Patents

Literature

61results about How to "Configure operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

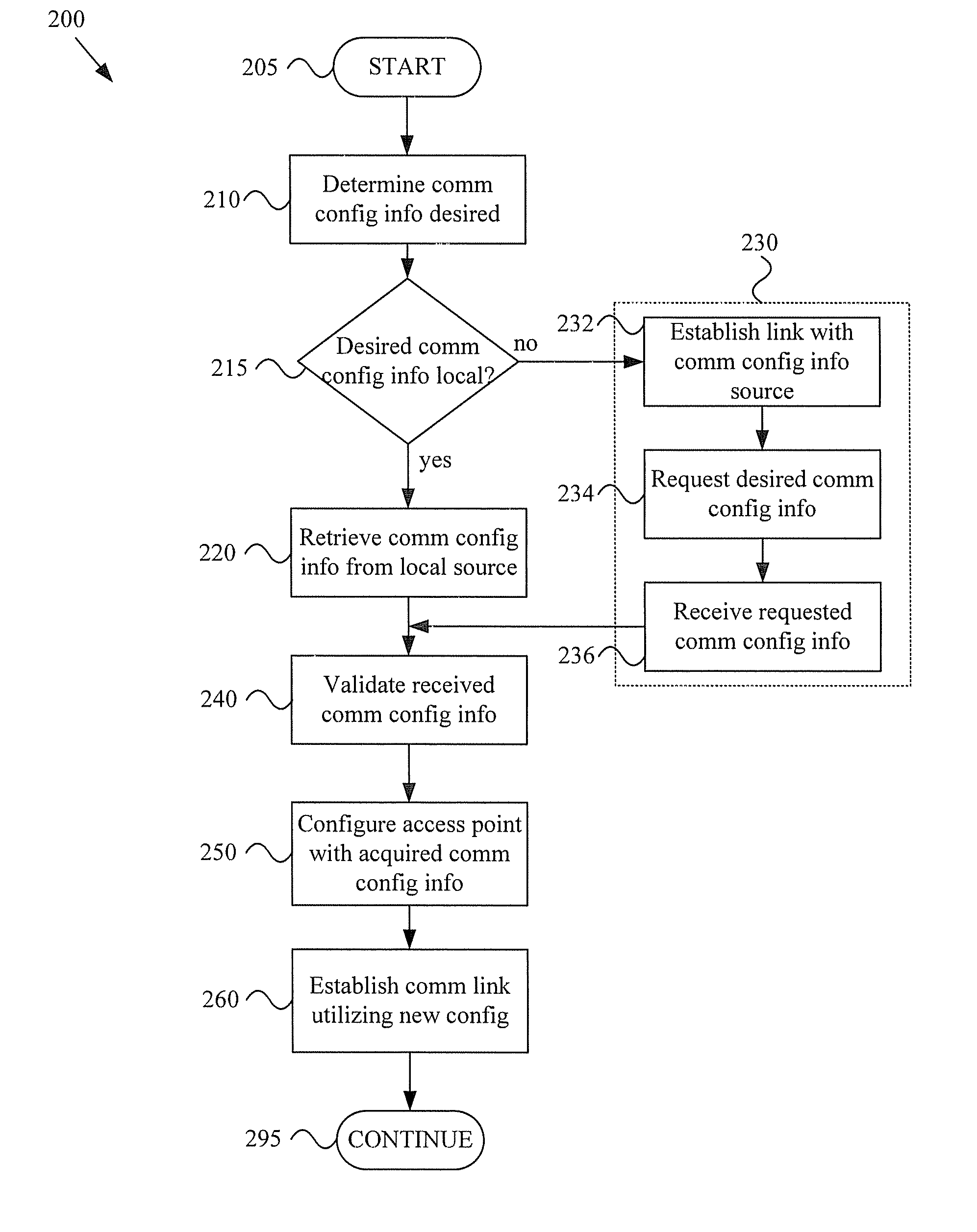

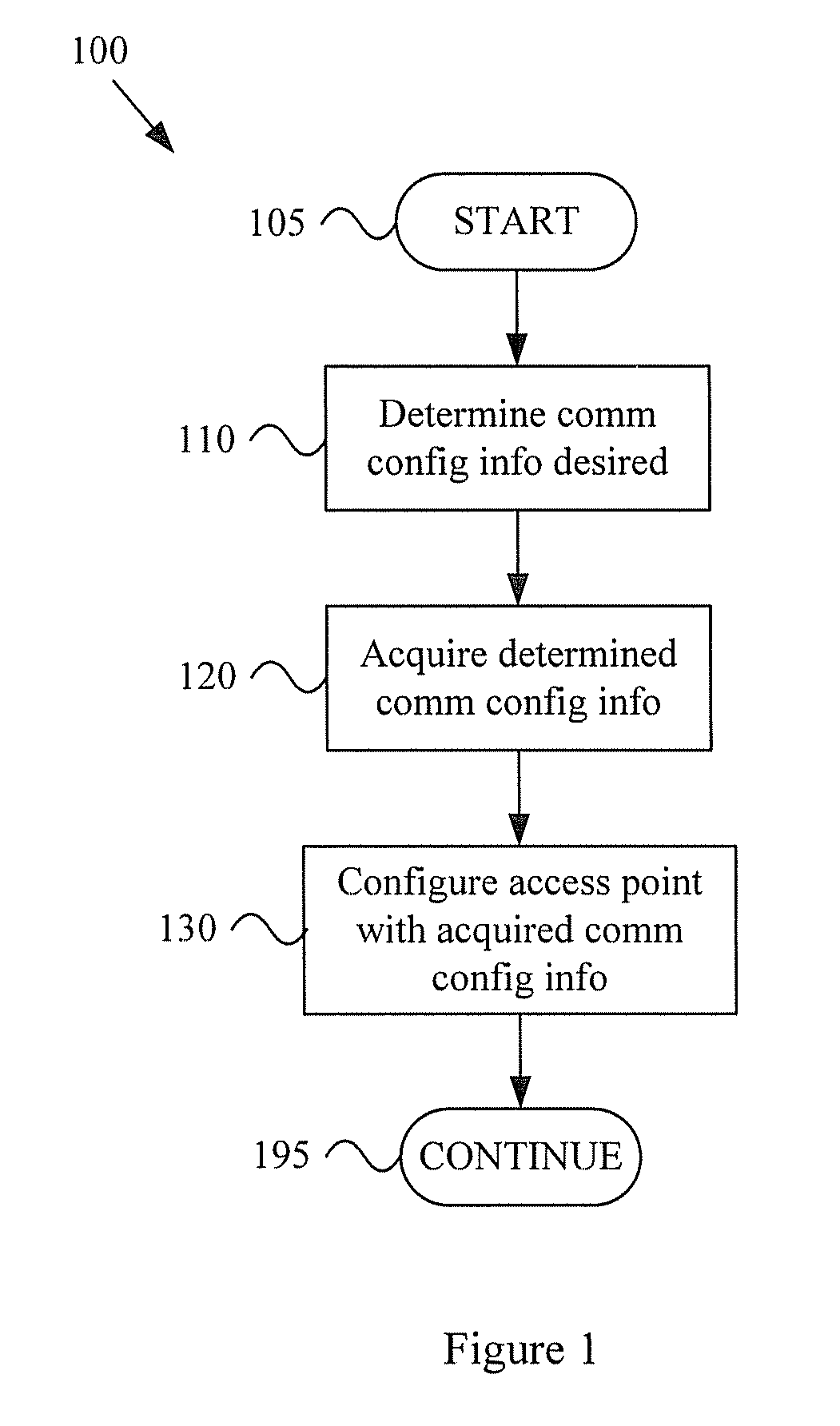

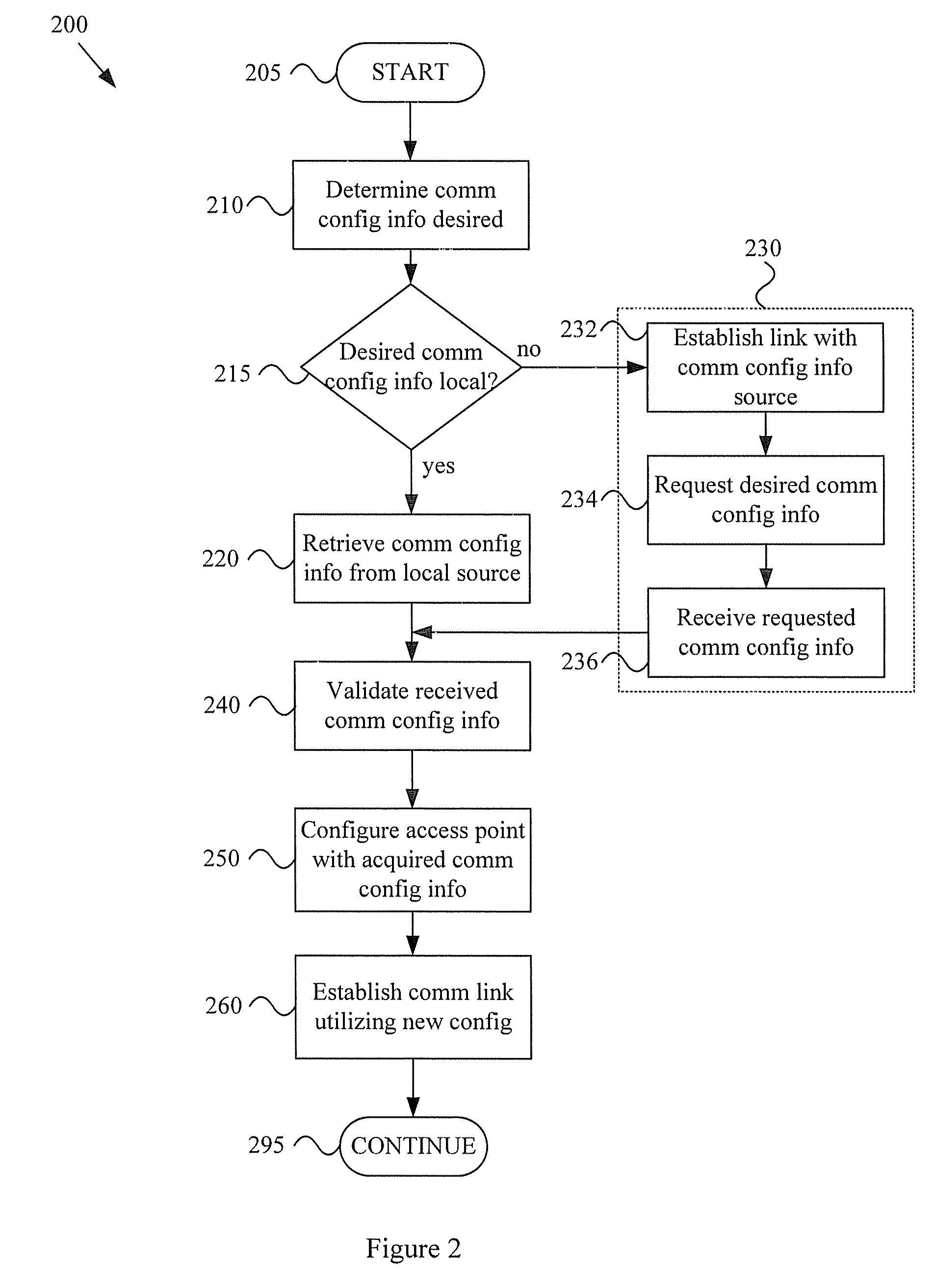

Programmable wireless access point supporting configuration profile updating

ActiveUS20070115950A1Configure operationMultiple digital computer combinationsWireless network protocolsComputer networkNetwork access point

A system and method in a wireless communication network access point for configuring operation of the access point. Various aspects of the present invention may comprise determining communication configuration information desired for the access point. Communication configuration information may, for example, correspond to a particular communication protocol. Communication configuration information may, for example and without limitation, comprise information selecting one or more particular modules or specifying operation of one or more modules. Communication configuration information may, for example, comprise executable code. Desired communication configuration information may, for example, be determined through communication with a user or other networked device. Determined communication configuration information may then be acquired (e.g., from a networked server or other device). Such acquisition may, for example, comprise receiving solicited or unsolicited communication configuration information. The access point may then be configured in accordance with the acquired communication configuration information.

Owner:AVAGO TECH INT SALES PTE LTD

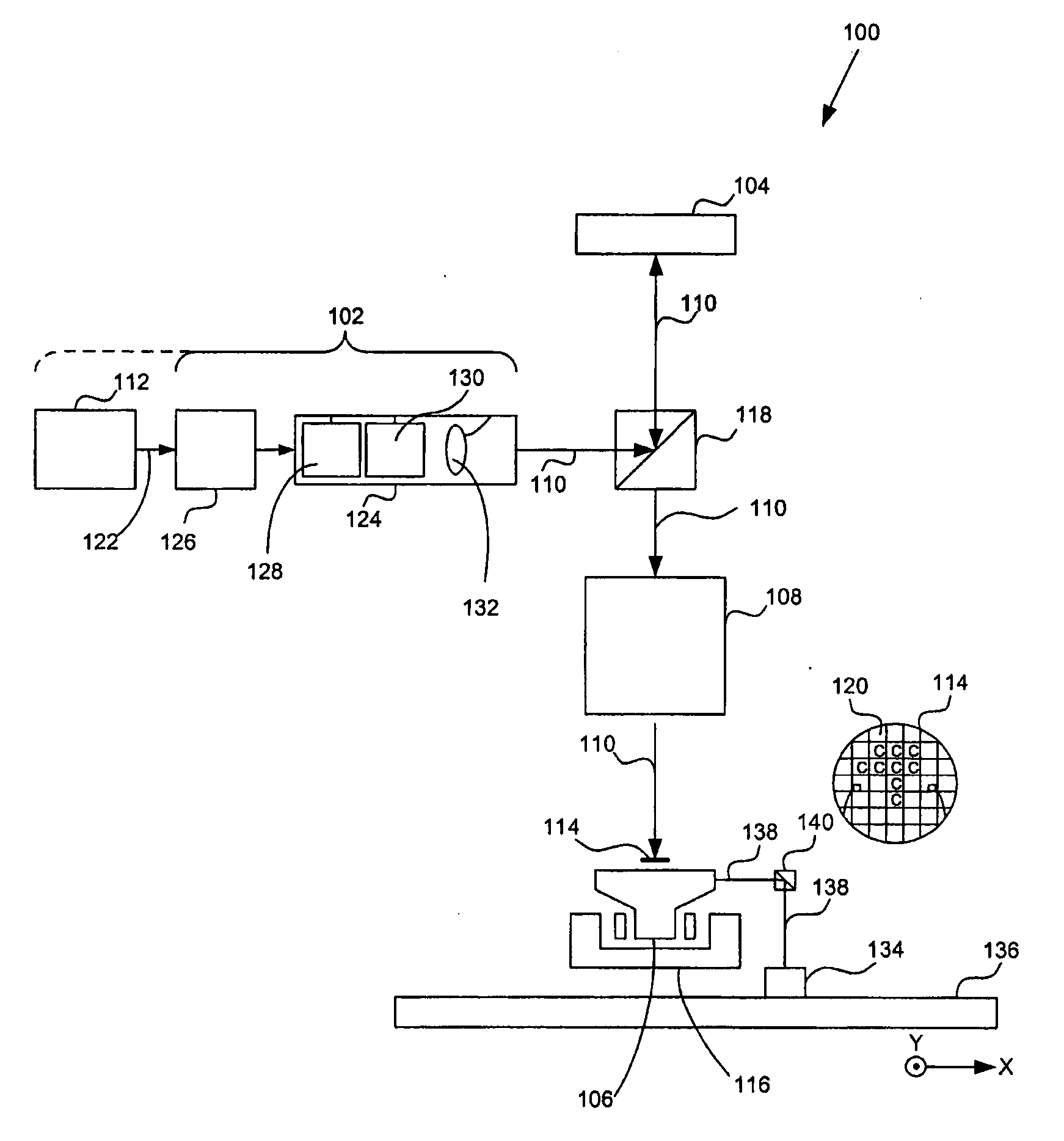

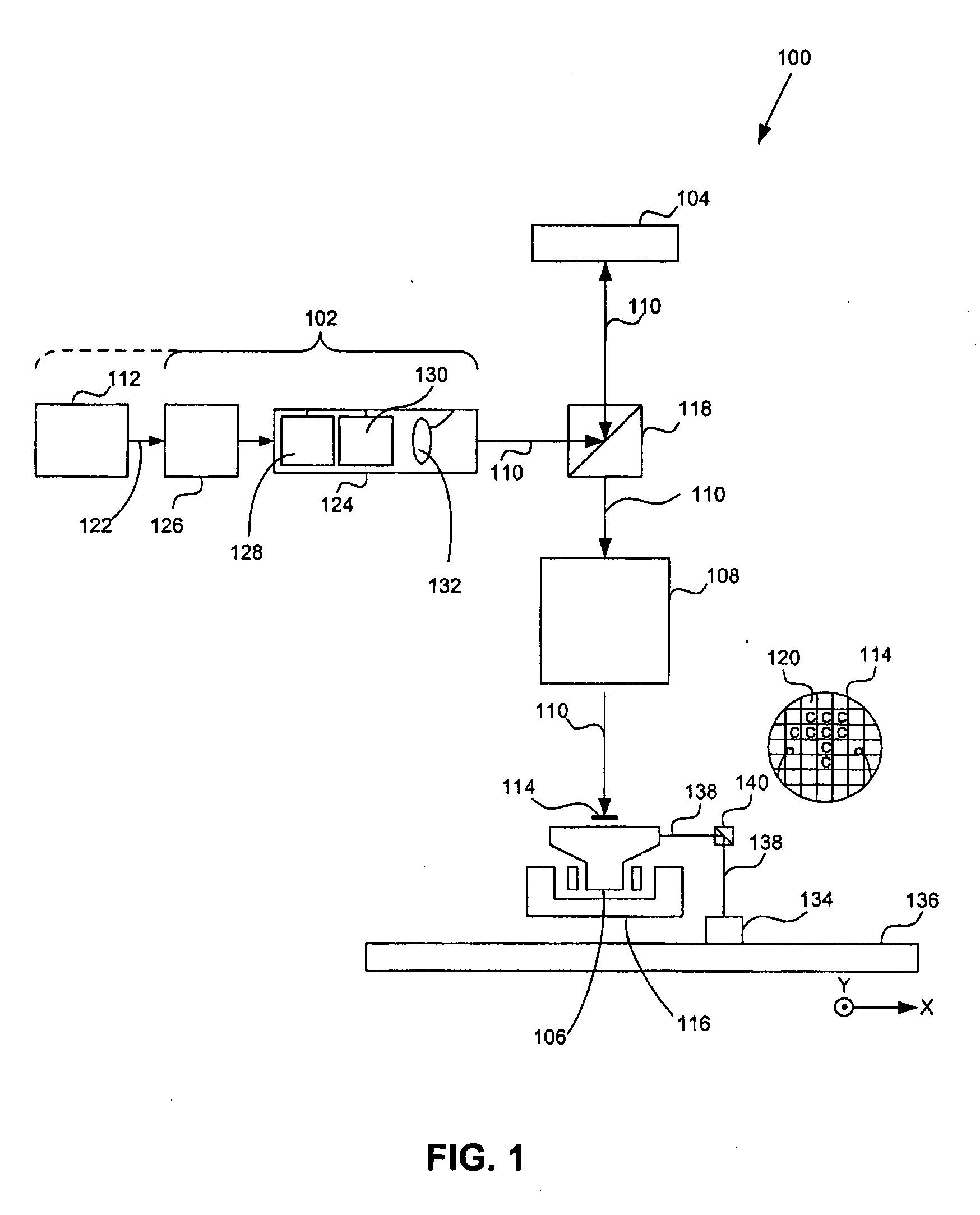

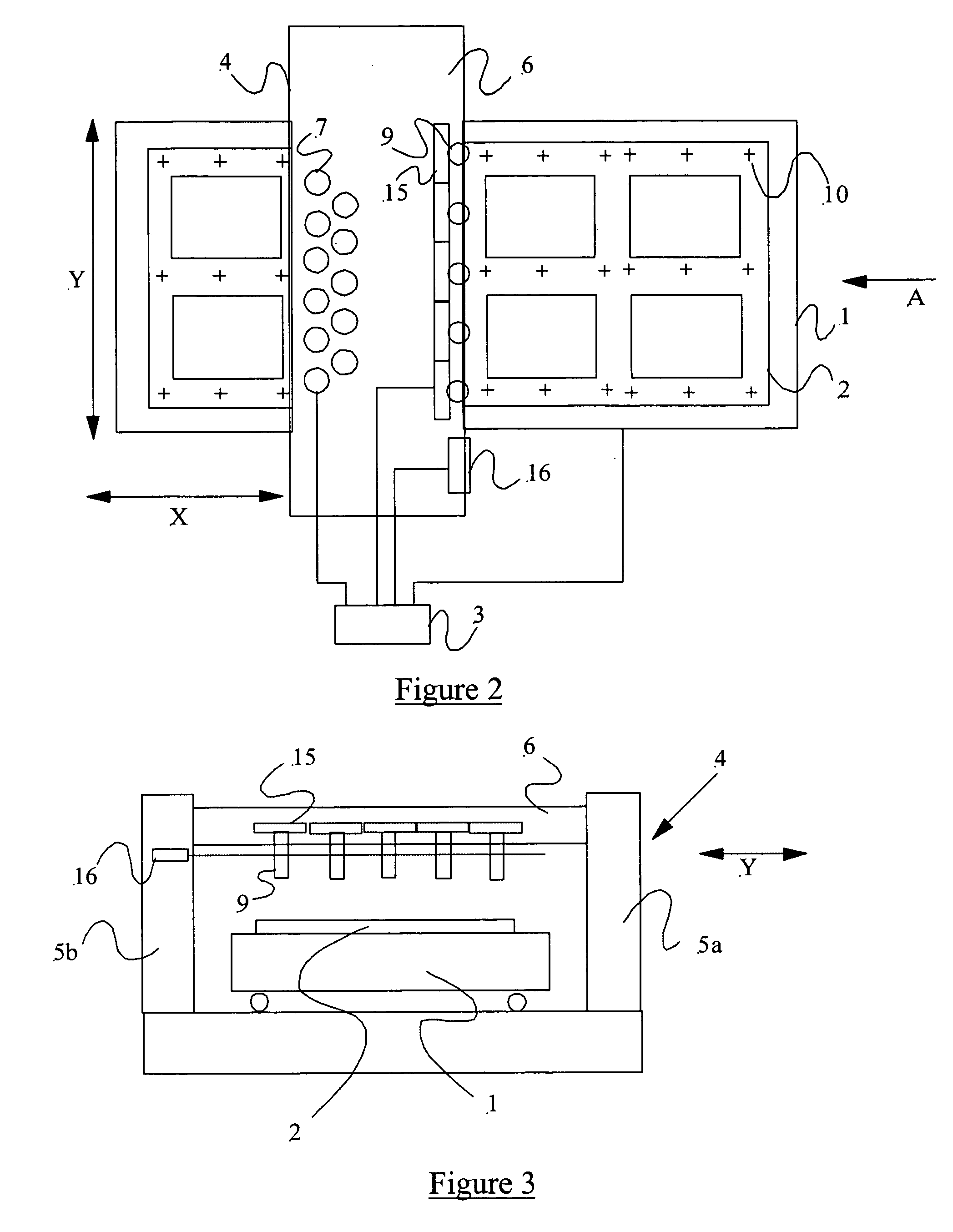

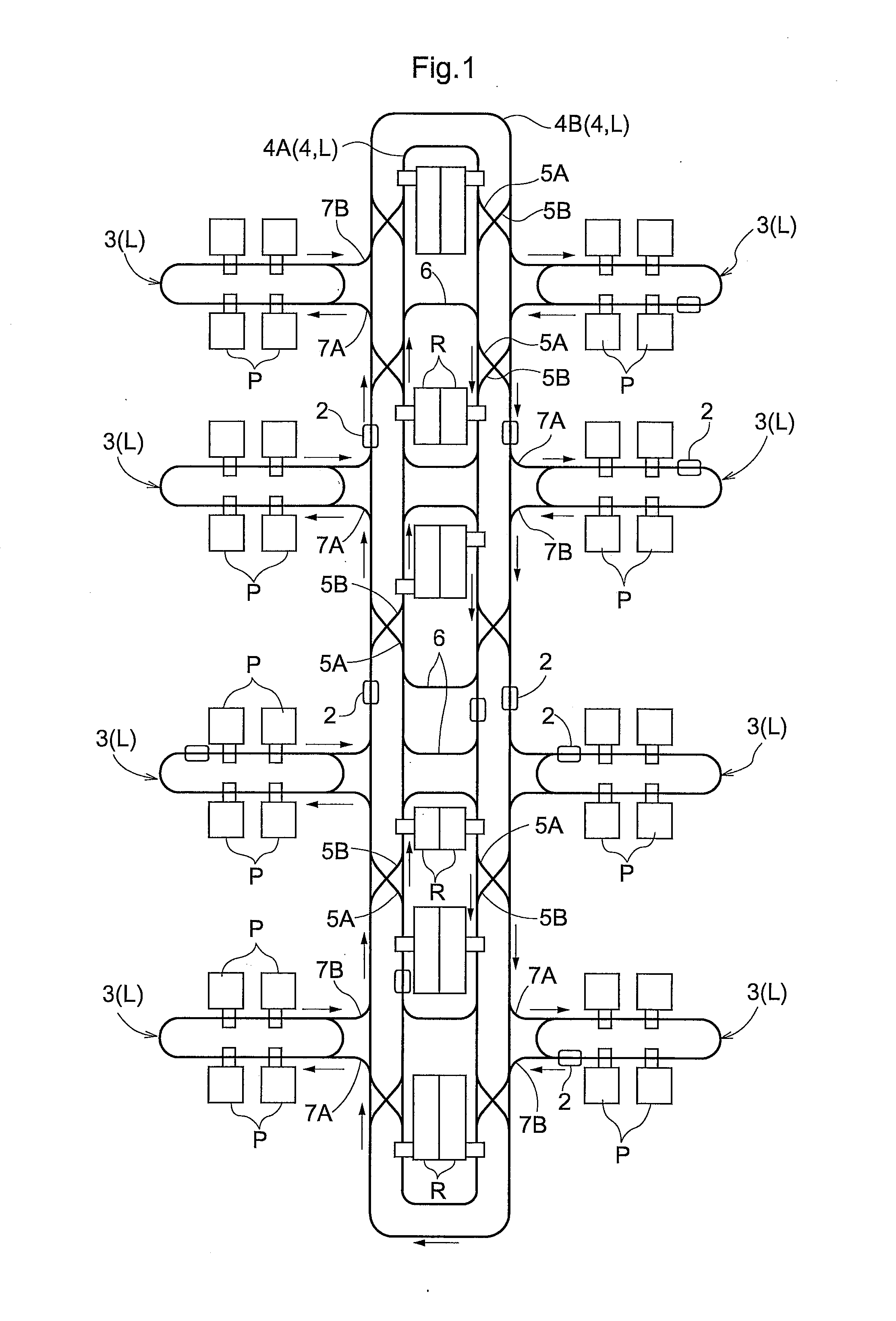

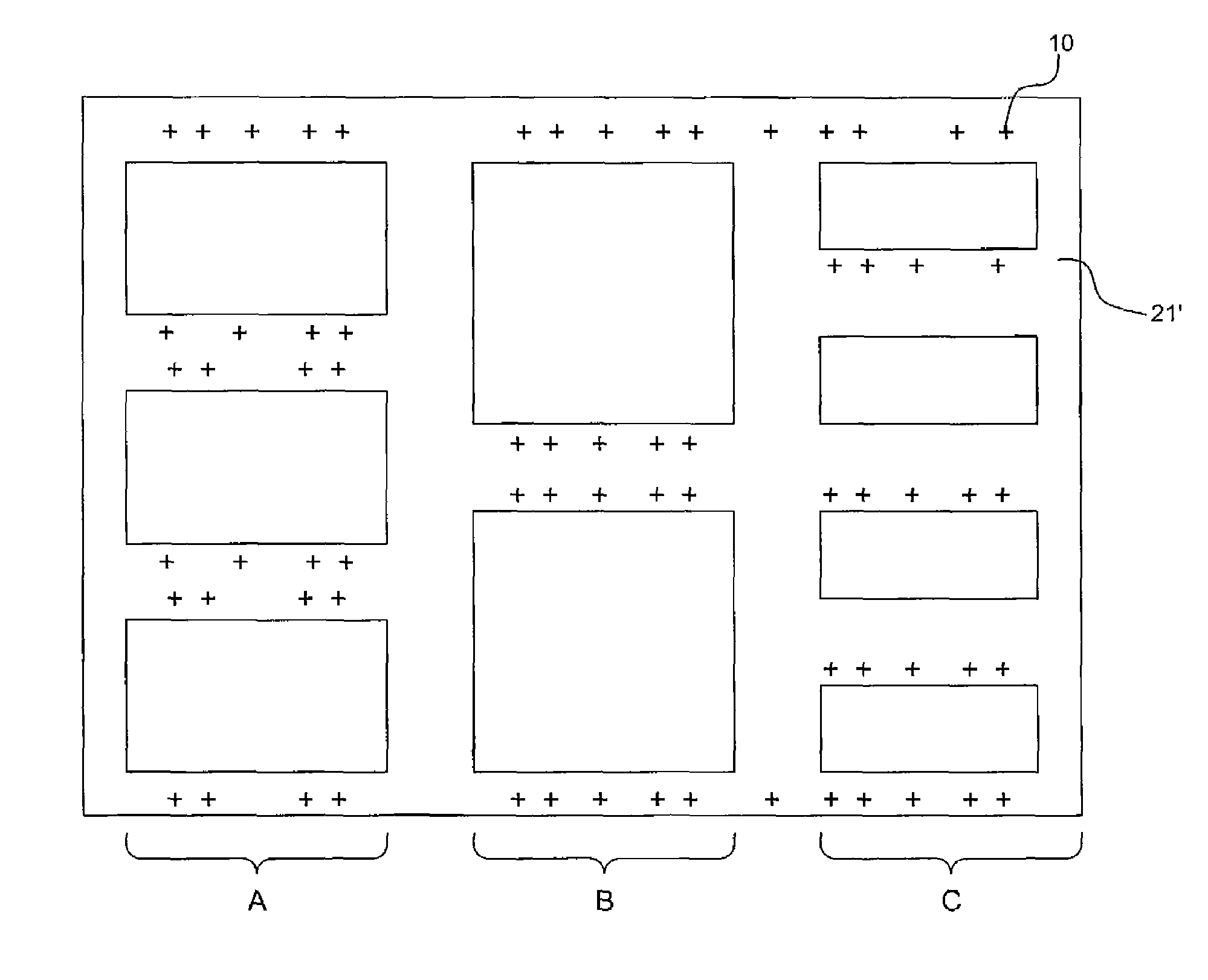

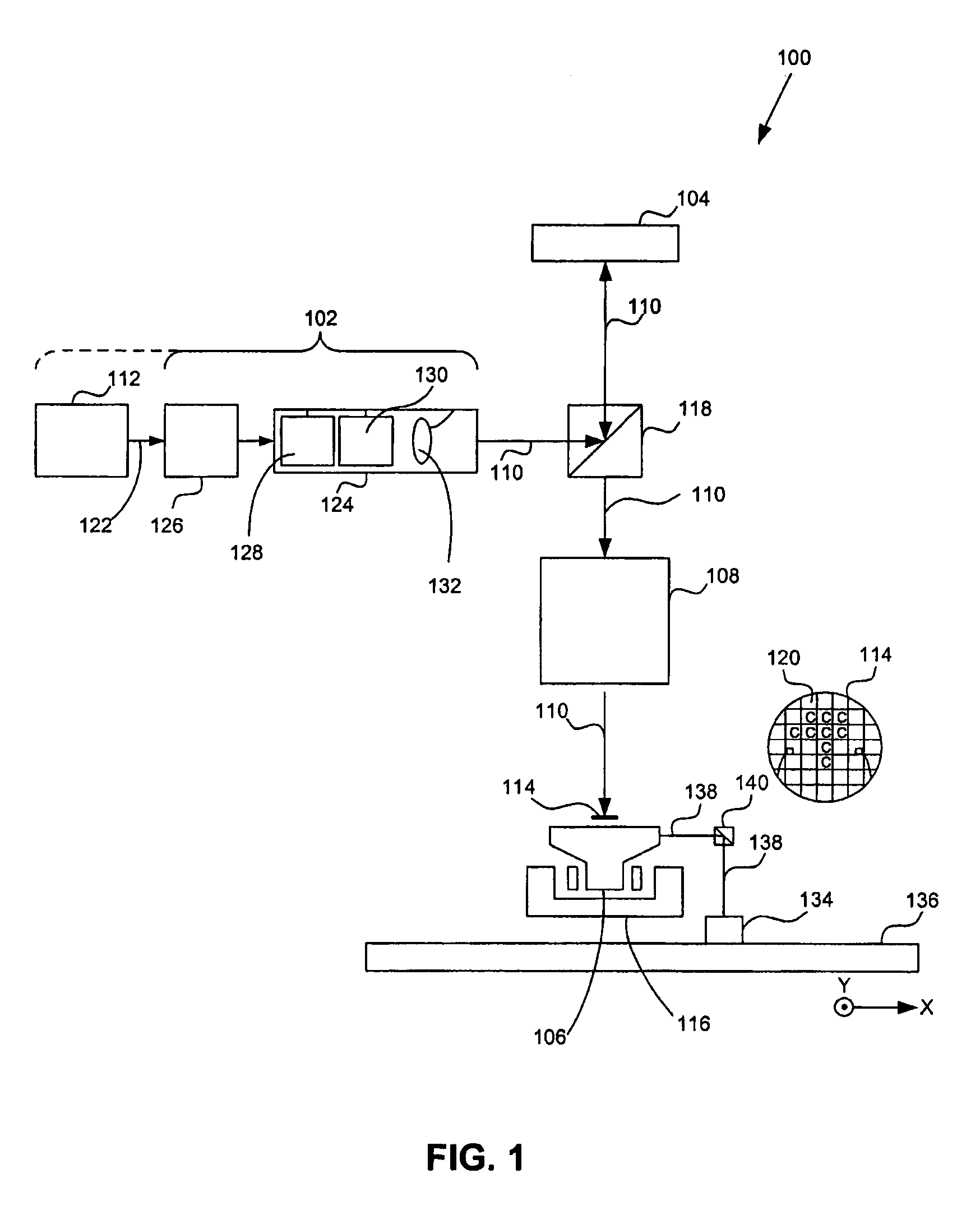

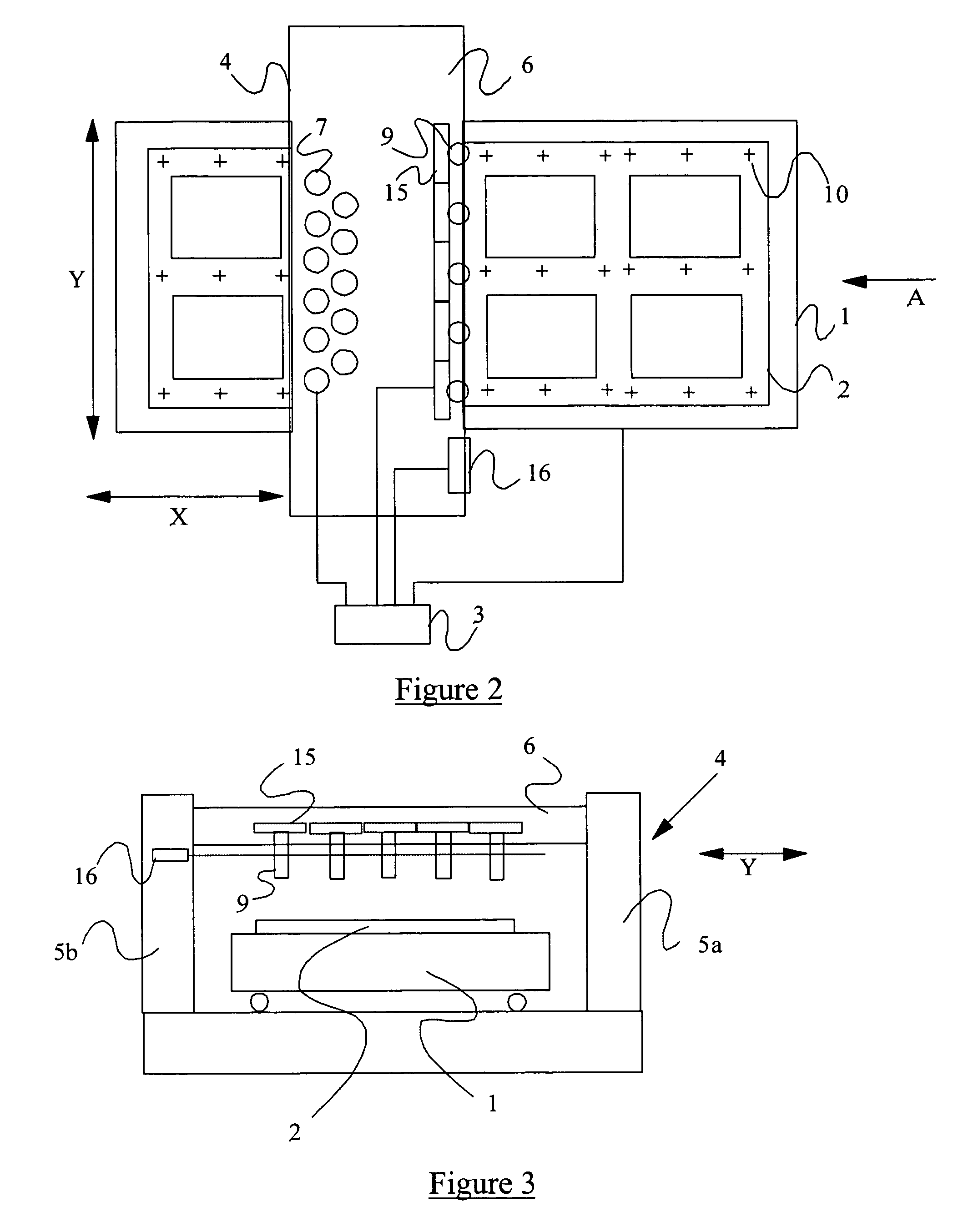

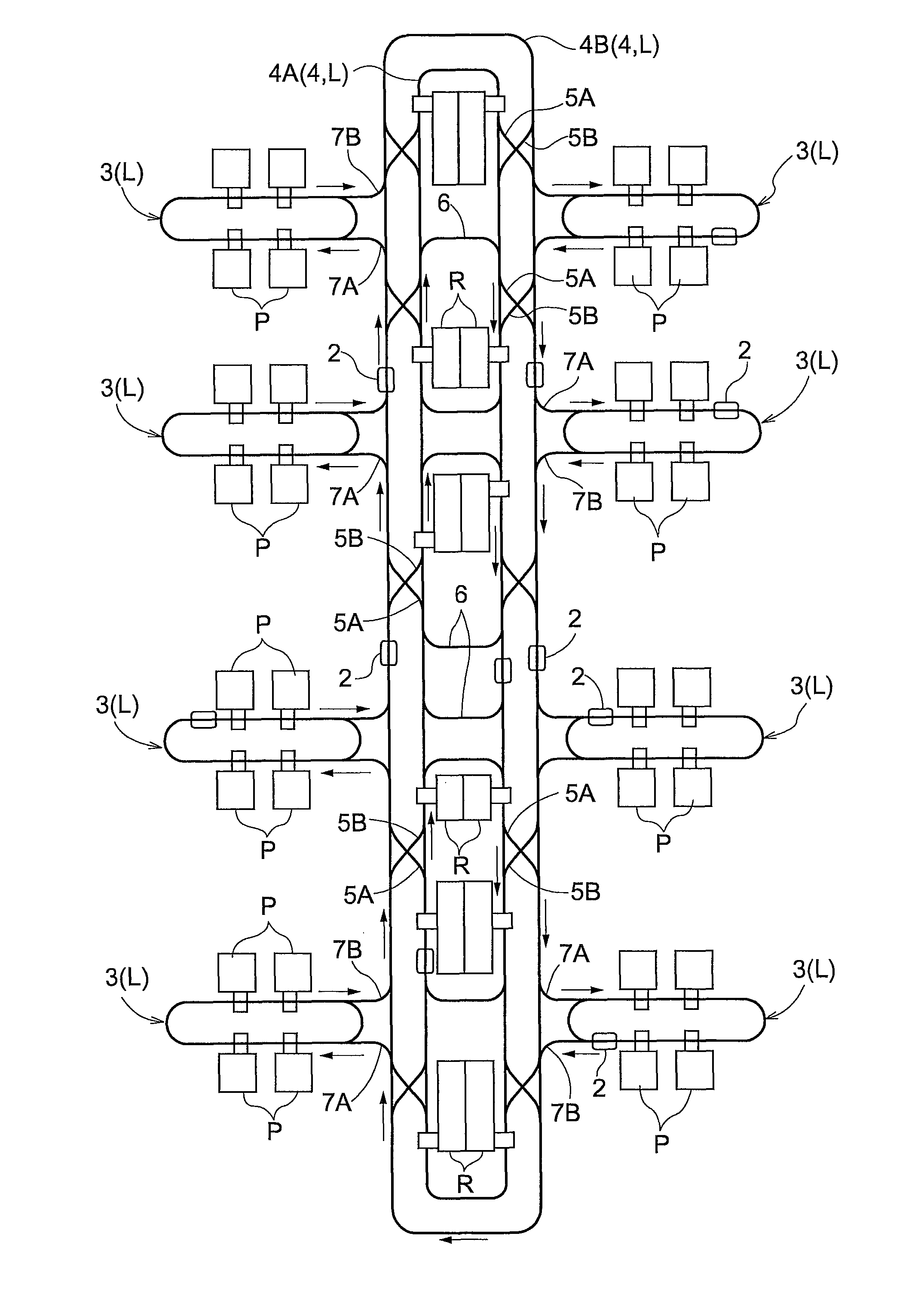

Optical position assessment apparatus and method

ActiveUS20060092419A1Improved production accuracy and flexibilityConfigure operationUsing optical meansPhotomechanical exposure apparatusProjection systemLinear drive

A lithographic apparatus comprises a substrate table that supports a substrate having alignment marks on a surface thereof. The apparatus further comprises a frame moveable relative to the substrate to provide for a scanning or stepping mode of operation. An array of projection systems is disposed across the frame for projecting respective patterned beams onto a target portion of the substrate. A plurality of alignment mark detectors are attached to the frame and are moveable with respect to the frame using respective linear drive mechanisms. A position sensor is associated with each alignment mark detector for determining the position of the detector relative to the frame. A control system is responsible for both initial positioning of the detectors above alignment mark patterns on the substrate, and for dynamic alignment of the frame and substrate during a lithographic process.

