Method for processing thin-walled tube of zirconium alloy specially used by nuclear reactor

A zirconium alloy tube and a technology for nuclear reactors, which are applied in the field of special zirconium alloy thin-walled tubes for making lattice ring tubes in nuclear reactor fuel assemblies, can solve the problem of dependence on imports, low technical precision, and difficulty in meeting the processing accuracy requirements of zirconium alloy thin-walled tubes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific implementation of the manufacturing process of the special-purpose zirconium alloy thin-walled tube for nuclear reactors will be further described in detail below in conjunction with the accompanying drawings. The specific manufacturing steps of the manufacturing method for the special-purpose zirconium alloy thin-walled tube for nuclear reactors are:

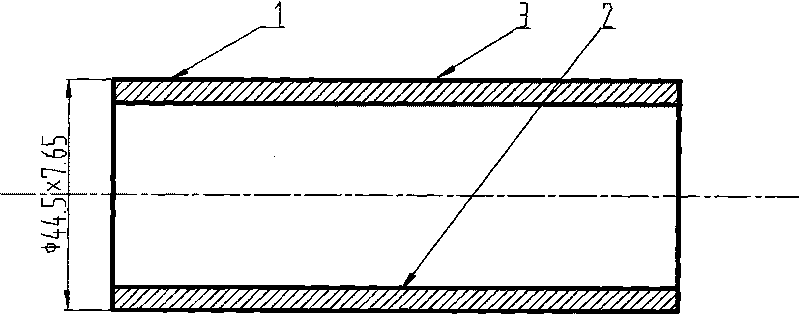

[0057] a) Blank preparation, such as figure 1 As shown, a zirconium alloy tube (1) with a certain length of Φ44.5×7.65mm is selected as the blank;

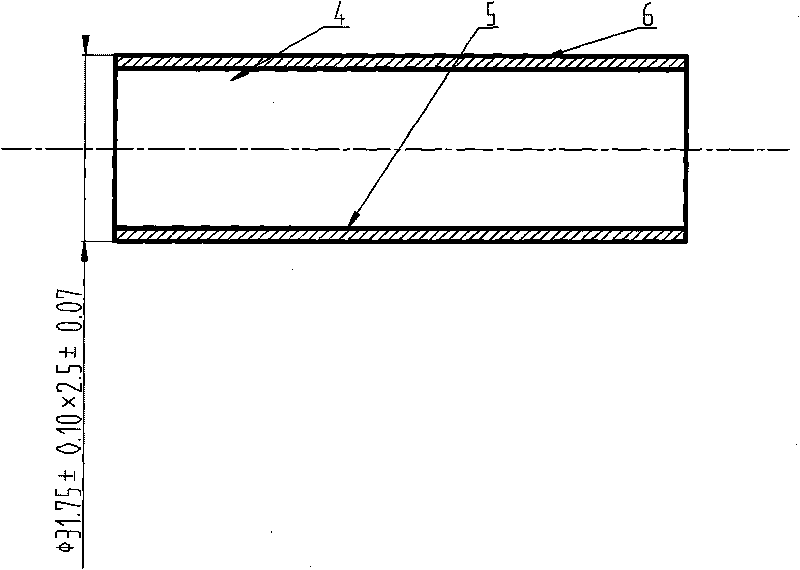

[0058] b) The first pass of cold rolling, such as figure 2 As shown, the zirconium alloy tube (1) is cold-rolled by KPW75 rolling mill and then cut into a certain length of zirconium alloy tube (4), wherein the rolling mill speed is 80-120 times / min, and the feed rate is 2.0-3.5mm / time. Adjust the rolling mill so that the rolled zirconium alloy tube (4) meets the process parameters of the zirconium alloy tube, strictly control the wall thickness deviation of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com