Chemical test tube cleaning device

A test tube and chemical technology, applied in the field of test tube mechanical automatic cleaning device, can solve the problems of waste of manpower, waste of financial resources, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

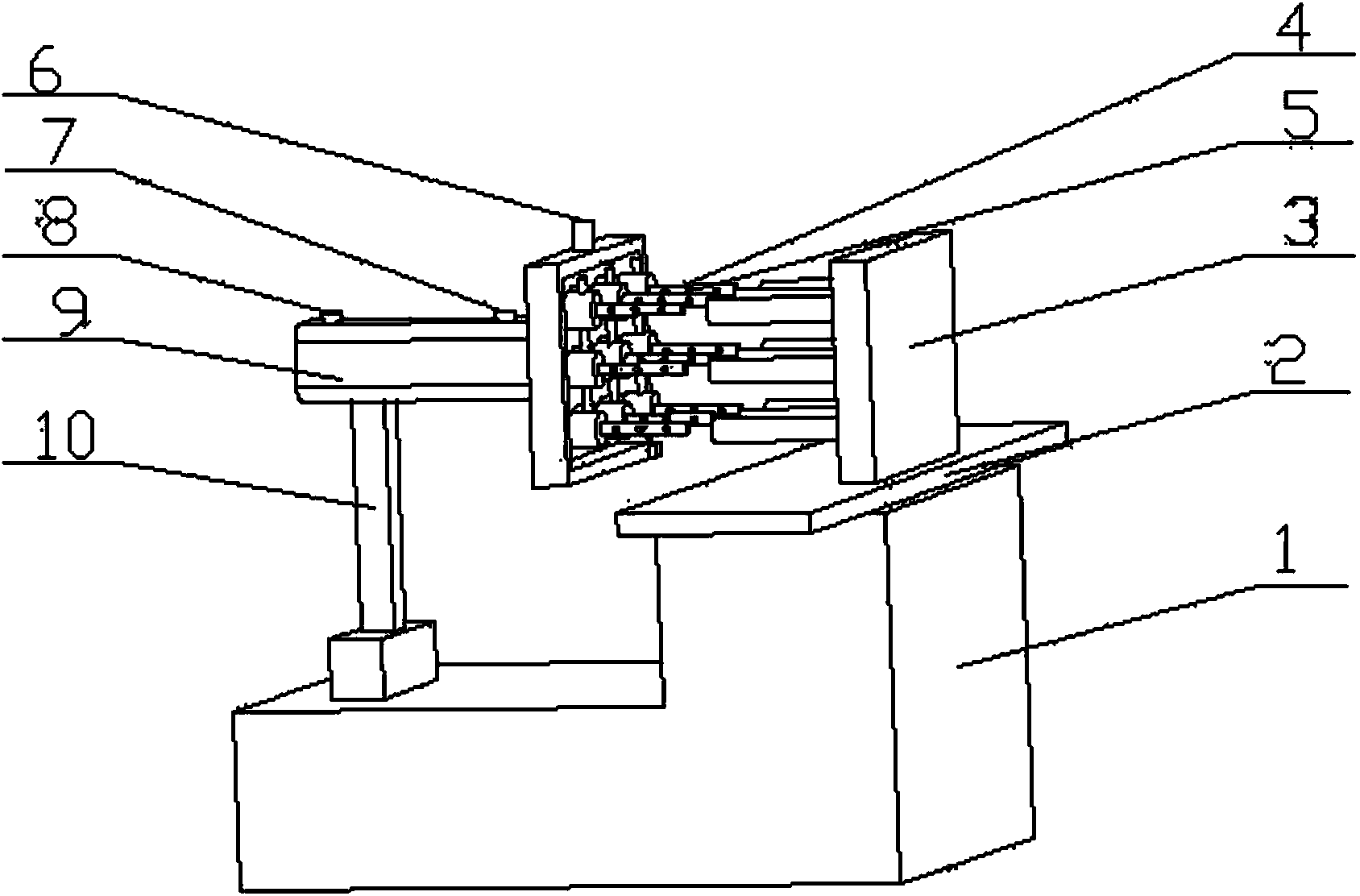

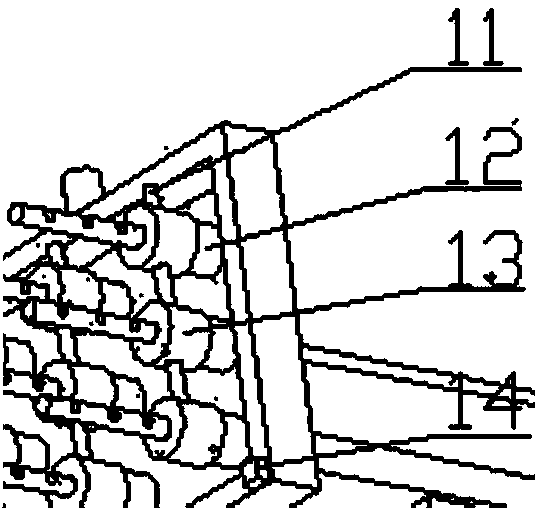

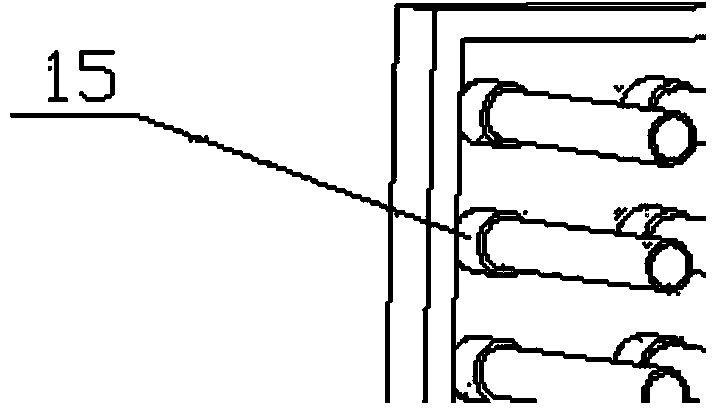

[0010] As shown in the figure, a chemical test tube mechanical cleaning device is composed of an operation table 1, a conveyor belt 2, a test tube holding box 3, a test tube brush 4, a test tube water spray hole 5, an external water inlet pipe 6, air holes 7, air holes 8, and a cylinder 9. Column 10, cylindrical water inlet pipe 11, motor 12, small cylindrical water tank 13, micro sensor 14, clamping test tube rubber sleeve 15, the conveyor belt 2 transmits the clamping test tube box 3 to the position of the console 1 through the motor. When the sensor 13 on the test tube brush box detects that it is in front of it, the signal will be sent to the PLC control device immediately to stop the conveyor belt 2, and the external water supply motor and the motor 12 connected to the test tube brush 4 will start, and the cylinder 9 and air hole 6 will start simultaneously. action, put the test tube brush 4 into the test tube accurately for rotary water spray cleaning, the external water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com