Owner:ASML NETHERLANDS BV

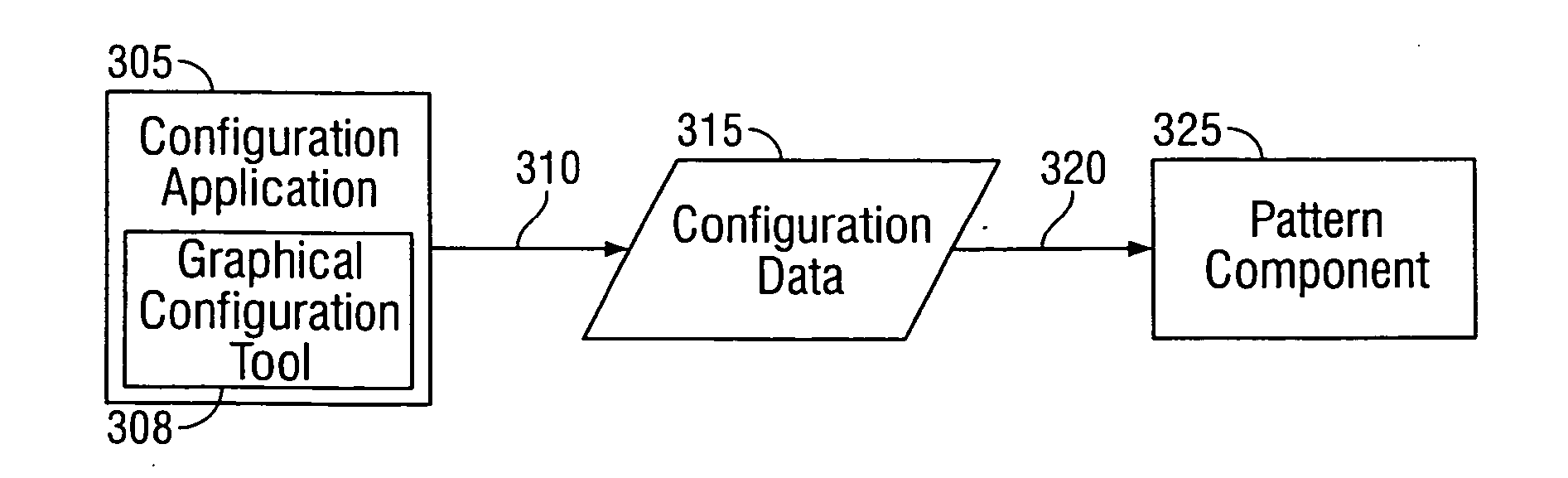

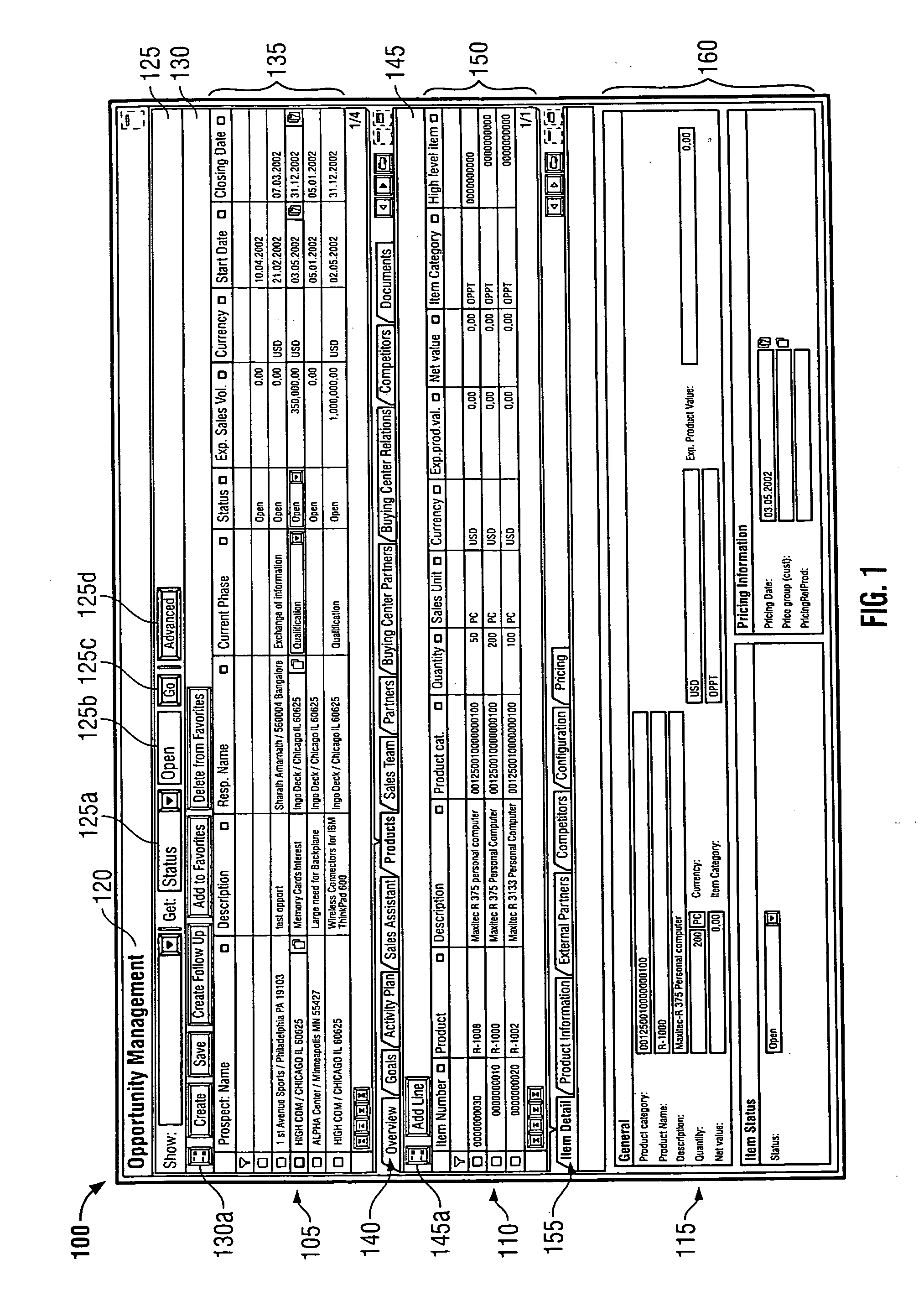

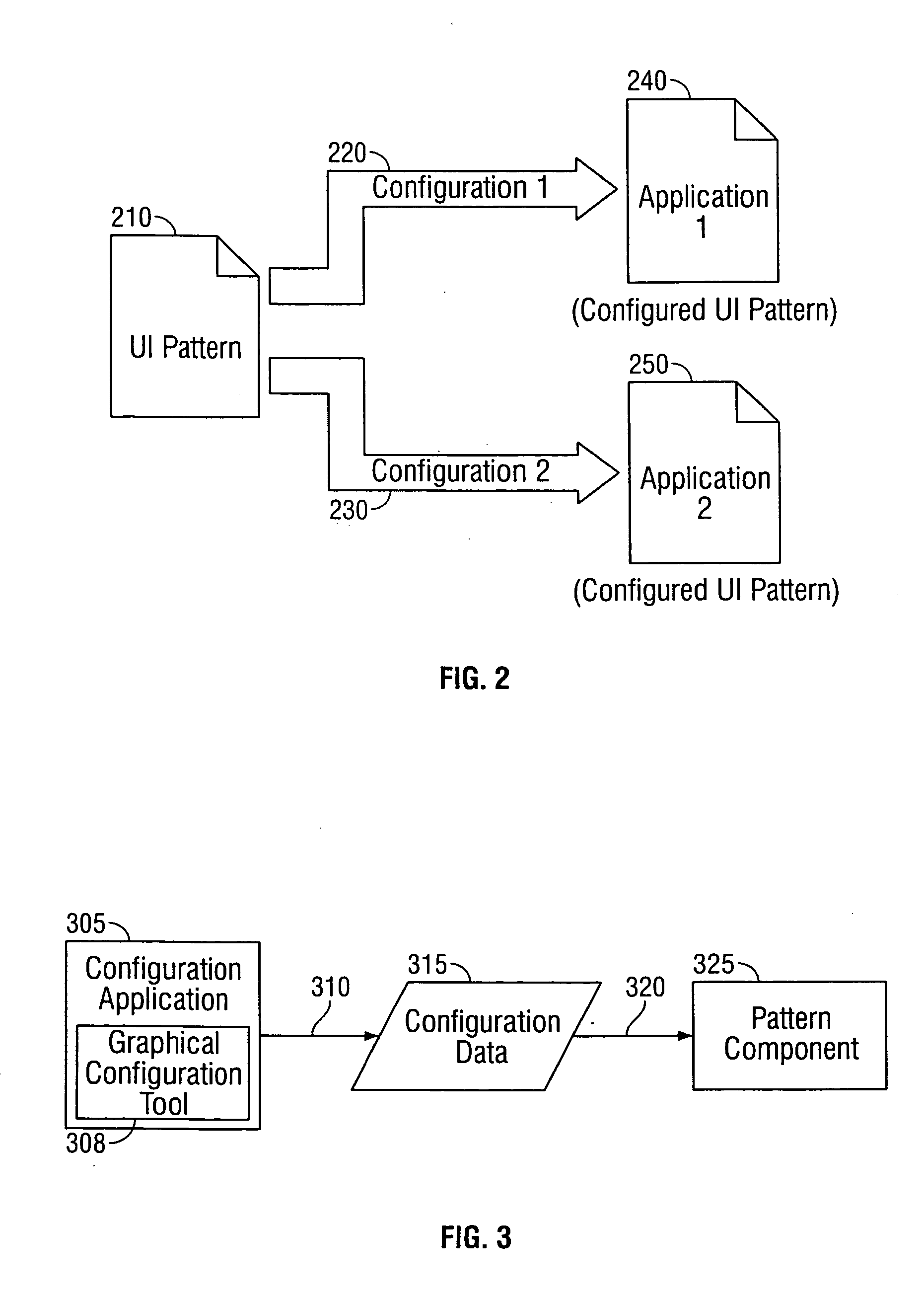

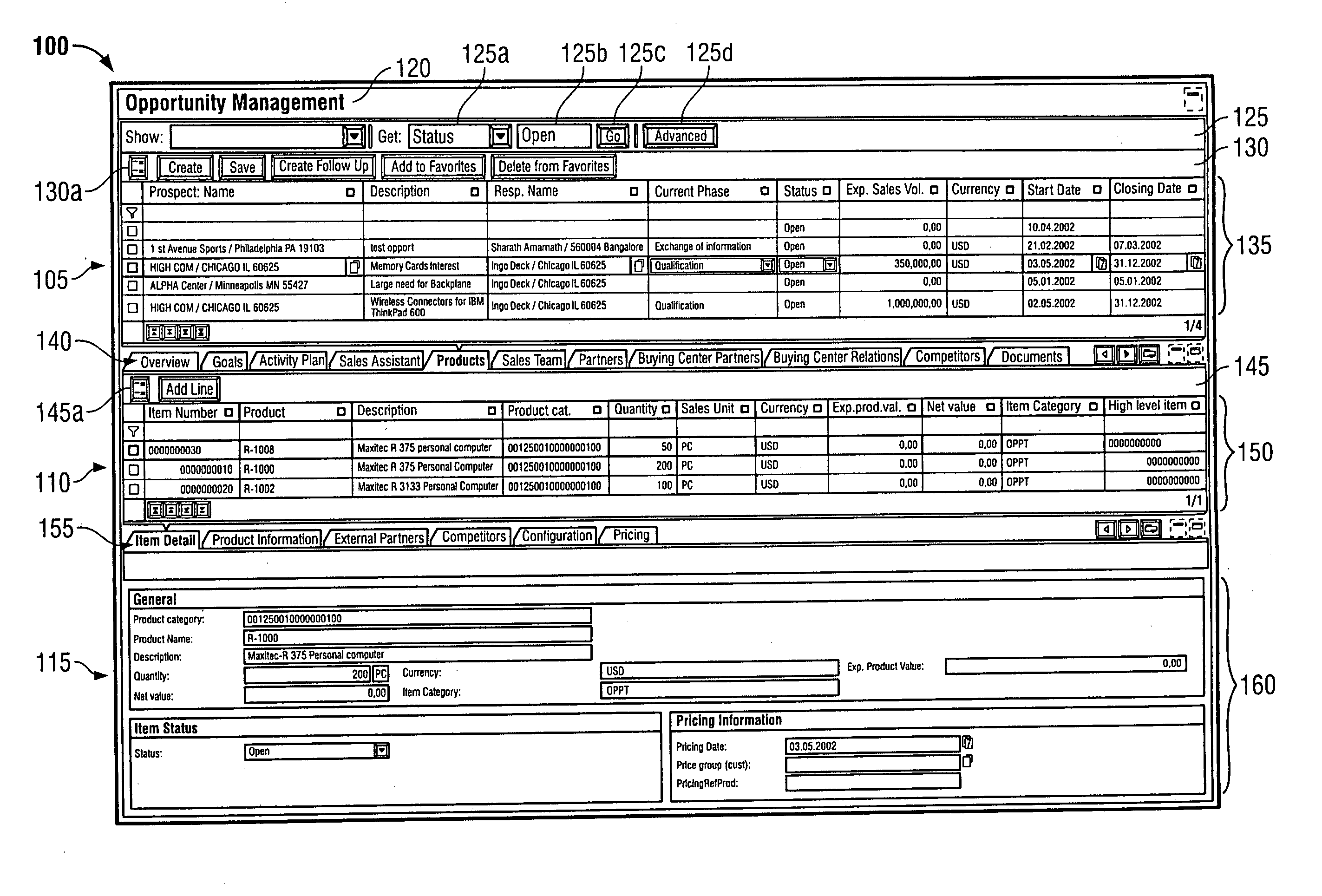

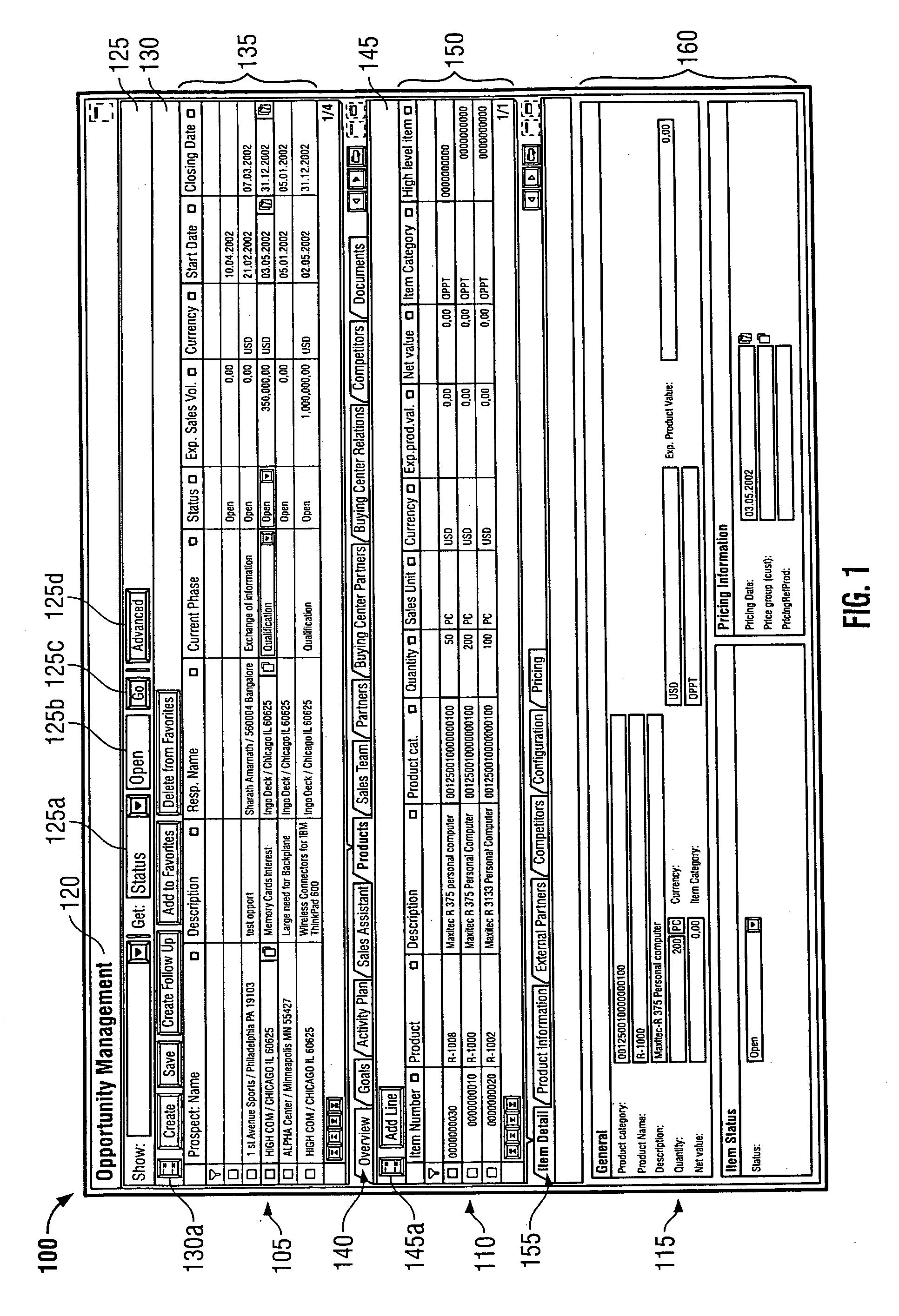

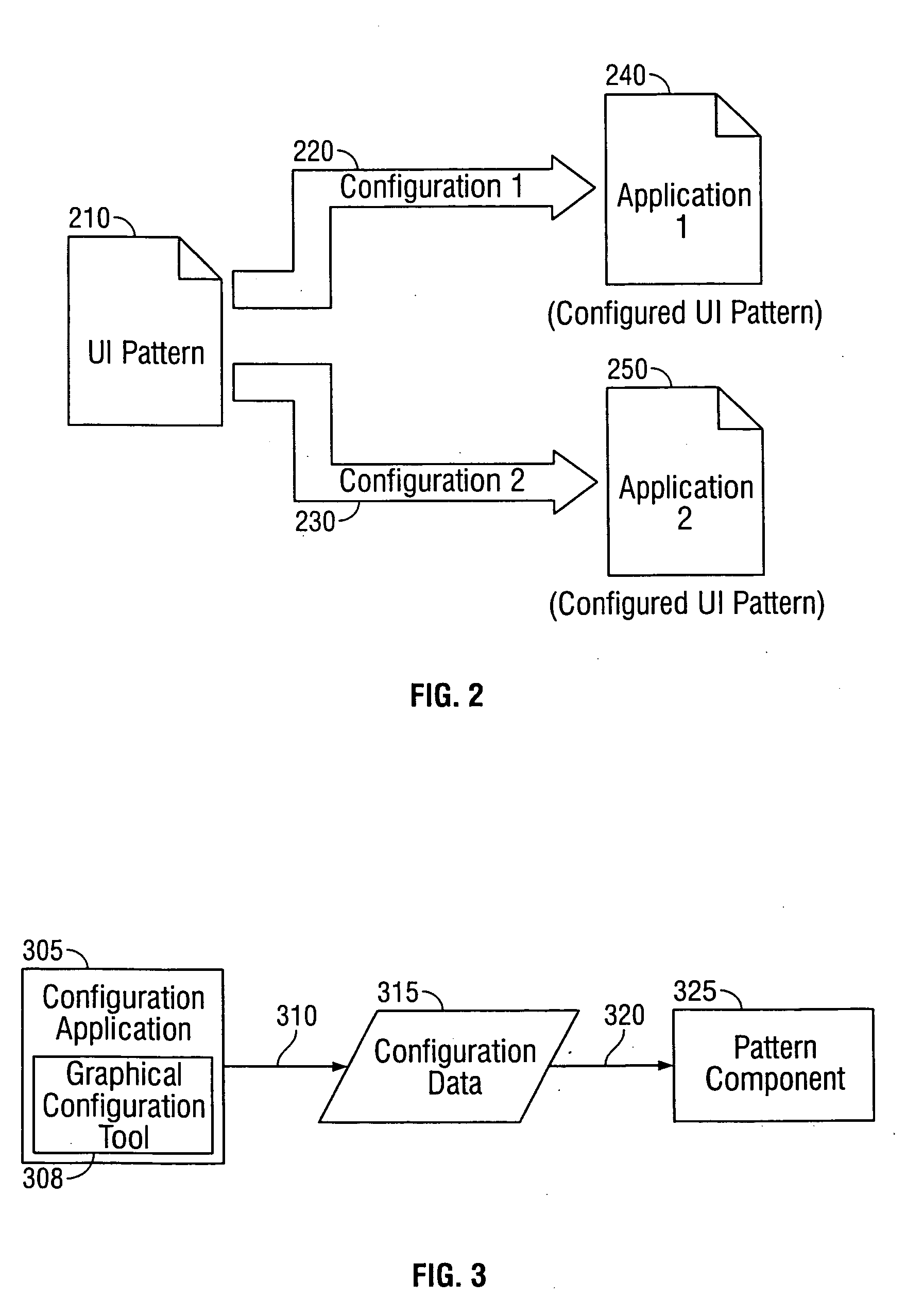

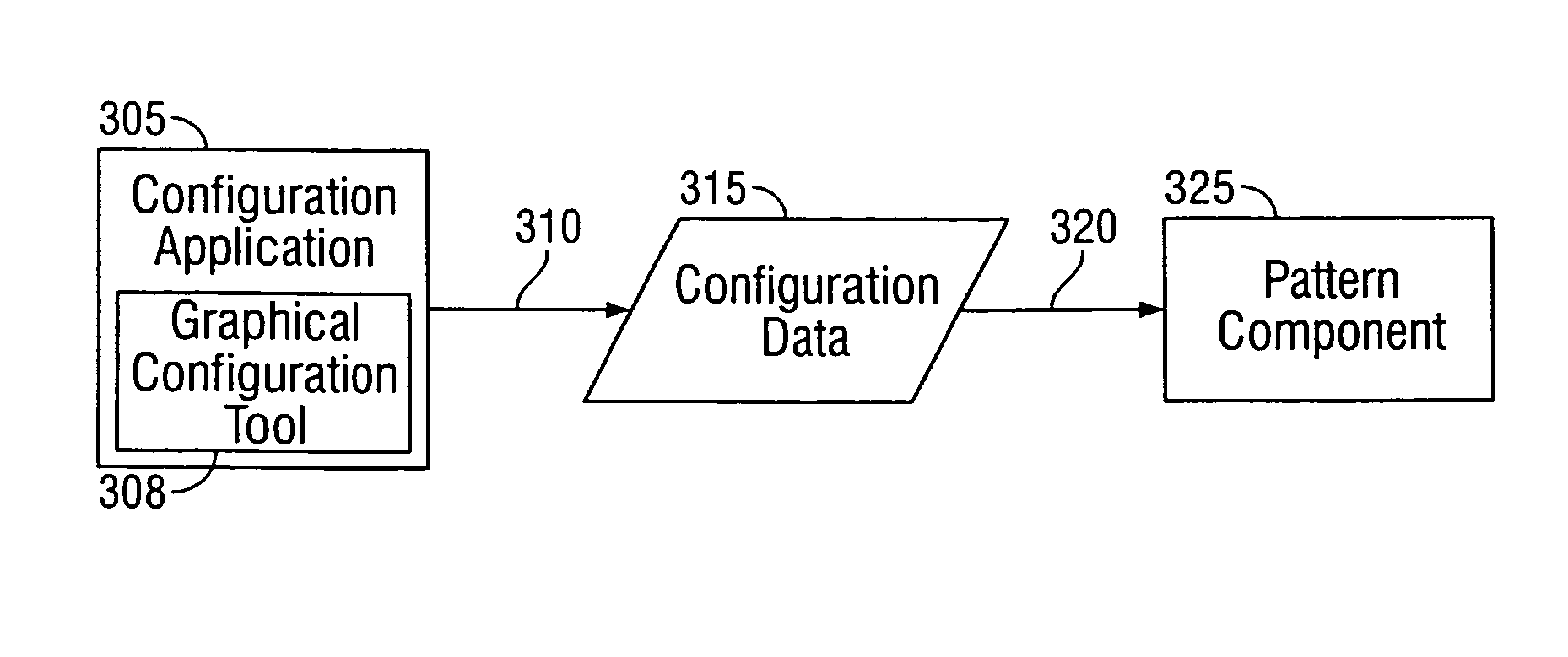

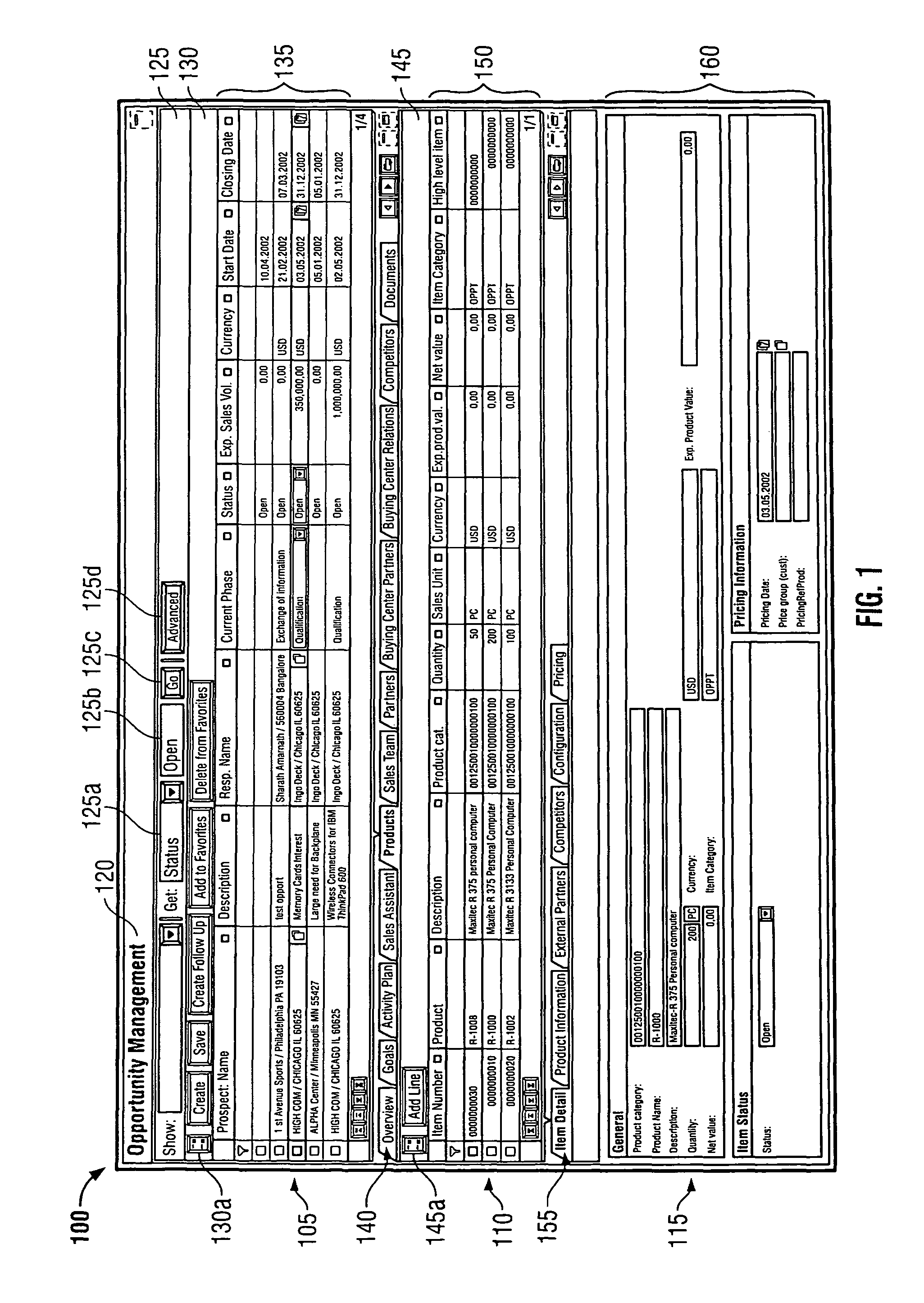

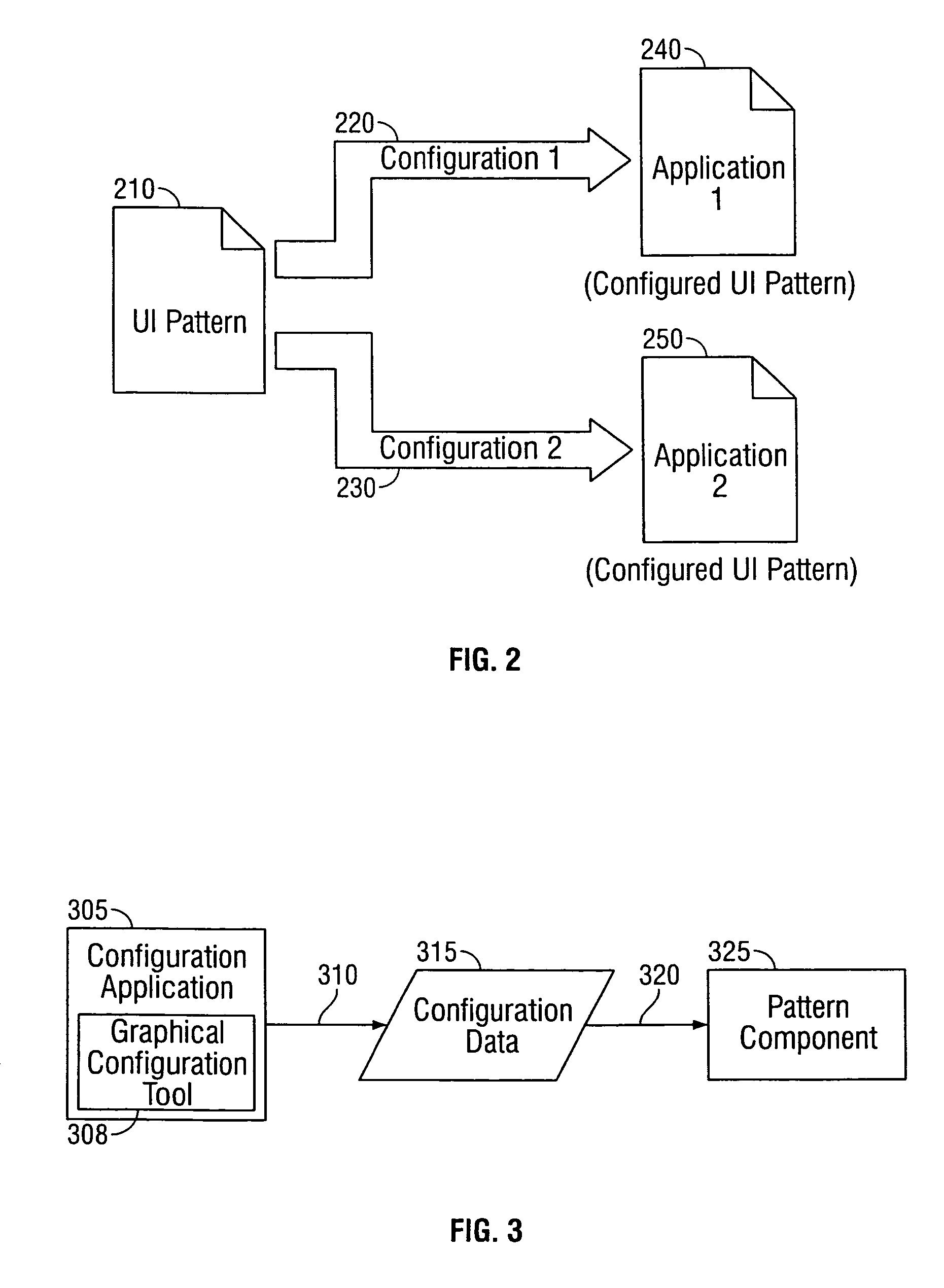

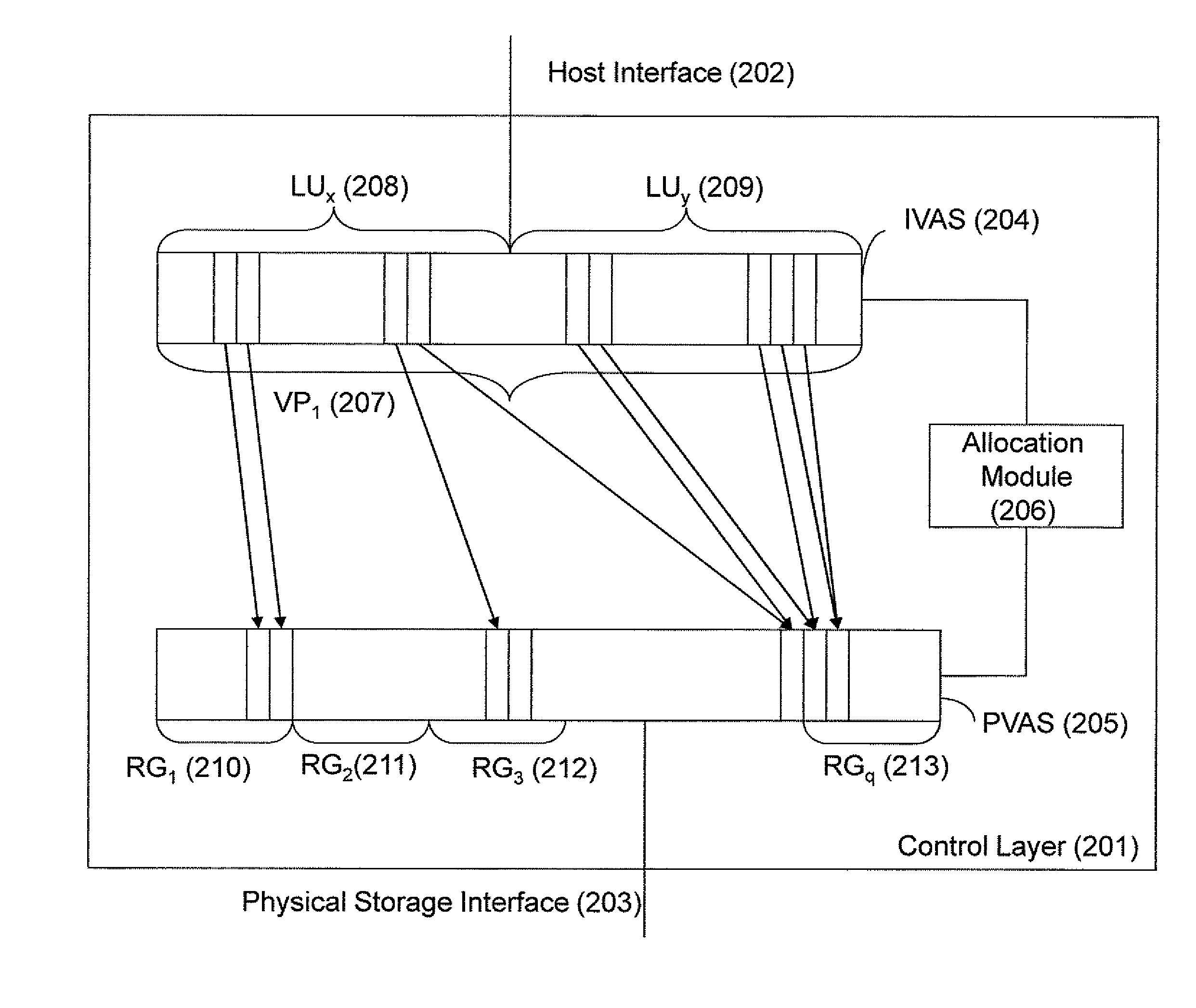

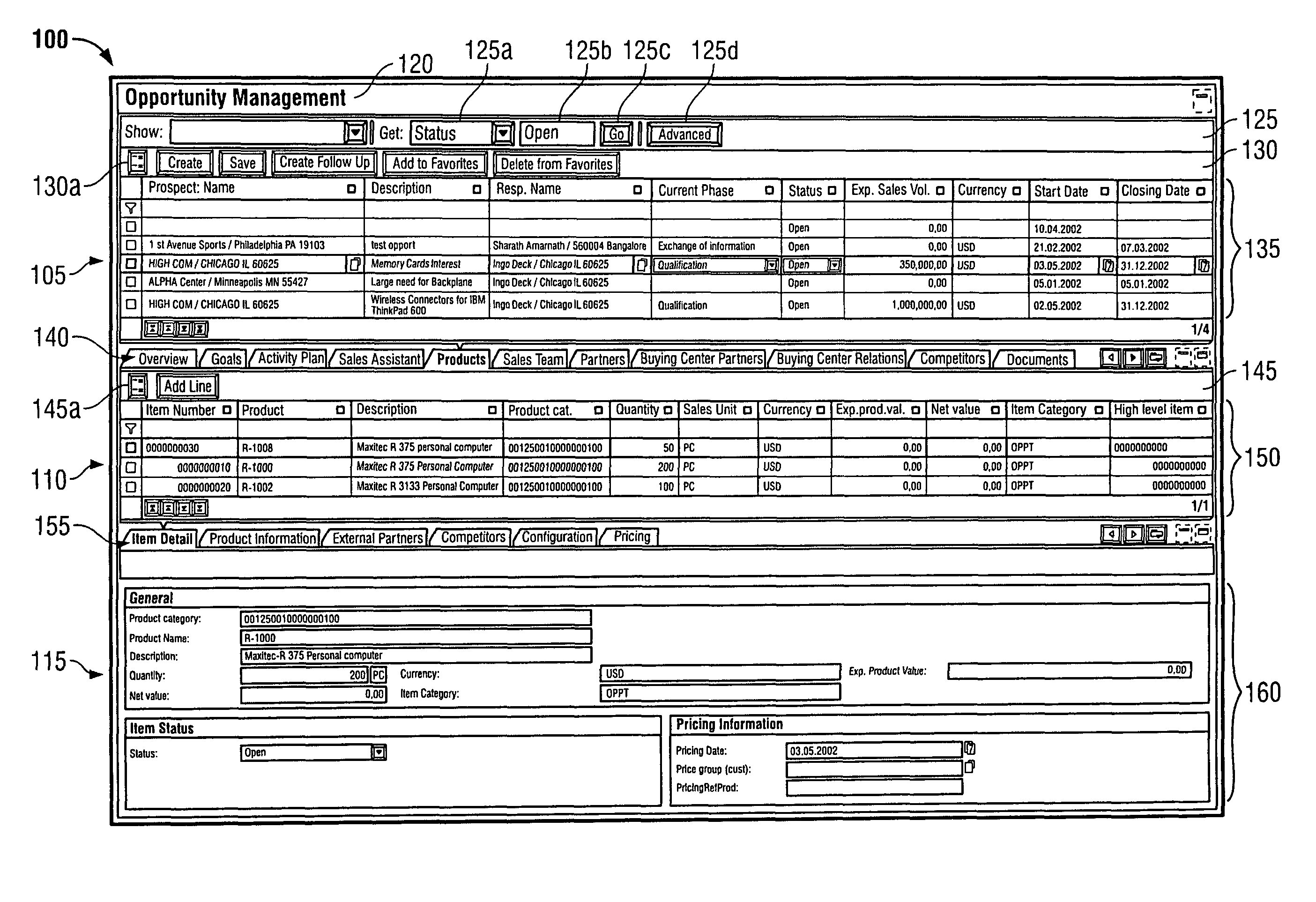

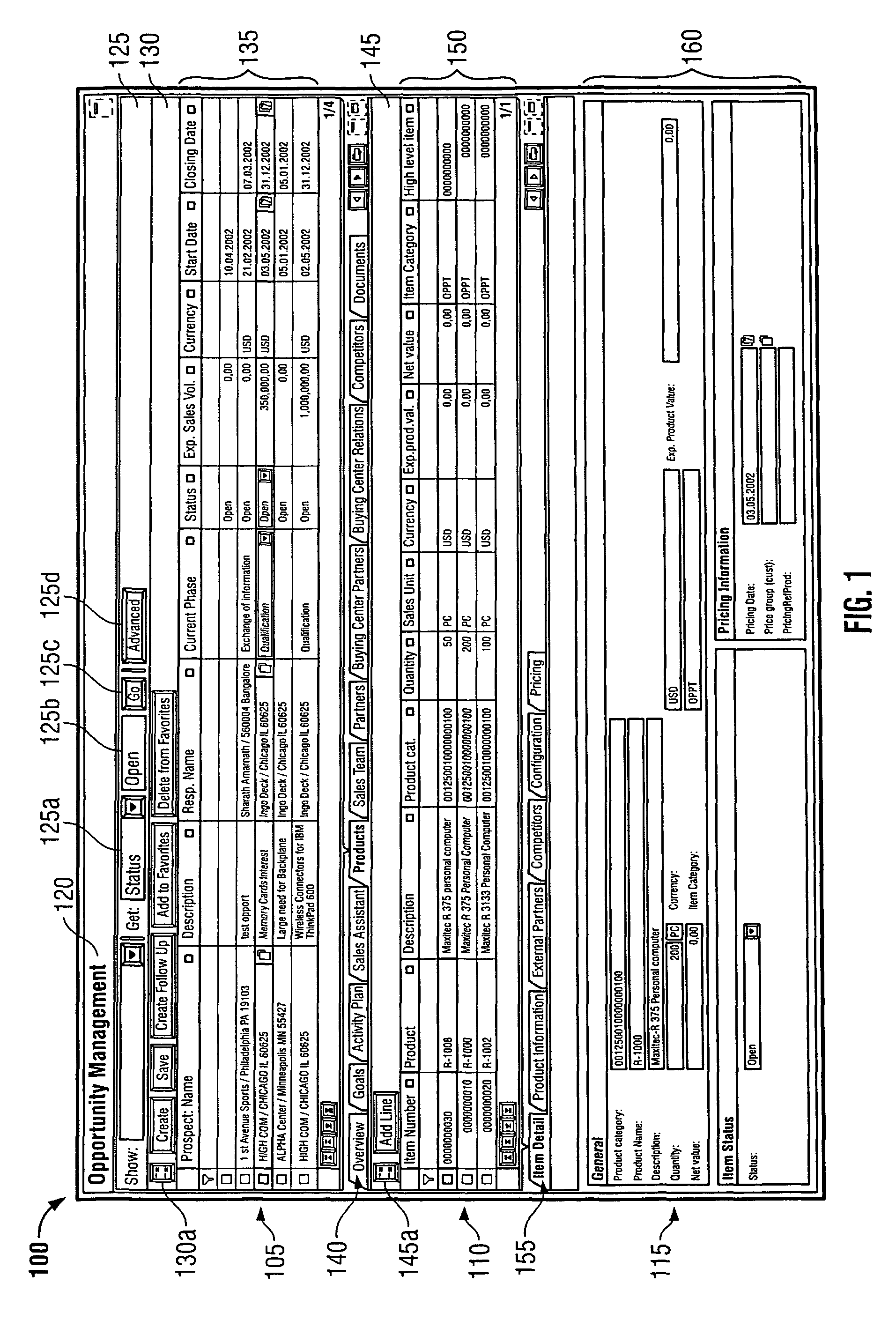

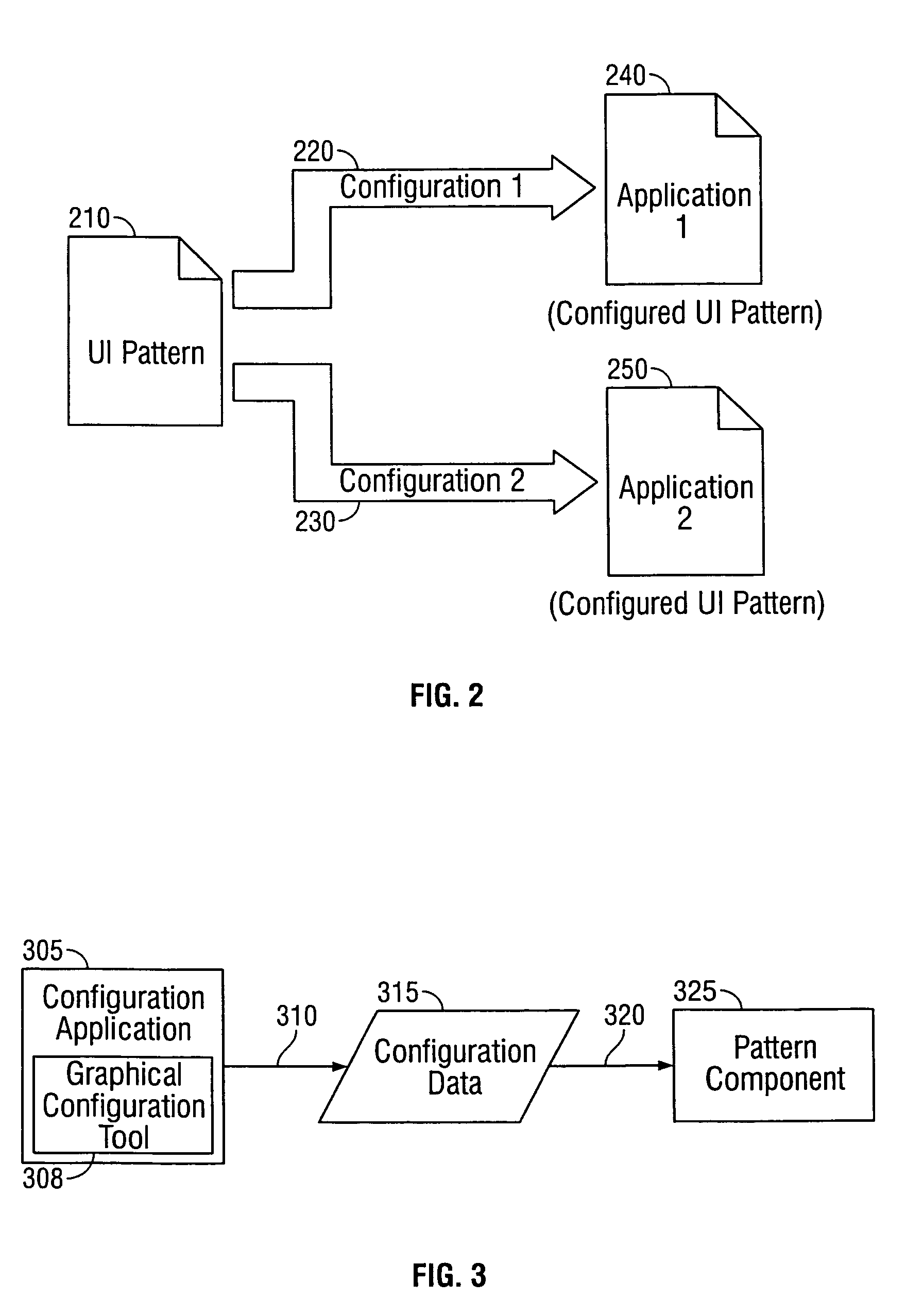

Developing applications using configurable patterns

ActiveUS20060075382A1Configure operationSimple processDigital data processing detailsVisual/graphical programmingApplication softwareQuery statement

Methods, systems, and computer program products, implementing techniques for developing applications using configurable patterns. The techniques include determining the functionality of a pre-existing application; selecting one or more patterns based on the functionality of the pre-existing application, and configuring the patterns so that the patterns execute similar functionality as the pre-existing application. The patterns comprise multiple pattern elements including prearranged user interface elements. The patterns specify predefined actions that can be performed using the user interface elements. The predefined actions match actions performed by the pre-existing application. Configuring the patterns includes importing database structure from a database used by the pre-existing application, generating a visual model of a query performed on the database by the pre-existing application, converting the visual model of a query into a query statement, and configuring the patterns to use the query statement.

