Corrosion product film wear property and corrosion electro-chemistry test device

A technology of corrosion products and wear performance, applied in measuring devices, testing wear resistance, weather resistance/light resistance/corrosion resistance, etc., can solve the limitation of the electrochemical reaction process of wear resistance performance, lack of corrosion product film wear performance and electrochemical behavior of the test device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

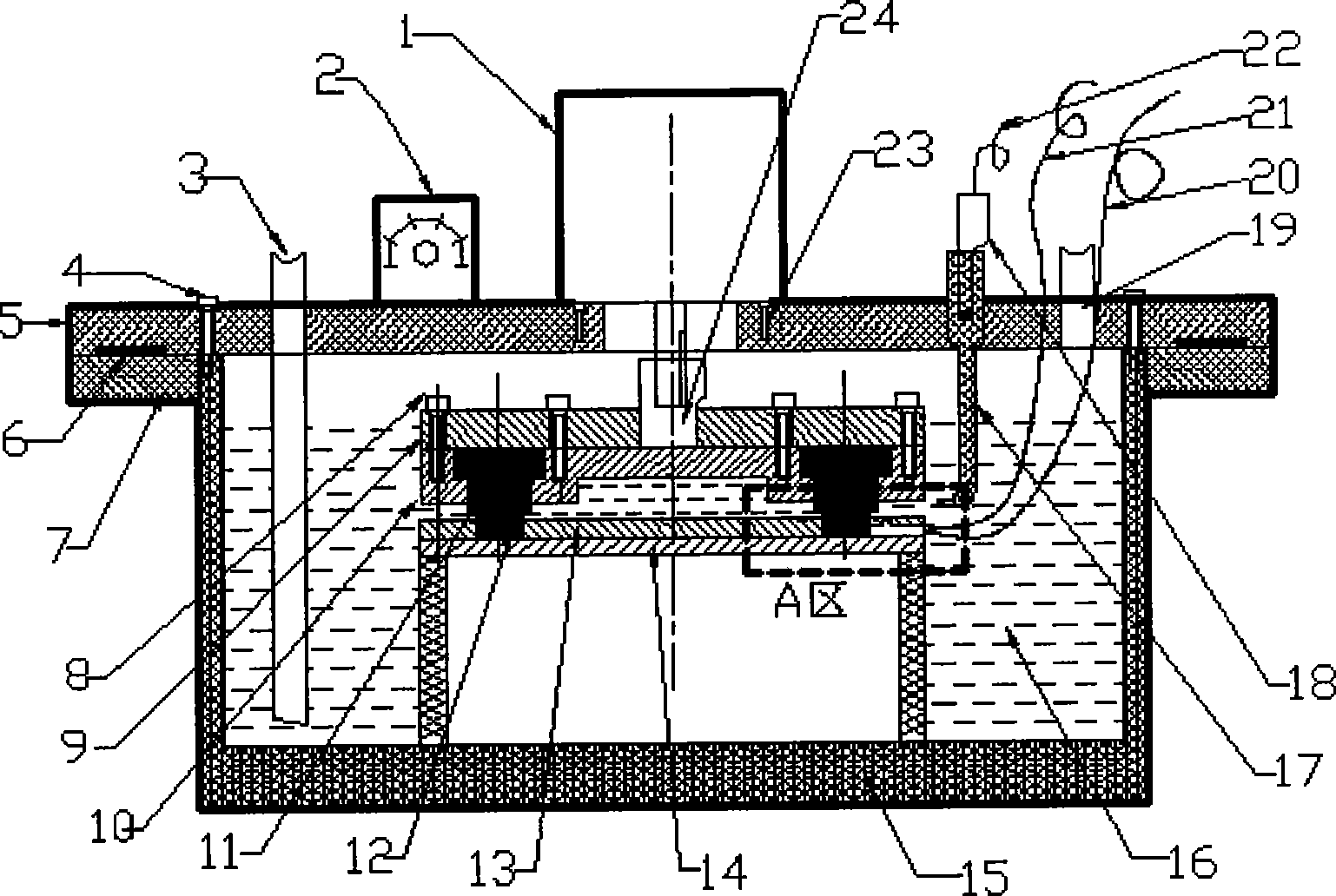

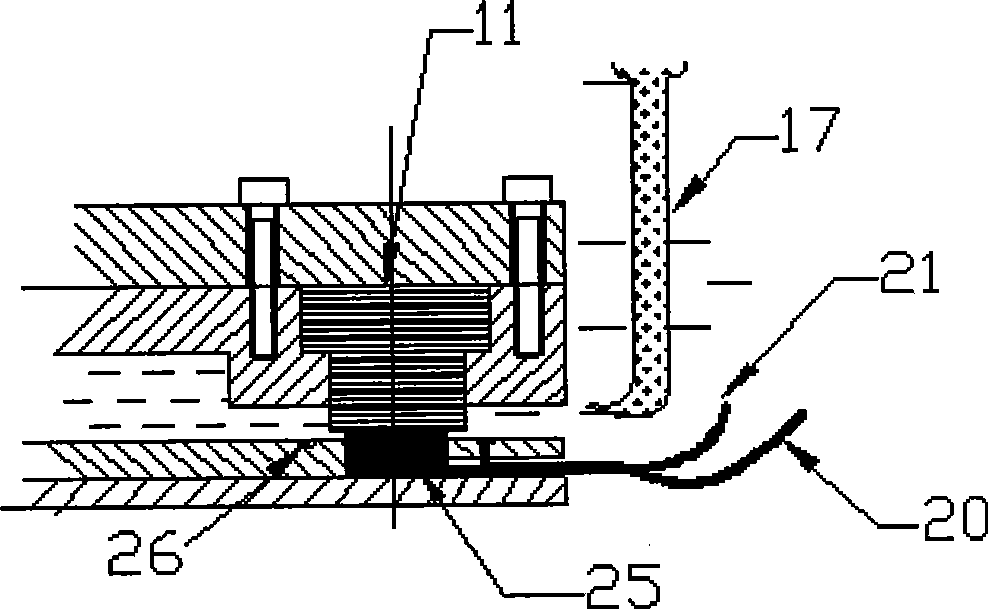

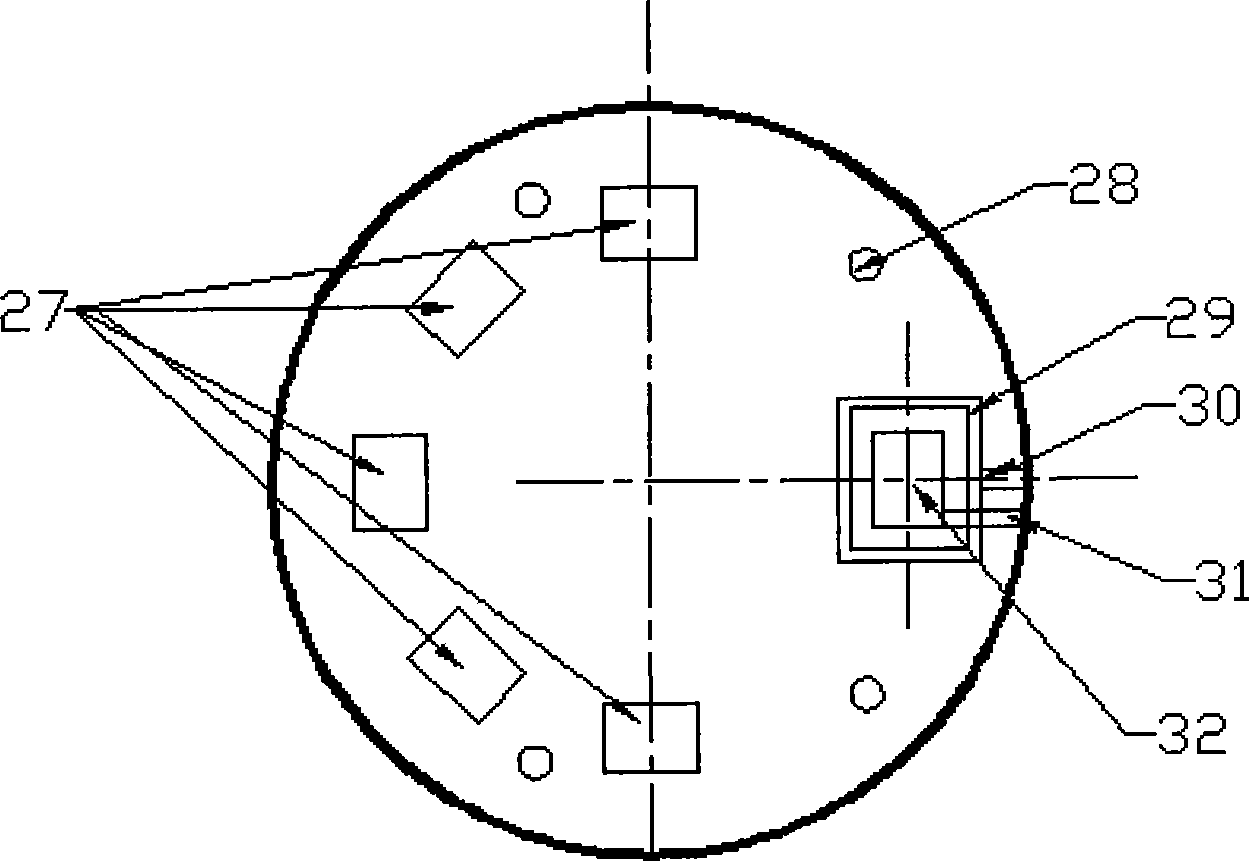

[0013] A sample 12 with a corrosion product film was prepared, and the sample 12 with a corrosion product film was weighed with an electronic analytical balance with an accuracy of 0.1 mg. figure 1 and image 3 As shown, the prepared sample 12 with a corrosion product film and the electrochemical sample 25 with a corrosion product film are respectively fixed in the wear sample groove 27 and the electrochemical sample groove 32 on the sample holder 13 . figure 2 As shown, the electrochemical sample 25 is drawn out through the electrochemical sample wire 21, and the platinum wire 26 is put into the platinum wire guide groove 30 outside the electrochemical sample 25, and is drawn out by the platinum wire wire 20 as the saturated sweetener of the reference electrode. The mercury electrode 18 is placed in the salt bridge 17, and the electrochemical sample 25, the platinum wire 26, and the calomel electrode 18 form a three-electrode system. figure 1 As shown, the sample holder 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com