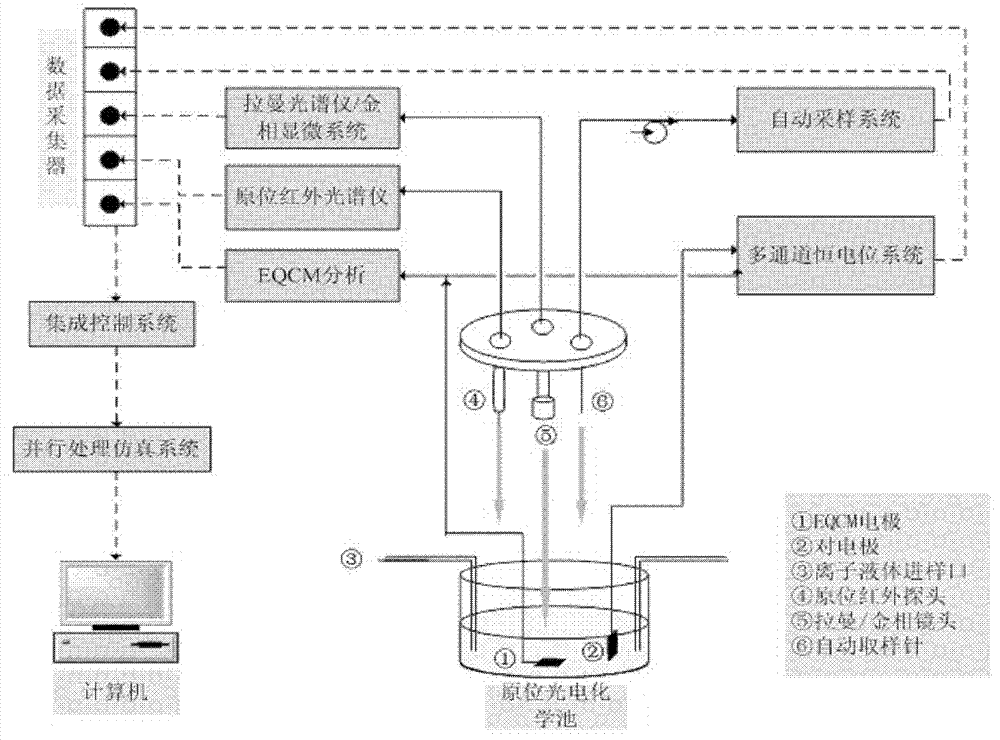

Ionic liquid system electrochemical process in-situ research device

An ionic liquid and electrochemical technology, applied in the field of electrochemical analysis, can solve the problems of insufficient understanding of physical and chemical microscopic changes, and achieve the effect of compact structure, high degree of operation automation and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Using the device of the present invention to detect the morphology of electrodeposited aluminum in ionic liquid and the change of electrolyte