Owner:SAP AG

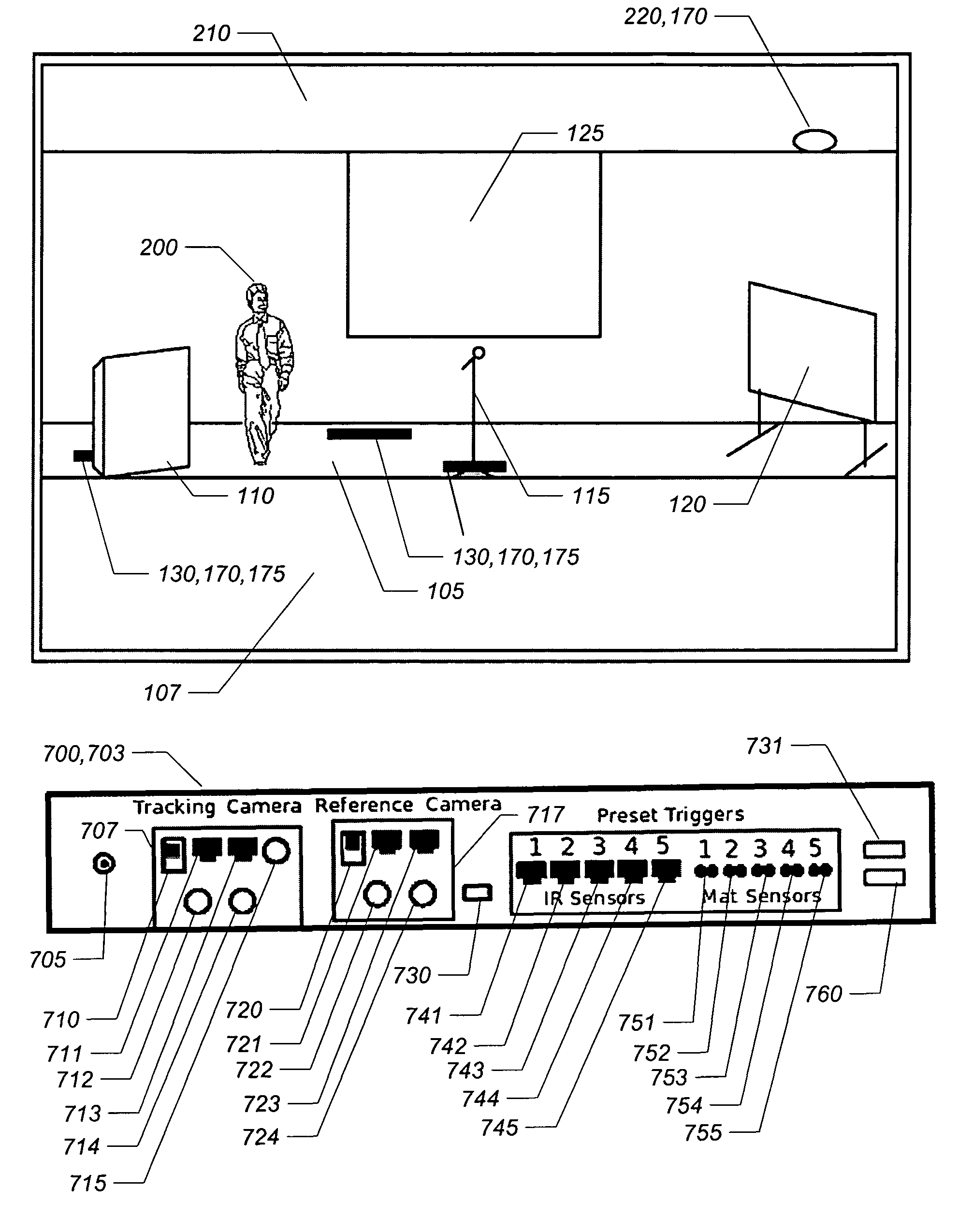

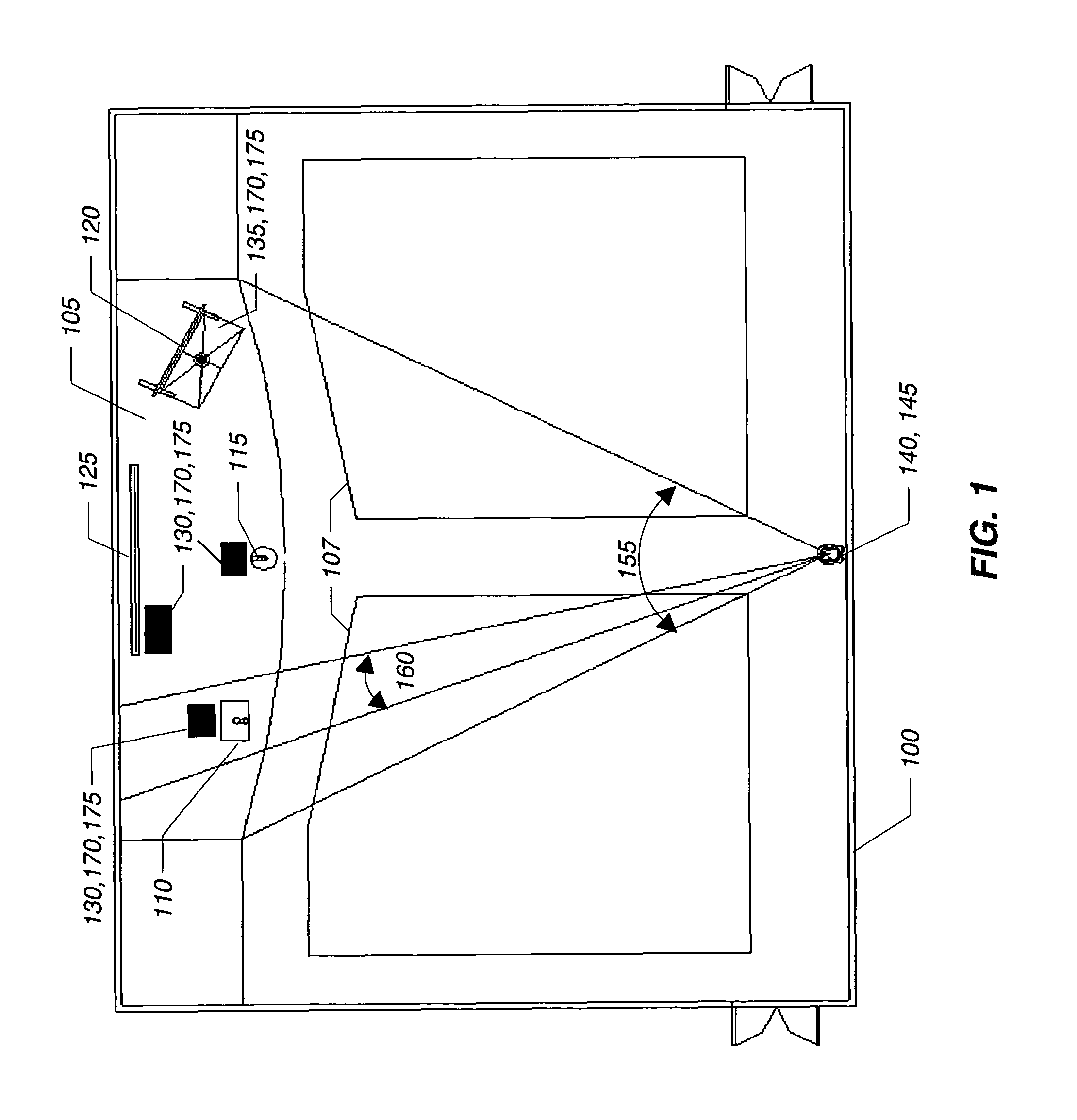

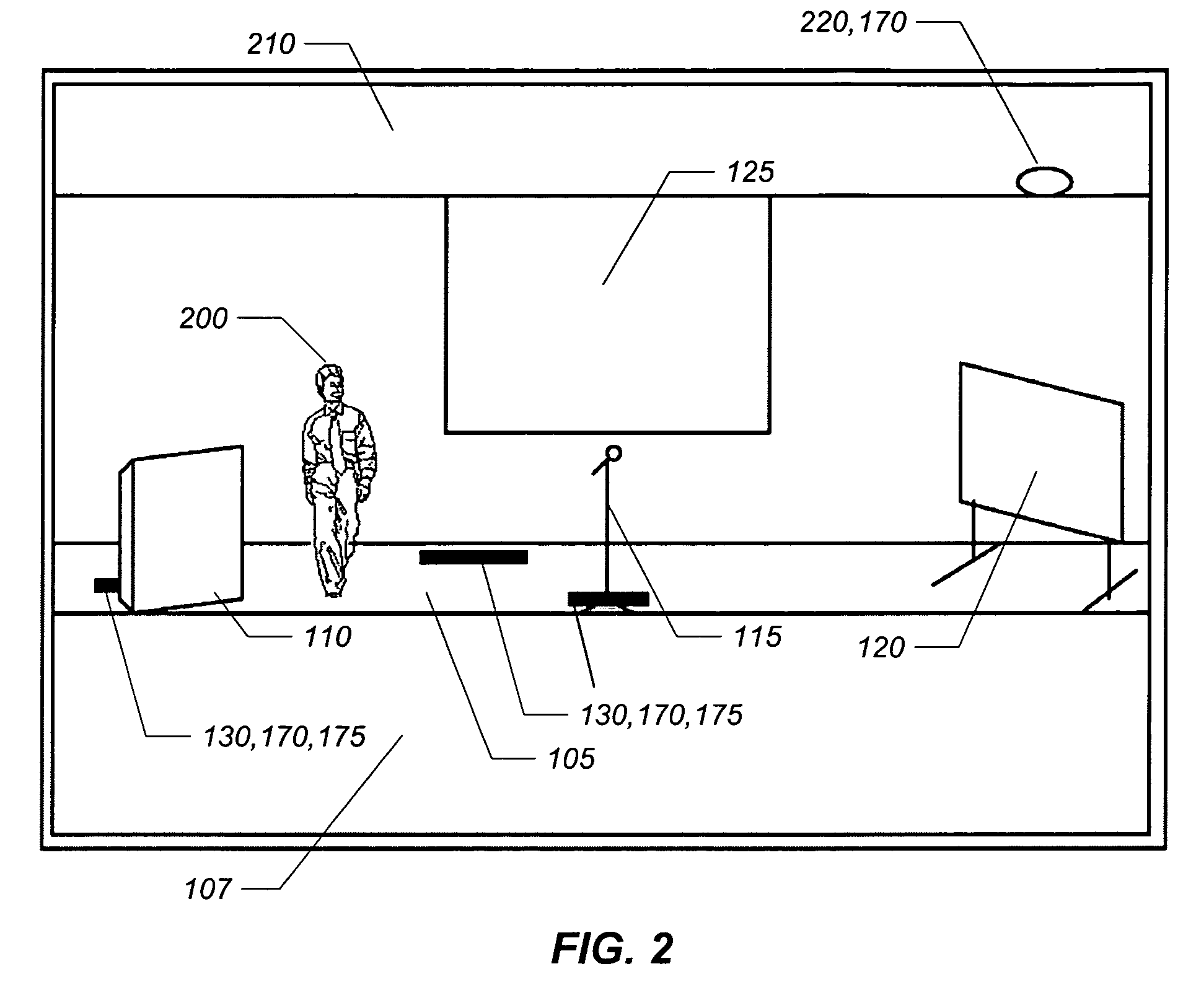

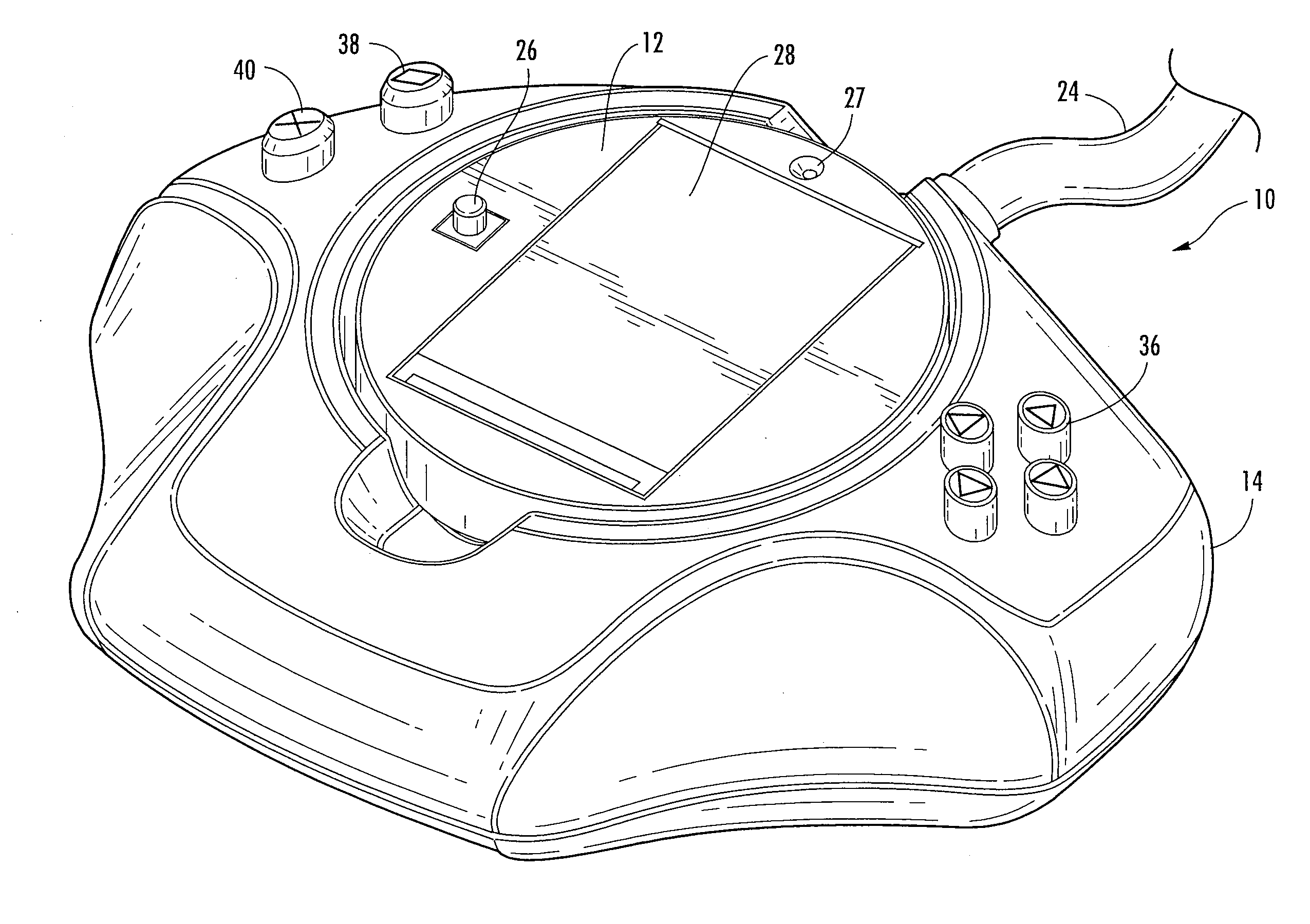

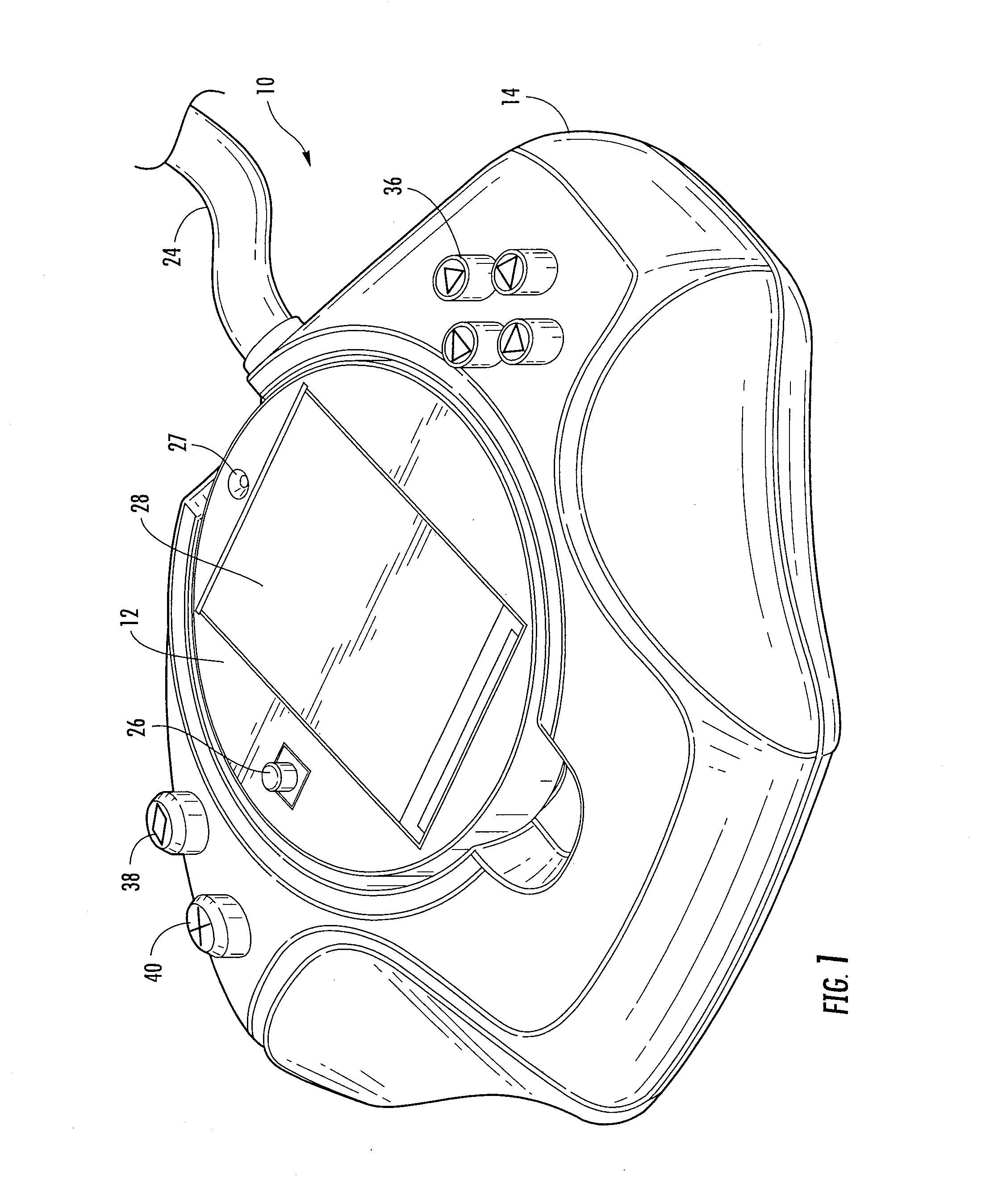

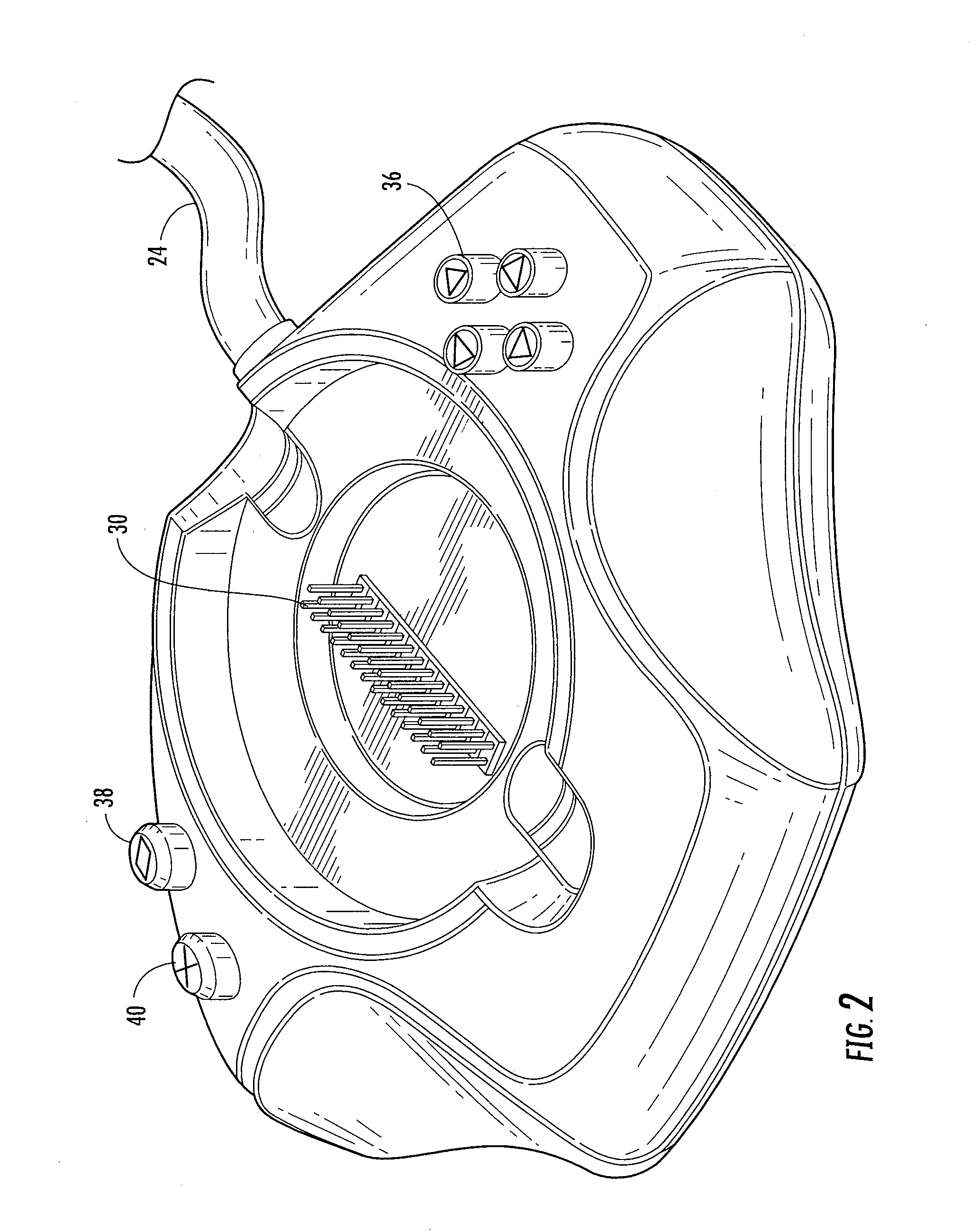

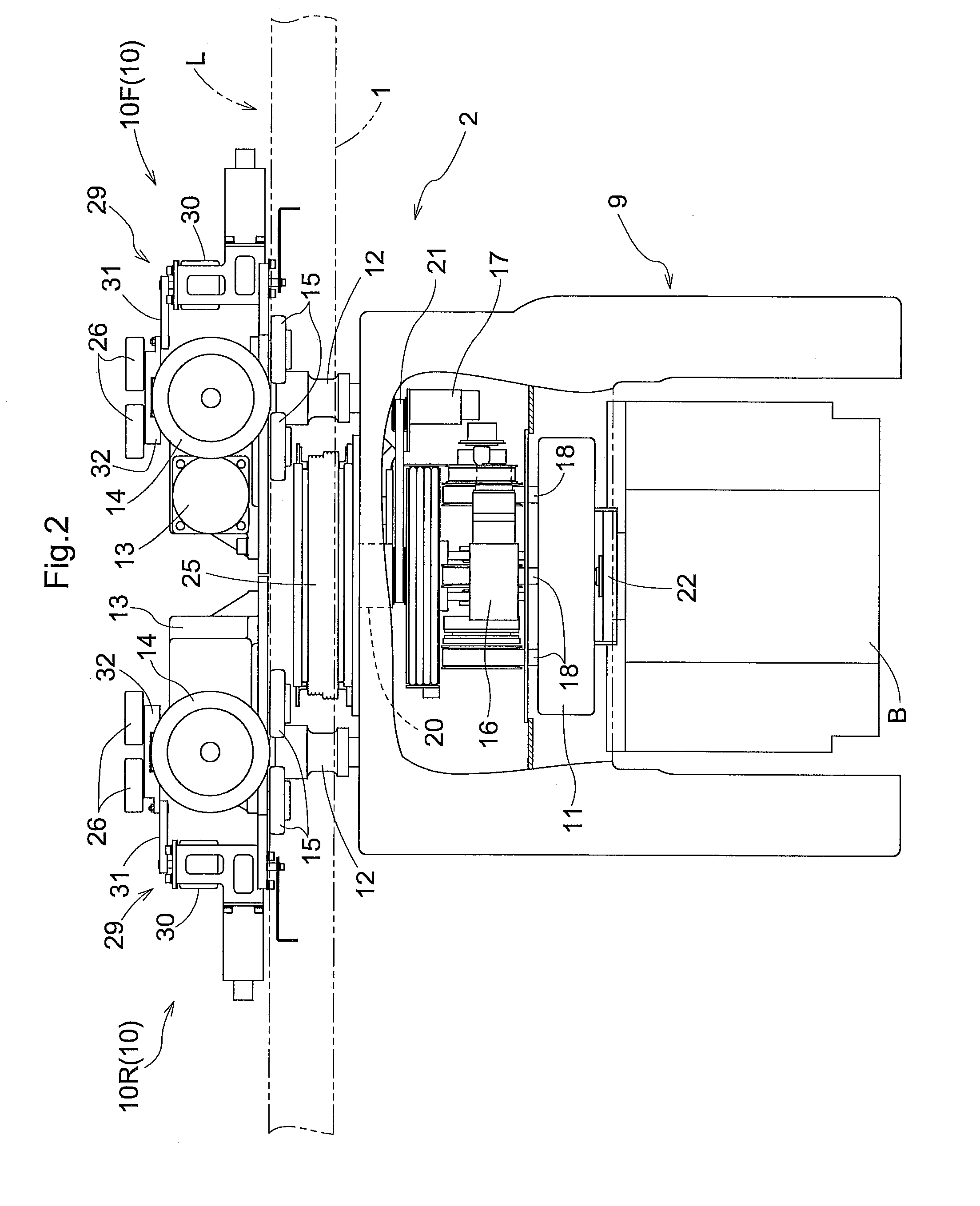

Presentation video control system

ActiveUS8094193B2Avoid detectionConfigure operationTelevision system detailsColor television detailsCamera controlSystems design

The present invention is a camera control system designed for video capture of a presentation made in a lecture hall or similar place. The system combines preset views triggered by presence-sensing devices at fixed locations with views tracking the motion of the presenter elsewhere. A tracking camera displays a preset view when the presenter steps on a switch mat or enters into the region of detection of some other presence sensor such as an infrared sensor. At other times, the tracking camera is guided by motion detection logic that uses a wide field of vision provided by a reference camera. The reference camera, the tracking camera, and the presence-sensing devices are integrated by a controller. Various parameters can be configured by a user through a graphical user interface on a computer, manual controls on the box housing the controller, or a hand-held remote control device.

Owner:NATURE VISION

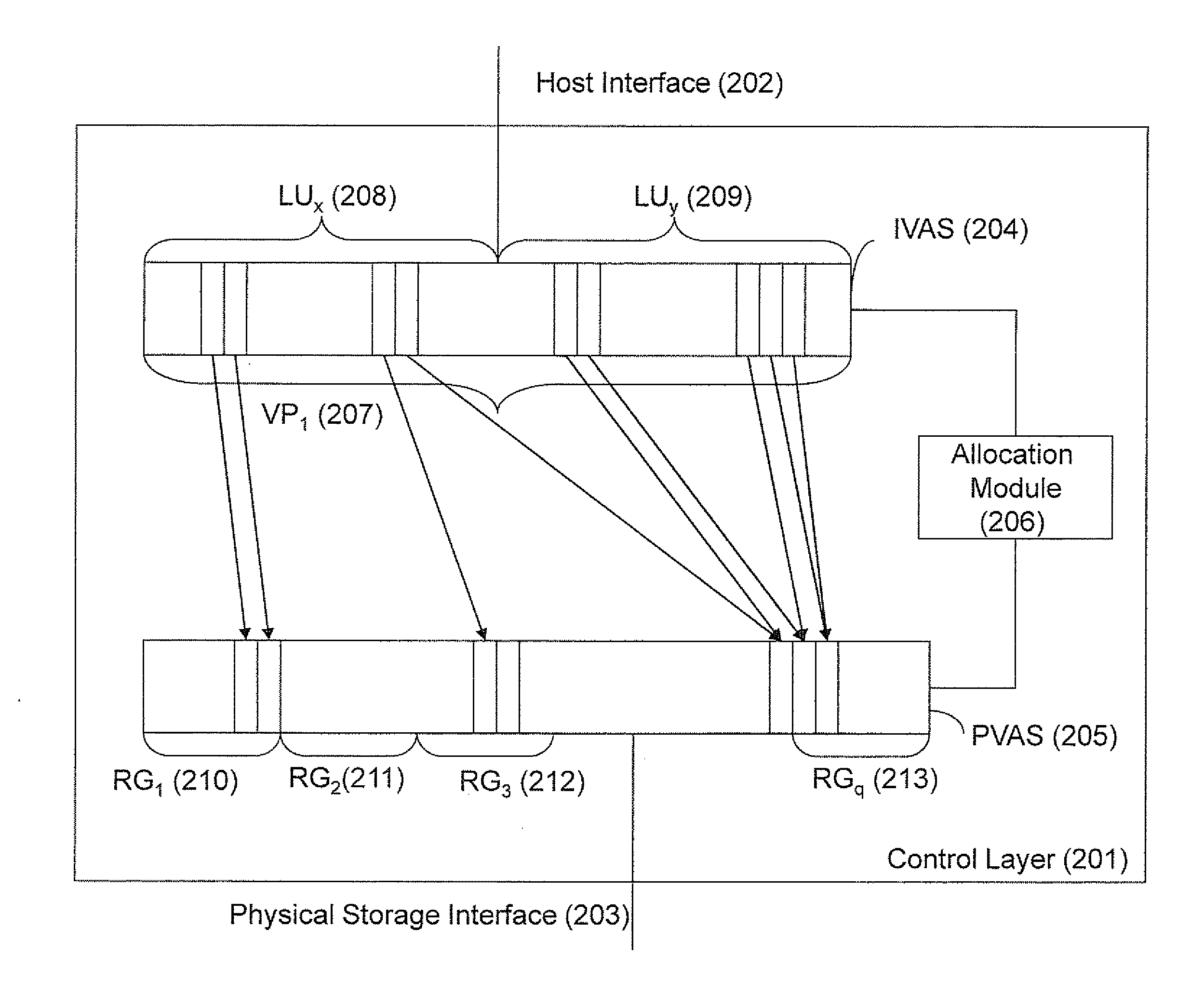

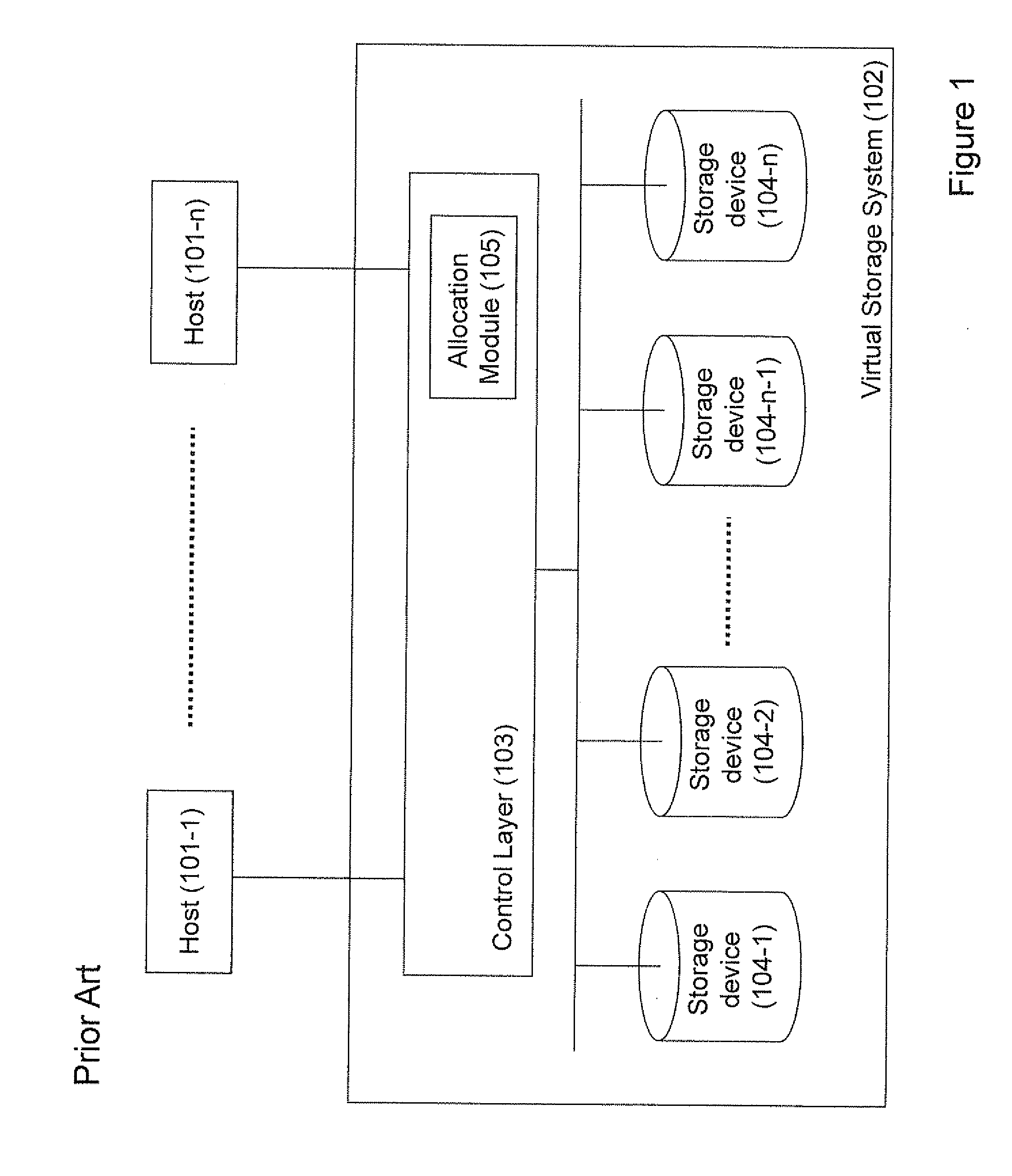

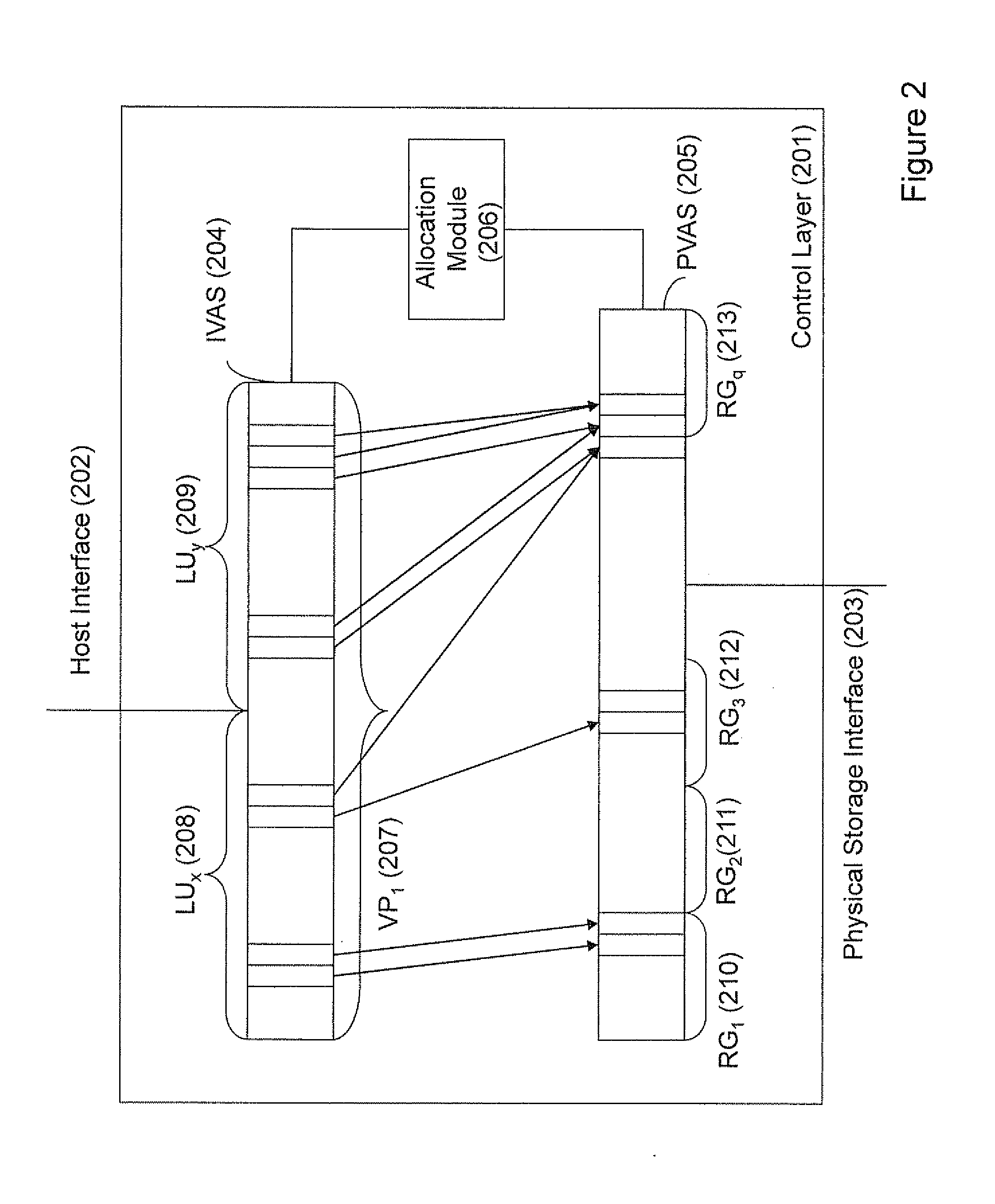

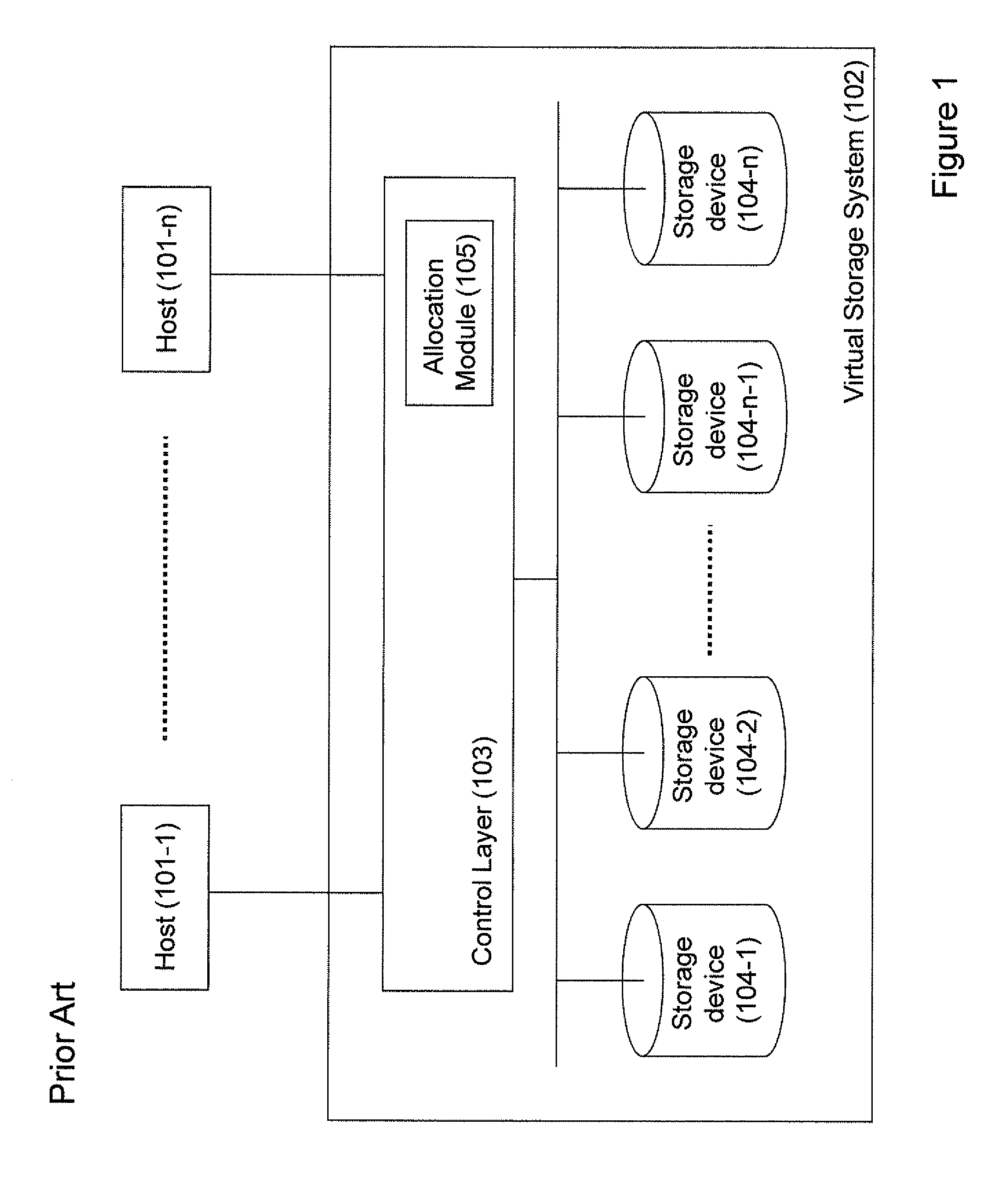

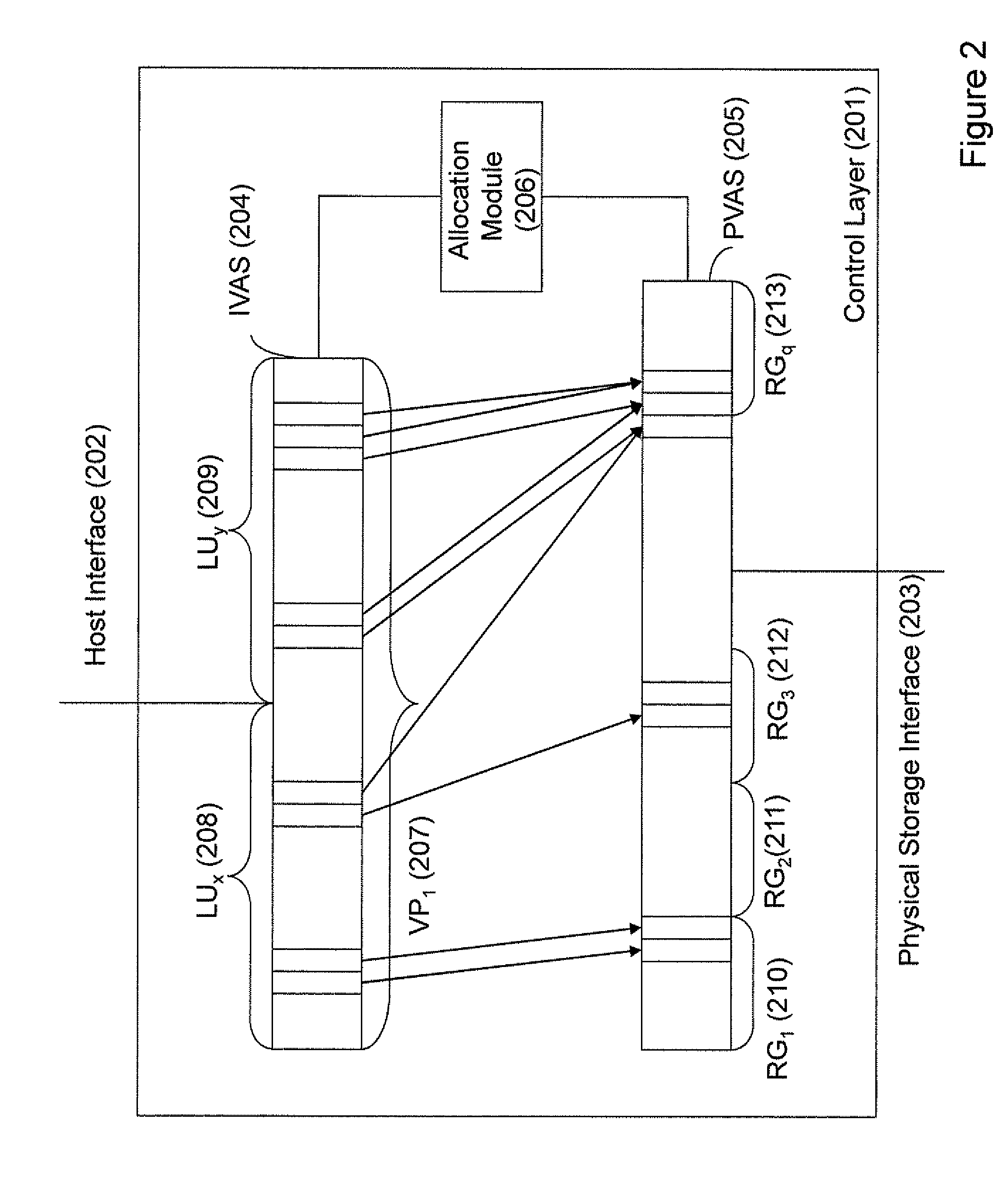

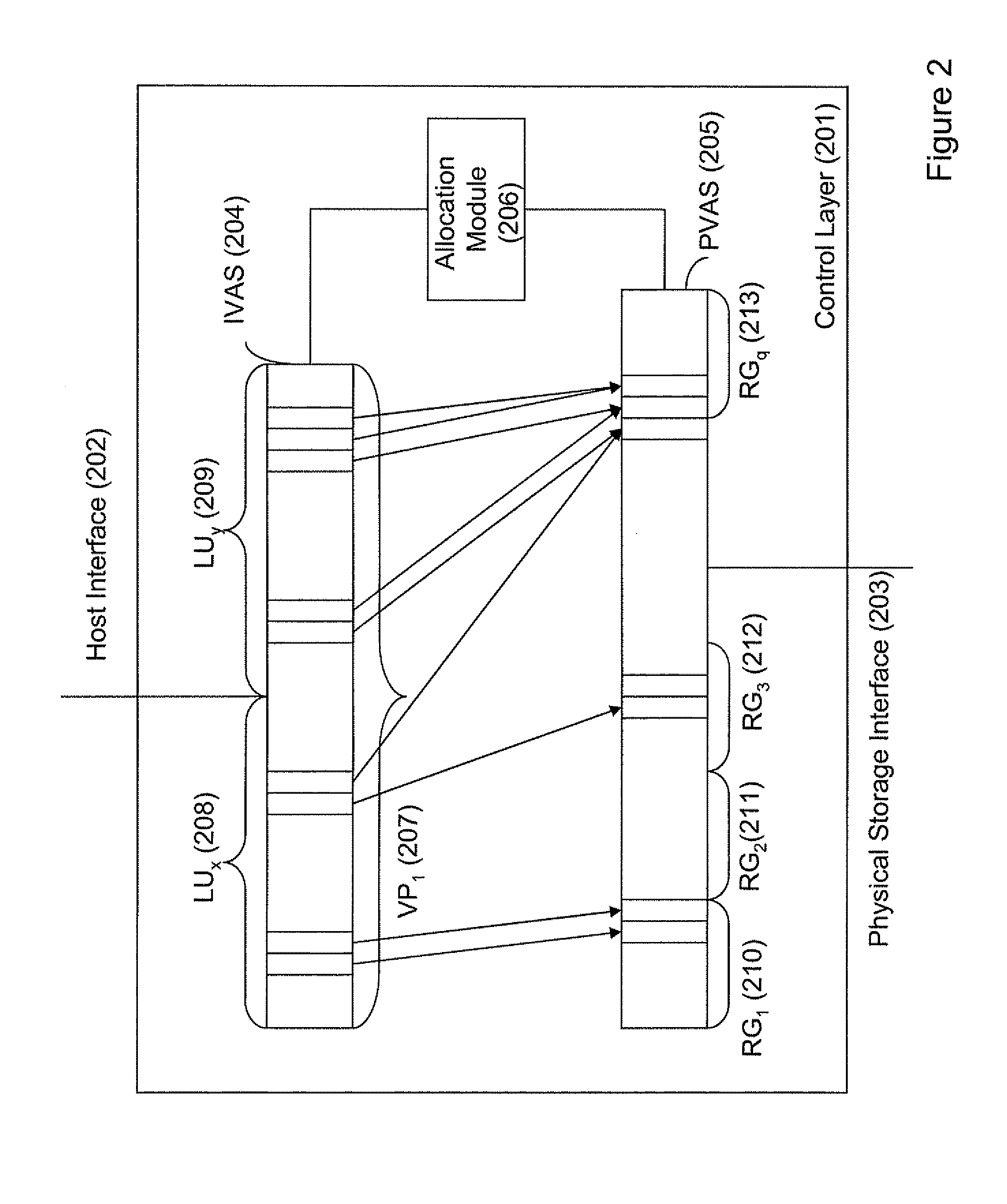

Virtualized storage system and method of operating thereof

ActiveUS20120066450A1Configure operationEasy to operateError detection/correctionMemory adressing/allocation/relocationVirtualizationPhysical space

