FeCrAl alloy material for preparing Nuclear reactor fuel cladding material

A technology for nuclear reactor fuel and alloy materials, which is applied to the assembly of reactor fuel elements, reactors, and fuel elements, can solve problems such as poor resistance to water vapor oxidation, meet the requirements of accident fault tolerance, prolong emergency response time, and improve resistance to water vapor. Effect of Water Vapor Oxidation Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below through specific examples.

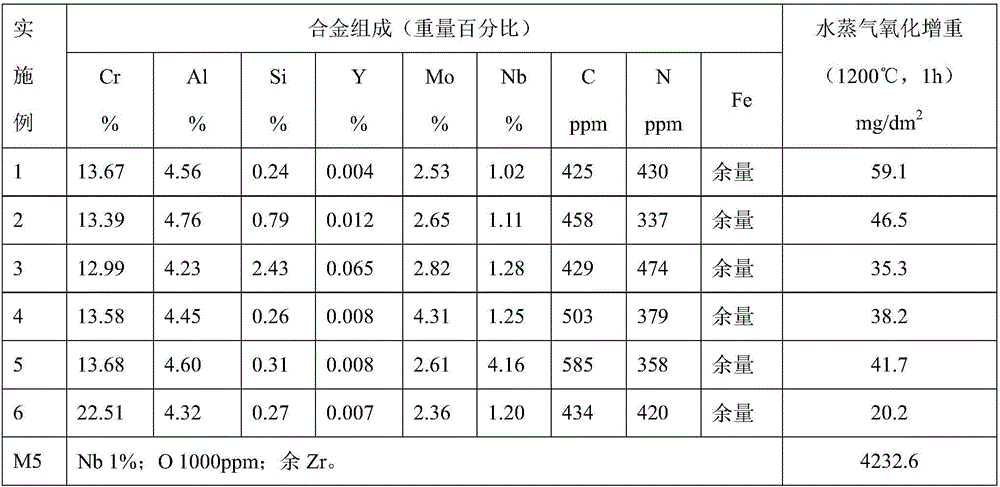

[0015] Fe, Cr, Al, Si, Y, Mo, Nb, C, N (wherein, N is Cr 2 The elements added in the form of N) were mixed by weight percentage and prepared into 6 alloy ingots by vacuum induction melting method. The chemical composition analysis of the 6 ingots was sampled. The composition is shown in Table 1. Samples were cut from 6 ingots for high temperature water vapor oxidation test.

[0016] For the six samples of the present invention, that is, Examples 1-6 and the commercial zirconium alloy M5 for nuclear power plants, a high-temperature steam oxidation test was carried out in a high-temperature steam oxidation equipment. Table 1 shows the distribution ratio of FeCrAl-based components of Examples 1-6 according to the present invention and their oxidation weight gain under the respective above-mentioned water vapor oxidation conditions. The water vapor oxidation weight gain data of commercial z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com