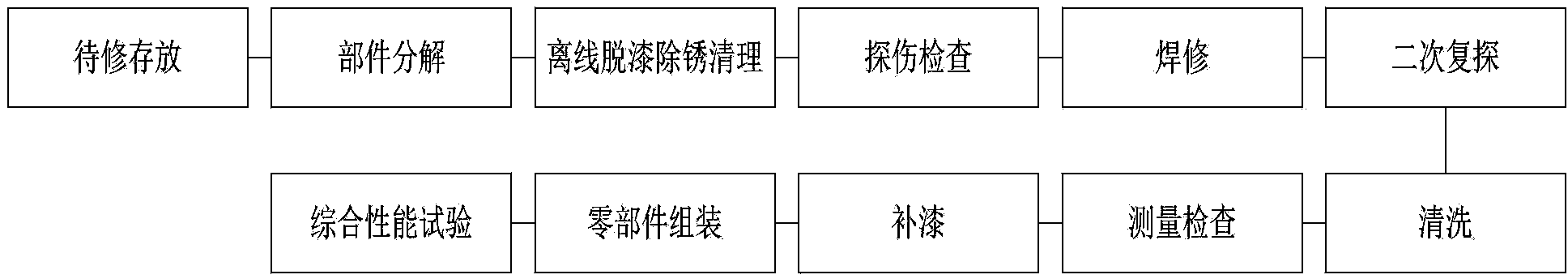

[0030] The basis for the overhaul of the coupler buffer is the EMU overhaul process.