A storage system and method is provided including physical storage devices controlled by storage control devices constituting a storage control layer operatively coupled to the physical storage devices and hosts. The storage control layer includes: a first virtual layer interfacing with the hosts, operable to represent a logical address space characterized by logical block addresses and available to said hosts and characterized by an Internal Virtual Address Space (IVAS) and operable, responsive to a configuration or I / O request addressed to the logical block addresses, to translate said logical block addresses into IVAS addresses; and a second virtual layer interfacing with the physical storage devices, operable to represent an available physical space to said hosts and characterized by a Physical Virtual Address Space (PVAS), addresses in PVAS having corresponding address in IVAS. The second virtual layer is operable to translate said respective IVAS addresses into addresses in the physical address space.

Owner:INFINIDAT

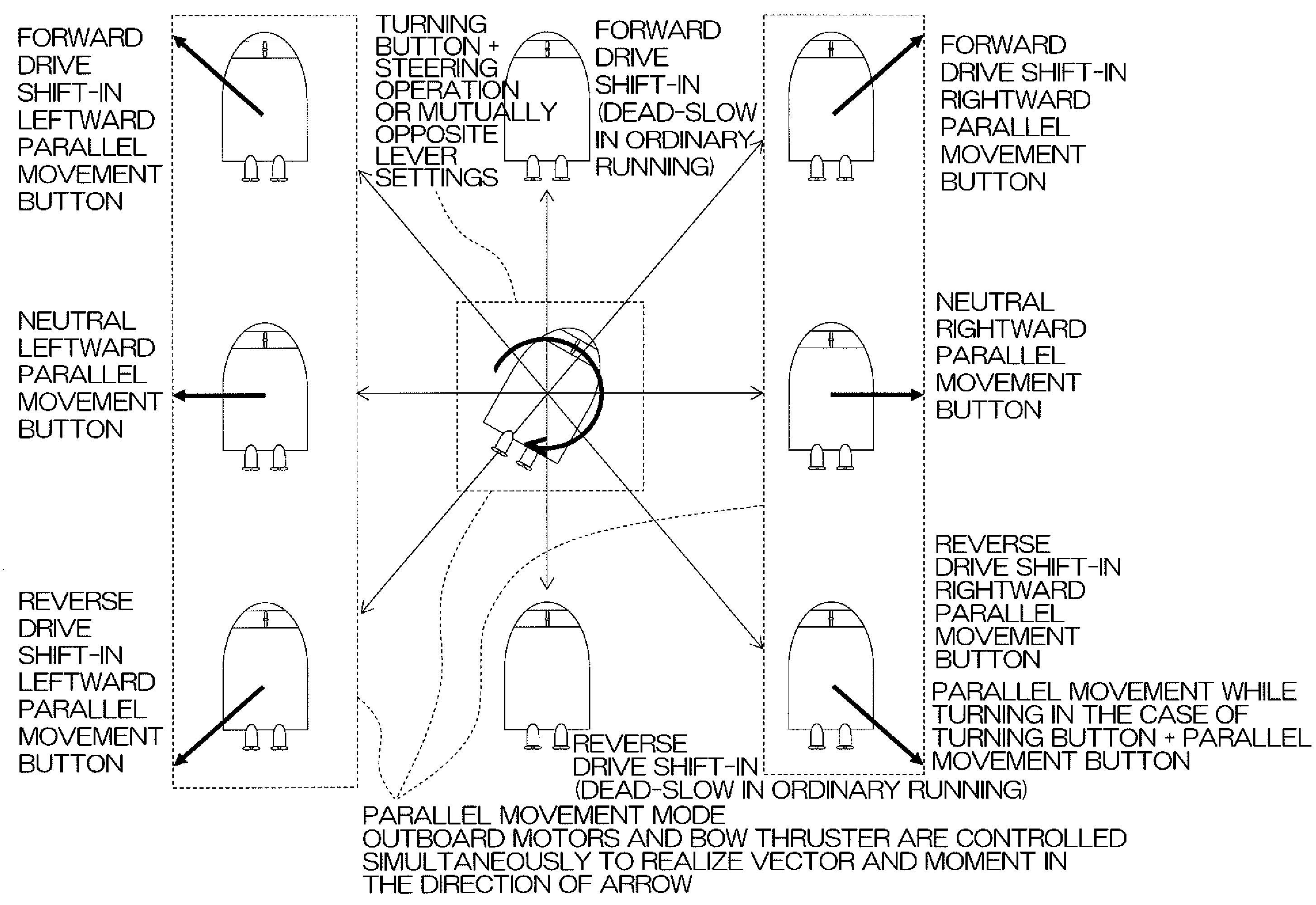

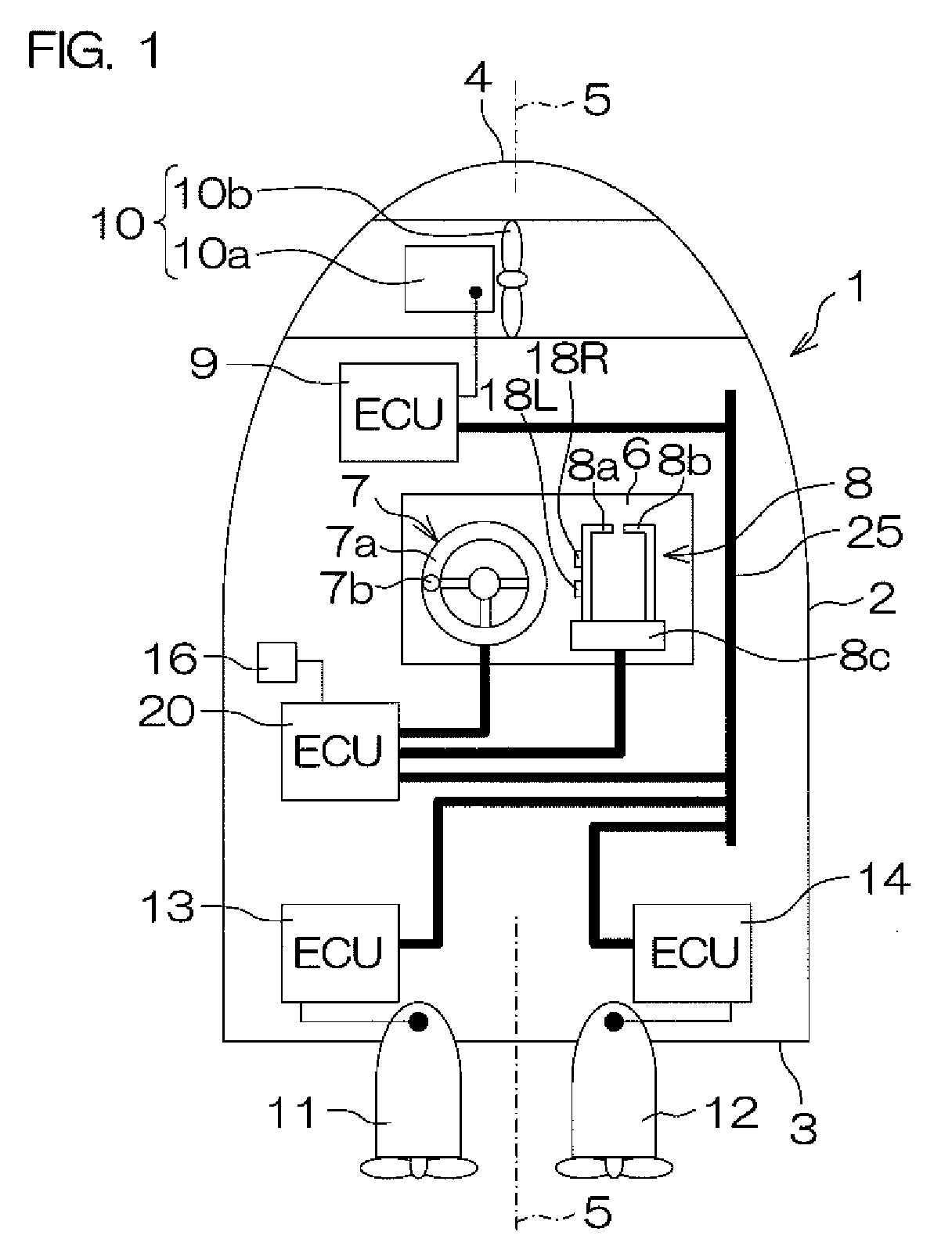

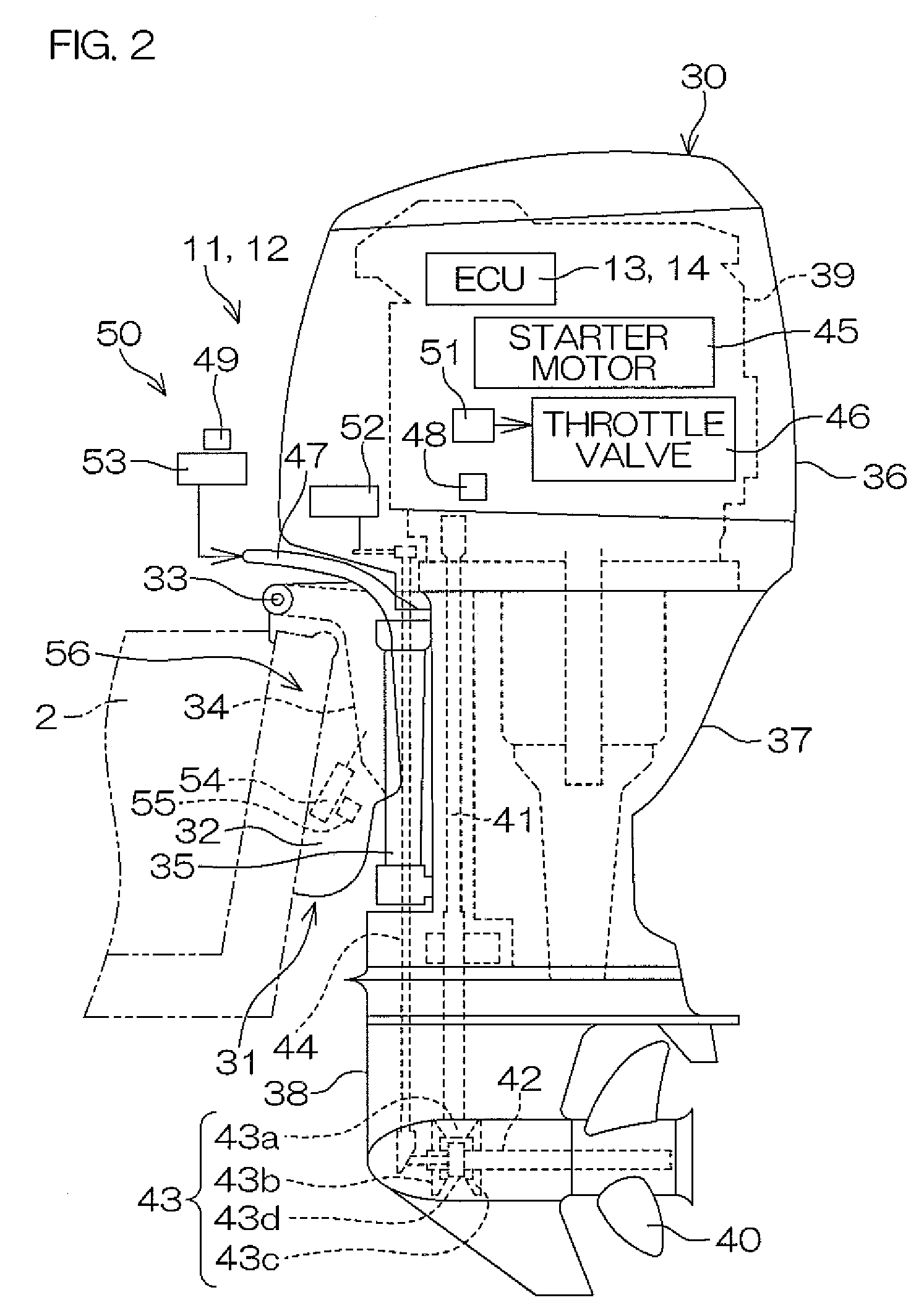

Marine vessel maneuvering supporting apparatus and marine vessel including the same

ActiveUS20100145558A1Easy to operateConfigure operationAuxillariesDigital data processing detailsMarine engineeringSteering angle

A marine vessel maneuvering supporting apparatus is used in a marine vessel which includes a propulsion system and a steering mechanism. The marine vessel maneuvering supporting apparatus includes a first operational unit arranged select a forward drive position for forward drive of the propulsion system, a reverse drive position for reverse drive of the propulsion system, and a neutral position for an inactive state of the propulsion system, a second operational unit arranged to command rightward and leftward movement of the marine vessel, and a target value computing unit arranged to determine target values including a target propulsive force for the propulsion system and a target steering angle for the steering mechanism, such that the marine vessel undergoes parallel movement in a direction that is in accordance with an operation position of the first operational unit when rightward or leftward movement is commanded by the second operational unit.

Owner:YAMAHA MOTOR CO LTD

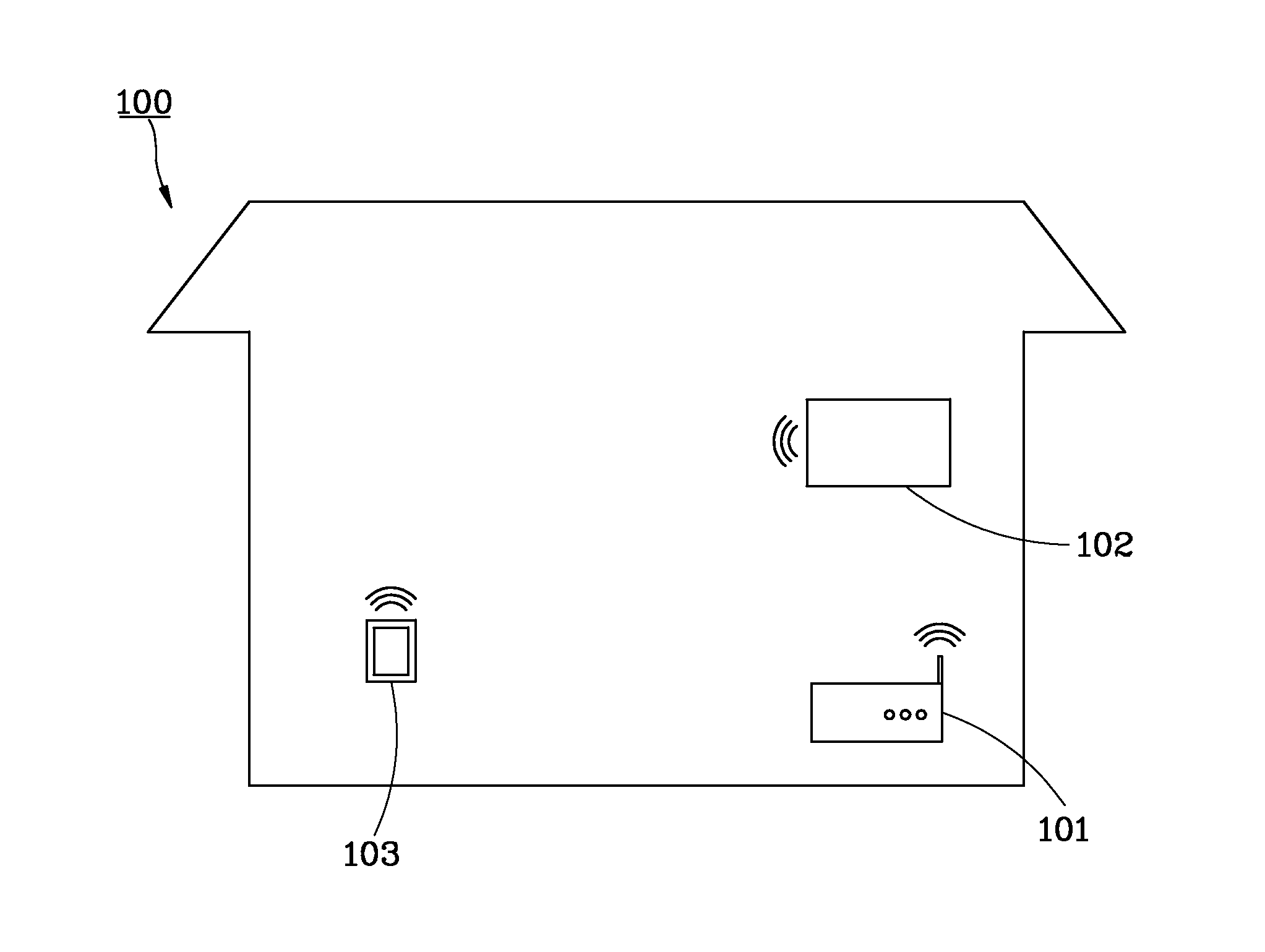

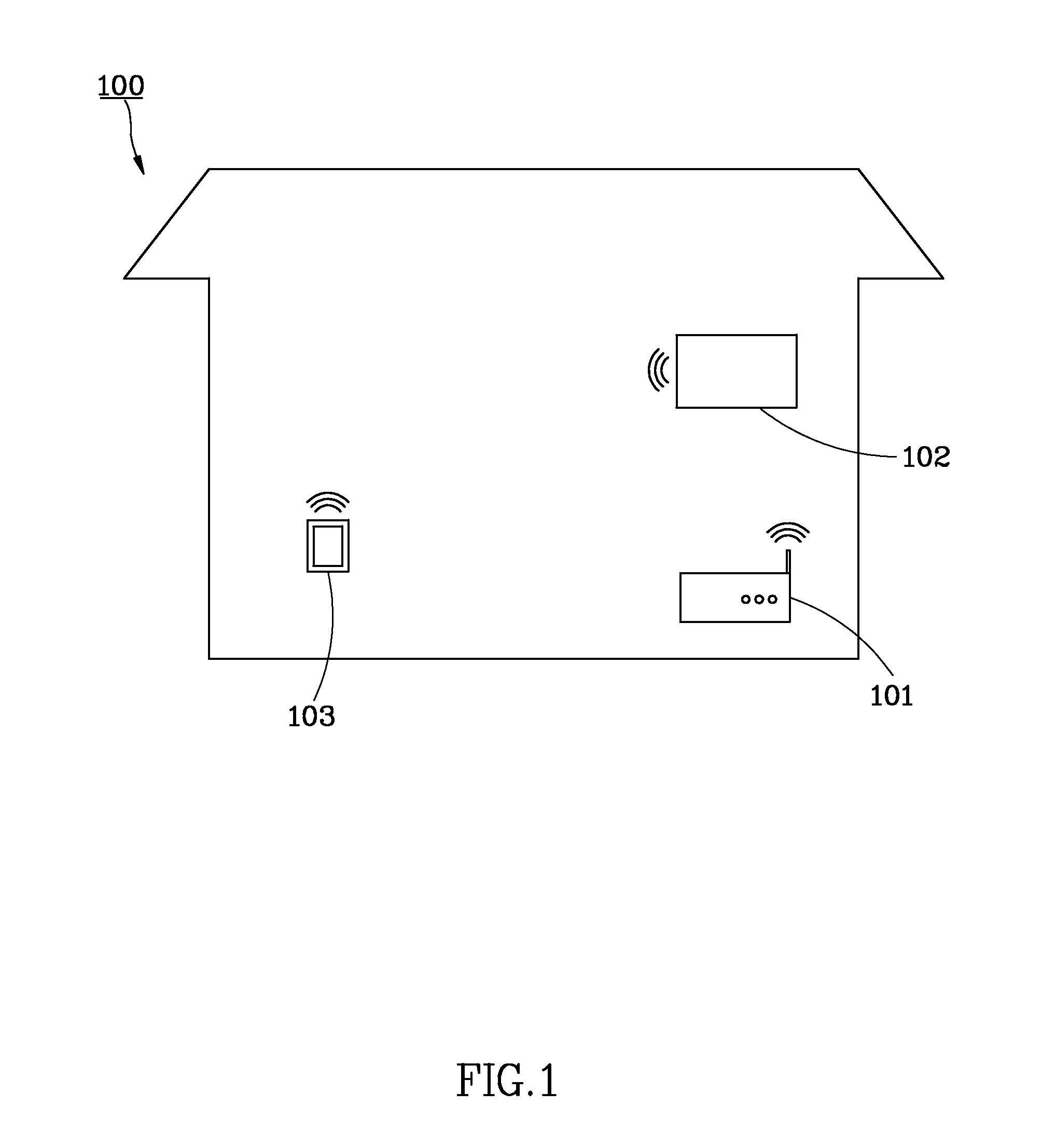

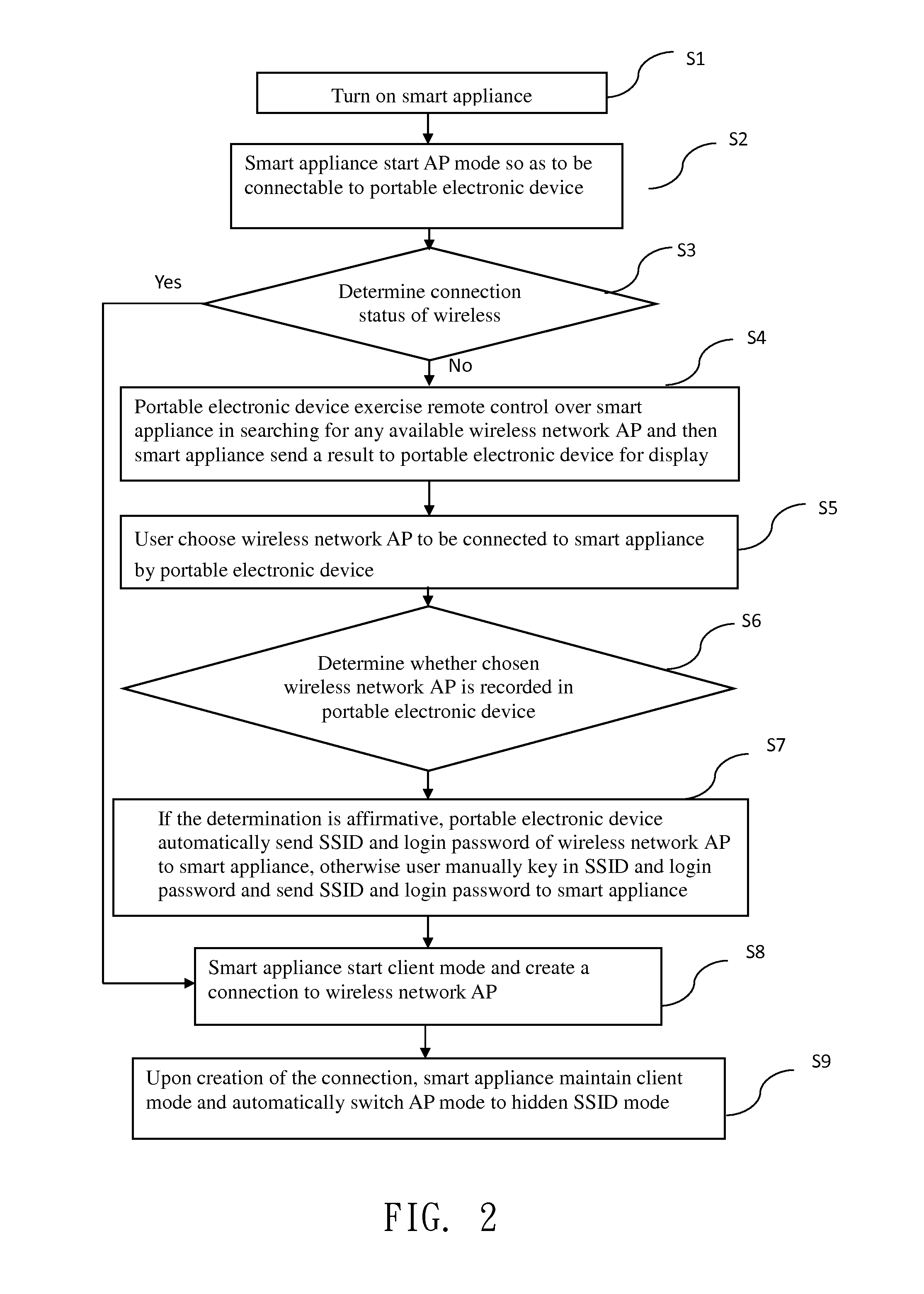

Wireless Network Configuration Method and System for Smart Appliance

ActiveUS20150139025A1Broaden applicationImprove ease of useAssess restrictionNetwork topologiesComputer hardwareWireless mesh network

A wireless network configuration method and system for a smart appliance, wherein the smart appliance can start a client mode and an AP mode to connect with a wireless network AP and a portable electronic device separately. When the smart appliance established the connection with the wireless network AP, it will switch from the AP mode to a hidden SSID mode automatically. If an SSID and password of the access point have been stored in the portable electronic device, the portable electronic device will transmit these data to the smart appliance to simplify the operation for wireless network configuration. Besides, the smart appliance will keep connecting with the portable electronic device and disappearing in an available wireless network list of the portable electronic device in the hidden SSID mode. The advantages of this invention are full function and ease of operation.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD +1

Vehicle Tuner And Display Module And Docking Station

ActiveUS20110153150A1Easy diagnosisConfigure operationVehicle testingRegistering/indicating working of vehiclesData displayDocking station

A data acquisition, data display, vehicle computer interface and programming tool in the form of a module. The module of the present invention can be set into a dock, which is connected to the vehicle's control modules. The vehicle can be reprogrammed to accept vehicle manufacture's updates and / or performance updates. Once the reprogramming is finished the module is removed from the dock and is be placed into / onto the vehicle's dashboard or other location readily viewable by the vehicle operator to report one or more of the vehicle's operating parameters. The present invention is readily connectable to a vehicle's data link for bi-directional communication with the various control modules on the vehicle.

Owner:E MOTION LLC

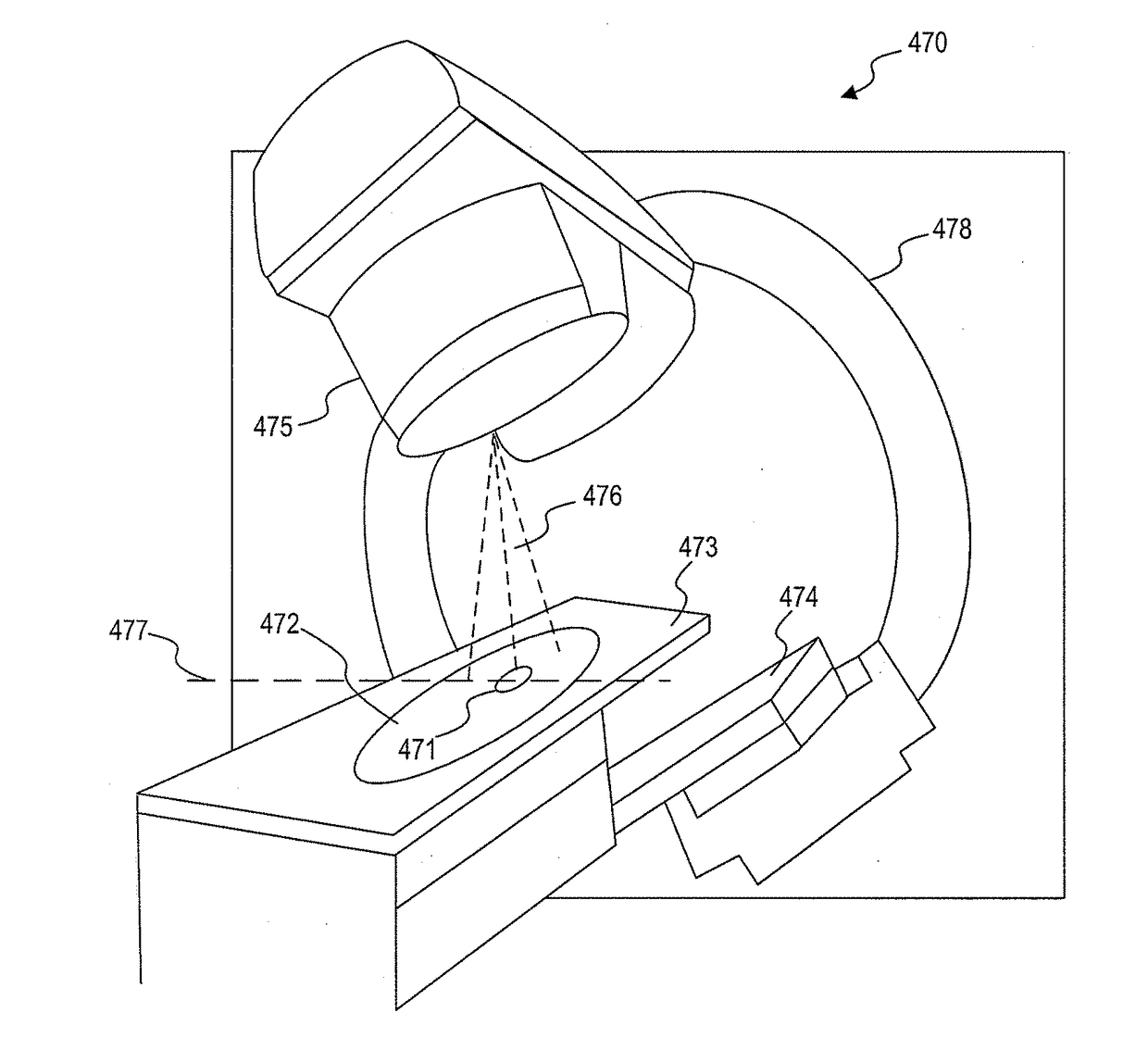

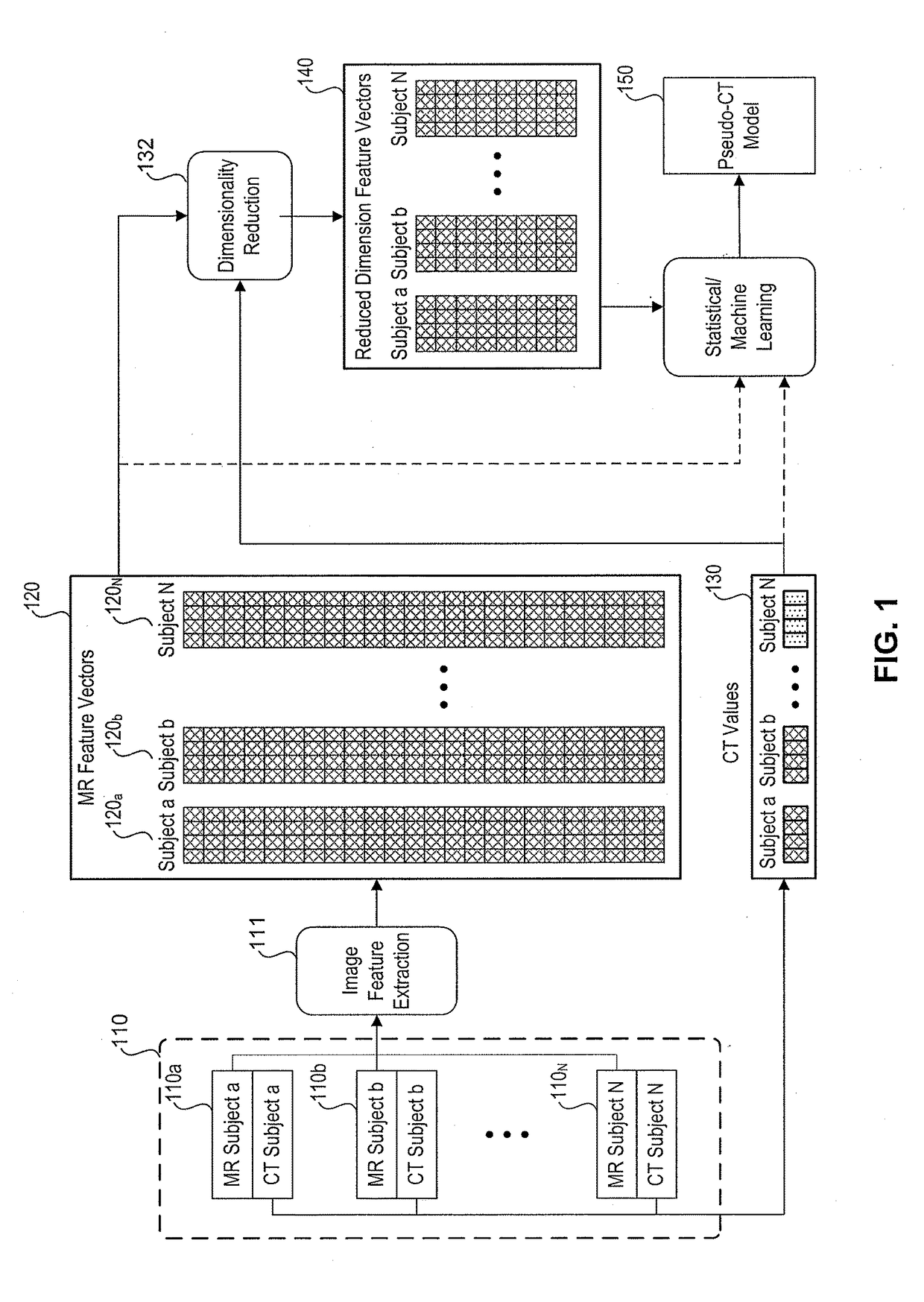

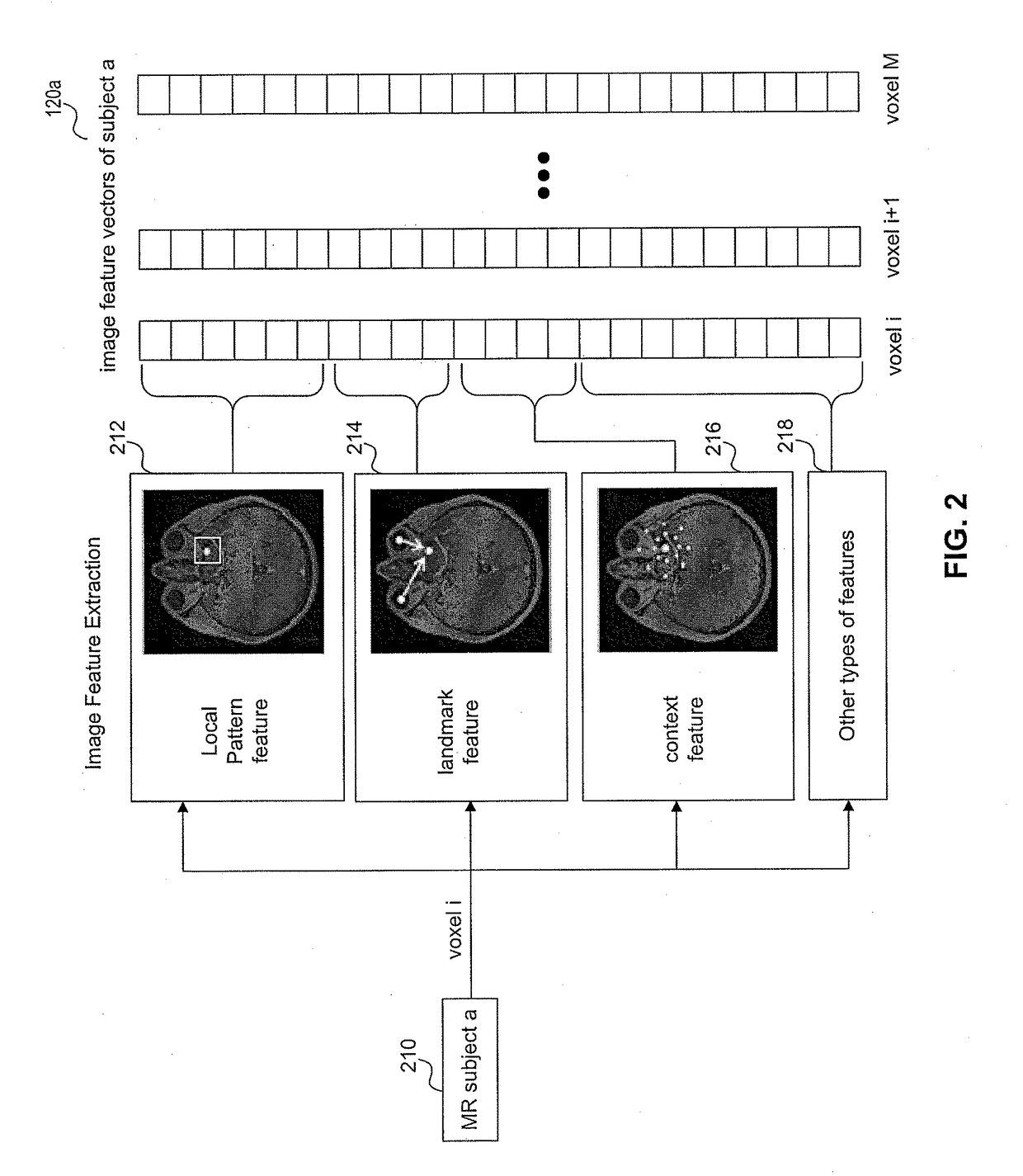

Pseudo-ct generation from mr data using a feature regression model

ActiveUS20170100078A1Configure operationMedical simulationImage enhancementFeature vectorModel system

Systems and methods are provided for generating a pseudo-CT prediction model that can be used to generate pseudo-CT images. An exemplary system may include a processor configured to retrieve training data including at least one MR image and at least one CT image for each of a plurality of training subjects. For each training subject, the processor may extract a plurality of features from each image point of the at least one MR image, create a feature vector for each image point based on the extracted features, and extract a CT value from each image point of the at least one CT image. The processor may also generate the pseudo-CT prediction model based on the feature vectors and the CT values of the plurality of training subjects.

