Working electrode for implementing electro-chemical test of high-temperature high-pressure water solution system

A working electrode, high temperature and high pressure technology, applied in the direction of material electrochemical variables, measuring devices, scientific instruments, etc., can solve the problems of difficult realization, high requirements for experimental equipment and working electrode preparation process, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

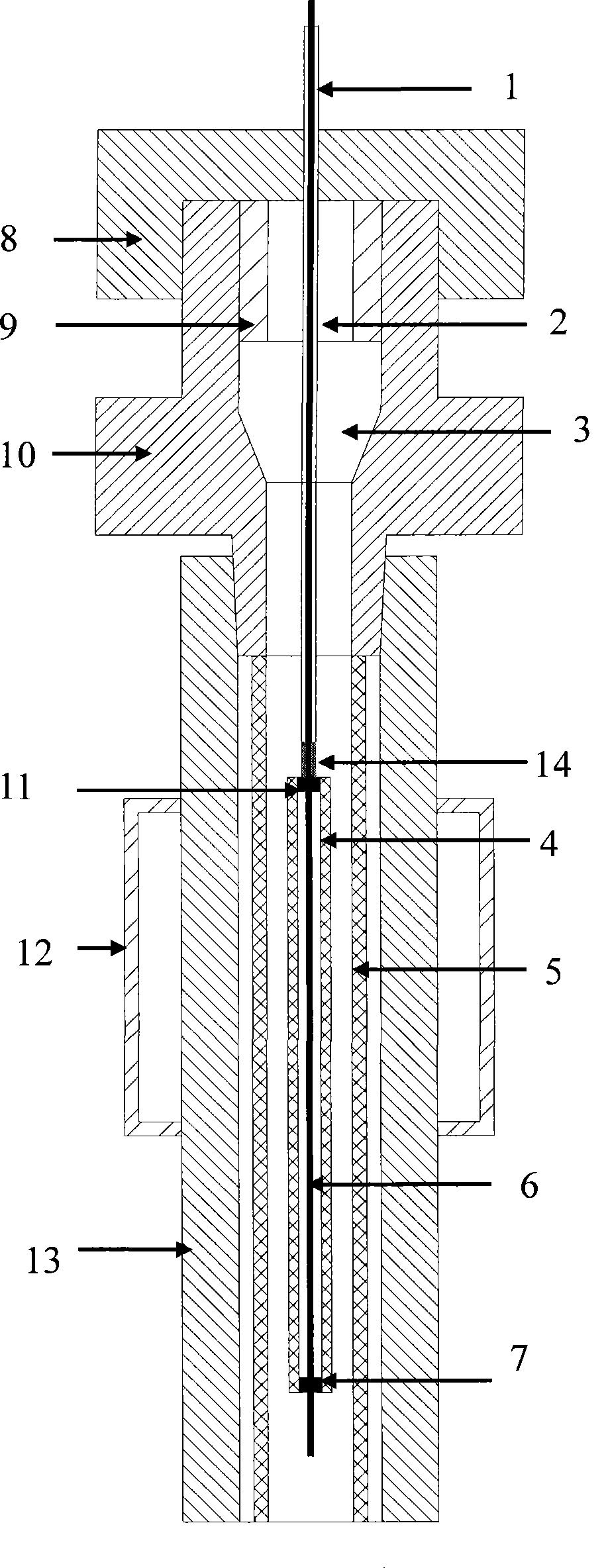

[0039] The preparation technology of working electrode is characterized in that as follows:

[0040] 1. Select a suitable length of working electrode wire 6 according to the test needs, and the diameter of the electrode wire is 0.5 ~ 3mm;

[0041] 2. Select a corundum tube with an inner diameter similar to that of the working electrode wire 6 (the inner diameter of the corundum tube is approximately 0.6-4mm) as the electrode high-temperature insulating tube 4;

[0042] 3. Insert the working electrode wire 6 into the electrode high-temperature insulating tube 4, and the distance between the two ends of the working electrode wire 6 exposed to the electrode high-temperature insulating tube 4 depends on the test requirements;

