Automatic defect recognition method and system for magnetic particle testing

A magnetic particle detection and automatic recognition technology, applied in character and pattern recognition, instruments, computer parts, etc., can solve the problems of monotonous repetition of work content, no fusion of magnetic particle detection technology, slow detection speed, etc., to improve workpiece recognition. effect on rate and discriminant accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solution and advantages of the present application clearer, the present application will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] In the following description, references to "one embodiment," "an embodiment," "an example," "example," etc. indicate that such described embodiment or example may include a particular feature, structure, characteristic, property, element, or limitations, but not every embodiment or example necessarily includes the specific feature, structure, characteristic, property, element or limitation. Additionally, repeated use of the phrase "according to one embodiment of the present application" does not necessarily refer to the same embodiment, although it may.

[0035] For simplicity, some technical features known to those skilled in the art are omitted from the following description.

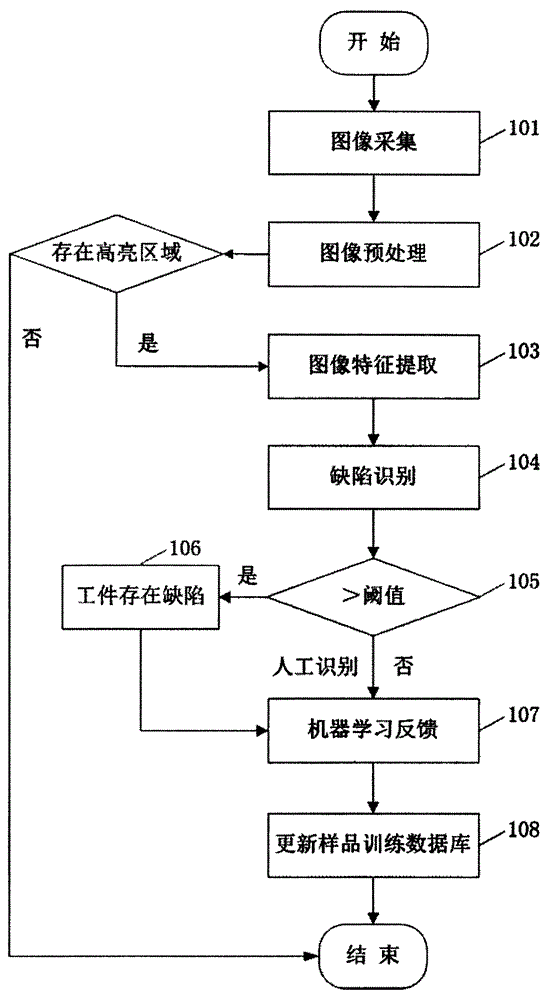

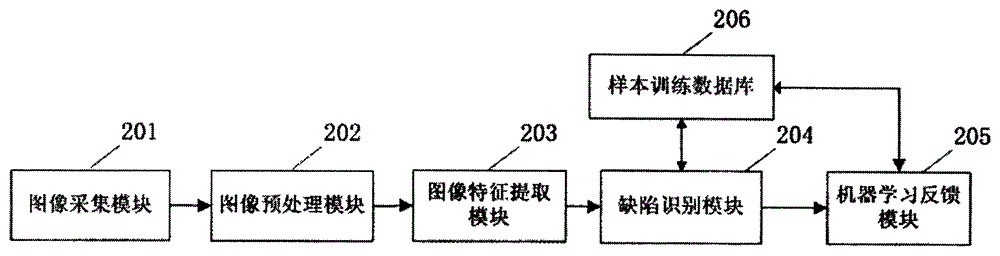

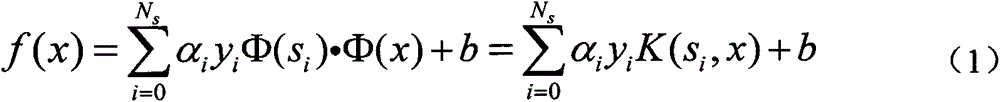

[0036] The invention provides a method for aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com