Owner:ELEKTA AB

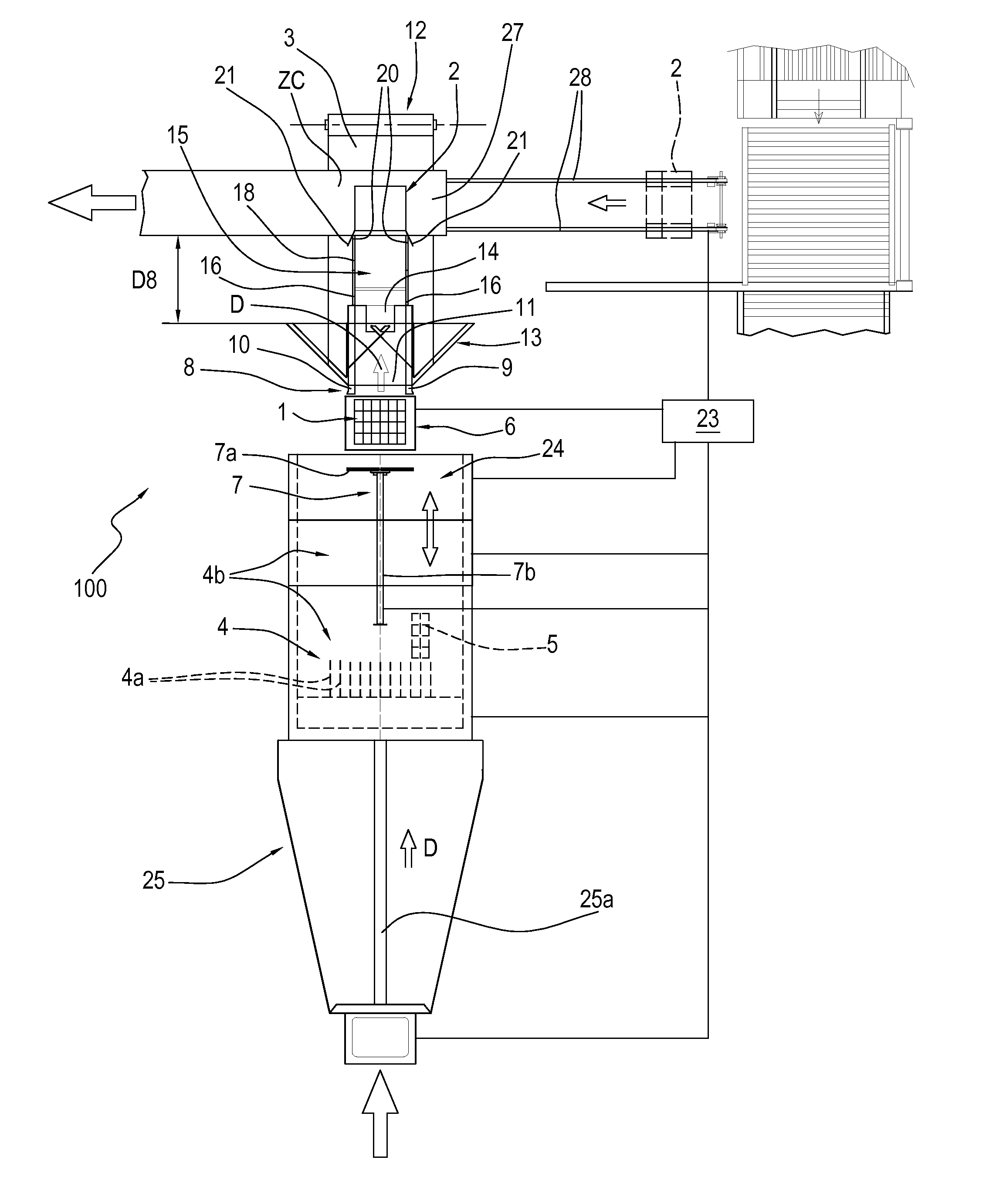

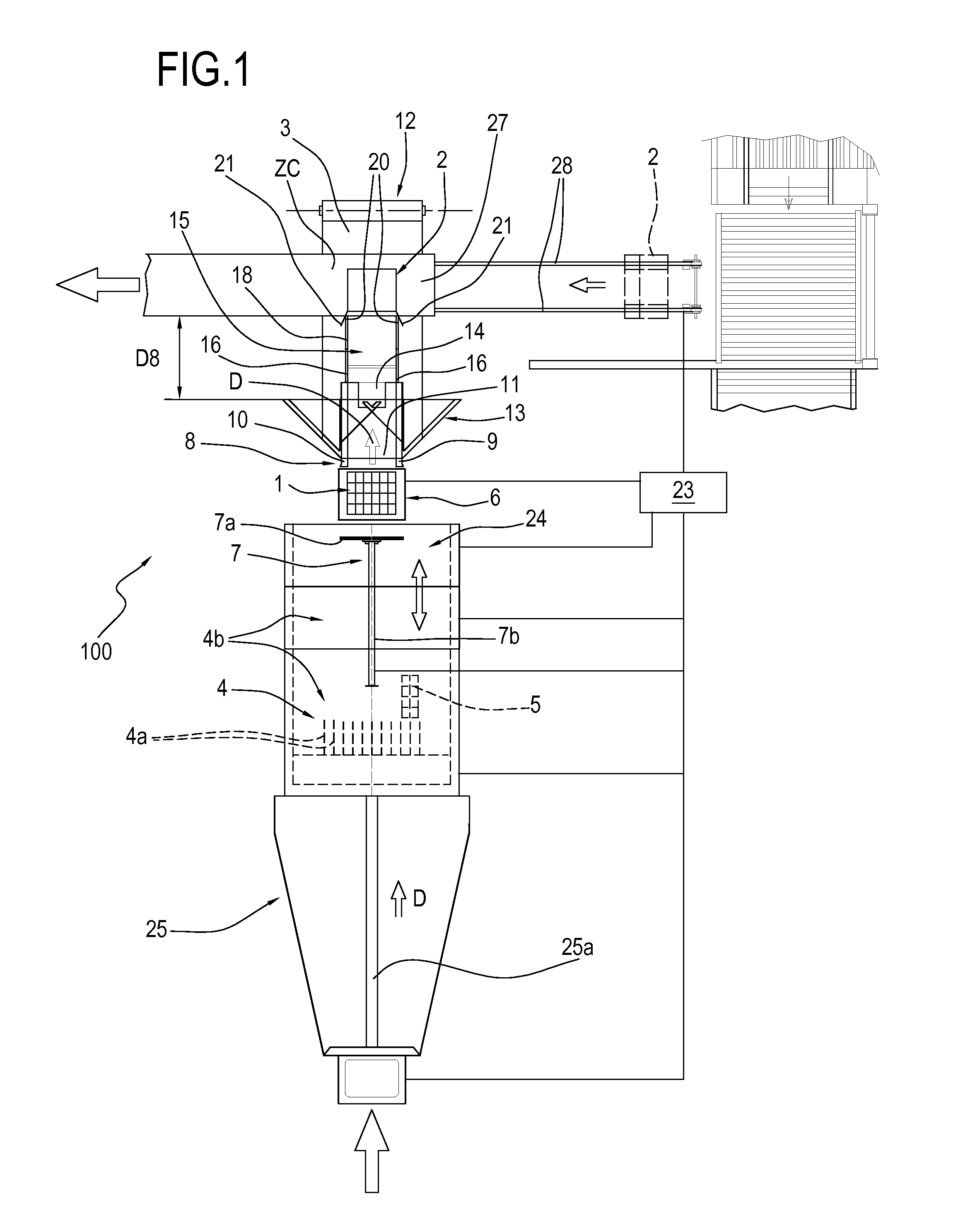

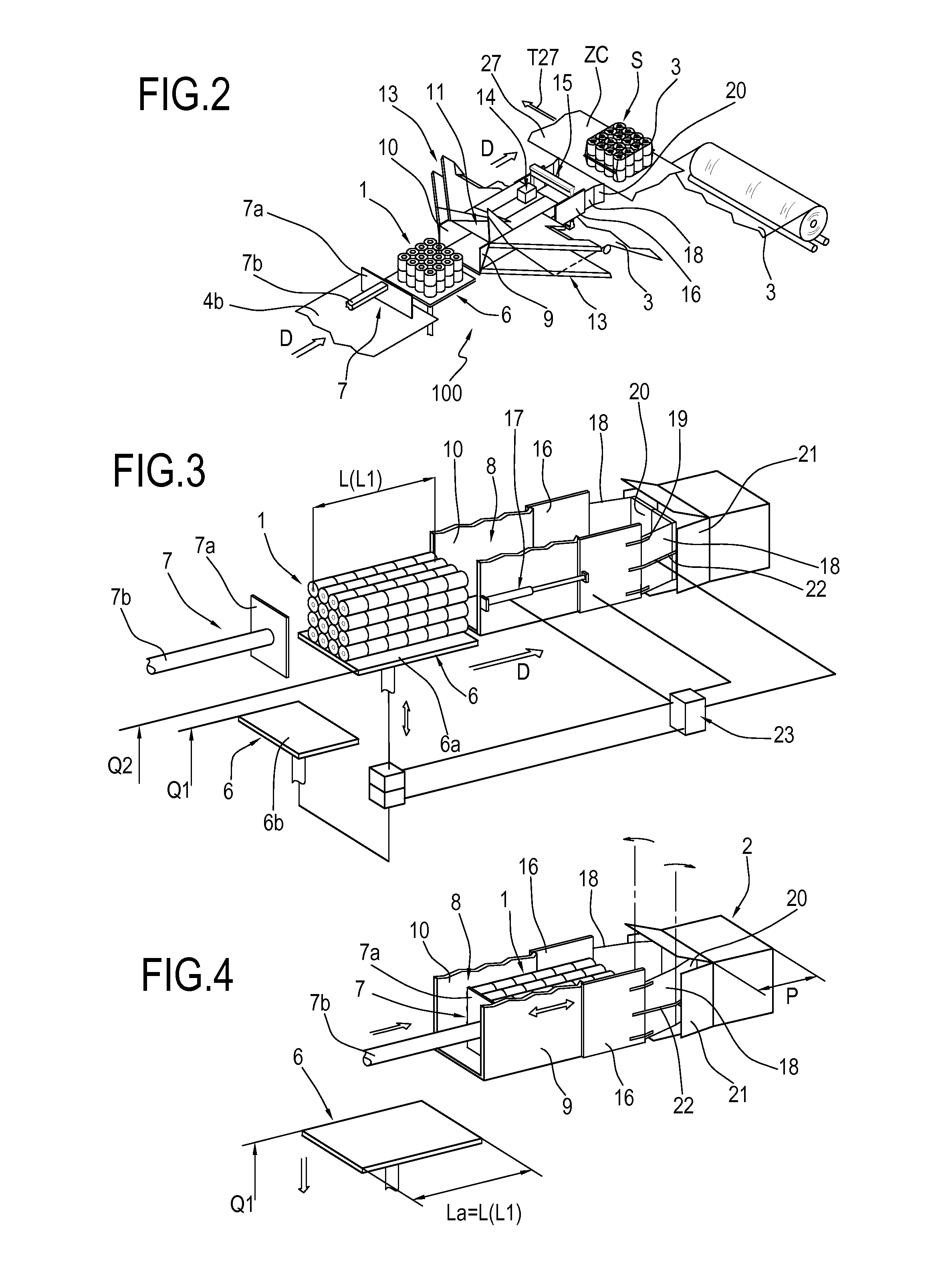

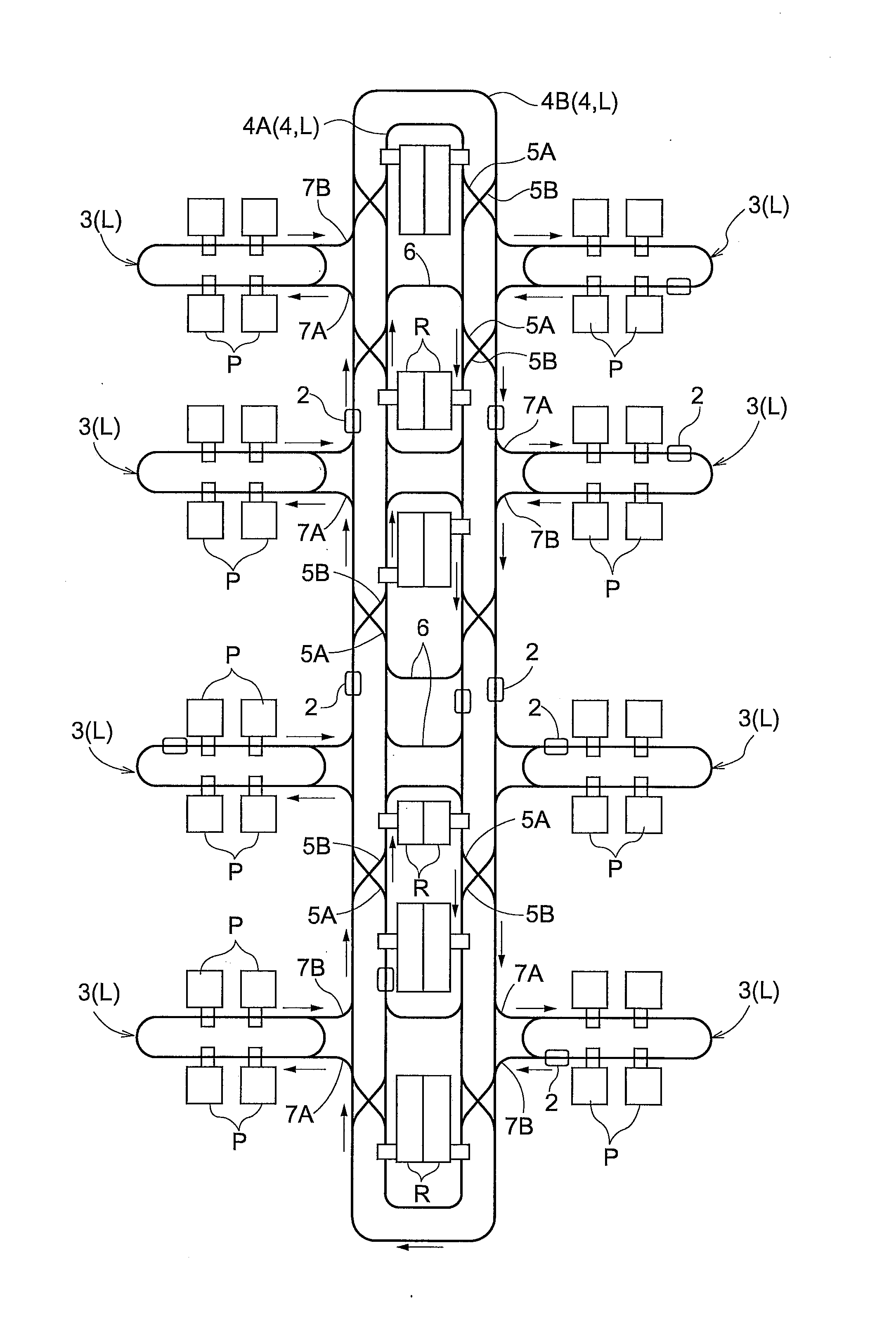

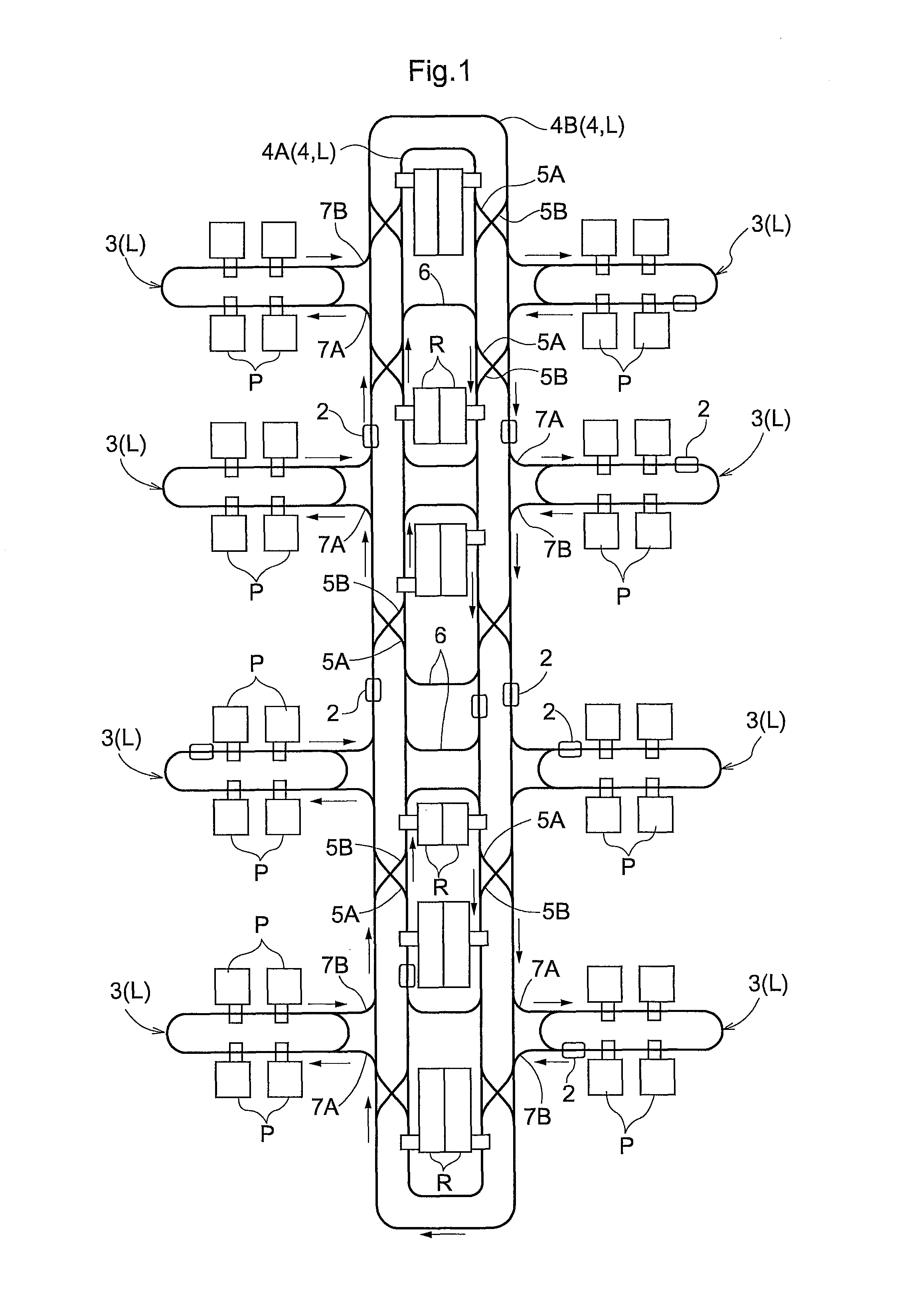

Apparatus for packaging batches of products packed in cartons or in wrapping film

ActiveUS20150329230A1Reduce timeFew manual operationPackaging automatic controlIndividual articlesEngineeringThin sheet

Described is an apparatus for packaging batches (1) of products packed in a carton (2) or wrapped in a wrapping film (3), comprising: means (4) of grouping individual packs (5) of products in batches (1) of products; a lifting surface (6) to lift the batch (1) from a first height (Q1) for receiving to a second height (Q2) for introducing; an element (7) for pushing the batch (1), positioned at the second height (Q2), configured to move, in both directions, along a direction (D) of movement, between a retracted non-operating end position and an extended operating end position for pushing the batch (1) towards a zone loading (ZC) designed to be engaged by a carton (2) to be filled; a connecting surface (8) for the sliding of the batch (1) interposed between the lifting surface (6) and the loading zone (ZC); the connecting surface having a pair of vertical side walls (9, 10) and an upper horizontal wall (11) in such a way as to form a tunnel (8); a station (12) for feeding wrapping film (3); folding means (13) for supporting and guiding the wrapping film (3) wound round the outer walls forming the tunnel (8); first means (14) for longitudinal sealing of the film (3) configured to join two longitudinal flaps of the film (3) to form a tubular shape; second means (15) for transversal sealing the film (3) positioned close to the rear end of the tunnel (8) for joining the top and bottom flaps of the tubular wrapping film (3); a first pair of panels (16) connected to the connecting tunnel (8) for containing / retaining the batch (1) coming out from the tunnel (8); the first pair of panels (16) having means (17) for their sliding along the side walls (9, 10), in both directions, in such a way as to modify the operating length of the tunnel (8).

Owner:TISSUE MACHINERY

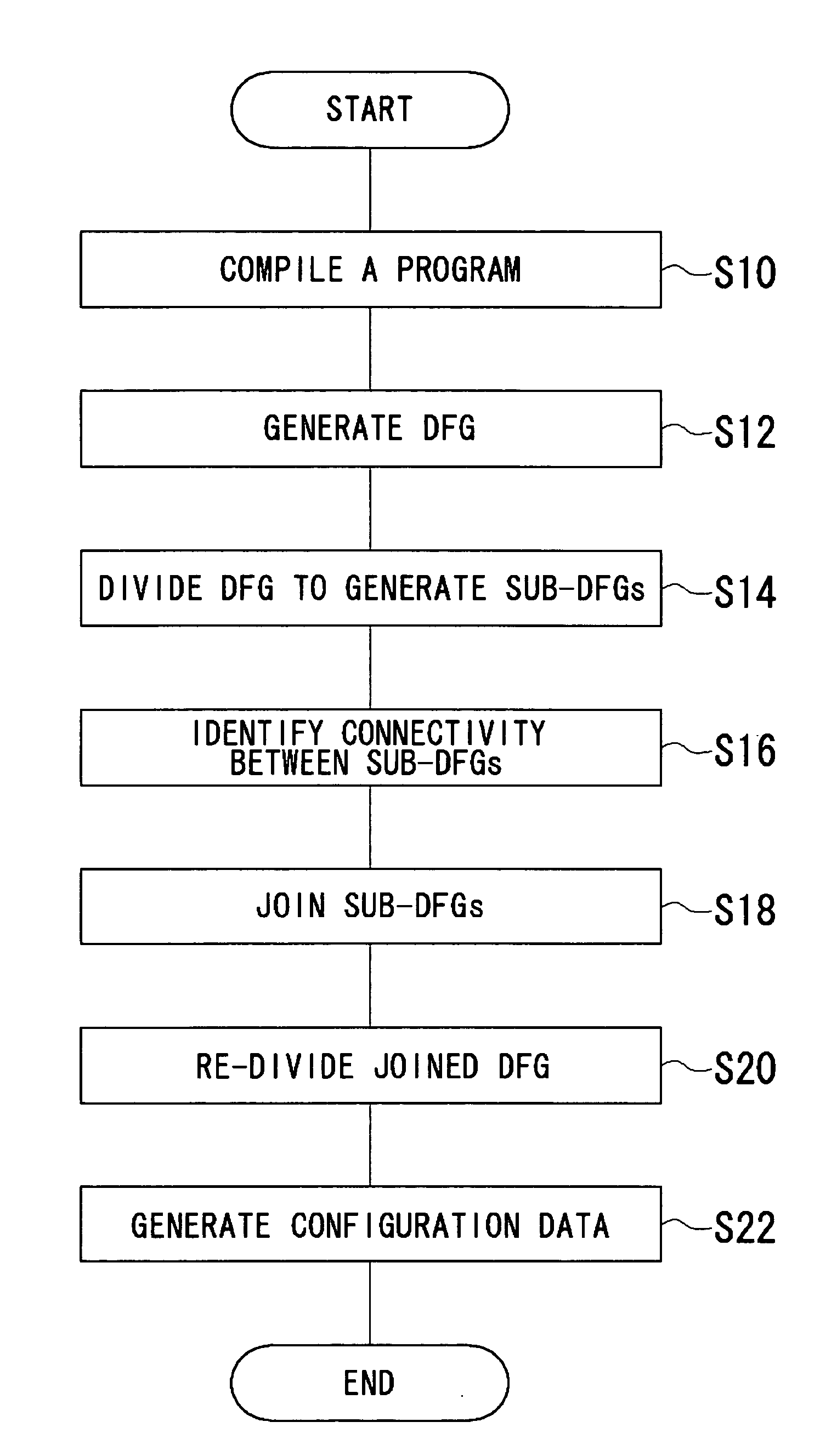

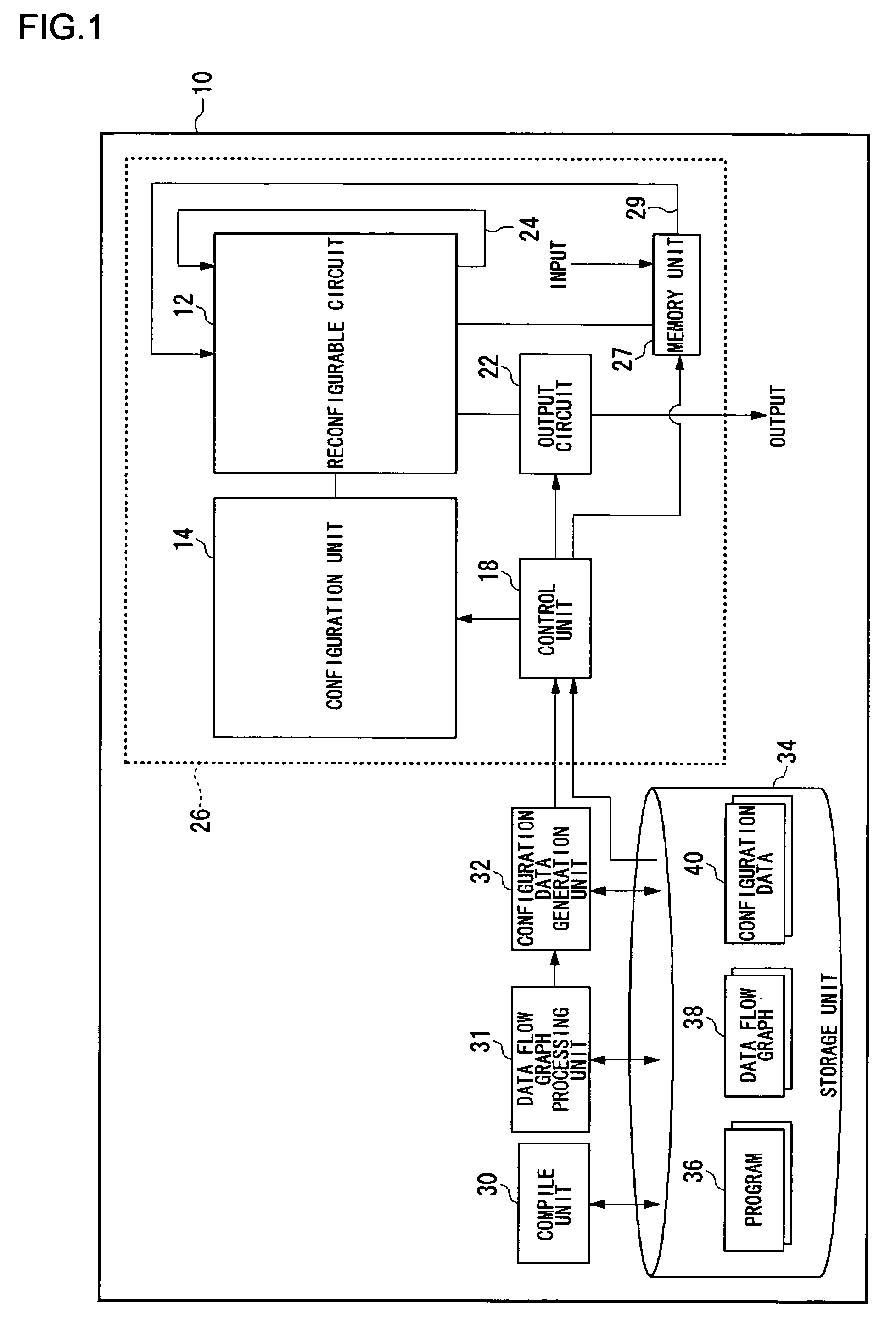

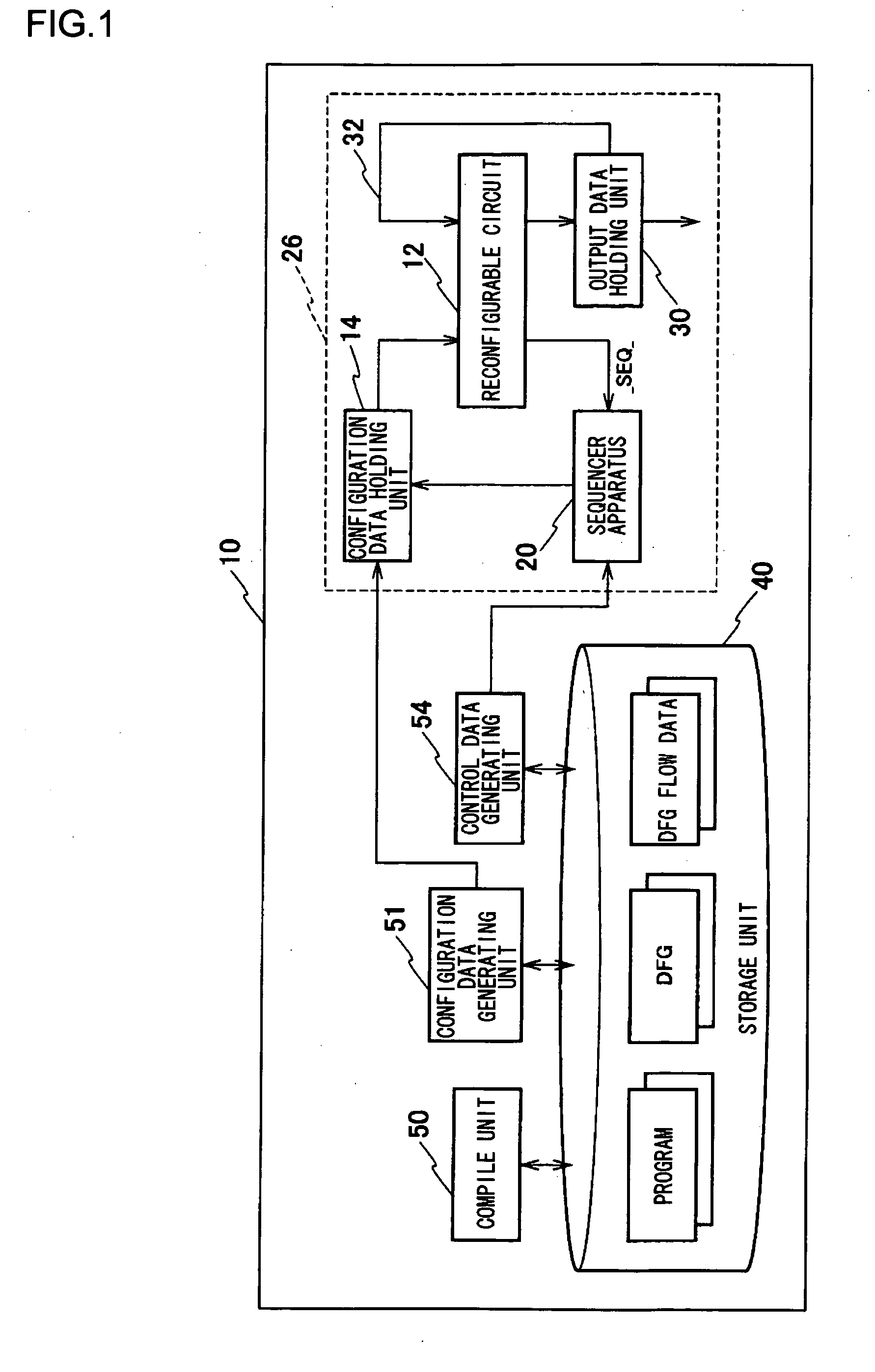

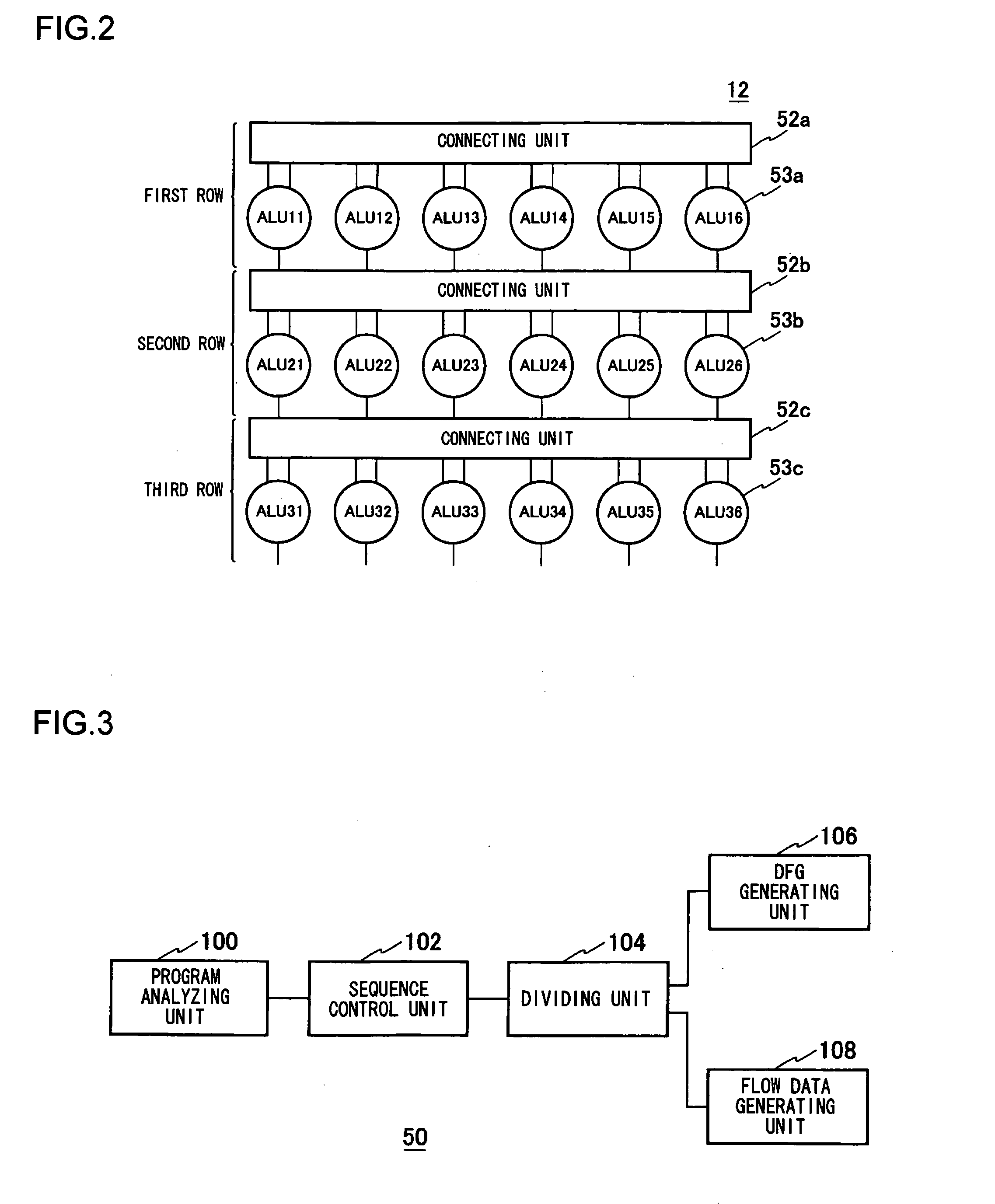

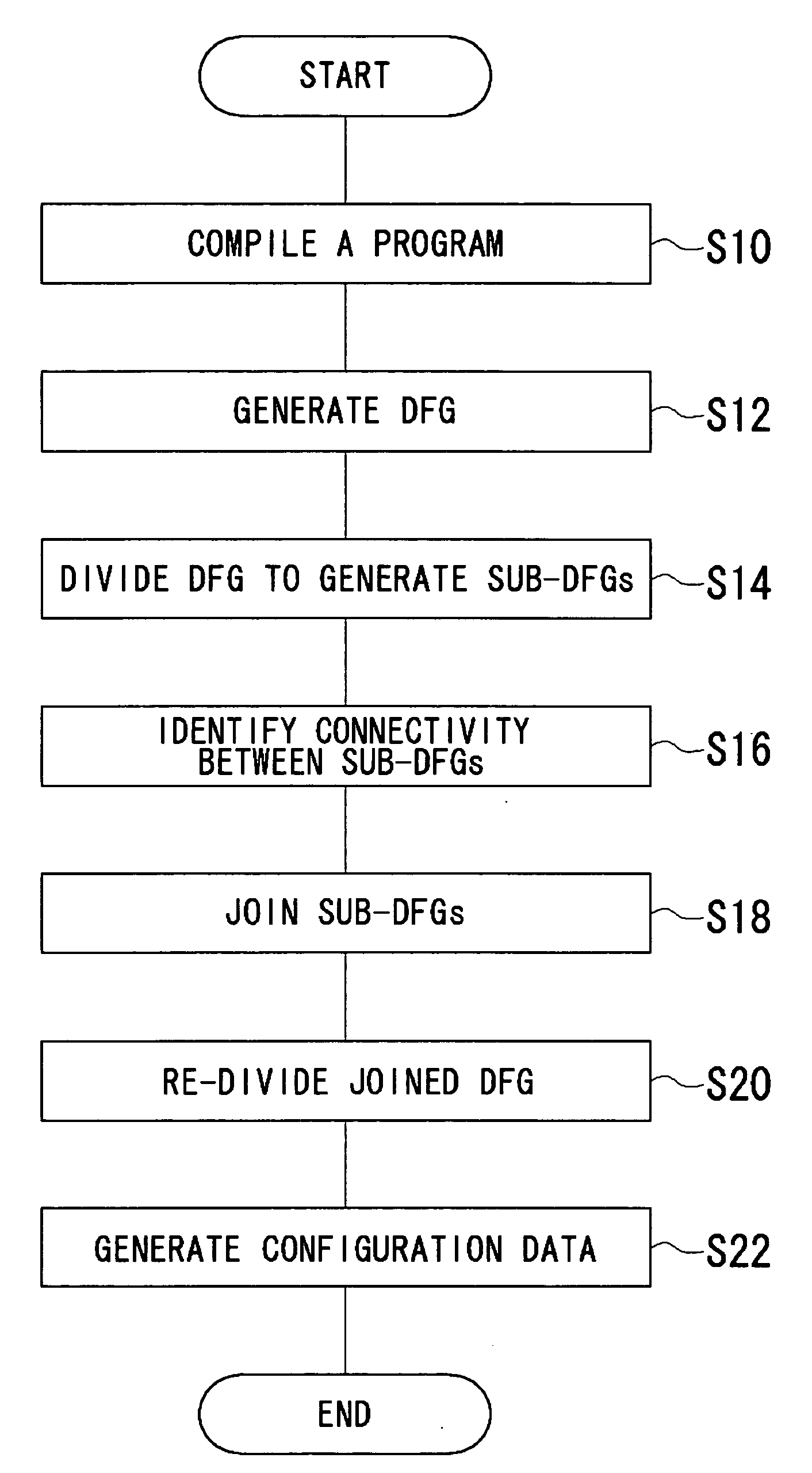

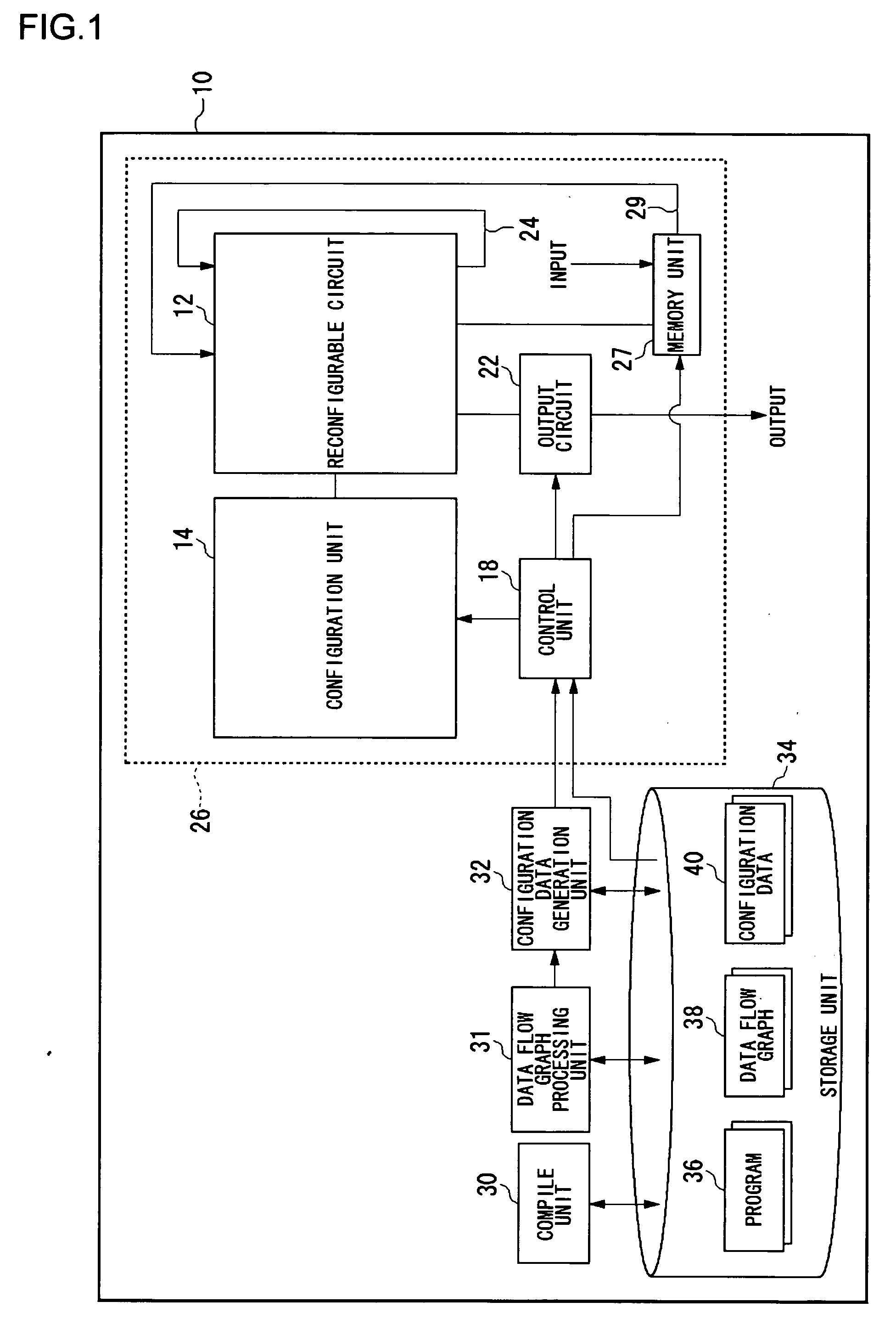

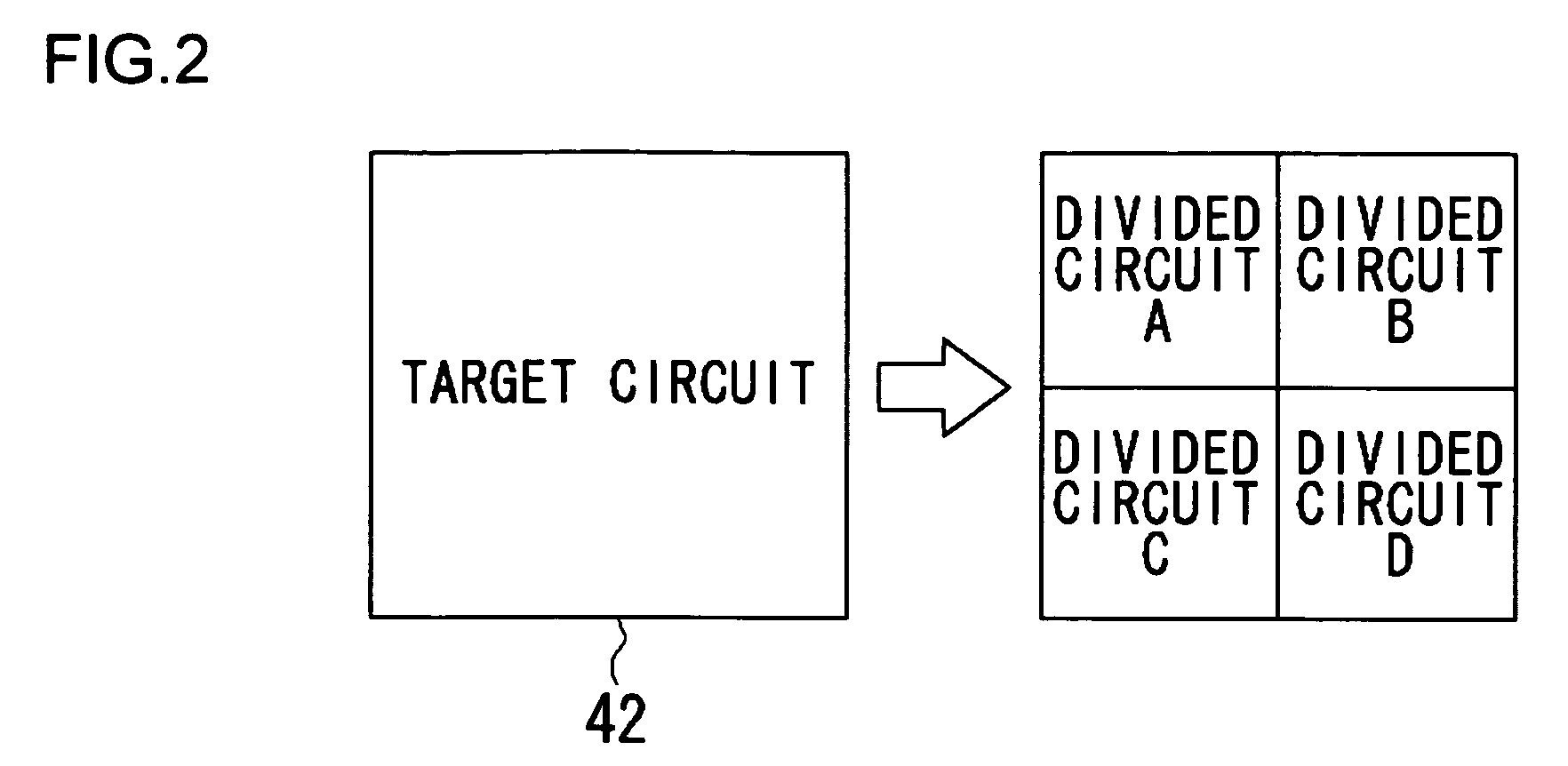

Data flow graph processing method, reconfigurable circuit and processing apparatus

ActiveUS7895586B2Efficient processingConfigure operationDigital computer detailsCAD circuit designTheoretical computer science

A data flow graph processing method divides at least one DFG generated into a plurality of sub-DFGs, in accordance with the number of logic circuits in a circuit set in a reconfigurable circuit. When the reconfigurable circuit is provided with a structure including multiple-row connections, the number of columns in the sub-DFG is configured to be equal to or fewer than the number of logic circuits per row in the reconfigurable circuit. Subsequently, the sub-DFGs are joined so as to generate a joined DFG. The number of columns in the joined DFG is also configured to be equal to or fewer than the number of columns per row in the reconfigurable circuit. The joined DFG is redivided to sizes with number of rows equal to or fewer than the number of rows in the reconfigurable circuit, so as to generate subjoined DFGs mappable into the reconfigurable circuit.

