Electromagnetic inspection method based on hall sensor array and electromagnetic inspection system based on hall sensor array

A Hall sensor and array technology, applied in the direction of material magnetic variables, etc., can solve the problems of high surface smoothness requirements, small detection range, and influence on magnetic particles, etc., to increase the application range and detection speed, and improve detection efficiency , to avoid the effect of waste and pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0049] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiment described in the present invention is only a preferred manner, and is only used to explain the present invention, but not to limit the present invention in any way.

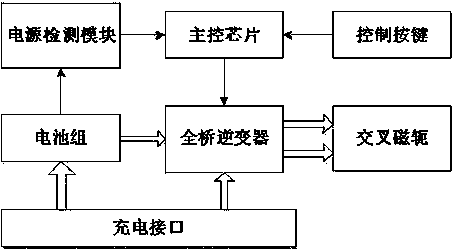

[0050] The invention provides a method and system for electromagnetic flaw detection, and the following steps are involved in using this flaw detection method:

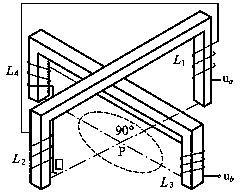

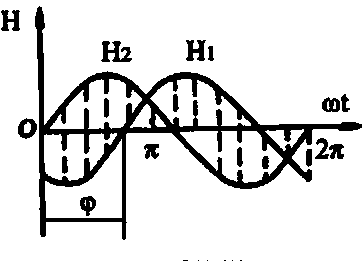

[0051] S01: The full-bridge inverter inverts the input DC power into AC power with controllable frequency, and provides AC currents with no less than two different frequencies to the cross yoke in each unit magnetization cycle;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com