Sample making method used for ageing and breakdown test

A technology for breakdown test and sample preparation, which is applied in the field of material processing and can solve the problems of small breakdown results and air corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

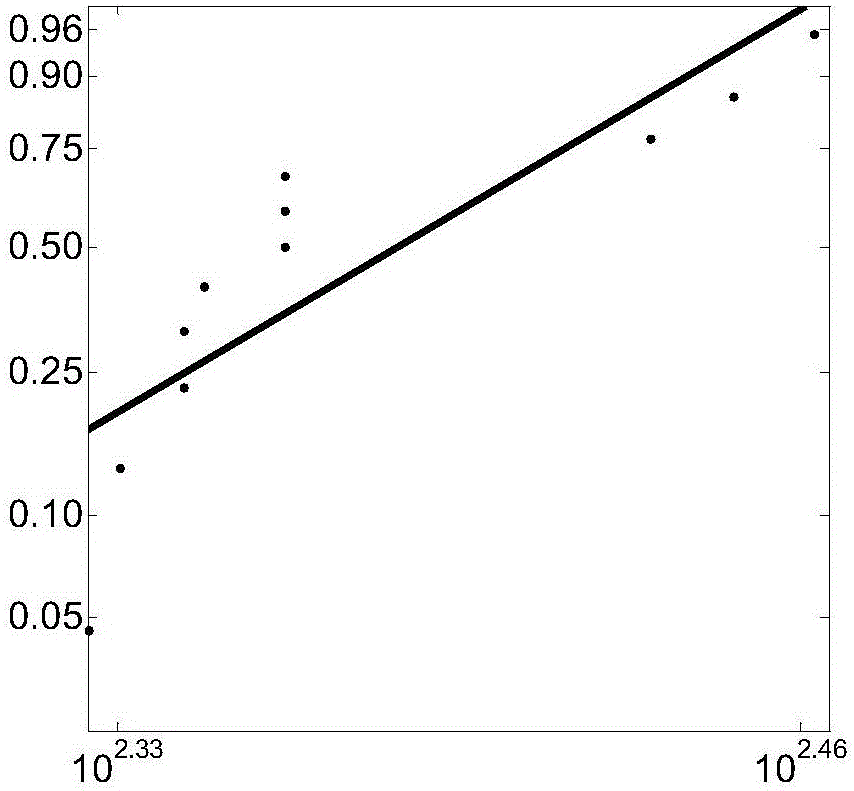

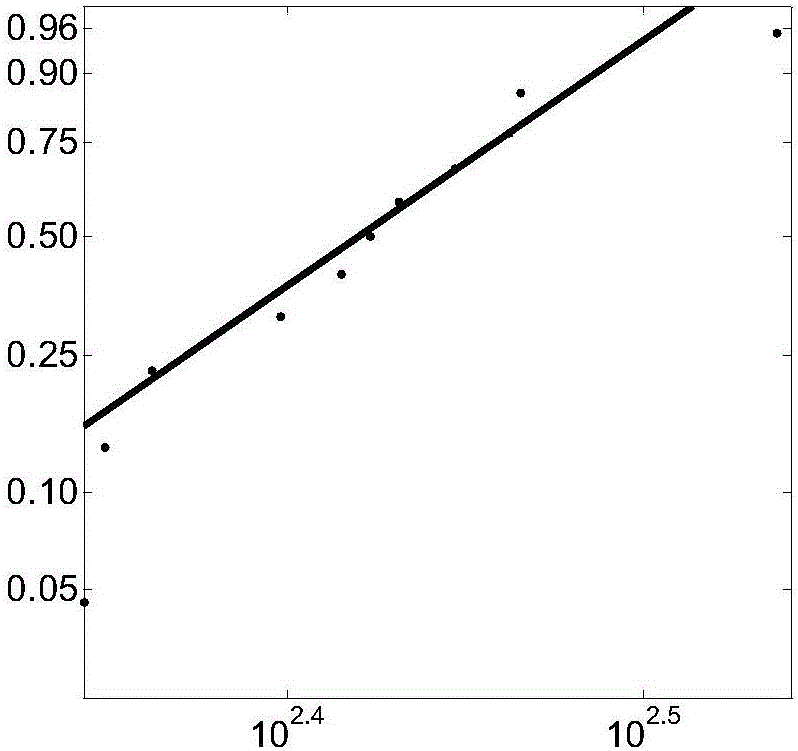

Image

Examples

Embodiment Construction

[0023] The equipment is a flat vulcanizing machine. In this case, the maximum hydraulic pressure of the flat vulcanizing machine is 15mpa. Other supporting tools include: 2 pieces of pressure-sampling steel plates of the same size (dimensions: length = 20 cm, width = 15 cm, height = 0.5 cm, one side of which is polished to a smooth mirror surface), mold 1 (dimensions: length = 20 cm, width = 15 centimeters, height = 3 centimeters, 6 diameters are evenly distributed to be the through hole of 6.6 centimeters), mold 2 (size: length = 7.8 centimeters, width = 7.8 centimeters, height = 1.5 centimeters, with a height of 2.8 millimeters, diameter 1.5cm convex cap), and alcohol, cotton, mylar.

[0024] Cut the polyester film to the size of the sample steel plate, wipe the 2 steel plates and the 2 cut polyester films with cotton smear alcohol, after the alcohol dries, attach the polyester film to the smooth mirror surface of the steel plate to protect The shape of the intermediate sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com