Owner:GK BRIDGE 1

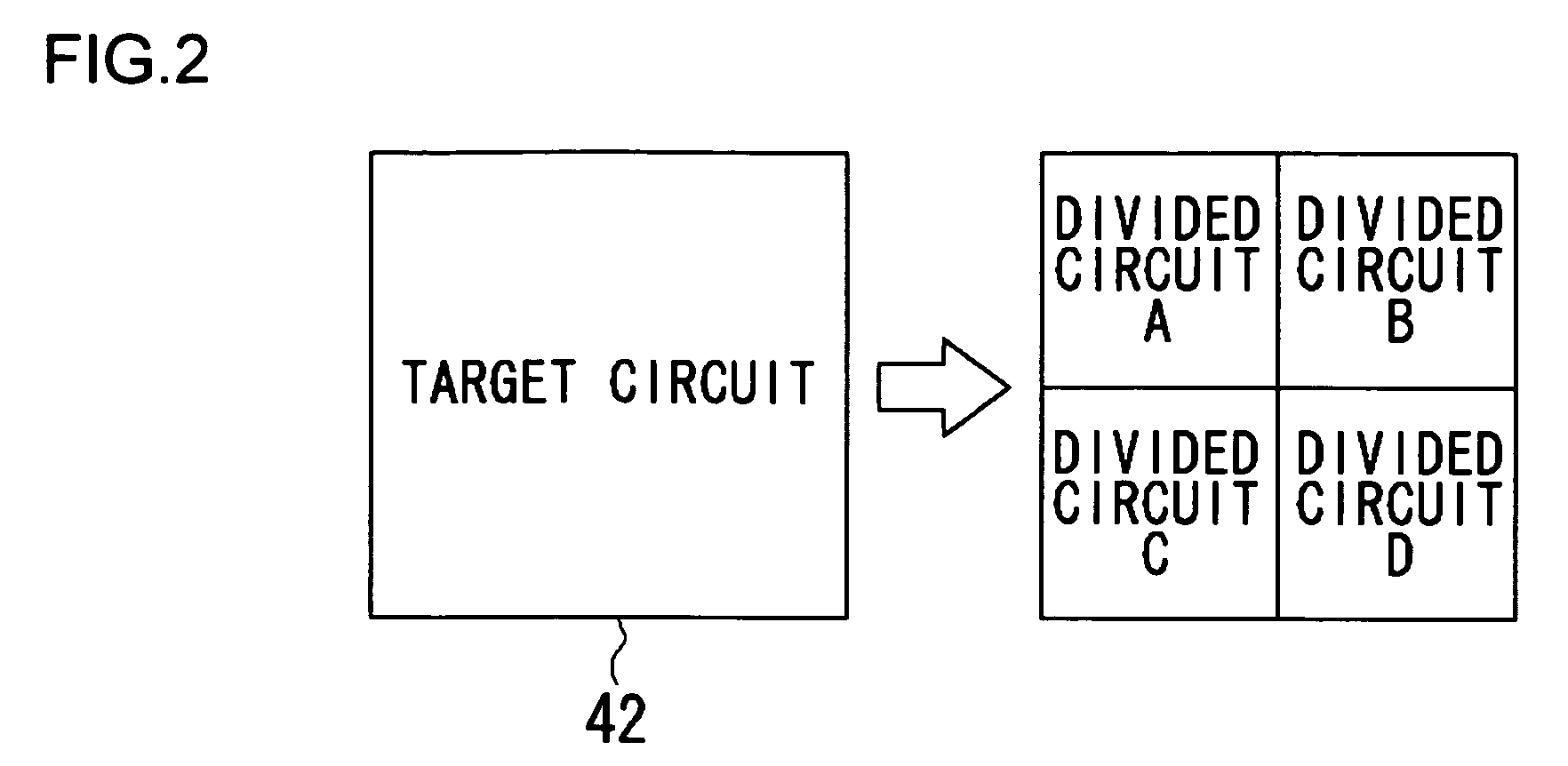

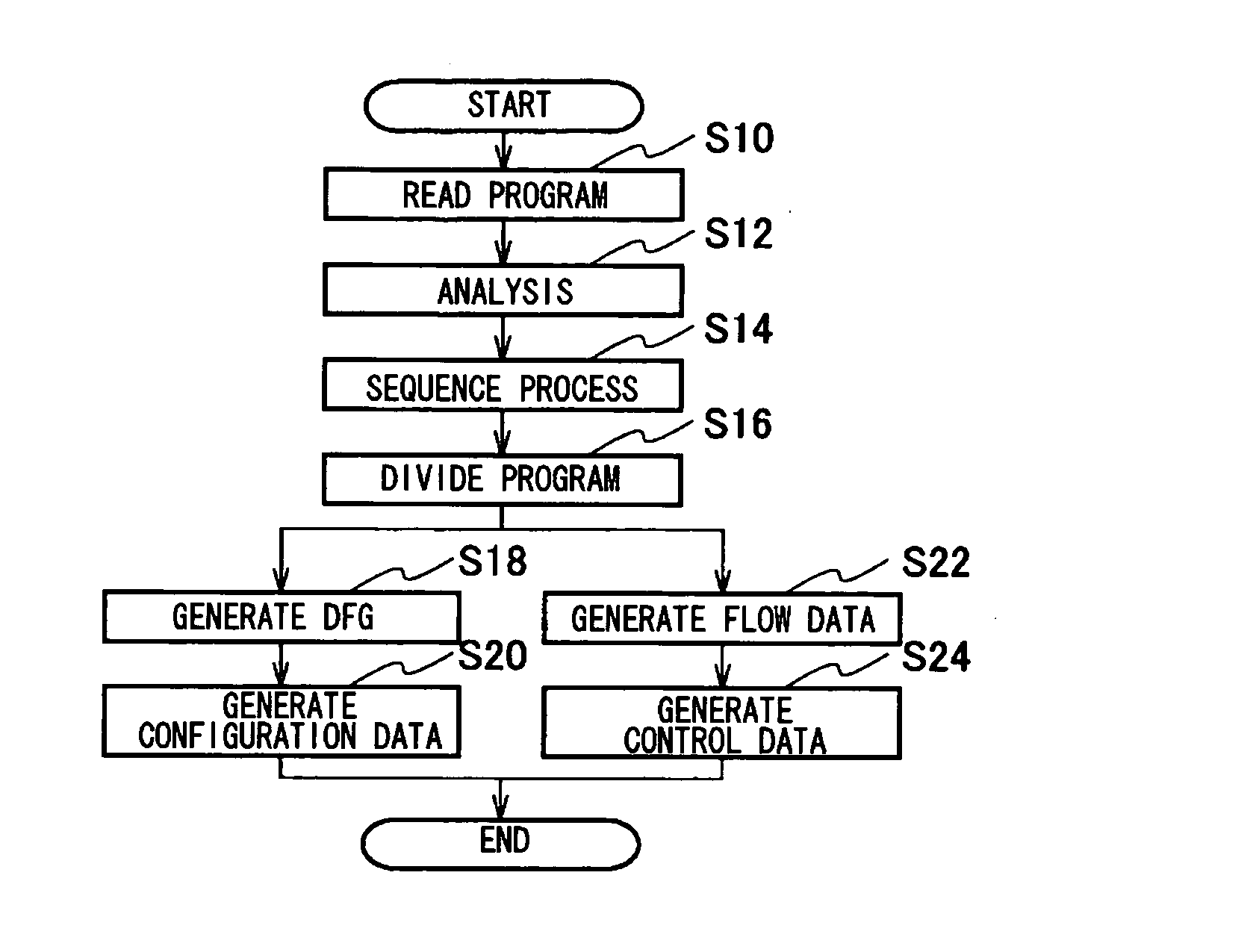

Data flow graph processing method and processing apparatus provided with reconfigurable circuit

ActiveUS20060048113A1Reduce processing timeEnsure efficient flowSoftware engineeringDigital computer detailsData streamParallel computing

A data flow graph processing method divides a program describing target operations into two or more subprograms and converts each of the two or more subprograms into a data flow graph (DFG) representing dependency in execution between operations carried out in sequence. Also generated is flow data indicating the order of execution of DFGs corresponding to respective subprograms. DFGs are converted into configuration data and the flow data is converted into control data.

Owner:GK BRIDGE 1

Data flow graph processing method, reconfigurable circuit and processing apparatus

ActiveUS20050283768A1Efficient processingConfigure operationDigital computer detailsCAD circuit designTheoretical computer scienceLogic circuitry

A data flow graph processing method divides at least one DFG generated into a plurality of sub-DFGs, in accordance with the number of logic circuits in a circuit set in a reconfigurable circuit. When the reconfigurable circuit is provided with a structure including multiple-row connections, the number of columns in the sub-DFG is configured to be equal to or fewer than the number of logic circuits per row in the reconfigurable circuit. Subsequently, the sub-DFGs are joined so as to generate a joined DFG. The number of columns in the joined DFG is also configured to be equal to or fewer than the number of columns per row in the reconfigurable circuit. The joined DFG is redivided to sizes with number of rows equal to or fewer than the number of rows in the reconfigurable circuit, so as to generate subjoined DFGs mappable into the reconfigurable circuit.

Owner:GK BRIDGE 1

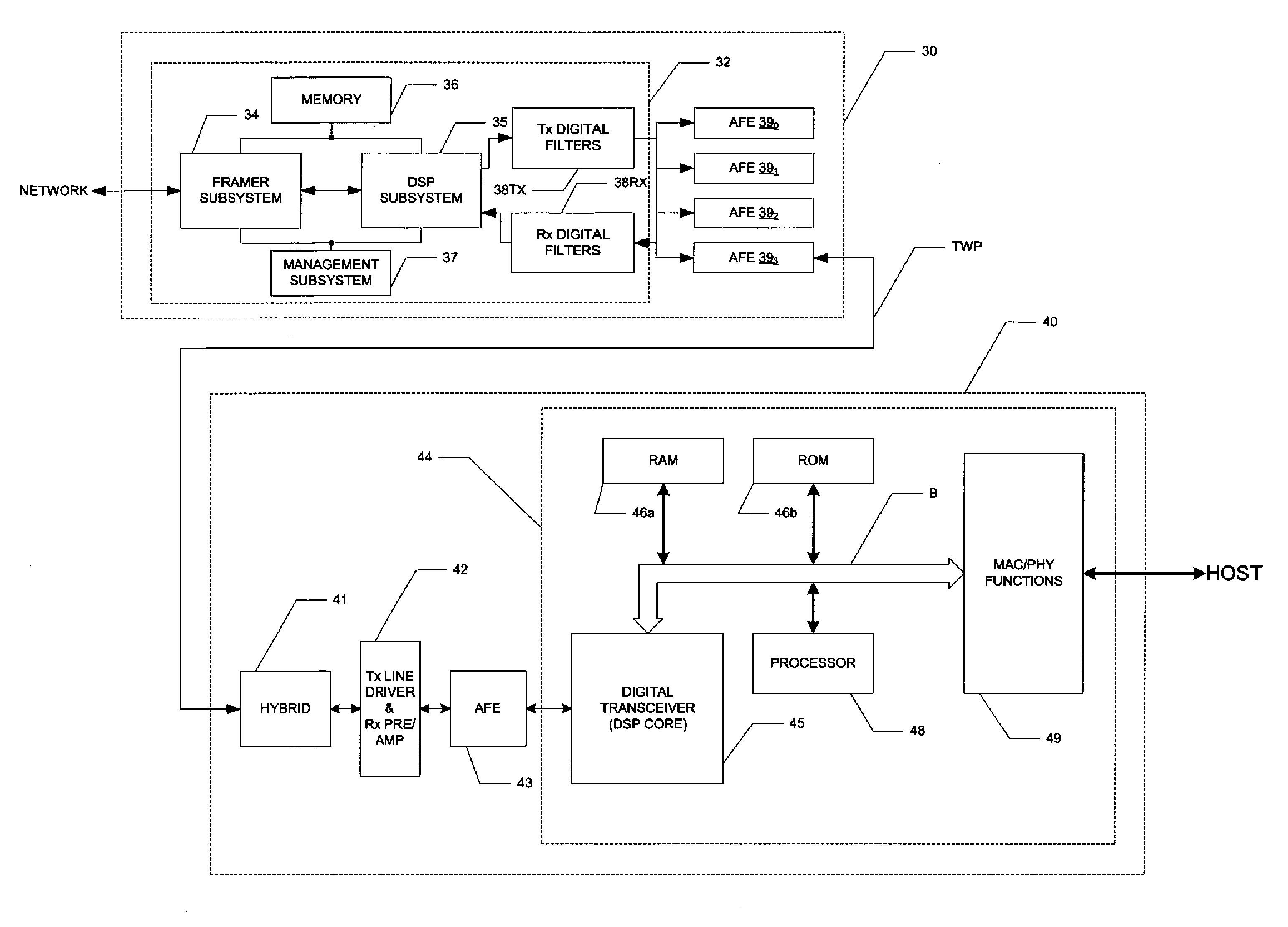

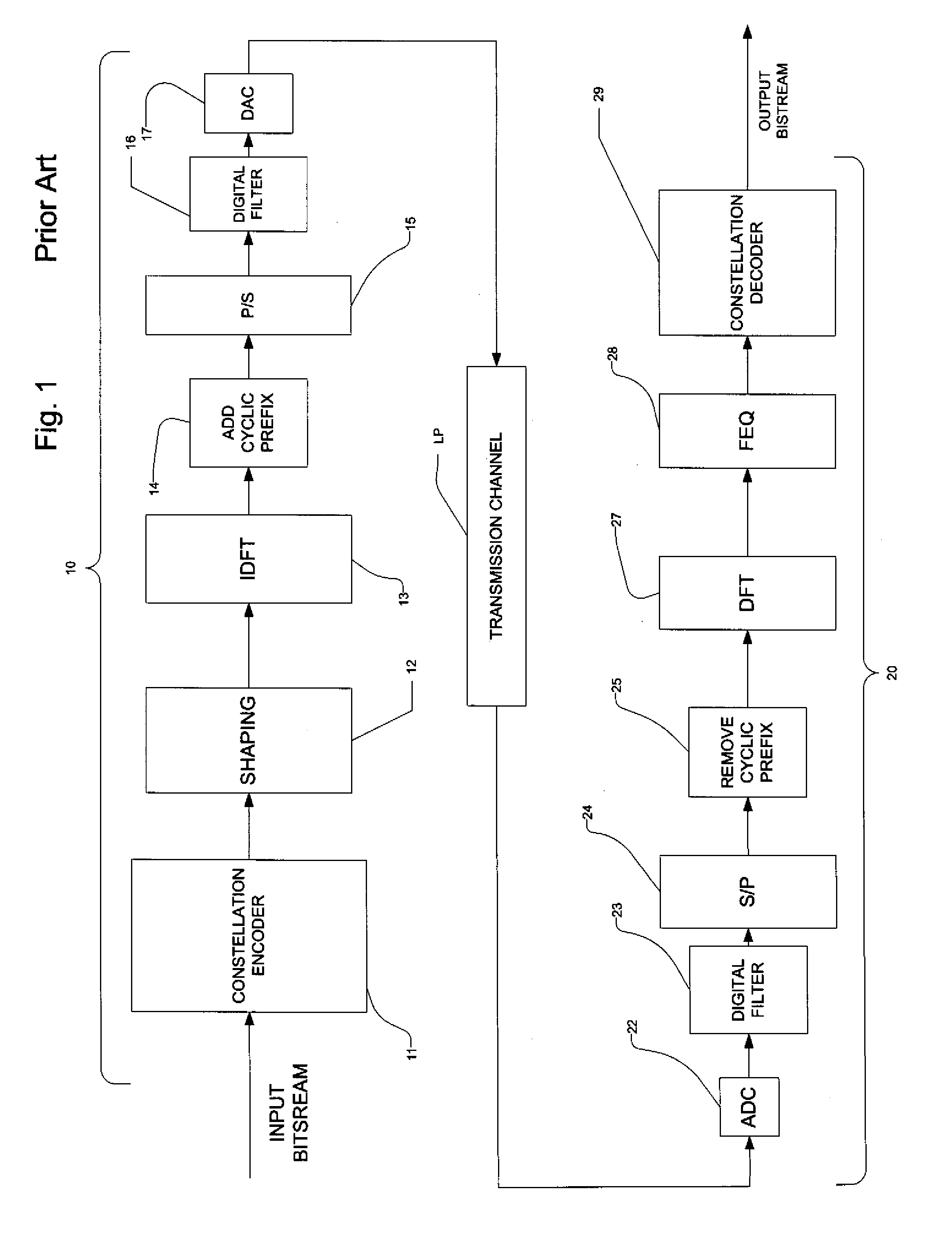

Optimized Short Initialization After Low Power Mode for Digital Subscriber Line Communications

ActiveUS20090022214A1Easily implemented into existing transceiver equipmentRaise the possibilityEnergy efficient ICTTelephonic communicationPower modeDigital subscriber line

A digital subscriber line (DSL) system that provides fast exit from an idle state is disclosed. The system includes a central office (CO) modem for communicating with a customer premises equipment (CPE) modem. Prior to entry into a low-power or idle state for the DSL link between the CO modem and the CPE modem, seamless rate adaptation is performed in order to improve the operating margin from that used in full-on operation, for example by selecting a reduced data rate. Transmission parameters, including data rate, and bits and gains, and corresponding to the improved operating margin are stored at the modems. Upon executing short initialization to return from the idle state, the stored transmission parameters are more likely to be adequate to meet current channel conditions, so the exchange of transmission parameters during short initialization is more likely to be avoided.

Owner:TEXAS INSTR INC

Visual database modeling

ActiveUS20060074942A1Configure operationSimple processDigital data information retrievalDigital data processing detailsGraphicsWeb browser

Methods, systems, and computer program products, implementing techniques for visual database modeling. The techniques include receiving in a web browser user input defining a structure for a database, the structure including one or more tables and one or more relations between the tables; and displaying in the web browser a visual model of the defined database structure, the visual model including one or more graphical objects representing the tables and relations.

Owner:SAP AG

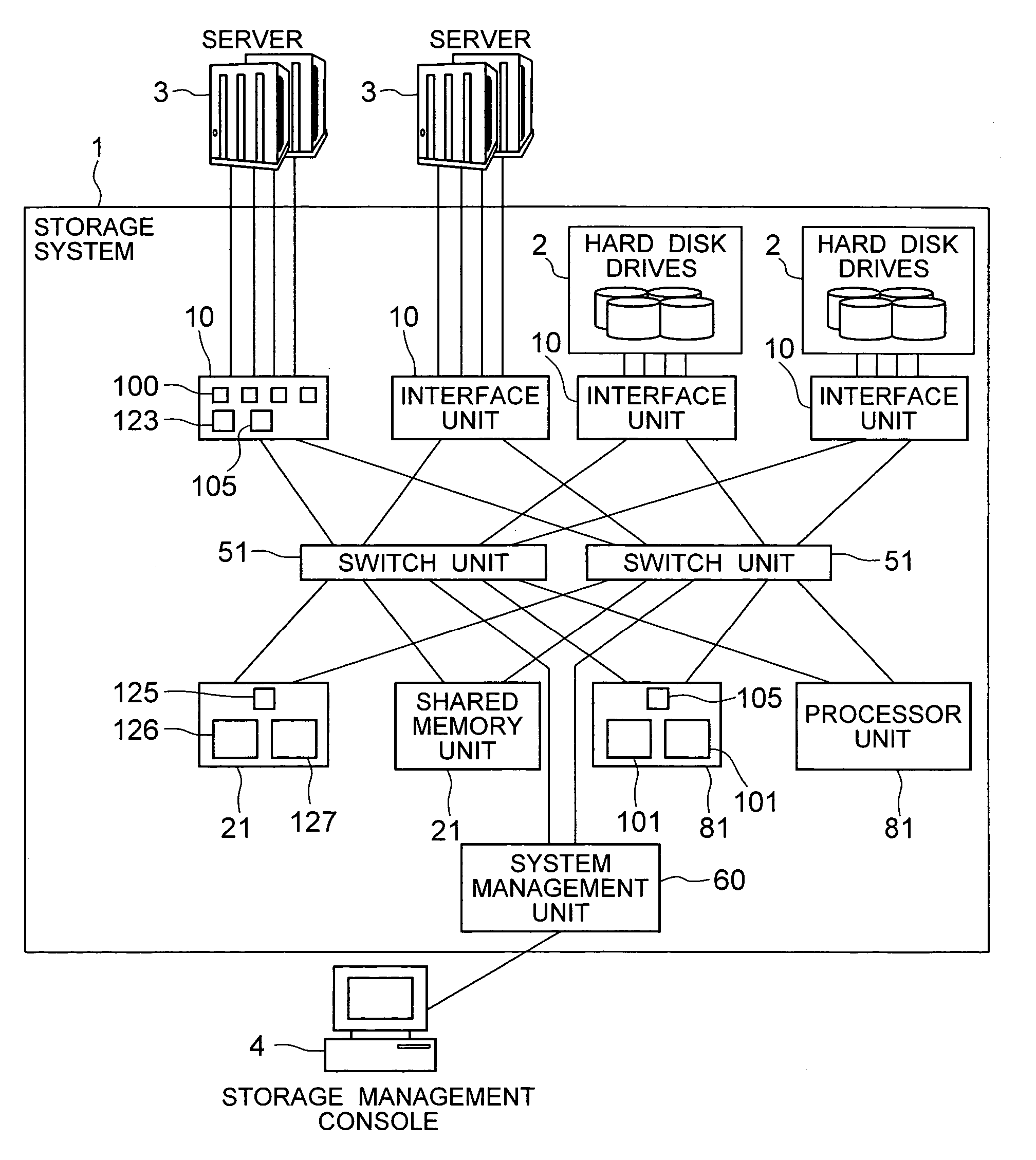

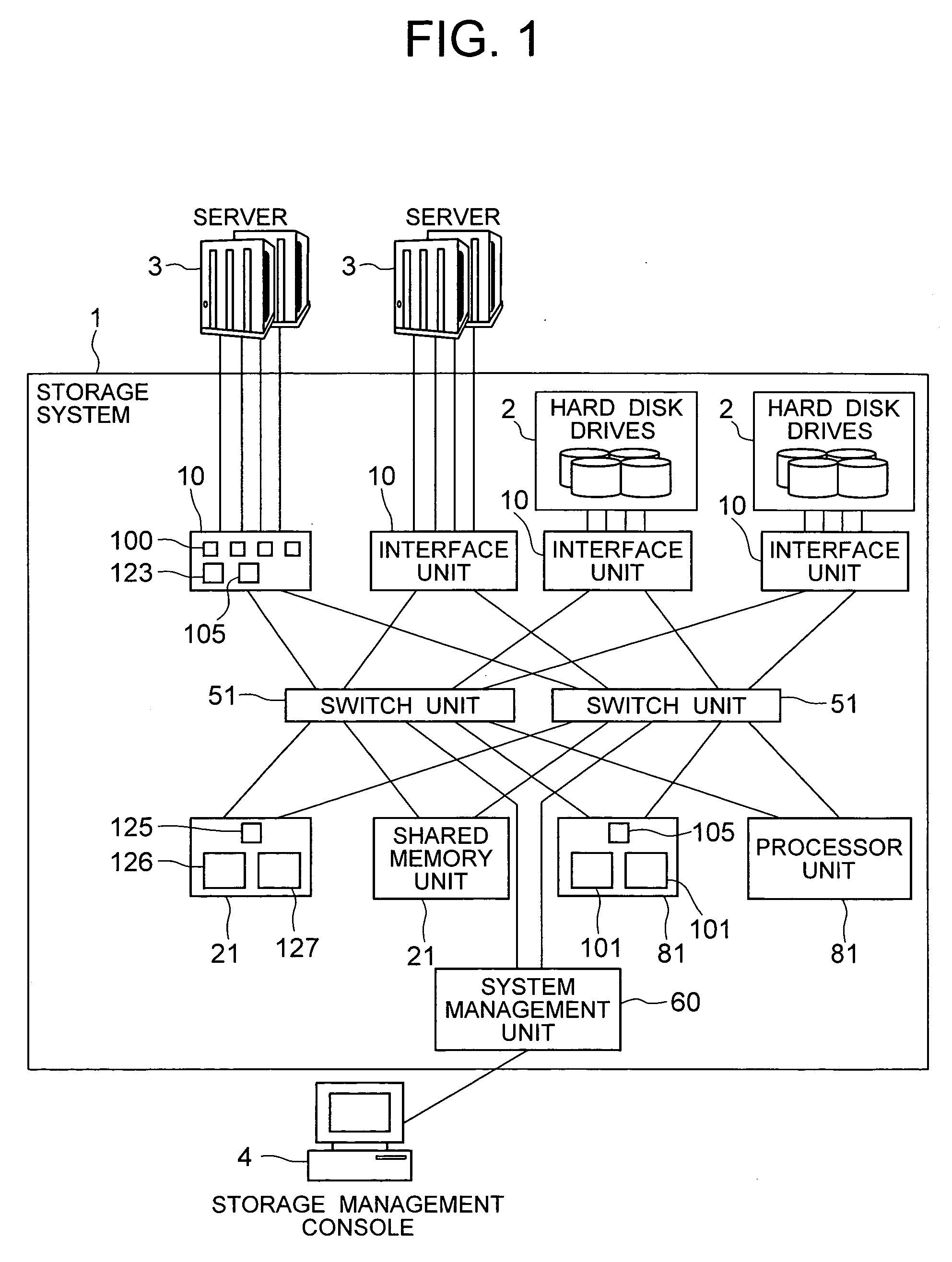

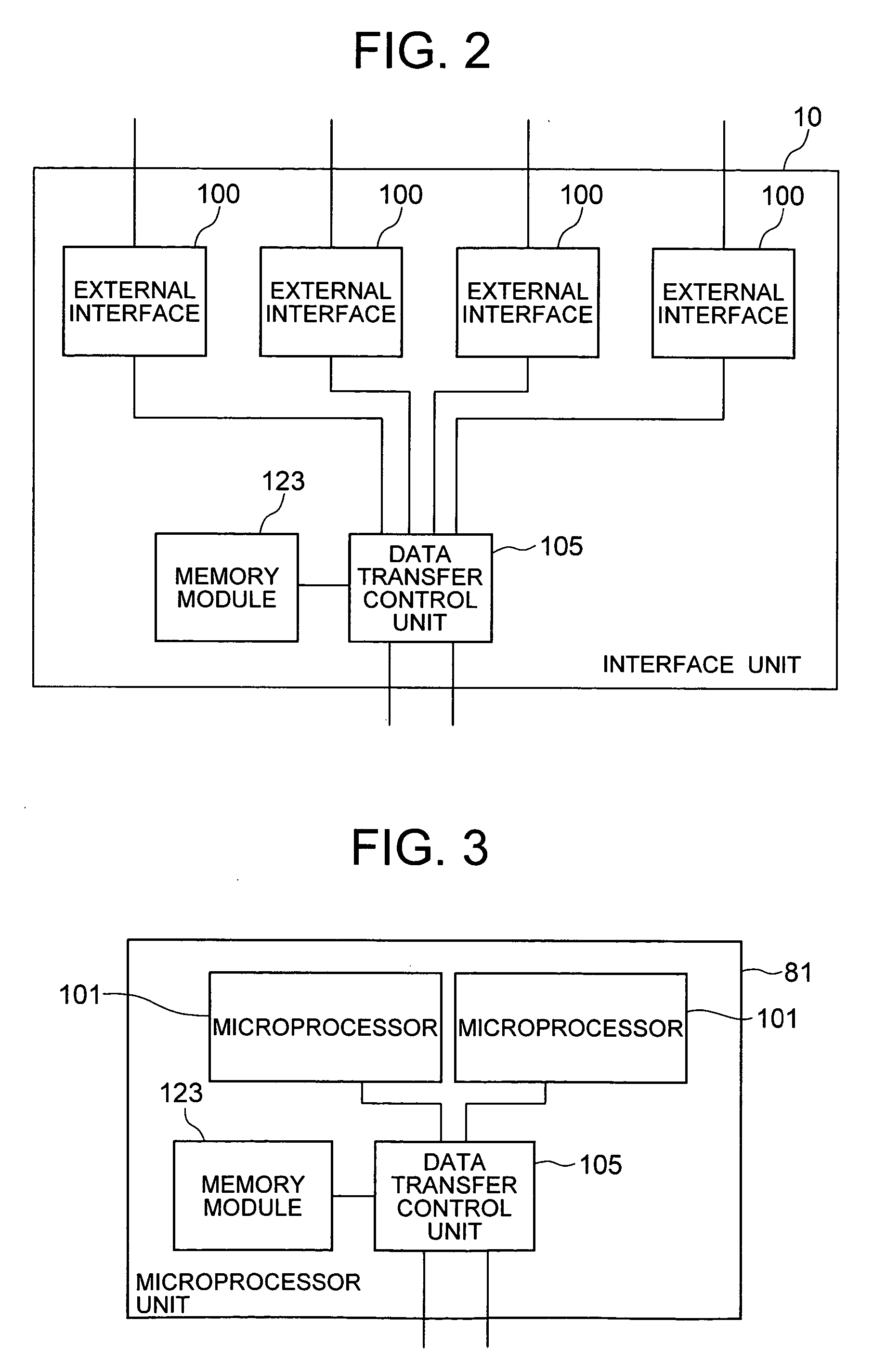

Storage system, computer system, and method of configuring storage system

InactiveUS20060031389A1Efficient use ofFlexible changeInput/output to record carriersError preventionHard disc driveMicro processor unit

A storage system is provided with a plurality of interface units each for connection with a server; an interface unit for connection with hard disk drives; a plurality of microprocessor units each for processing commands; and a switch unit for interconnecting the interface units and microprocessor units. A management console is also connected to the storage system. The storage system forces the management console to select an unused interface unit from among the plurality of interface units for use in a data input / output process between the server and the storage system, select a microprocessor unit which meets required performance of the server from among the plurality of microprocessor units for use in the data input / output process, and notify the administrator of the selected interface unit and microprocessor unit.

Owner:GOOGLE LLC

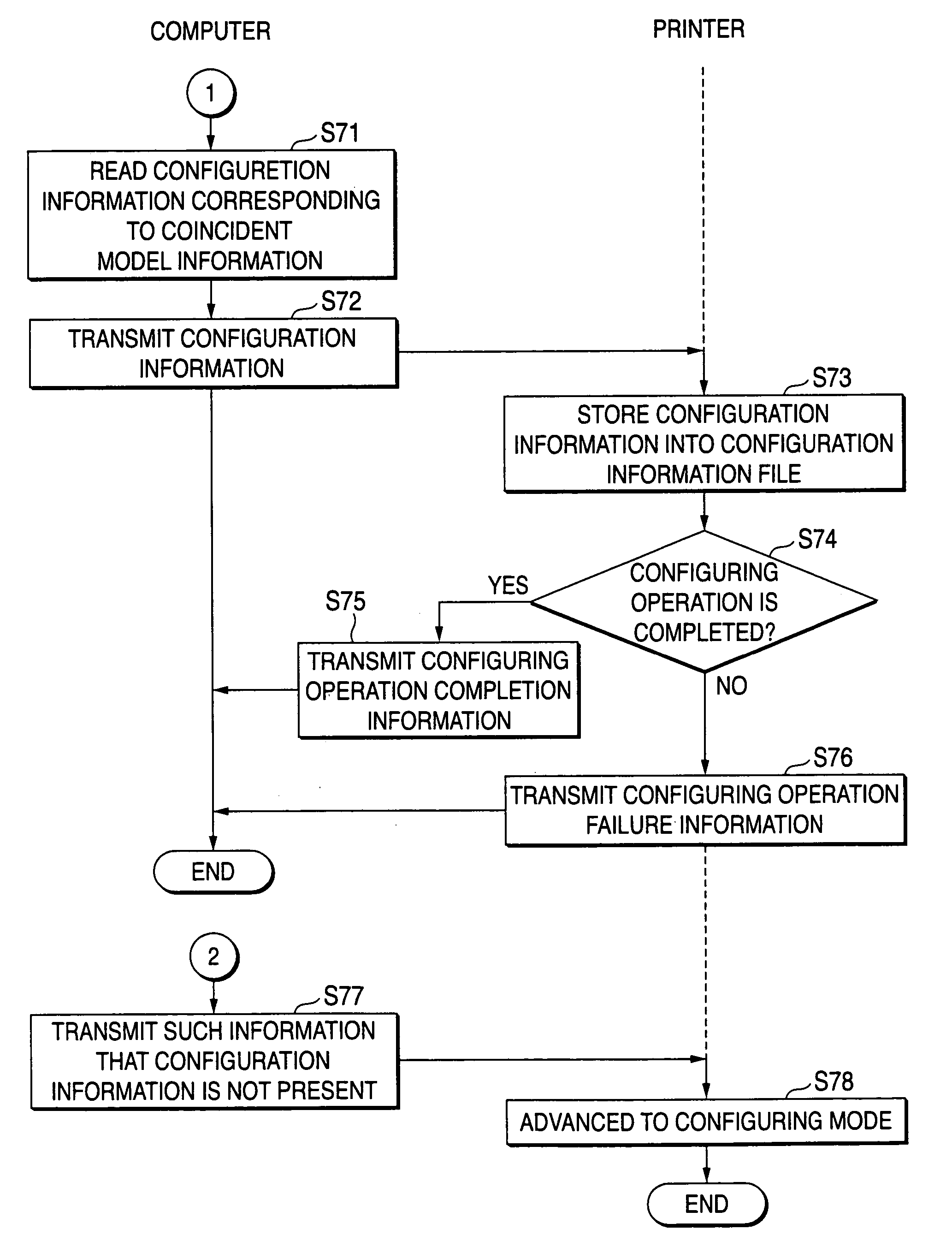

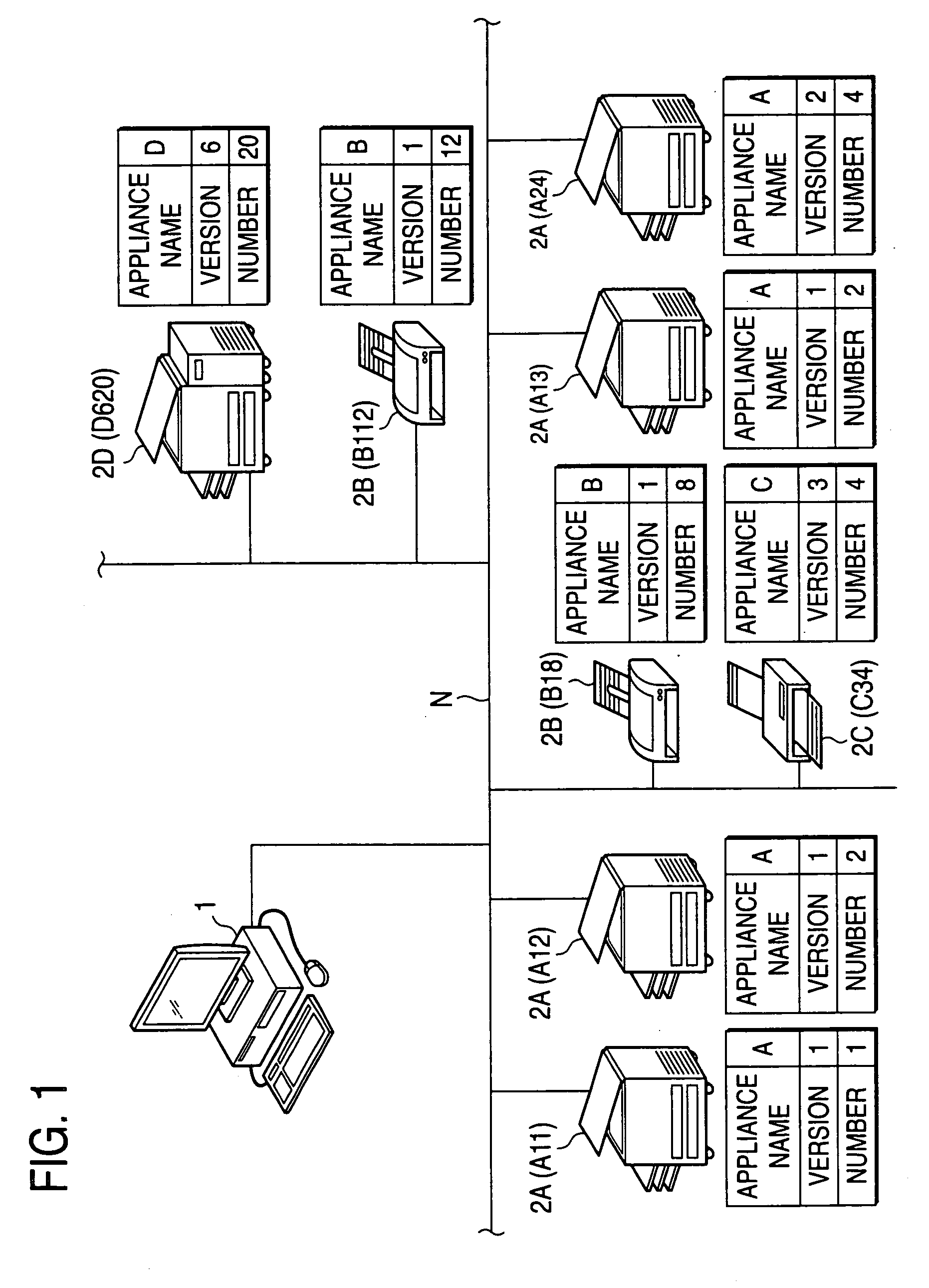

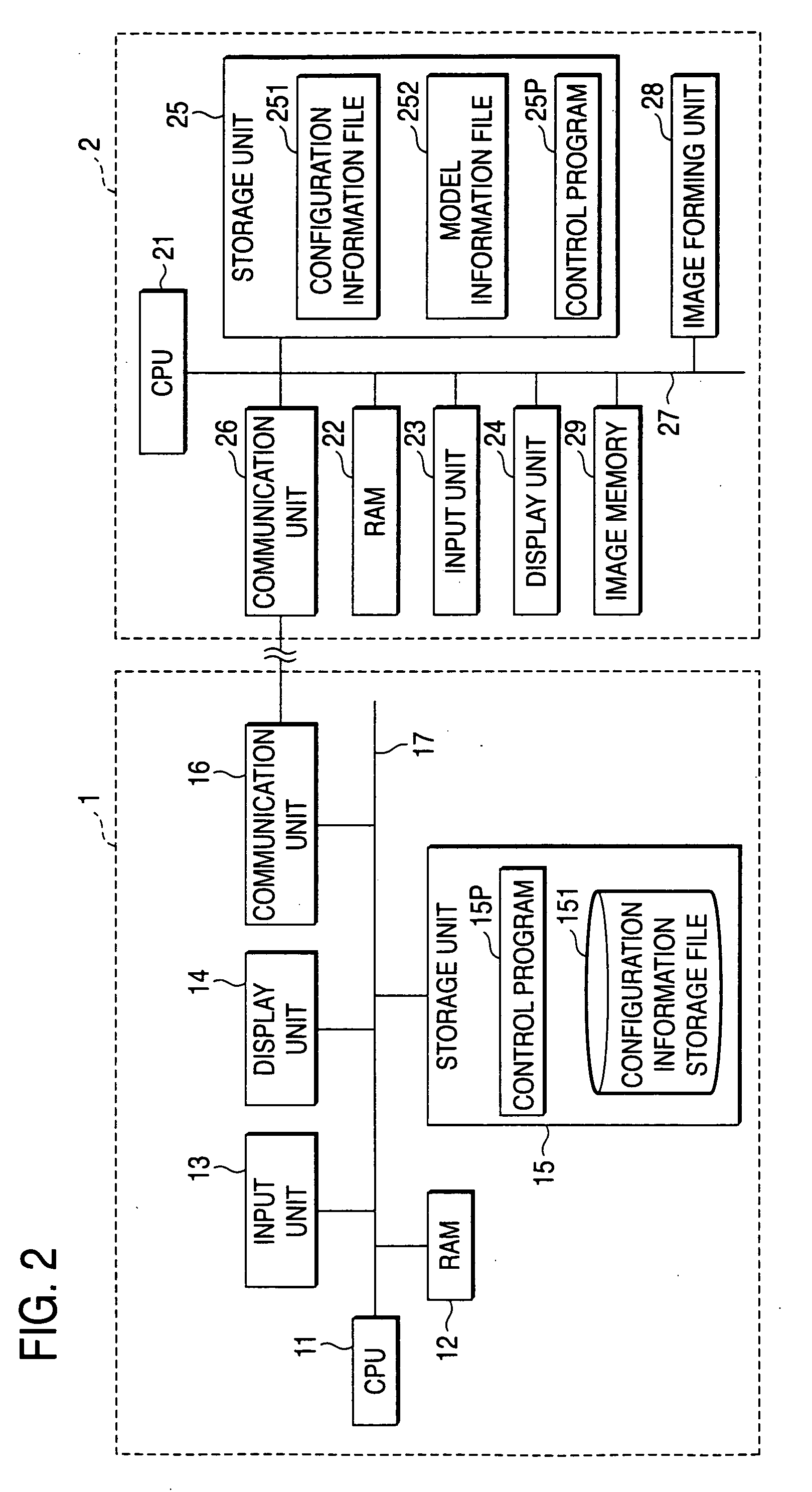

Network device configuring method, network device configuring system and program for configuring network device

InactiveUS20040153532A1Configure operationDigital computer detailsData switching networksInformation processingModel Number

An information processing apparatus acquires both model information of a first device and identification information specific to the first device from the first device, and acquires configuration information of the first device. Then, the information processing apparatus stores the acquired configuration information in a status correlated with the model information and the identification information. On the other hand, in such a case that both the model information and the identification information are transmitted from a second device, the information processing apparatus determines whether the stored model information is made coincident with the transmitted model information. When the transmitted model information is made coincident with the stored model information, the information processing apparatus transmits the stored configuration information to the second device. The second device receives the configuration information and configures in accordance with the transmitted configuration information.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Developing applications using configurable patterns