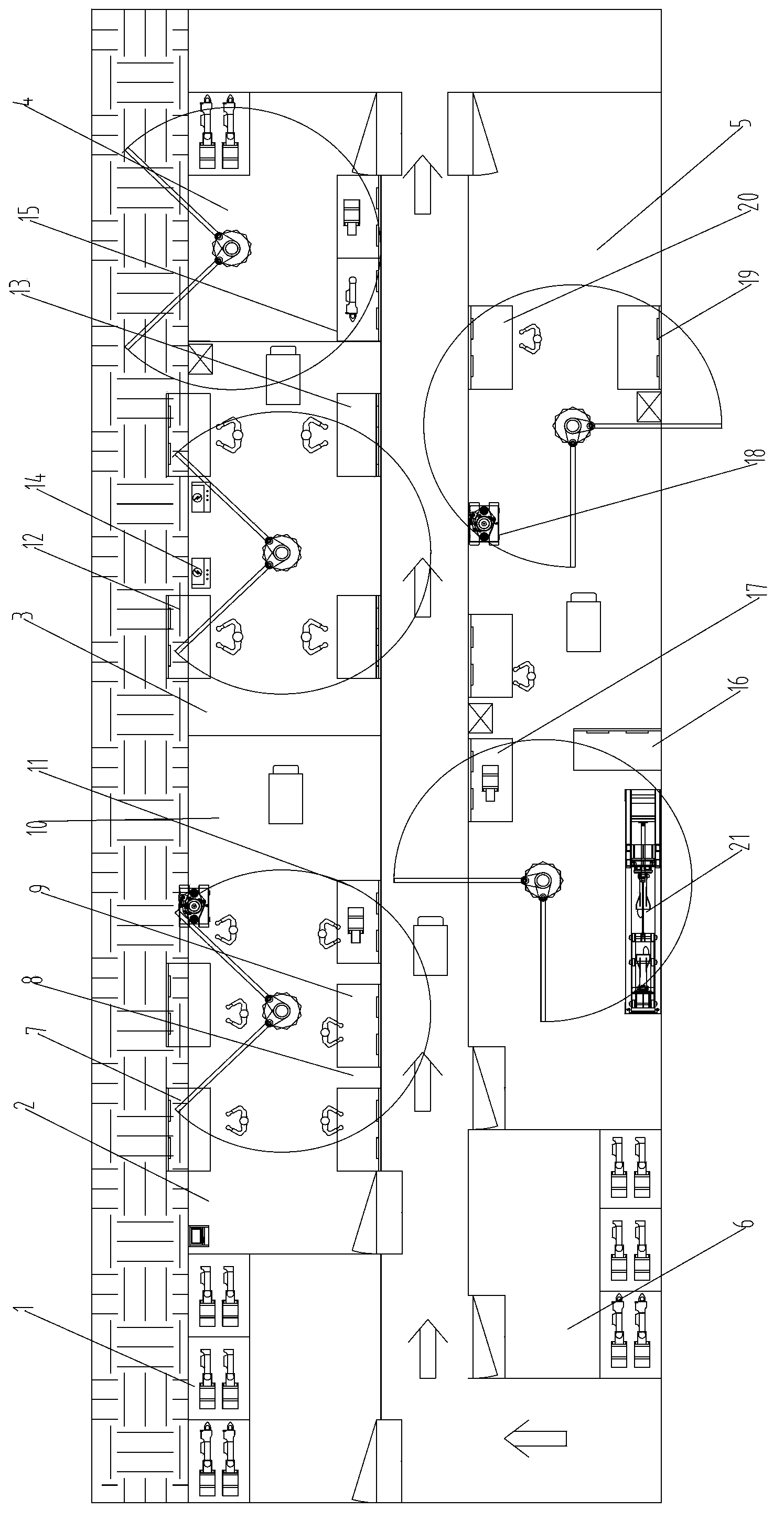

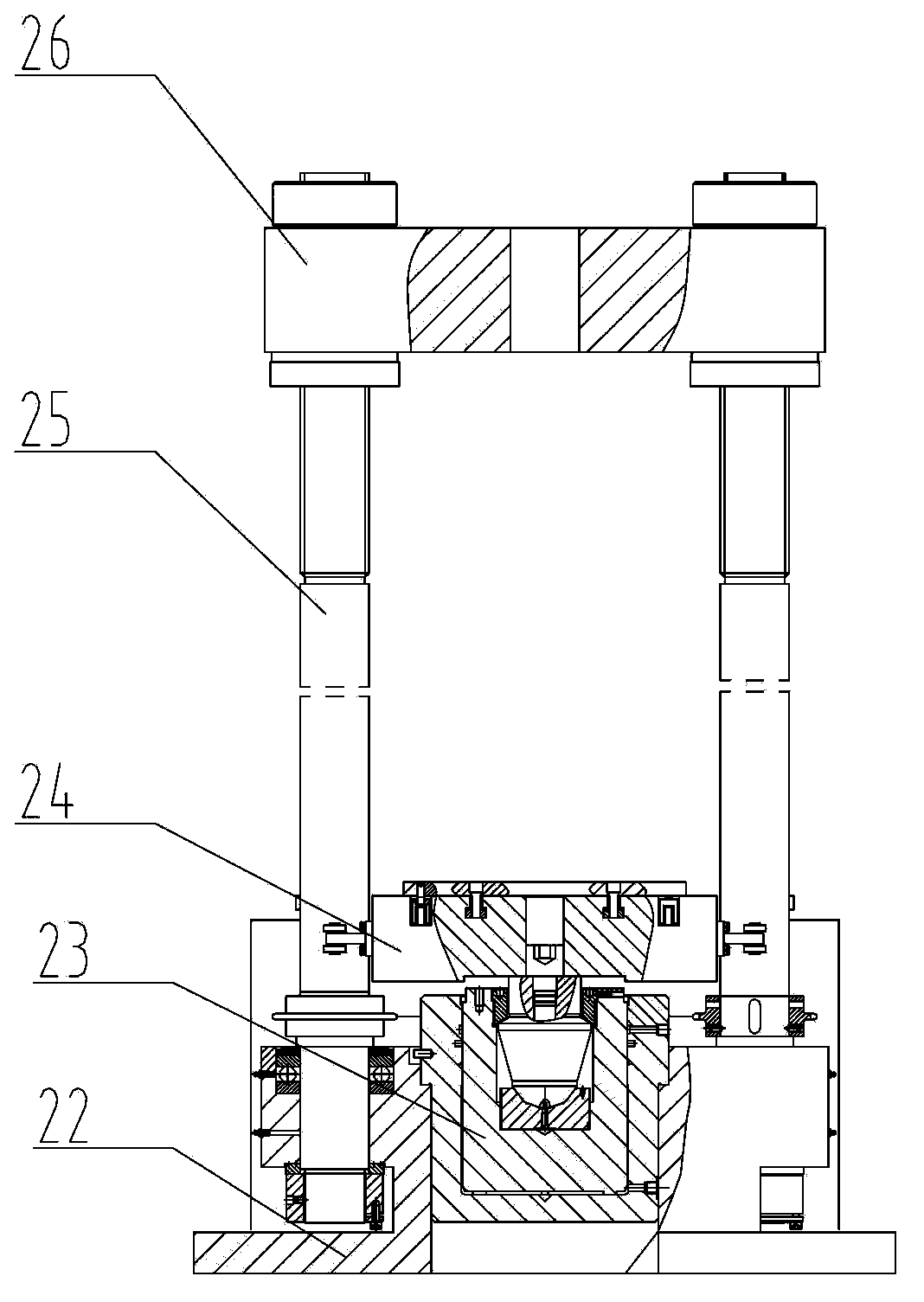

[0031] An overhaul line for coupler buffers, the overhaul line sequentially includes a cache area to be repaired 1, a decomposition inspection area 2, a flaw detection area 3, a paint repair area 4, an assembly test area 5, and a qualified product storage area 6 according to the maintenance process. There are suspension arms inside, which are used to drive the components to be transferred between each station, so that each station can be checked and repaired according to the beat and process. A plurality of three-dimensional storage racks are arranged in the buffer area to be repaired; a disassembly worktable 7, a coupler slow disassembly device 8, a coupler head disassembly device 9, a buffer crushing tube press 10 and a buffer press are provided in the disassembly inspect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com