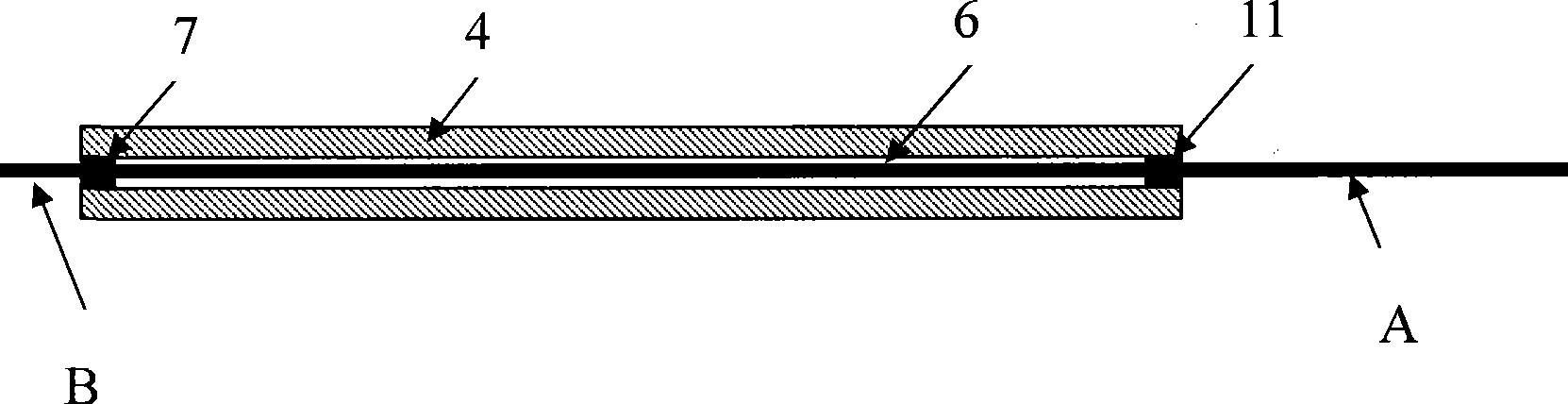

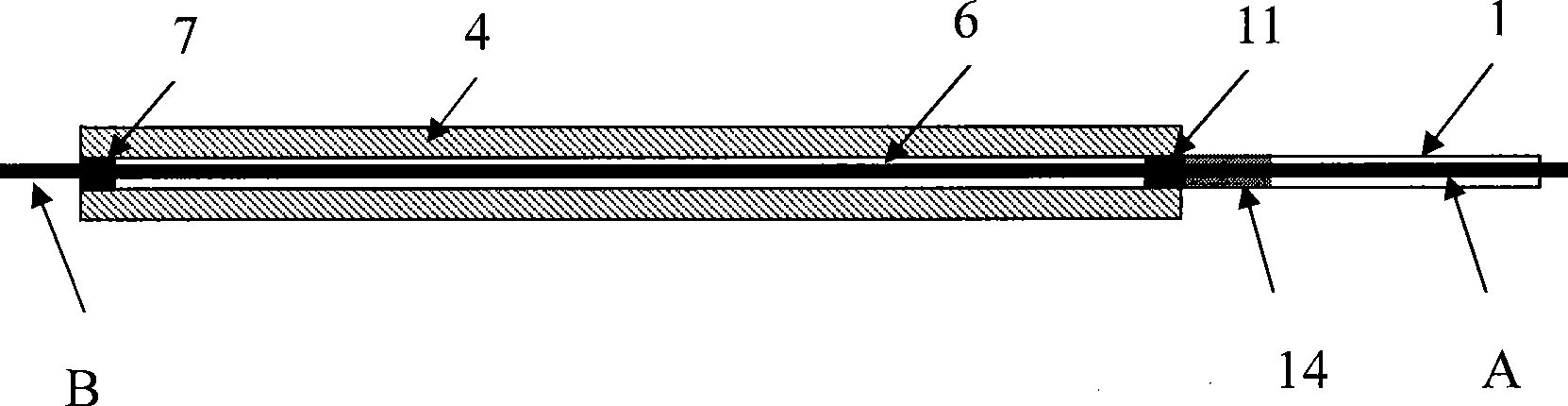

[0043] 4. The two ports of the electrode high-temperature insulating tube 4 (namely: the lower seal 7 and the middle seal 11) and the working electrode wire 6 are sealed with a high-temperature resistant glue of 400°C to 450°C (such as figure 2 shown);

[...

Embodiment 1

[0053] Example 1 High temperature working electrode with austenitic 304 stainless steel as electrode material

[0054] 1. Put a corundum tube with a length of 20cm and an inner diameter of 0.6mm on the front end of a 304 stainless steel wire with a length of 45cm and an outer diameter of 0.5mm for insulation, and seal the two with a high temperature resistant glue of 400°C to 450°C.

[0055] 2. The other end is insulated with a polytetrafluoroethylene (PTFE) tube with a length of 20cm and an inner diameter of 0.6mm, and the PTFE tube and the 304 stainless steel wire are sealed with a high temperature resistant epoxy resin of 180°C to 200°C.

[0056] 3. Leave 2cm at the front end as the working surface, grind it step by step with 240#, 400#, 600# and 1000# metallographic sandpaper, degrease with acetone, and finally clean it with deionized water.

[0057] 4. The lead end is connected to the instrument through the sealing assembly, and the working electrode is prepared ( Figur...

Embodiment 2

[0062] Example 2 High-temperature working electrode with metal Cu as electrode material

[0063] 1. Put a corundum tube with a length of 20cm and an inner diameter of 0.6mm on the front end of a Cu wire with a length of 45cm and an outer diameter of 0.5mm for insulation, and seal the two with a high temperature resistant glue of 400°C to 450°C.

[0064] 2. The other end is insulated with a polytetrafluoroethylene (PTFE) tube with a length of 20cm and an inner diameter of 0.6mm, and the PTFE tube and the Cu wire are sealed with a high-temperature resistant epoxy resin of 180°C to 200°C.

[0065] 3. Leave 2 mm at the front end for the working electrode surface, and use 240#, 400#, 600# and 1000# metallographic sandpaper to polish step by step, degrease with acetone, and finally clean with deionized water.

[0066] 4. The lead end is connected to the instrument through the sealing assembly, and the working electrode is prepared ( Figure 9 ).

[0067] 5. Using the prepared Cu e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com