ActiveUS7953767B2Configure operationSimple processDigital data processing detailsVisual/graphical programmingQuery statementUser interface

Owner:SAP AG

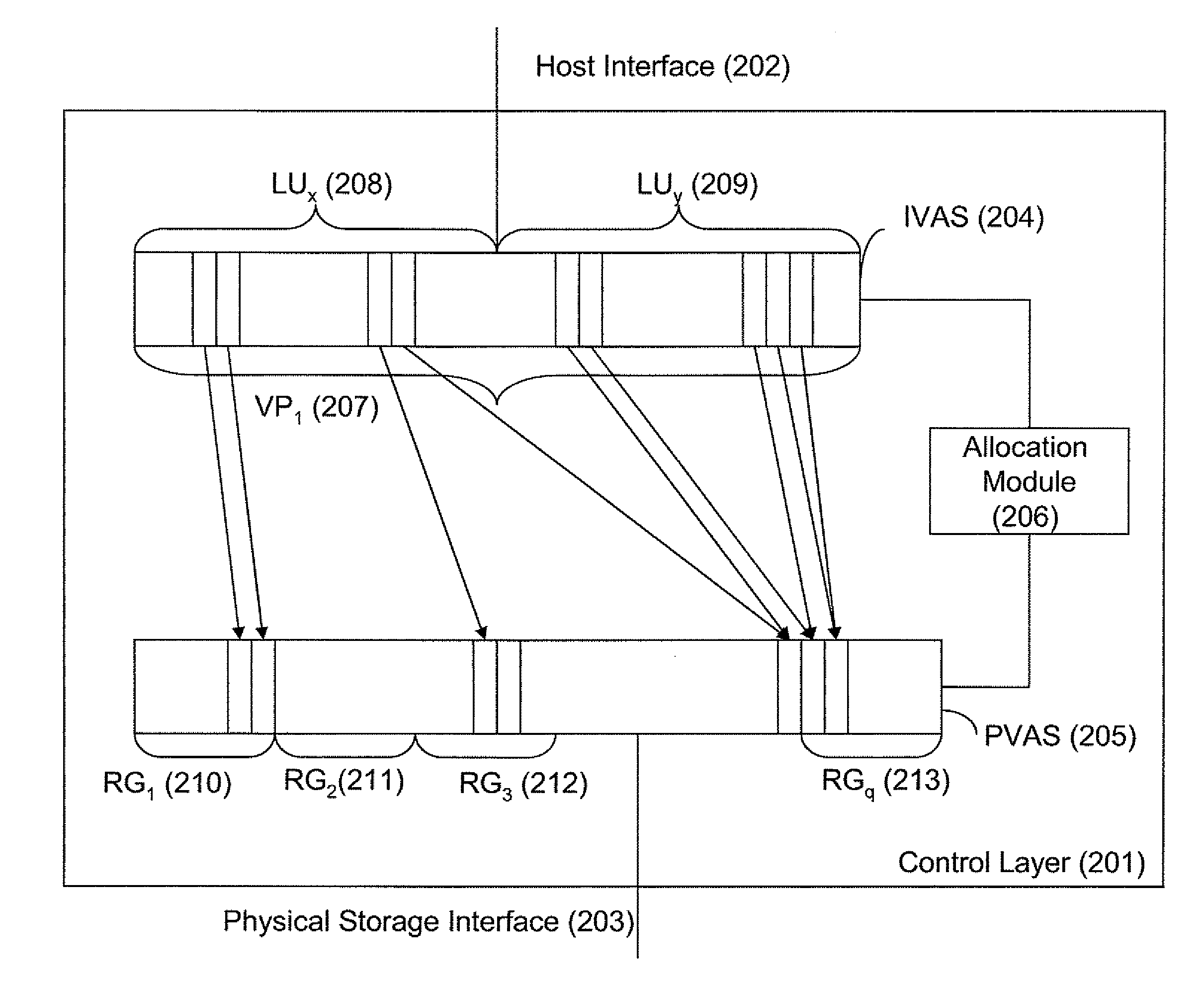

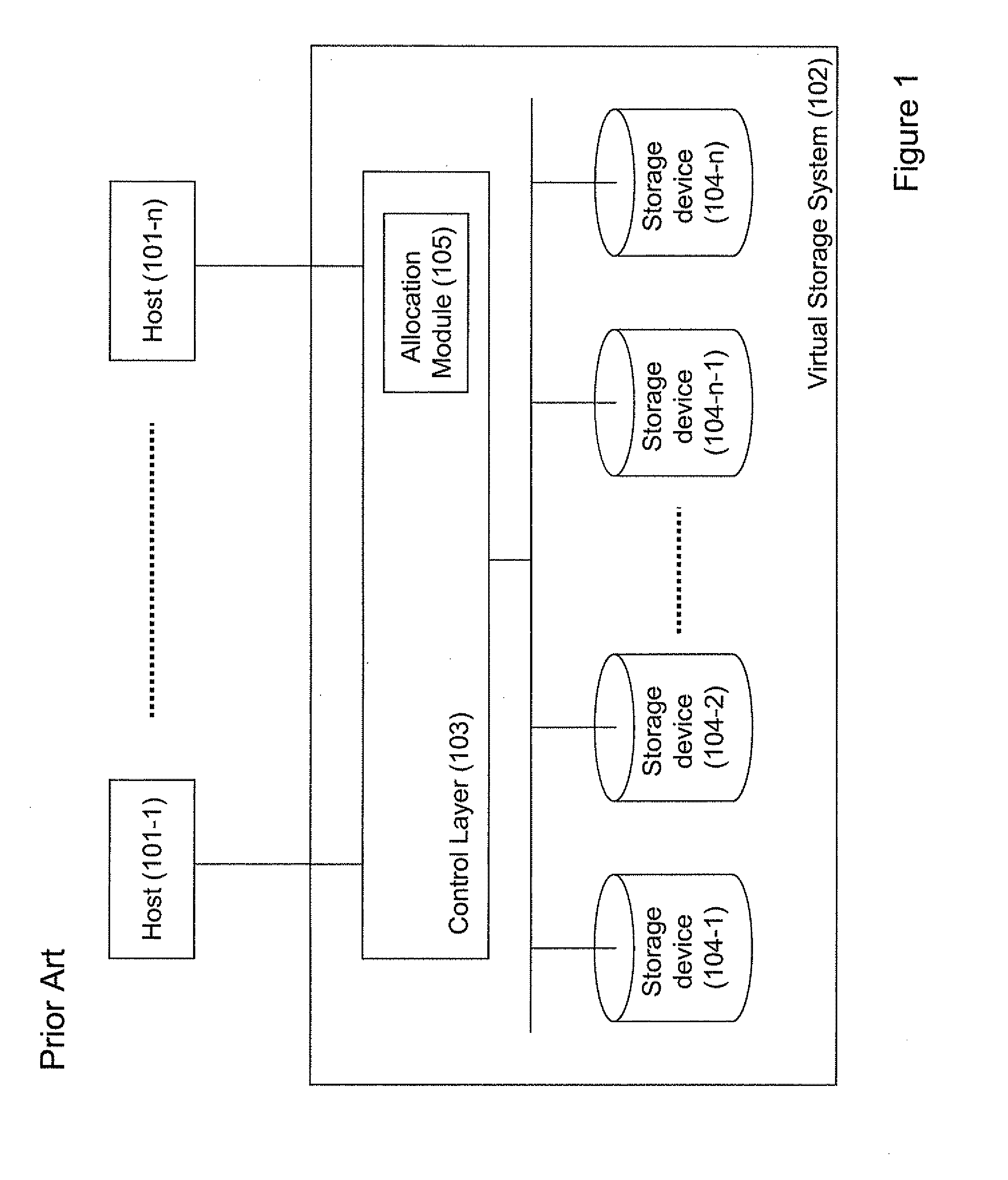

Virtualized storage system and method of operating thereof

ActiveUS20120072694A1Configure operationEasy to operateError detection/correctionMemory adressing/allocation/relocationVirtualizationControl layer

A storage system and method is provided including physical storage devices controlled by storage control devices constituting a storage control layer operatively coupled to the physical storage devices and hosts. The storage control layer includes a first virtual layer interfacing with the hosts, operable to represent a logical address space available to said hosts and characterized by an Internal Virtual Address Space (IVAS); a second virtual layer characterized by a Physical Virtual Address Space (PVAS), interfacing with the physical storage devices, and operable to represent an available storage space; and an allocation module operatively coupled to the first and second virtual layers and providing mapping between IVAP and PVAS. Each address in PVAS is configured to have a corresponding address in IVAS. The allocation module facilitates management of IVAS and PVAS, enabling separation of a process of deleting certain logical object into processes performing changes in IVAS and PVAS, respectively.

Owner:INFINIDAT

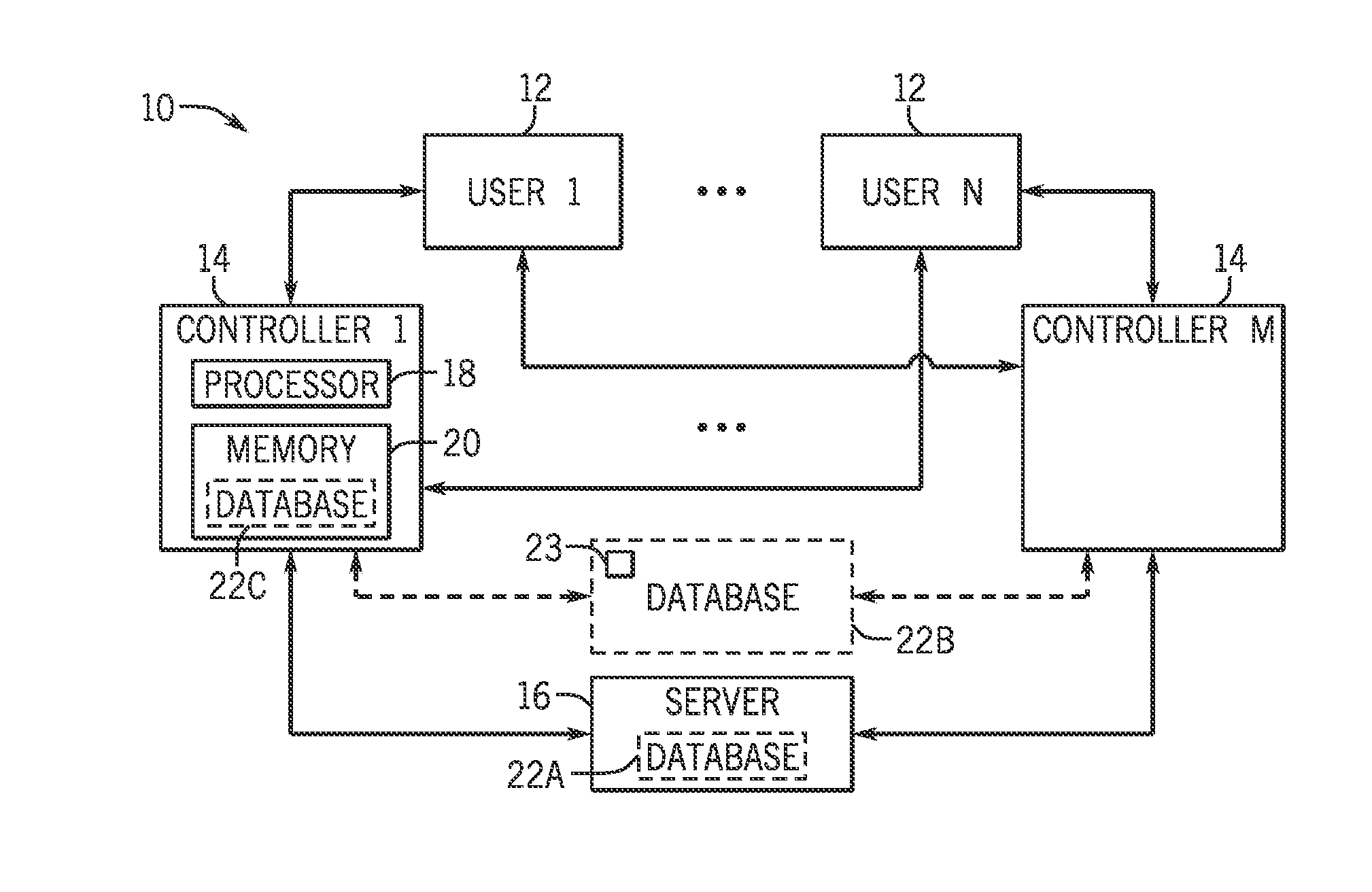

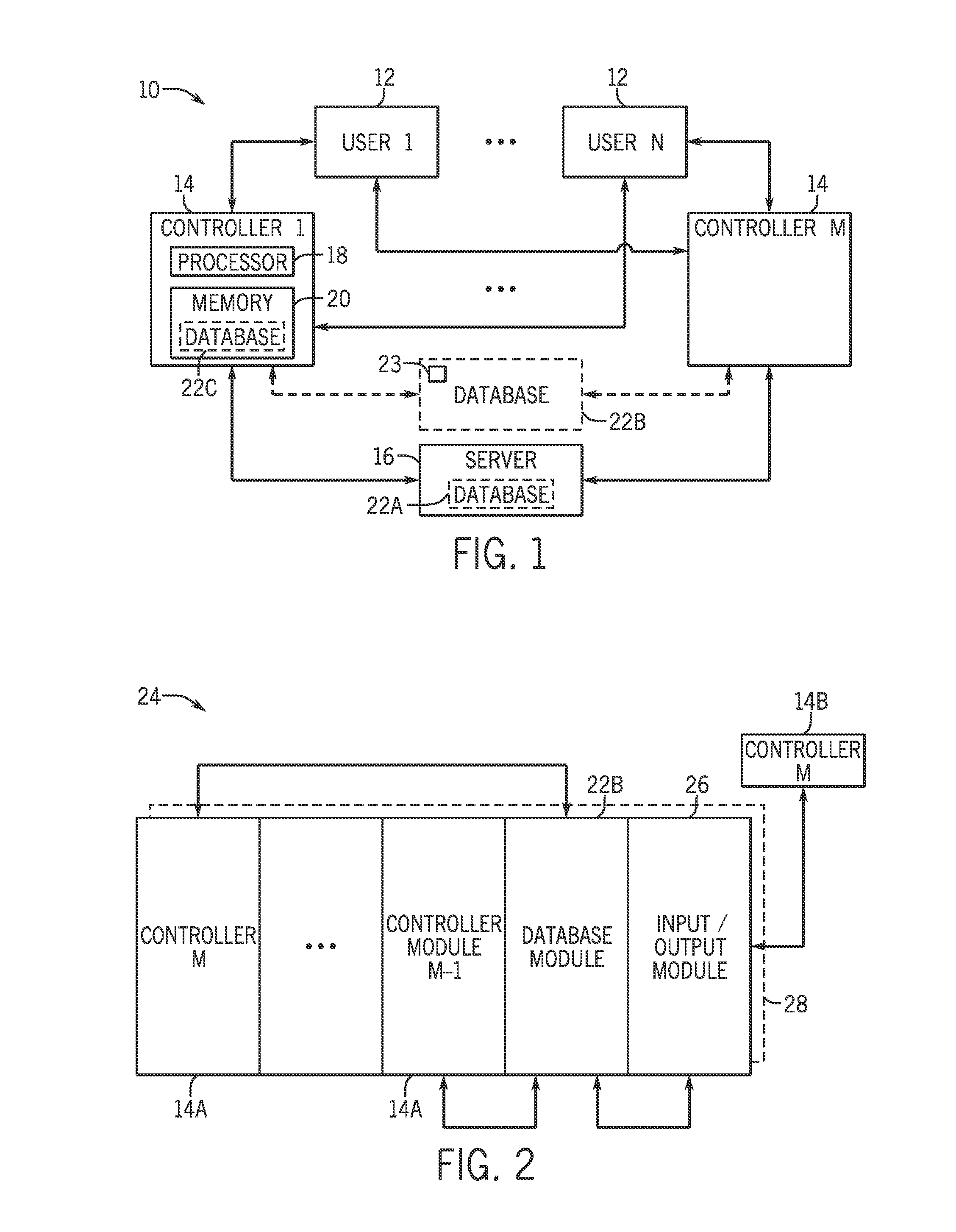

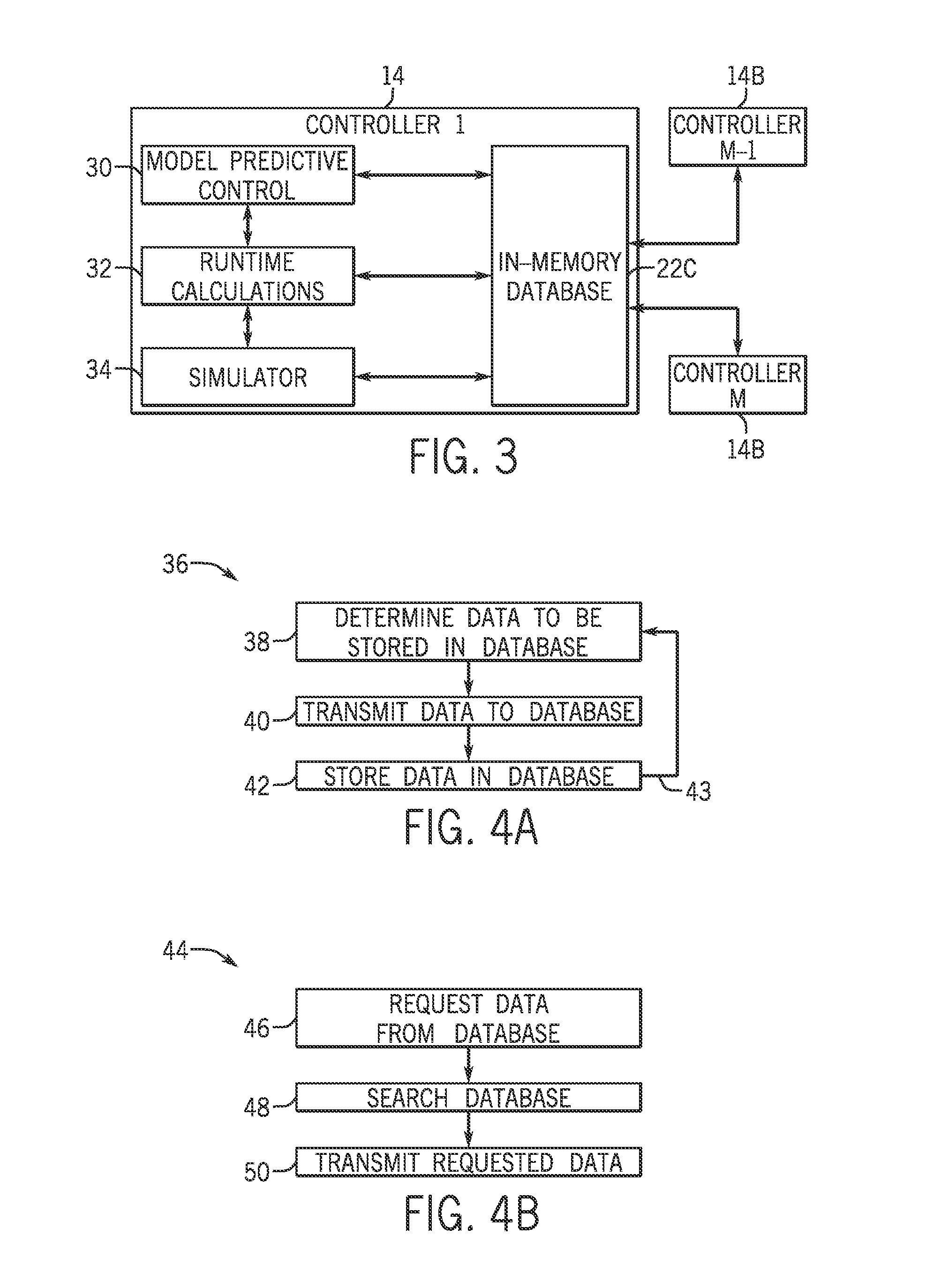

Control system database systems and methods

ActiveUS20150134647A1Configure operationDigital data information retrievalDigital data processing detailsControl systemComputer science

The embodiments described herein include one embodiment that provides a control method that includes connecting a first controller to a control system; receiving control system configuration data from a database, in which the configuration data comprises holistic state data of a second controller in the control system; and configuring operation of the first controller based at least in part on the configuration data received.

Owner:ROCKWELL AUTOMATION TECH

Article Transport Facility

ActiveUS20130313070A1Simplify workEfficient transportSemiconductor/solid-state device manufacturingElevatorsTransport engineeringTransport facility

Owner:DAIFUKU CO LTD

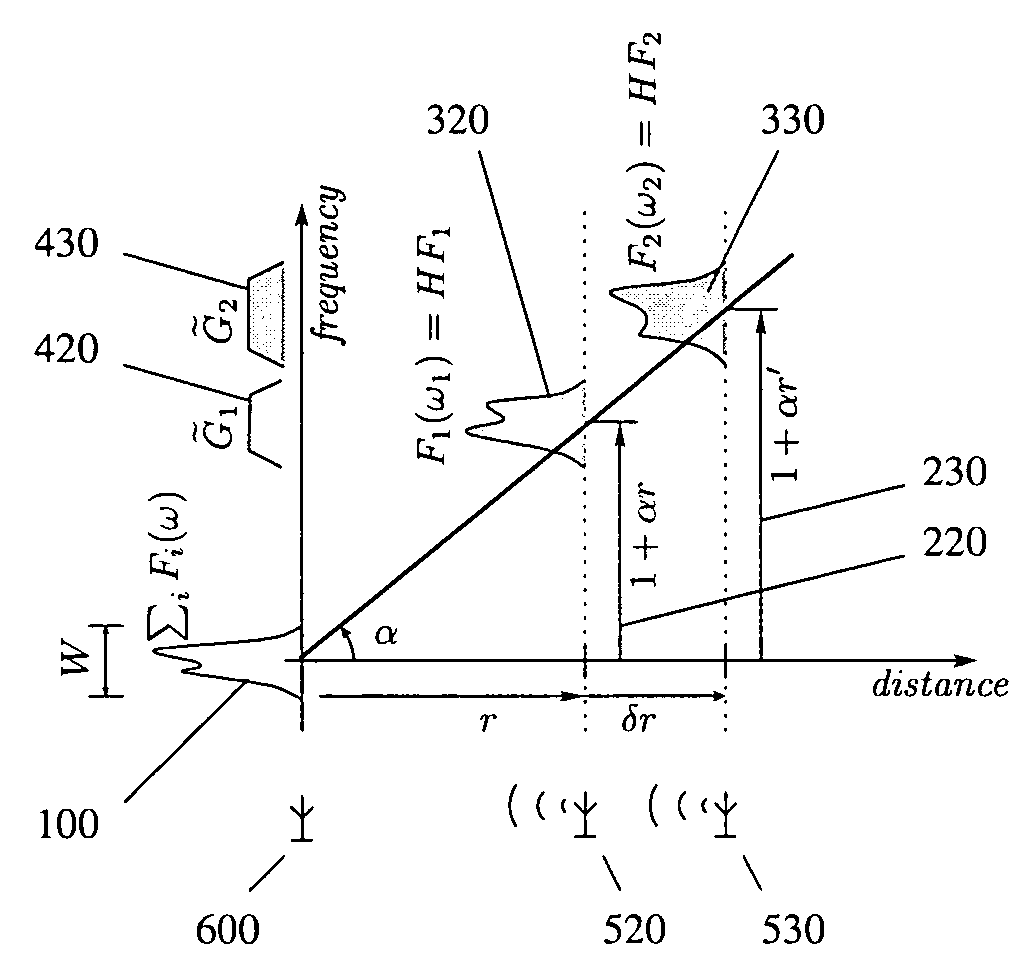

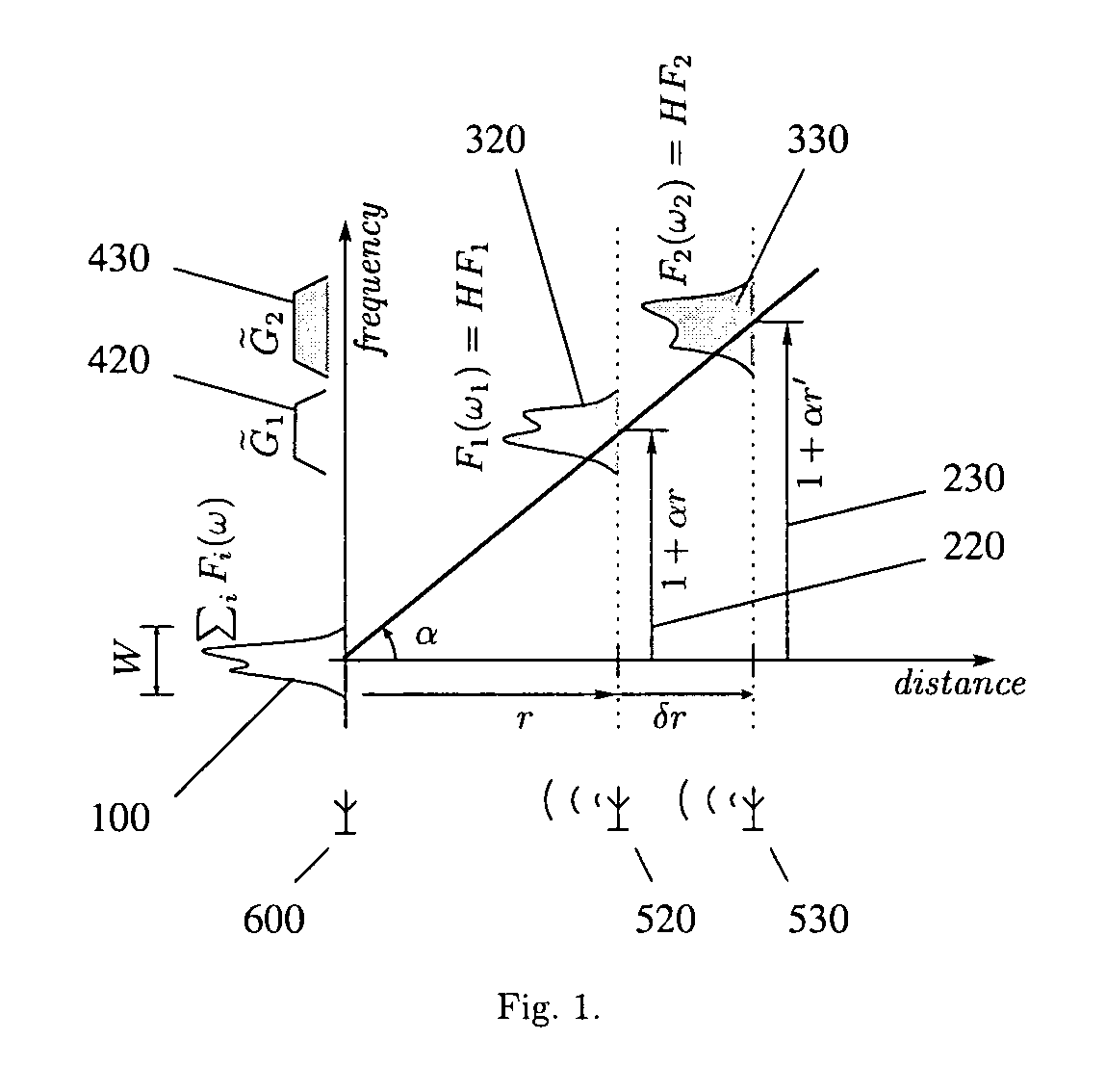

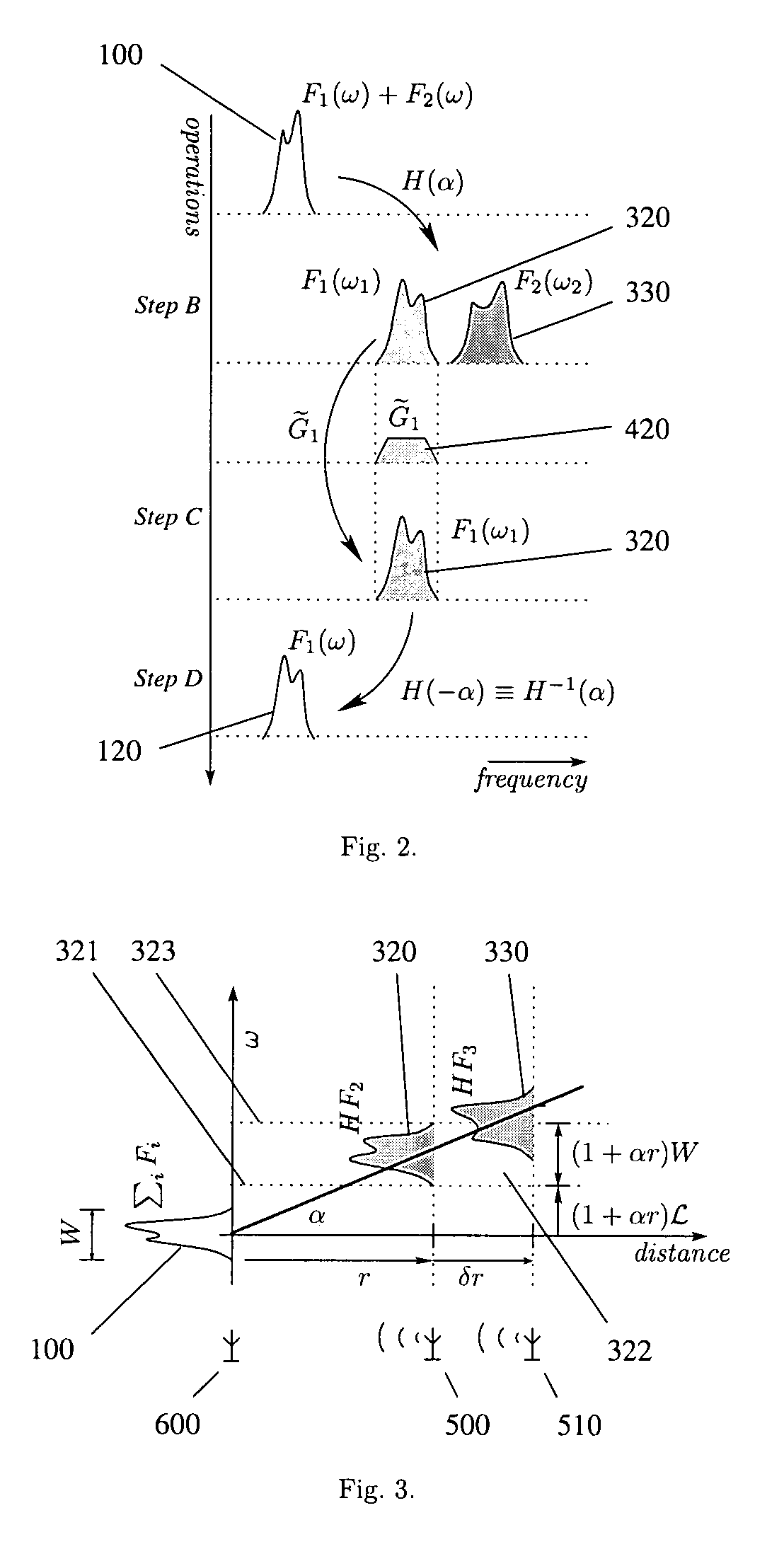

Distance division multiplexing

ActiveUS7106801B1Easy to separateIncreased complexitySecret communicationMulti-frequency code systemsBandpass filteringFrequency spectrum

A general method for extracting an electromagnetic or other wave-propagated signal of a desired source from the overall received waveform containing the sum of signals from a multitude of such sources, independently of signal contents and modulation. The method comprises the steps of first expanding the spectrum of the received sum of signals in proportion to their source distances so as to spectrally isolate the signal from the desired source, selecting the isolated signal spectrum using a bandpass filter, and finally, spectrally compressing the selected signal back to its original band of frequencies. The distance dependent expansion is performed by scanning the phase gradient of the signal spectrum. Related method for computing the spread of source distances by measuring low and high frequency bounds of the expanded sum of signals or subbands, or by plotting the expanded sum of signals or subbands on a graph.

Owner:GURUPRASAD VENKATA

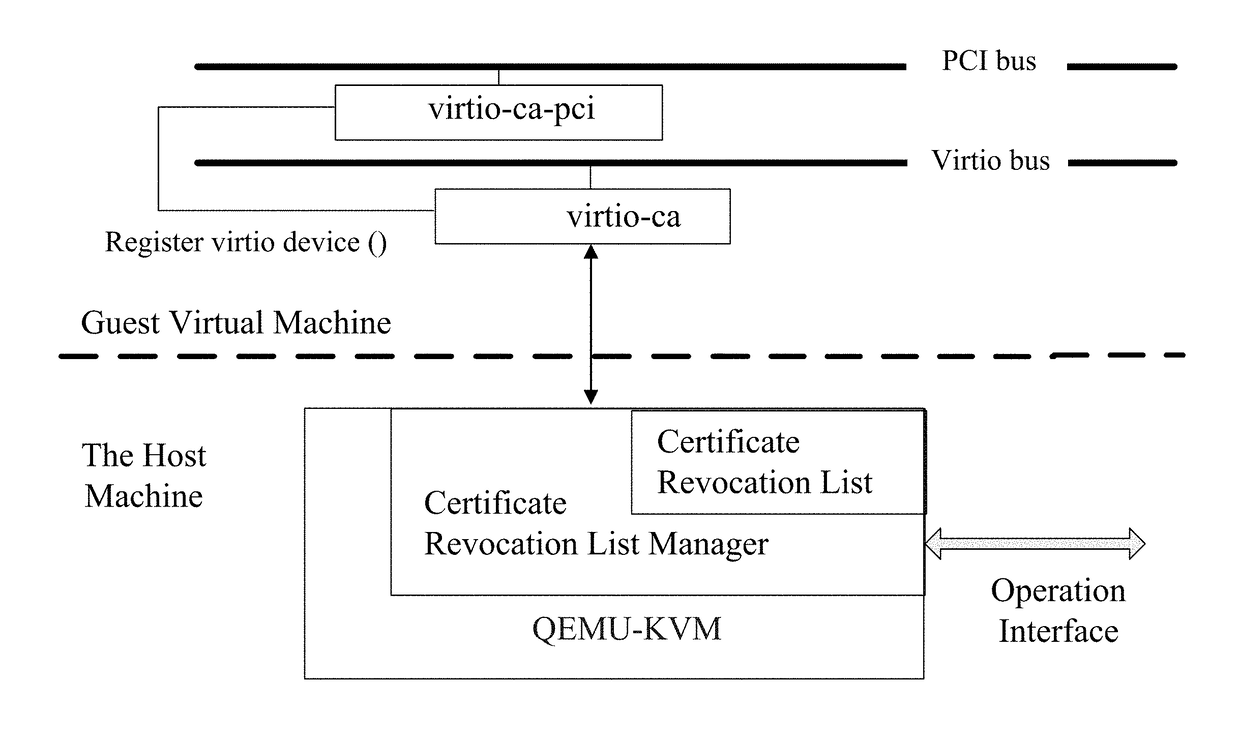

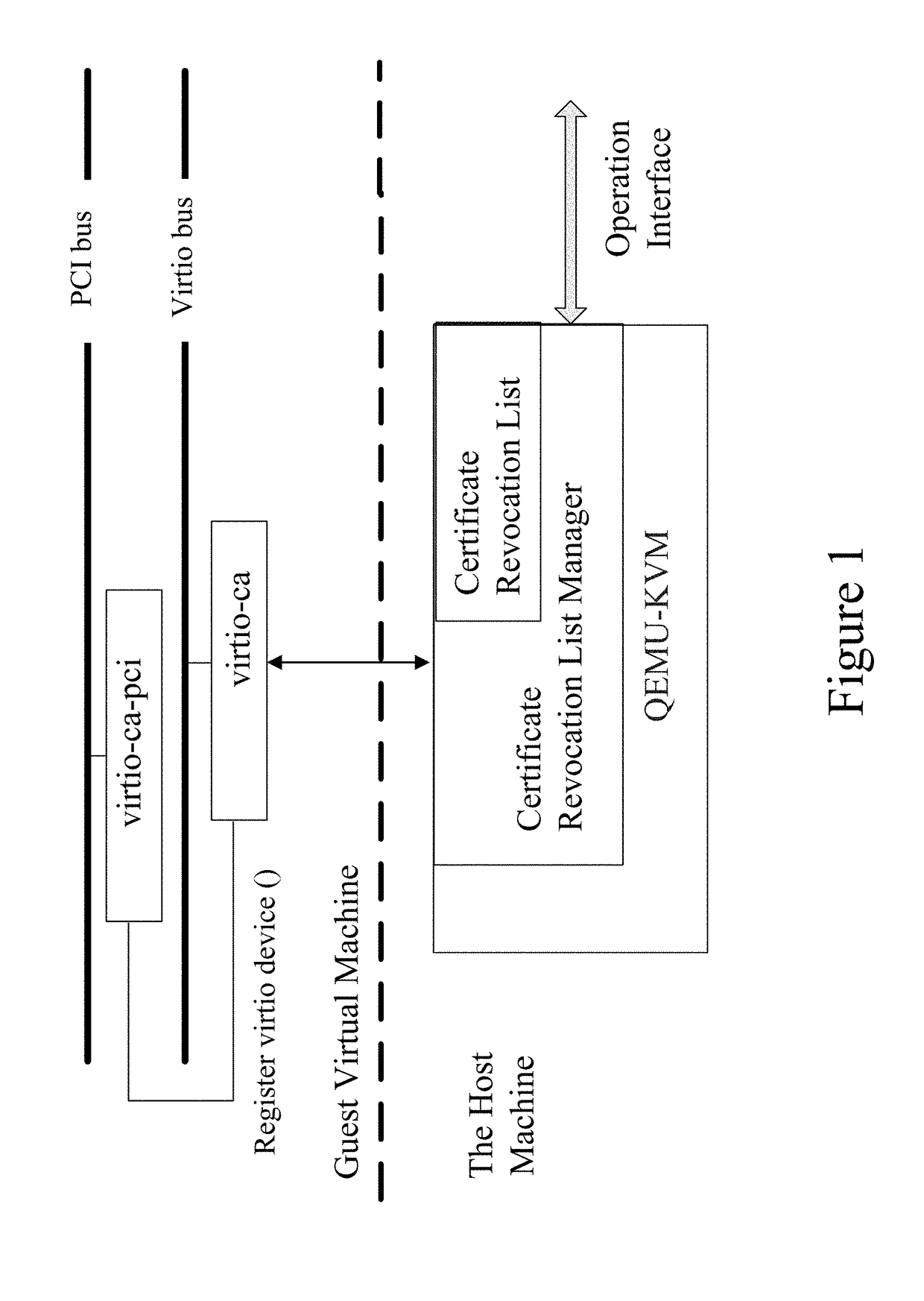

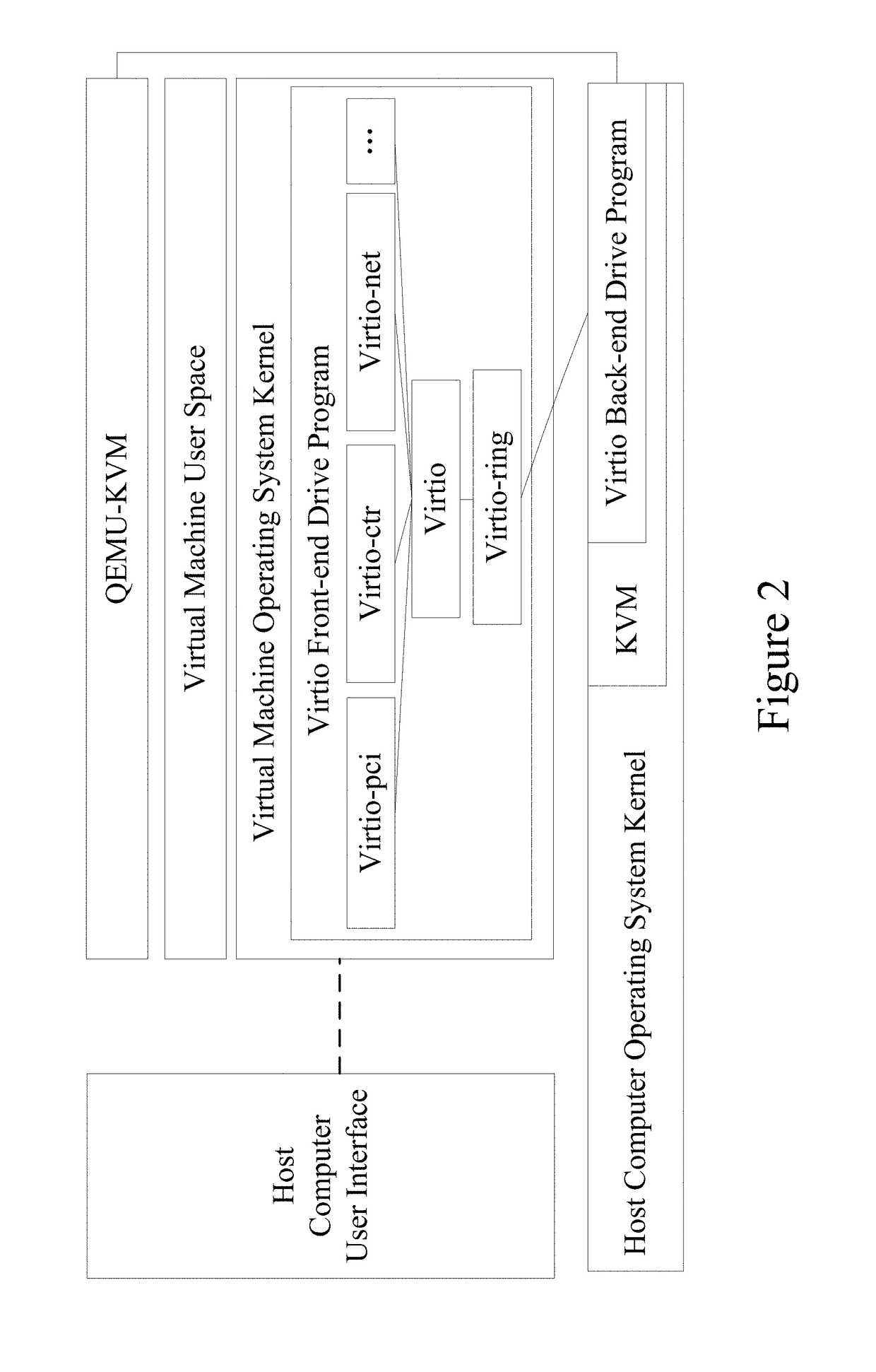

Method and system for checking revocation status of digital certificates in a virtualization environment

ActiveUS20180102904A1Reduce delaysImprove efficiencyKey distribution for secure communicationPublic key for secure communicationVirtualizationSerial code

The present invention discloses a method and a system for checking revocation status of digital certificates in a virtualization environment. The method includes: 1) Setting up multiple virtual machines in a host computer; setting up a certificate revocation list manager within the virtual machine monitor of the host computer; 2) The certificates relying party in the virtual machines sends a service request for checking certificate revocation status to the certificate revocation list manager; 3) The certificate revocation list manager searches locally for the CRL file corresponding to the service request for checking certificate revocation status: a) If such a corresponding CRL file exists, the CRL file is returned to the certificate relying party in the virtual machines; or, the certificate revocation list manager checks whether the corresponding certificate serial number exists in the CRL file, then returns the result; b) if the corresponding CRL file does not exist, the corresponding CRL file is downloaded and verified according to the configuration file; then the CRL file is returned to the certificate relying party in the virtual machines; or, the certificate revocation list manager checks whether the corresponding certificate serial number exists in the CRL file, then returns the result. The present invention greatly improves the efficiency of checking revocation status of certificates.

