Preparing method of metal material surface nitriding deposition composite antifriction wear-resisting modification layer

A technology of metal materials and modified layers, applied in the direction of metal material coating process, coating, solid diffusion coating, etc. problems, to achieve uniform hardness, improved friction and wear resistance, and avoid edge effect problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] AISI304 austenitic stainless steel, its composition is (wt.%): 0.05C; 0.80Si; 1.50Mn; 17.5Cr; 9.50Ni; 0.013Mo; The surface of the sample was smoothed from coarse to fine with SiC sandpaper, and then polished. After cleaning with alcohol, place it on the anode potential platform in the nitriding furnace.

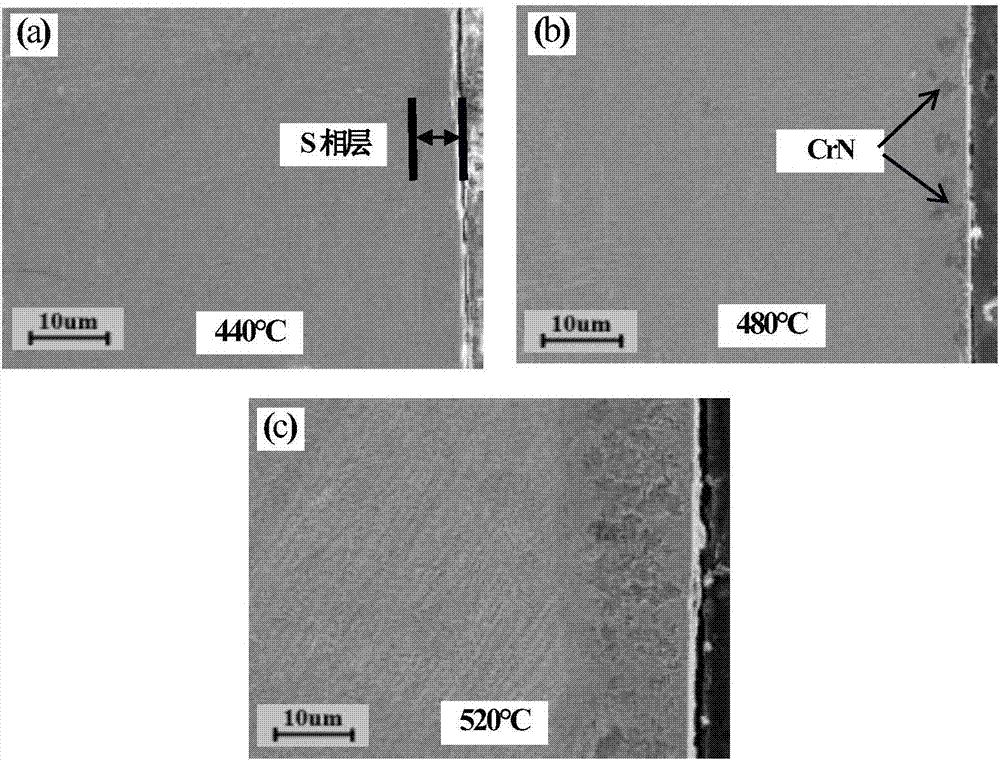

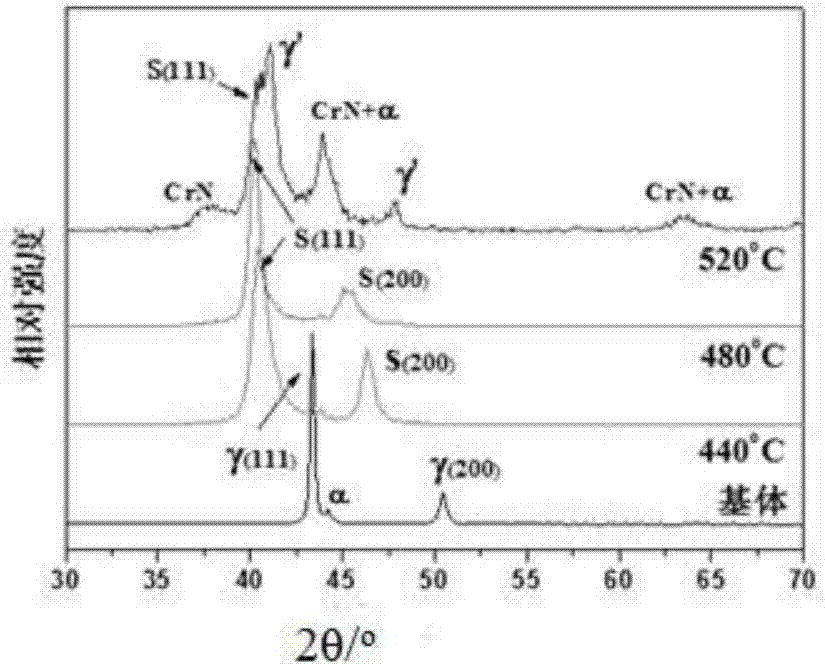

[0026] The furnace is evacuated to 15Pa, filled with ammonia gas and maintained at a working pressure of about 500Pa, the nitriding temperature is 440°C, the heat preservation nitriding treatment is carried out for 8 hours, and the furnace is cooled to below 200°C in an ammonia atmosphere to obtain a composite reduced nitriding deposition. wear-resistant modified layer, the cross-sectional morphology was observed by scanning electron microscope as figure 1 As shown in (a), a nitride layer with uniform thickness (about 6 μm) was prepared on the surface of AISI304 austenitic stainless steel, which has good corrosion resistance.

Embodiment 2

[0028] AISI304 austenitic stainless steel, its composition is (wt.%): 0.05C; 0.80Si; 1.50Mn; 17.5Cr; 9.50Ni; 0.013Mo; The surface of the sample was smoothed from coarse to fine with SiC sandpaper, and then polished. After cleaning with alcohol, place it on the anode potential platform in the nitriding furnace.

[0029] The furnace is evacuated to 15Pa, filled with ammonia gas and maintained at a working pressure of about 500Pa, the nitriding temperature is 480°C, the heat preservation nitriding treatment is carried out for 8 hours, and the furnace is cooled to below 200°C in an ammonia atmosphere to obtain a composite reduced nitriding deposition. wear-resistant modified layer, the cross-sectional morphology was observed by scanning electron microscope as figure 1 As shown in (b), the nitride layer on the surface of AISI304 austenitic stainless steel is thickened but accompanied by the precipitation of black phase.

Embodiment 3

[0031] AISI304 austenitic stainless steel, its composition is (wt.%): 0.05C; 0.80Si; 1.50Mn; 17.5Cr; 9.50Ni; 0.013Mo; The surface of the sample was smoothed from coarse to fine with SiC sandpaper, and then polished. After cleaning with alcohol, place it on the anode potential platform in the nitriding furnace.

[0032] The furnace is evacuated to 15Pa, filled with ammonia gas and maintained at a working pressure of about 500Pa, the nitriding temperature is 520°C, the heat preservation nitriding treatment is carried out for 8 hours, and the furnace is cooled to below 200°C in an ammonia atmosphere to obtain the nitriding deposition composite reduction. wear-resistant modified layer, the cross-sectional morphology was observed by scanning electron microscope as figure 1 As shown in (c), the thickness of the nitride layer on the surface of AISI304 austenitic stainless steel reaches 16 μm, and at the same time, the proportion of black dot phase precipitation continues to expand. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com