Test tube cleaning and drying device for chemical tests

A technology for drying devices and chemical experiments, applied in drying, drying machines, heating devices, etc., can solve problems such as inability to store immediately and incomplete cleaning of test tubes, so as to improve cleaning efficiency and cleanliness, save electric energy, and improve The effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

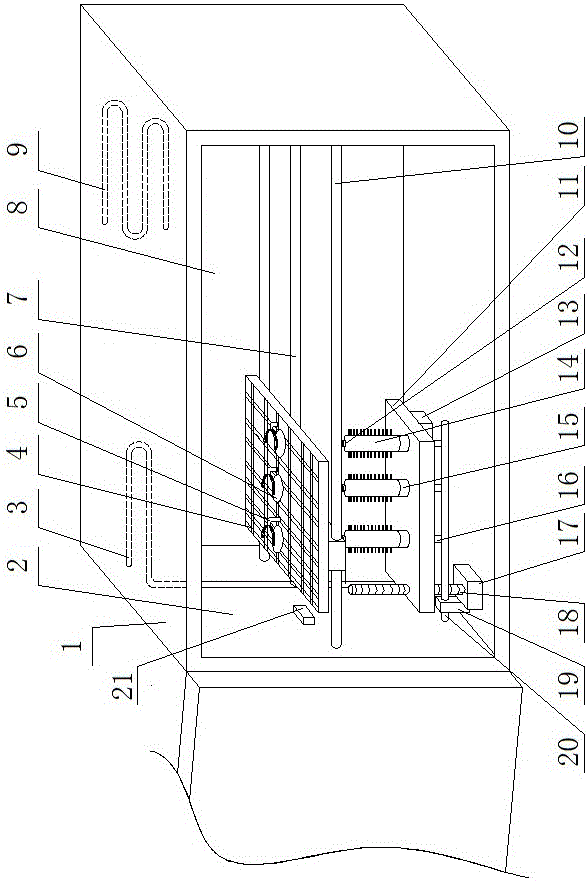

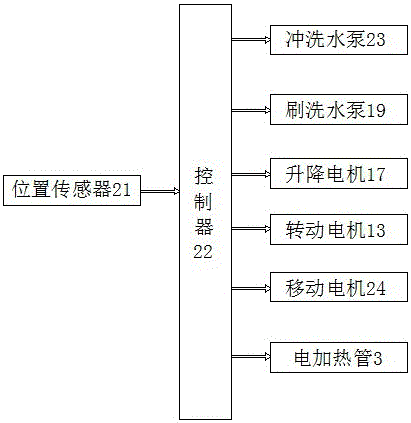

[0030] as attached figure 1 And attached figure 2 As shown, the chemical experiment test tube cleaning and drying device of the present invention includes a casing 1, and the inside of the casing 1 is divided into a cleaning chamber 2 and a drying chamber 8 connected to the left and right, and a cleaning device is fixed in the cleaning chamber 2. A drying device is fixed in the drying chamber 8, and a test tube moving device is fixed in the cabinet 1. A grid-shaped test tube fixing plate 4 is fixed on the test tube moving device, and the test tube moving device can drive the test tube fixing plate 4 in the cleaning chamber. Chamber 2 and the drying chamber 8 slide, and a plurality of scrubbing holes 6 are provided on the test tube fixing plate 4, and a test tube fixing clip 5 is fixed at each scrubbing hole 6 on the test tube fixing plate 4, and the test tube fixing clip 5 includes The column and the U-shaped clamp fixed on the top of the column, the column is vertically fix...

Embodiment 2

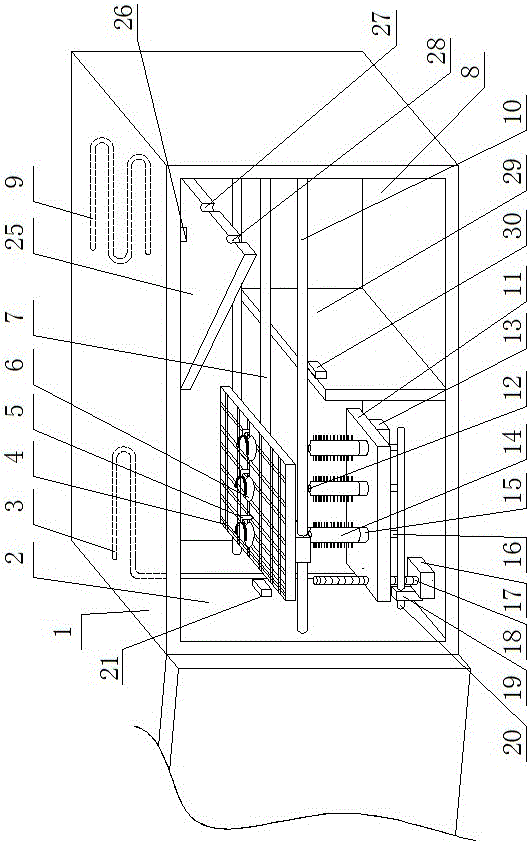

[0044] attached image 3 And attached Figure 4 As shown, this embodiment is a further improvement on the basis of Embodiment 1. The difference between this embodiment and Embodiment 1 is that a partition is provided between the cleaning chamber 2 and the drying chamber 8, and the partition includes an upper Partition 25 and lower partition 29, lower partition 29 is vertically fixed in casing 1 and is positioned at the below of test tube moving device, and the top of upper partition 25 is hinged on the top wall of casing 1 by hinge, upper A rotary drive device is connected between the partition plate 25 and the top wall of the chamber. The rotary drive device can drive the rotation of the upper partition plate 25 to realize the on-off of the cleaning chamber 2 and the drying chamber 8. The upper end of the lower partition plate 29 A lower limit sensor 30 is arranged on the top, and an upper limit sensor 26 is arranged on the top wall of the box body 1. The rotary drive device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com