Owner:INST OF INFORMATION ENG DATA ASSURANCE & COMM SECURITY CENT CHINESE ACADEMY OF SCI

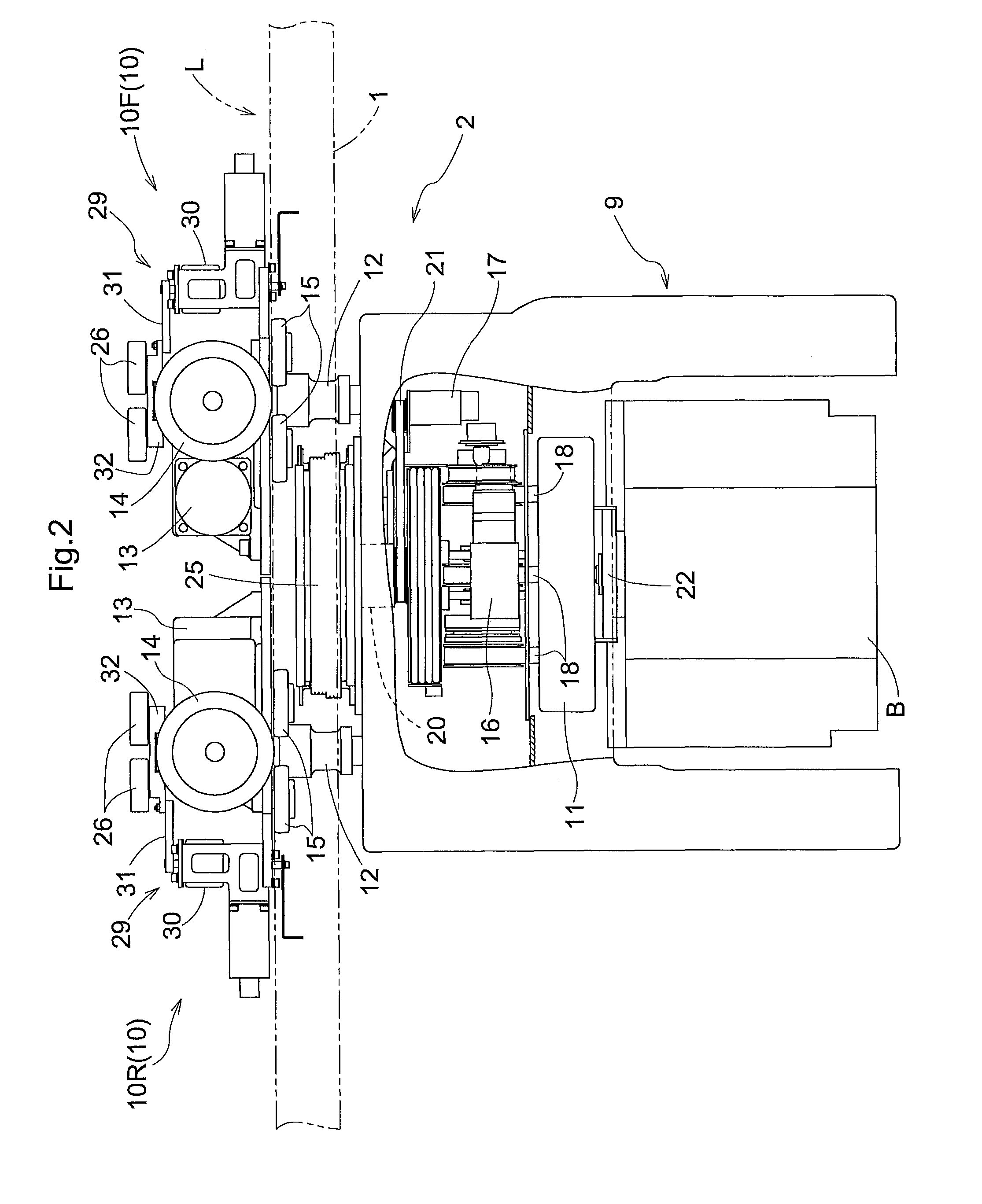

Optical position assessment apparatus and method

ActiveUS7388663B2Improve accuracyIncrease flexibilityUsing optical meansPhotomechanical exposure apparatusLithography processLight beam

A lithographic apparatus comprises a substrate table that supports a substrate having alignment marks on a surface thereof. The apparatus further comprises a frame moveable relative to the substrate to provide for a scanning or stepping mode of operation. An array of projection systems is disposed across the frame for projecting respective patterned beams onto a target portion of the substrate. A plurality of alignment mark detectors are attached to the frame and are moveable with respect to the frame using respective linear drive mechanisms. A position sensor is associated with each alignment mark detector for determining the position of the detector relative to the frame. A control system is responsible for both initial positioning of the detectors above alignment mark patterns on the substrate, and for dynamic alignment of the frame and substrate during a lithographic process.

Owner:ASML NETHERLANDS BV

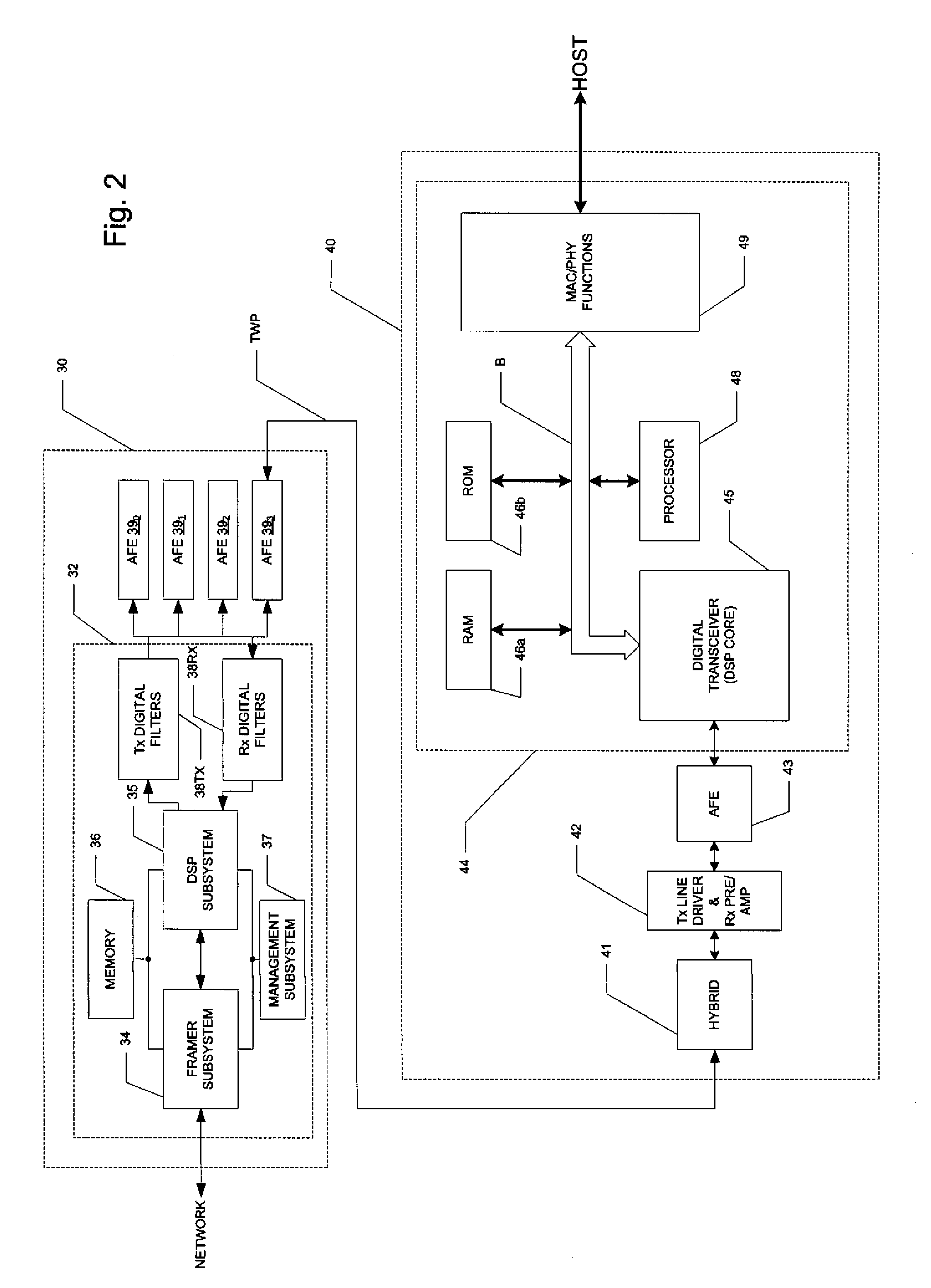

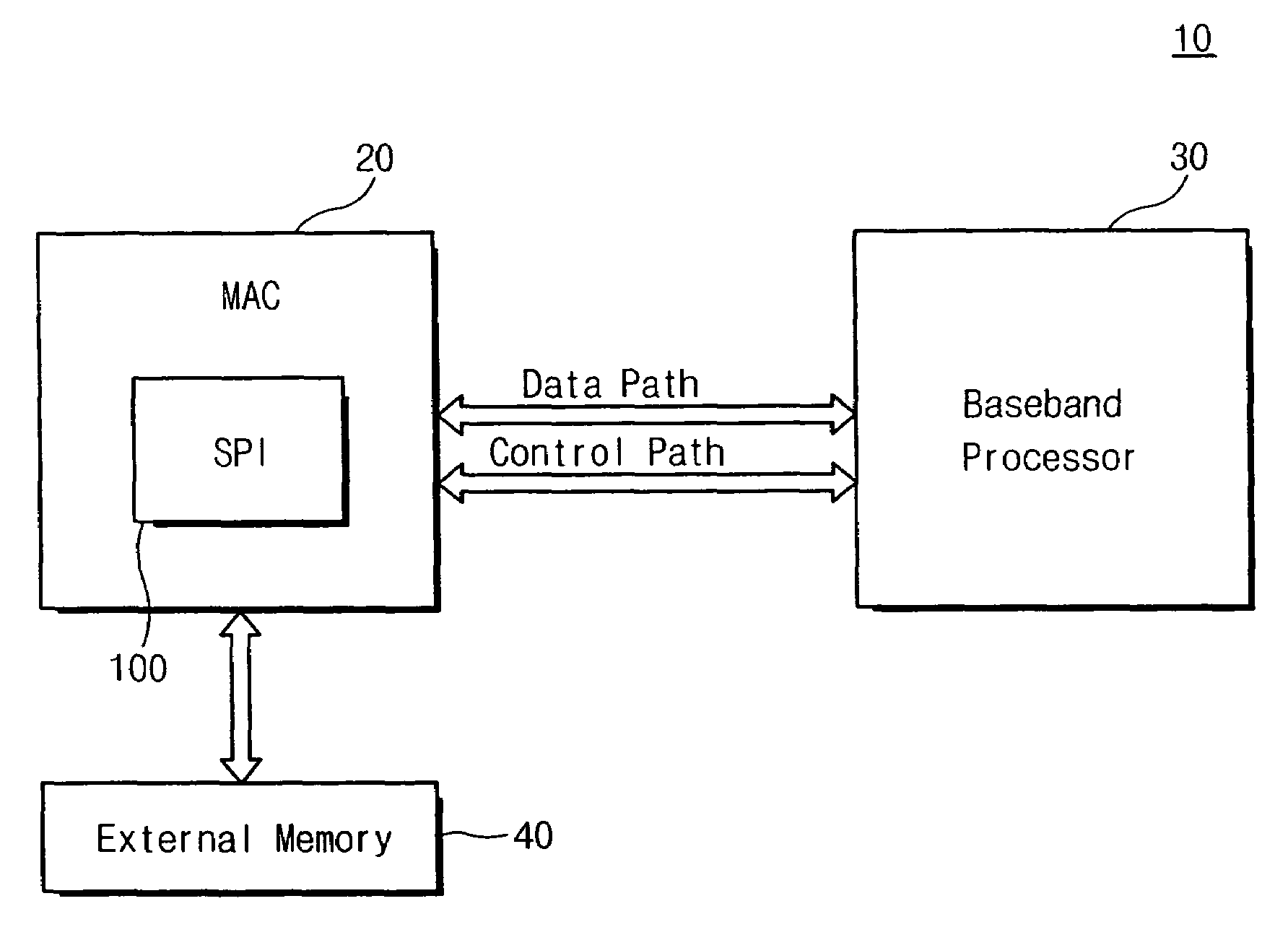

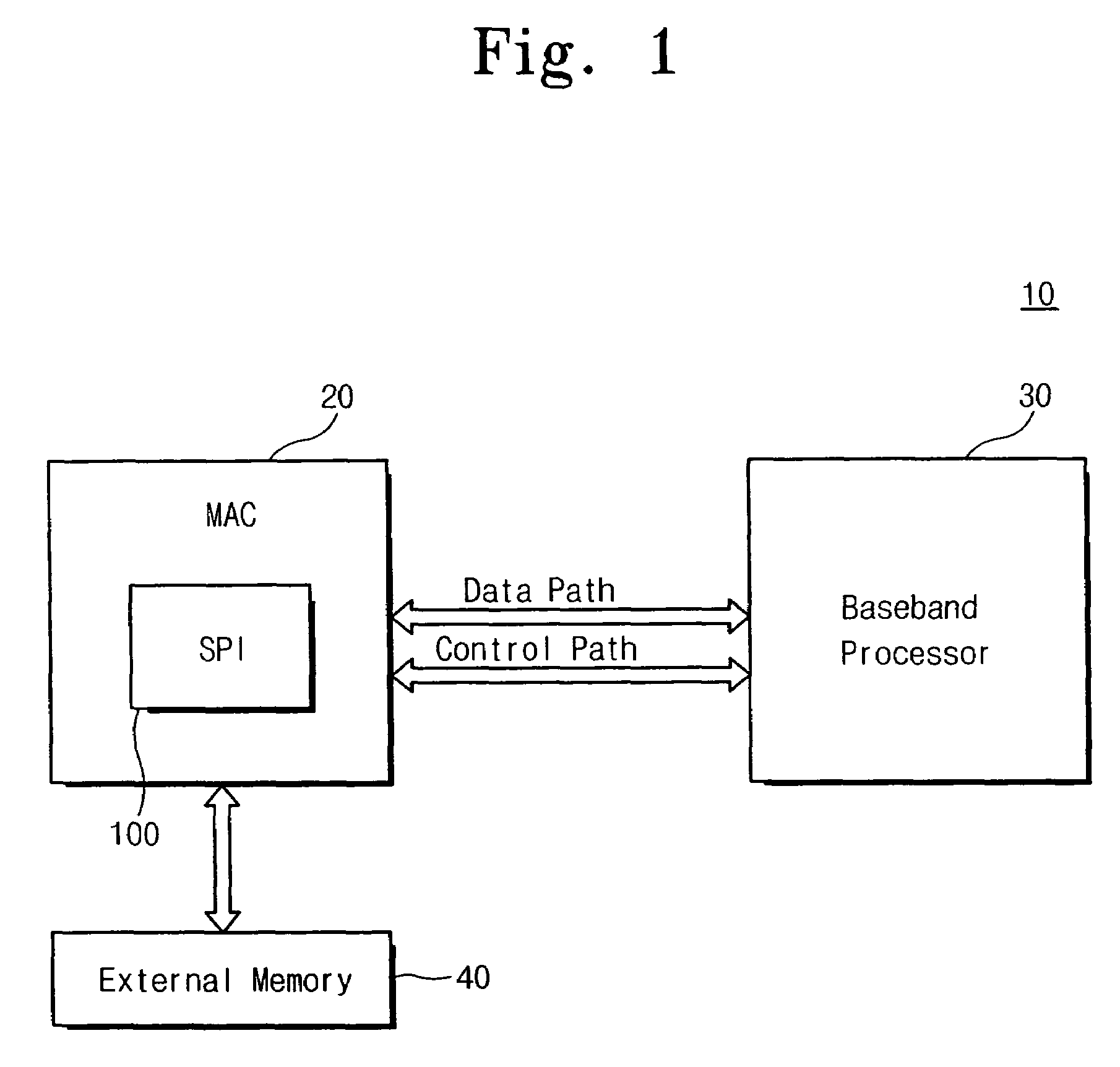

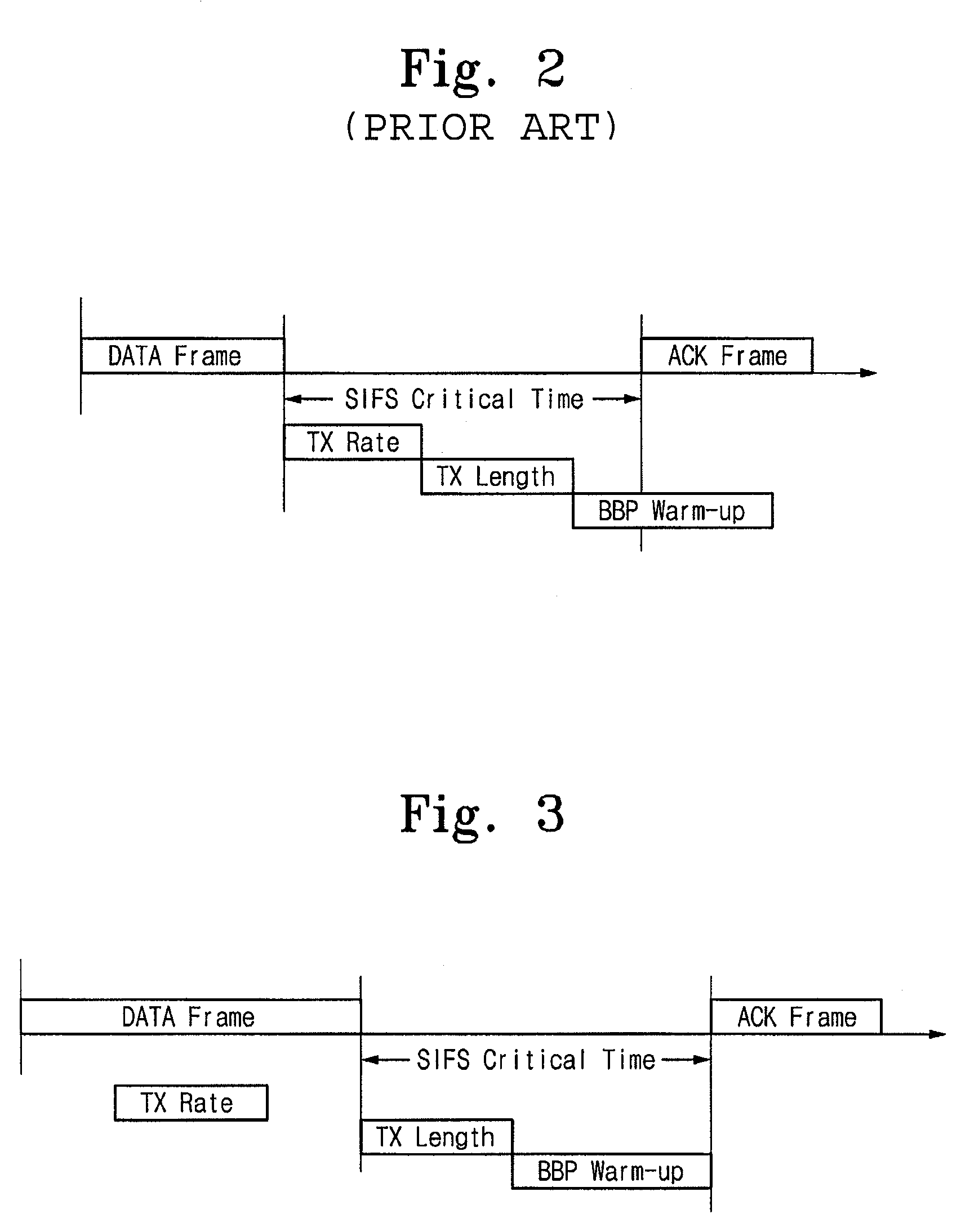

Hybrid-type data transmission apparatus and method suitable for high-performance wireless LAN

ActiveUS7453833B2Configure operationNetwork traffic/resource managementTransmission control/equalisingHybrid typeWireless lan

In a method and apparatus for data transmission suitable for a high-performance wireless LAN, the apparatus utilizes a serial communication interface device to perform data transmission between a master and a slave. The data transmission apparatus includes a data input unit for receiving at least one of transmission rate data and transmission length data to be transmitted from the master to the slave. A selection unit receives the at least one of the transmission rate data and the transmission length data from the data input unit, and receives at least one of a corresponding first event signal and a second event signal for selectively transmitting at least one of the transmission rate data and the transmission length data respectively to the slave. A controller receives the at least one of the transmission rate data and the transmission length data from the selection unit and controls a serial communication interface used to transmit the at least one of the transmission rate data and the transmission length data to the slave. A control unit automatically controls critical timing of the transmission of the at least one of the transmission rate data and the transmission length data, in response to activation of the corresponding at least one first event signal and second event signal.

Owner:SAMSUNG ELECTRONICS CO LTD

Bending device and method for bending a plate

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Virtualized storage system and method of operating thereof

ActiveUS20120066469A1Efficient and smooth interactionEfficient implementationError detection/correctionMemory adressing/allocation/relocationVirtualizationControl layer

A storage system and method are provided including physical storage devices controlled by storage control devices constituting a storage control layer operatively coupled to the physical storage devices and hosts. The storage control layer includes: a first virtual layer interfacing with the hosts, operable to represent a logical address space characterized by logical block addresses, characterized by an Internal Virtual Address Space (IVAS) and operable, responsive to I / O requests addressed to logical block addresses, to provide protocol-dependent translation of said logical block addresses into IVAS addresses; and a second virtual layer interfacing with the physical storage space, and operable to represent available physical space to said hosts and characterized by a Physical Virtual Address Space (PVAS). Each address in PVAS having a corresponding address in IVAS. The second virtual layer is operable to translate PVAS addresses corresponding to IVAS addresses into addresses in physical address space in a protocol-independent manner.

Owner:INFINIDAT

Visual database modeling

ActiveUS8126937B2Configure operationSimple processDigital data information retrievalDigital data processing detailsGraphicsWeb browser

Methods, systems, and computer program products, implementing techniques for visual database modeling. The techniques include receiving in a web browser user input defining a structure for a database, the structure including one or more tables and one or more relations between the tables; and displaying in the web browser a visual model of the defined database structure, the visual model including one or more graphical objects representing the tables and relations.

Owner:SAP AG

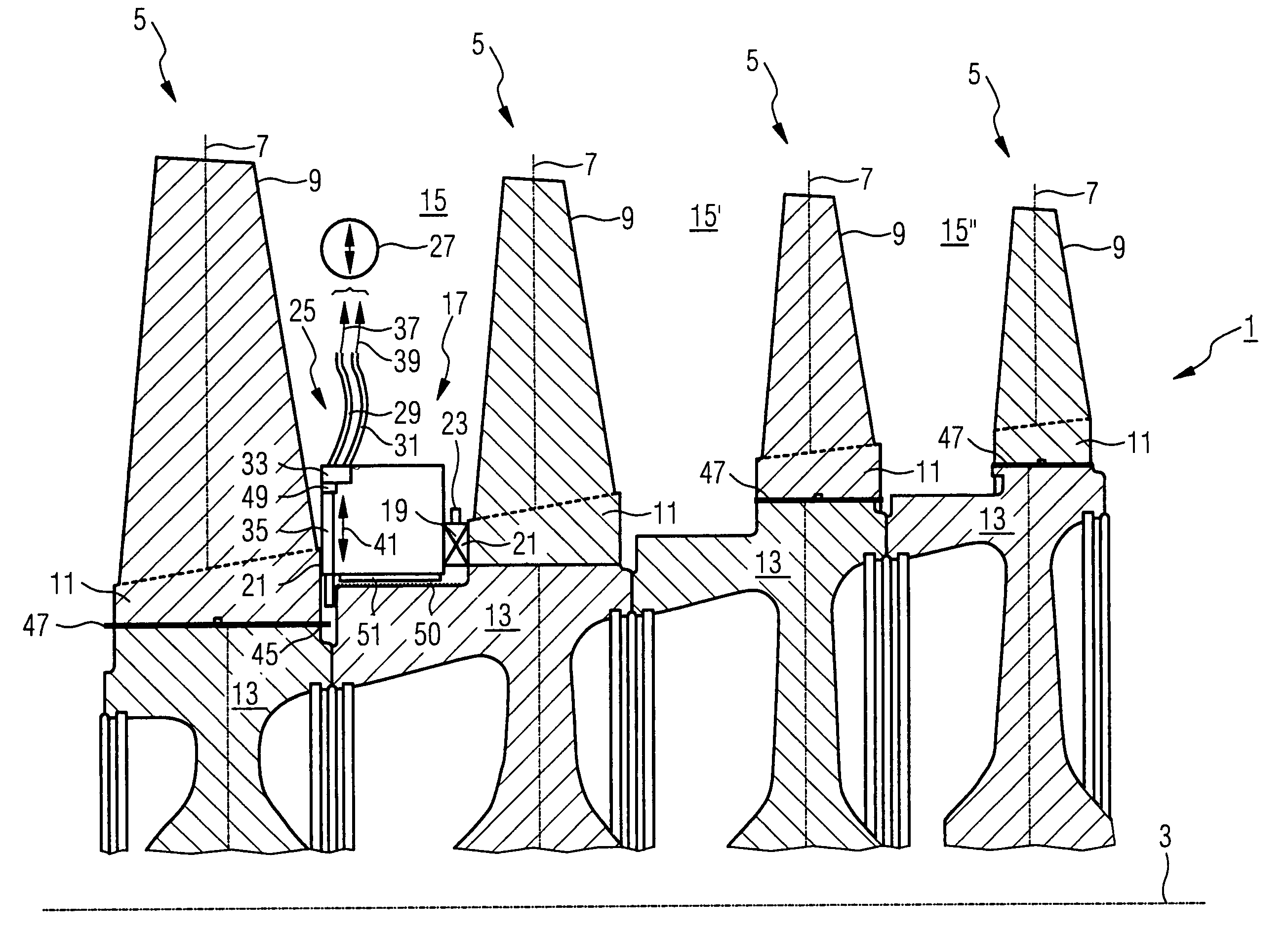

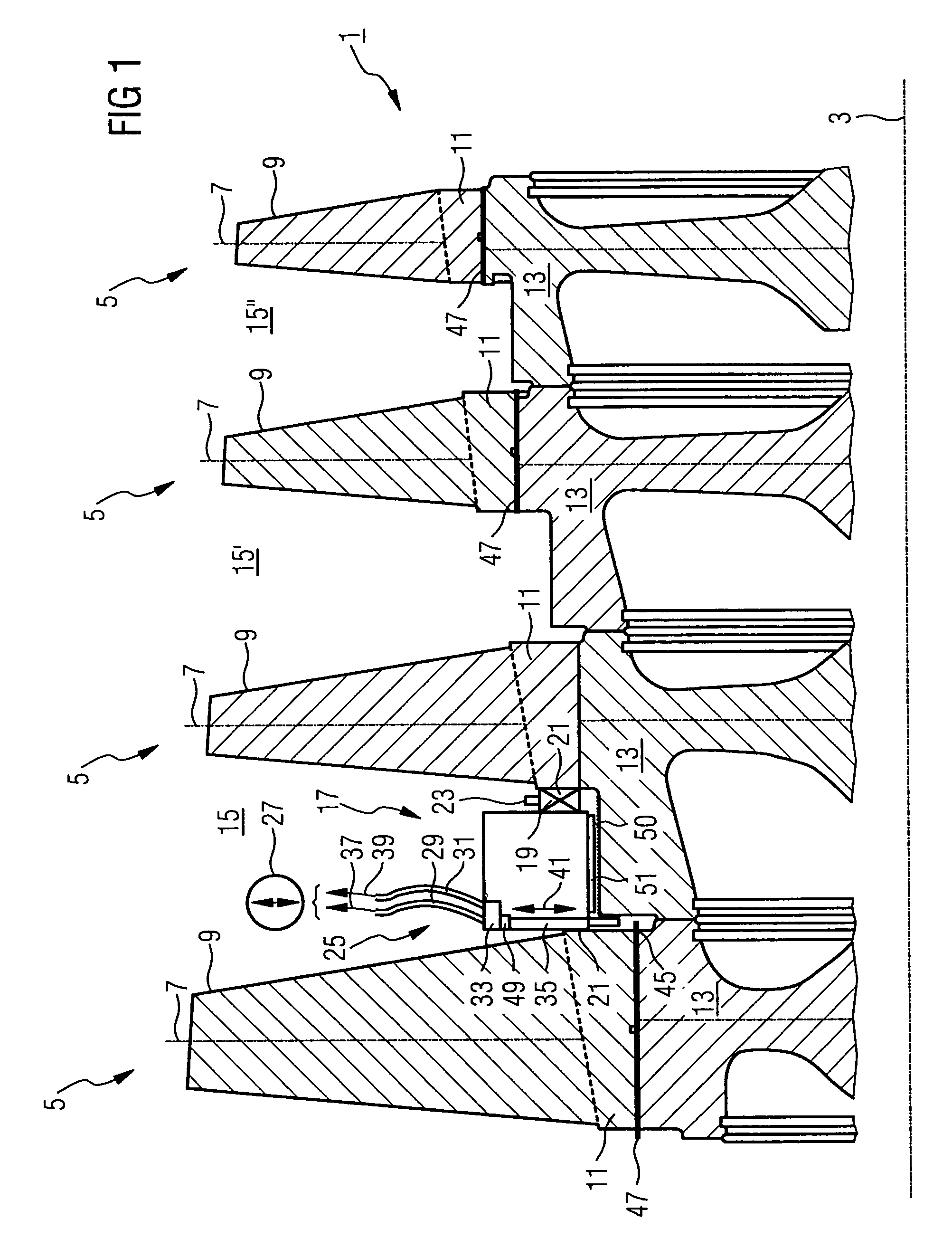

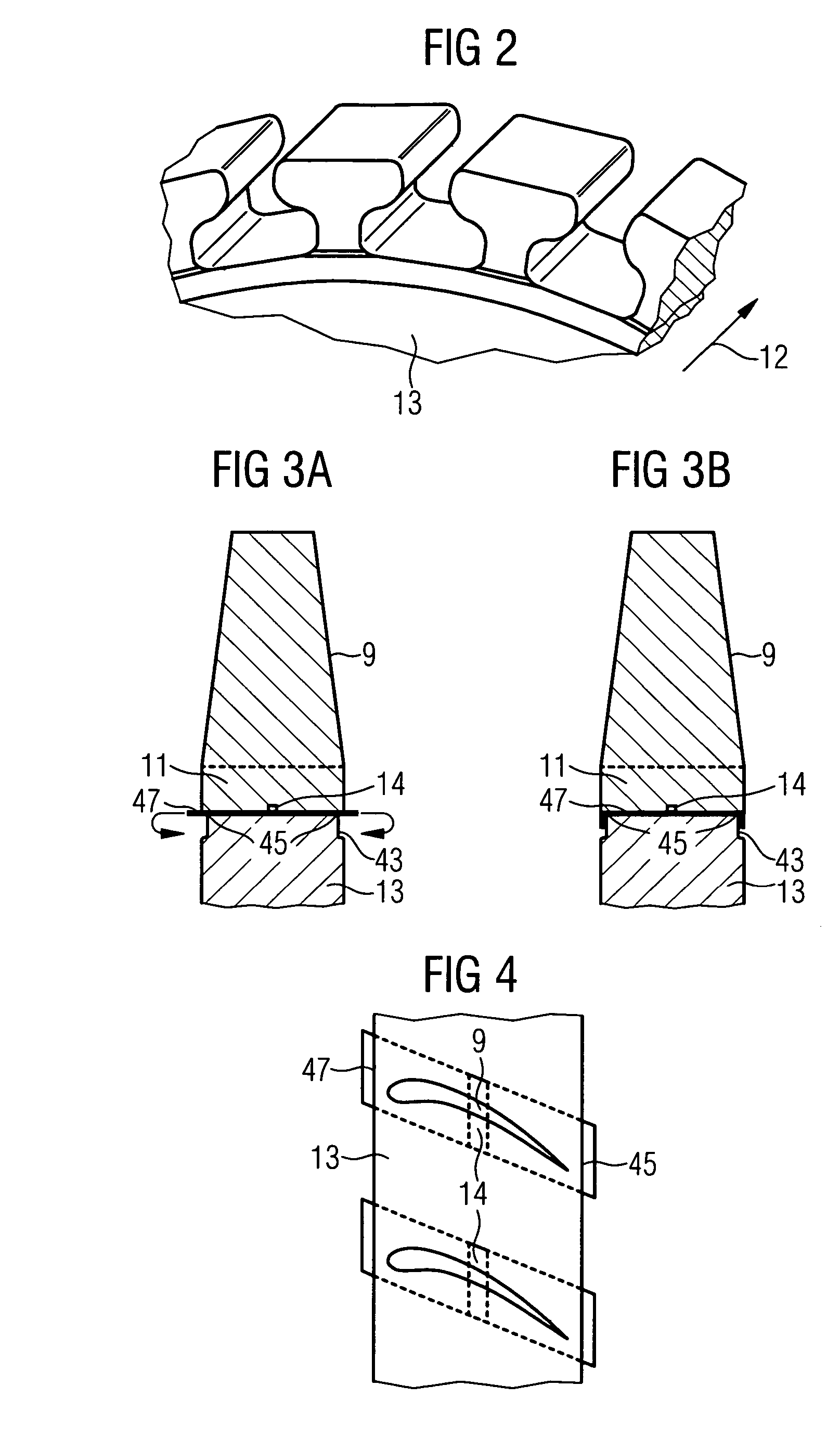

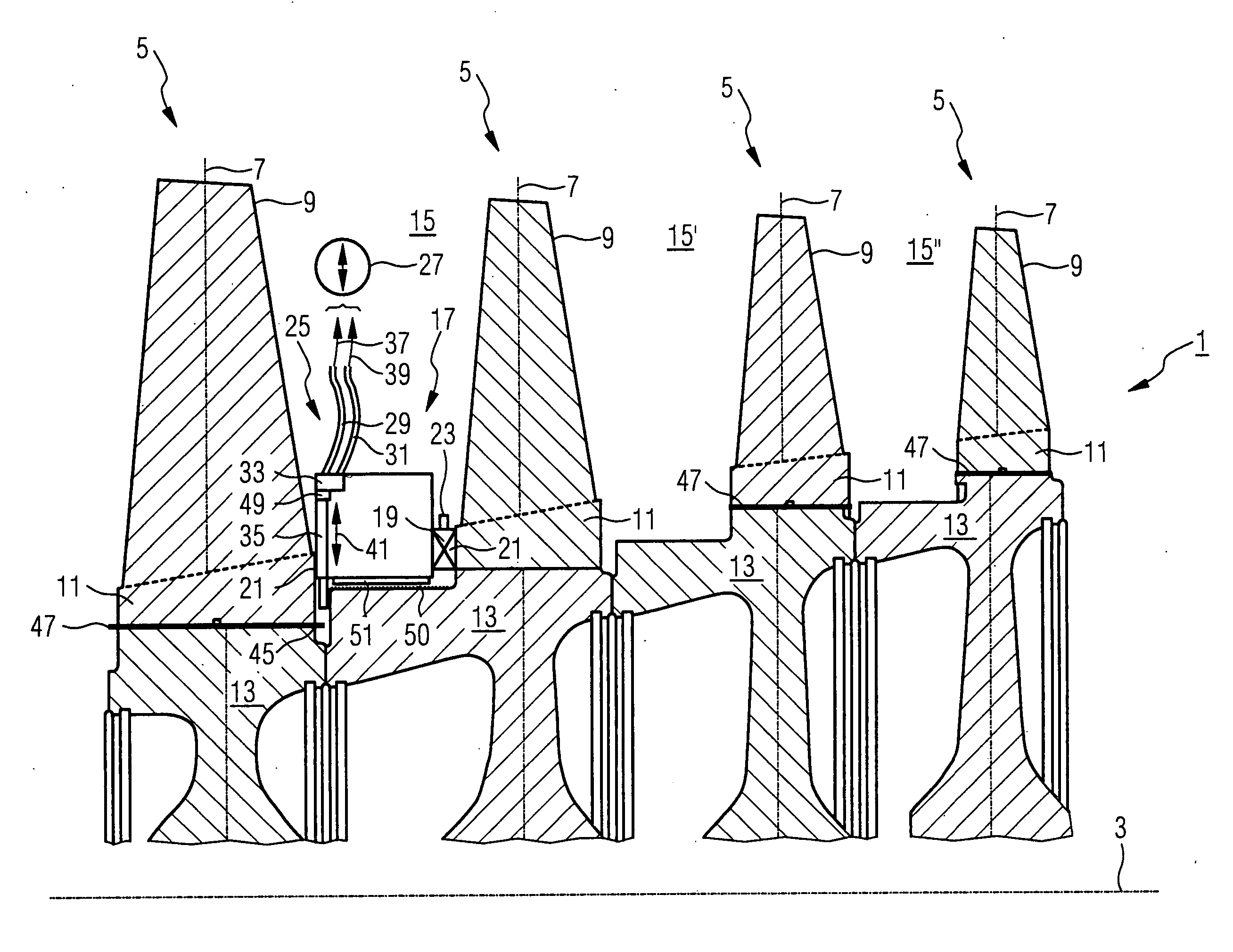

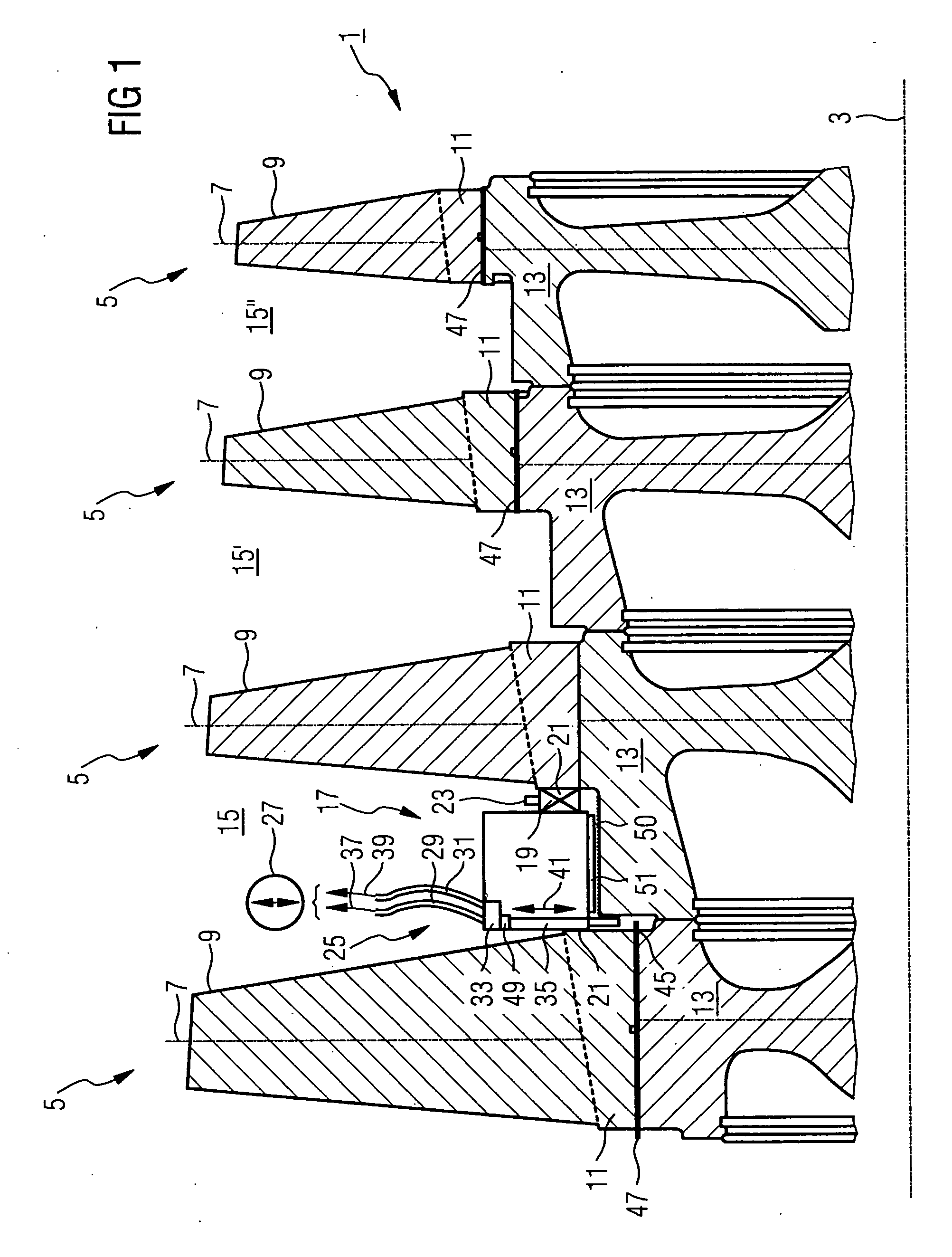

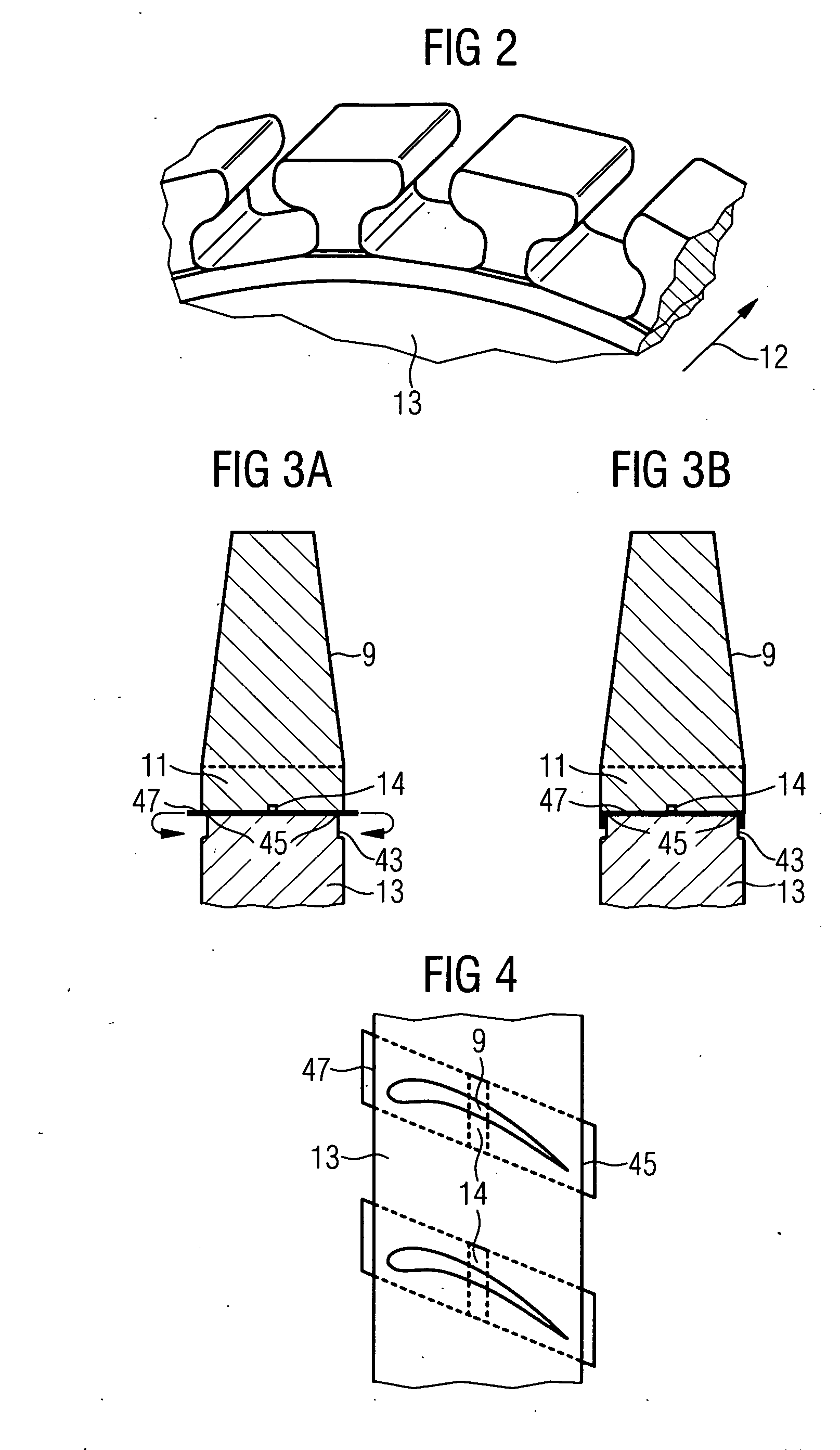

Bending device and method for bending a plate

ActiveUS20060207309A1Configure operationEngine fuctionsBlade accessoriesEngineeringMechanical engineering

In order to configure the bending of a plate in an intermediate space between two blade rings, arranged along an axis of a compressor and having blades extending along a radius in a simpler and more effective manner, the novel concept provides a bending device which can be positioned in the intermediate space and has, according to the invention, a fixing element for the bending device, a hydraulic system and a punch which can be actuated by the hydraulic system. Accordingly, a method for bending a plate in the intermediate space provides for a bending device to be positioned in the intermediate space, for the bending device to be fixed in the intermediate space, and for a punch of the bending device to be hydraulically actuated for bending the plate, the punch being moved toward the plate to be bent, and the plate being bent under the effect of the punch.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com