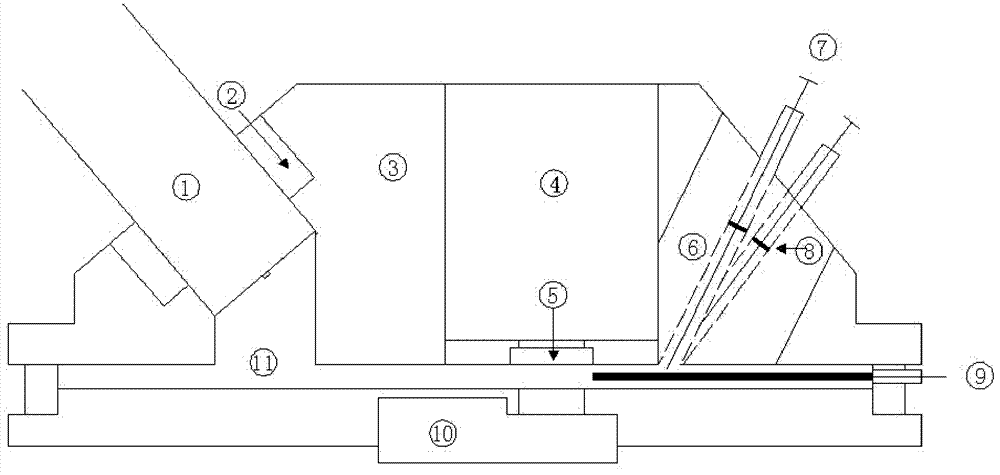

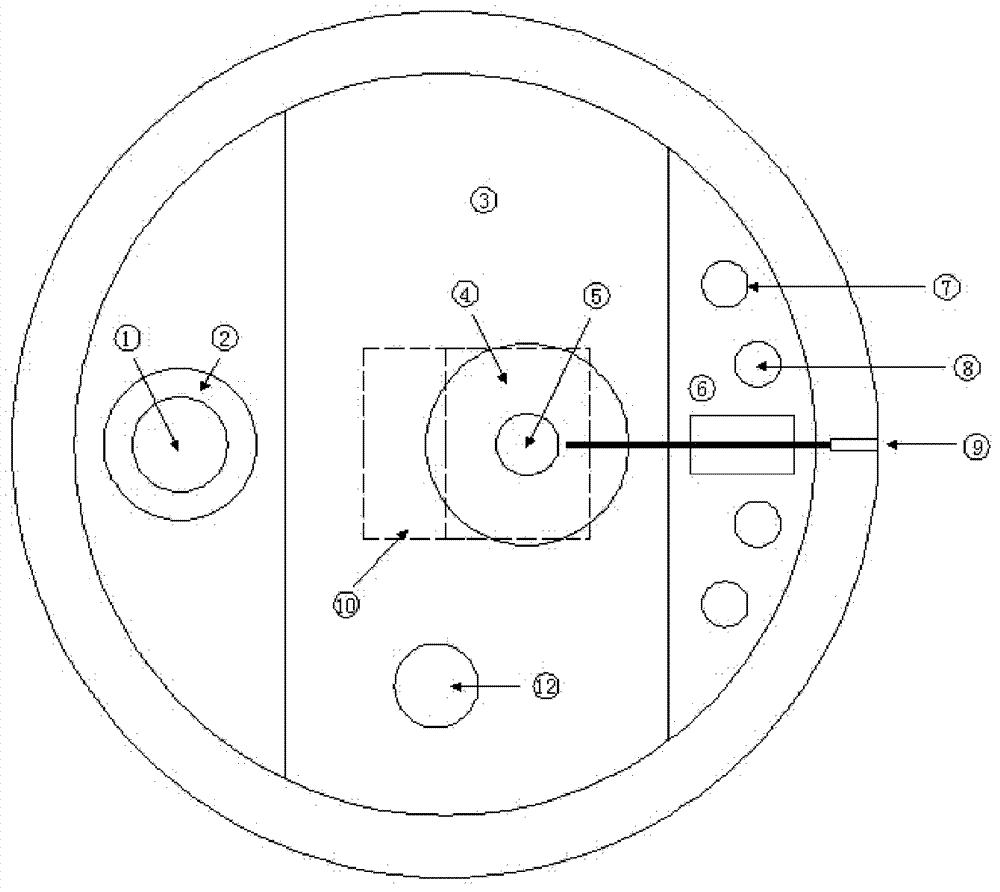

[0032] The ionic liquid adopts [BmimCl] / AlCl 3 In the system, an aluminum wire with an outer diameter of 1 mm is installed on the counter electrode, and the quartz crystal oscillator of the working electrode is made of quartz crystal sputtered platinum. First, install the counter electrode aluminum wire on the right side of the in-situ photoelectrochemical cell, fix the platinum quartz crystal oscillator in the quartz crystal microbalance reactor, install the quartz crystal microbalance reactor under the in-situ photoelectrochemical cell, and fix it. . Insert the poly in situ infrared probe into the reactor socket 1, fix and seal it with a sealing gasket to ensure that the reactor does not leak, and use a multifunctional automatic adjustment bracket to fix the extended part of the infrared probe. After the infrared ...

Embodiment 2

[0033] Embodiment 2: Using the device of the present invention to detect changes in the electrolyte during the electrolysis of metals in ionic liquids

[0034] The ionic liquid uses [EmimCl] / AlCl 3 system, the counter electrode 9 is equipped with cylindrical glassy carbon with an outer diameter of 1 mm, and the quartz crystal oscillator is made of quartz crystal sputtered platinum. First, install the counter electrode glassy carbon on the right side of the in-situ photoelectrochemical cell, fix the platinum quartz crystal oscillator in the quartz crystal microbalance reactor, install the quartz crystal microbalance reactor under the in-situ photoelectrochemical cell, and fix it. . Insert the poly in situ infrared probe into the reactor socket 1, fix and seal it with a sealing gasket to ensure that the reactor does not leak, and use a multifunctional automatic adjustment bracket to fix the extended part of the infrared probe. After the infrared probe is fixed, use the three-d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com