Corrosion test device with in-situ electrochemical test function

An in-situ electrochemical and test function technology, which is applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, scientific instruments, etc., can solve the complex in-situ electrochemical test process, the inability to directly perform electrochemical tests, and the complex structure of the device and other issues, to achieve the effect of improving test ability and scientific research level, significant economic and social benefits, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

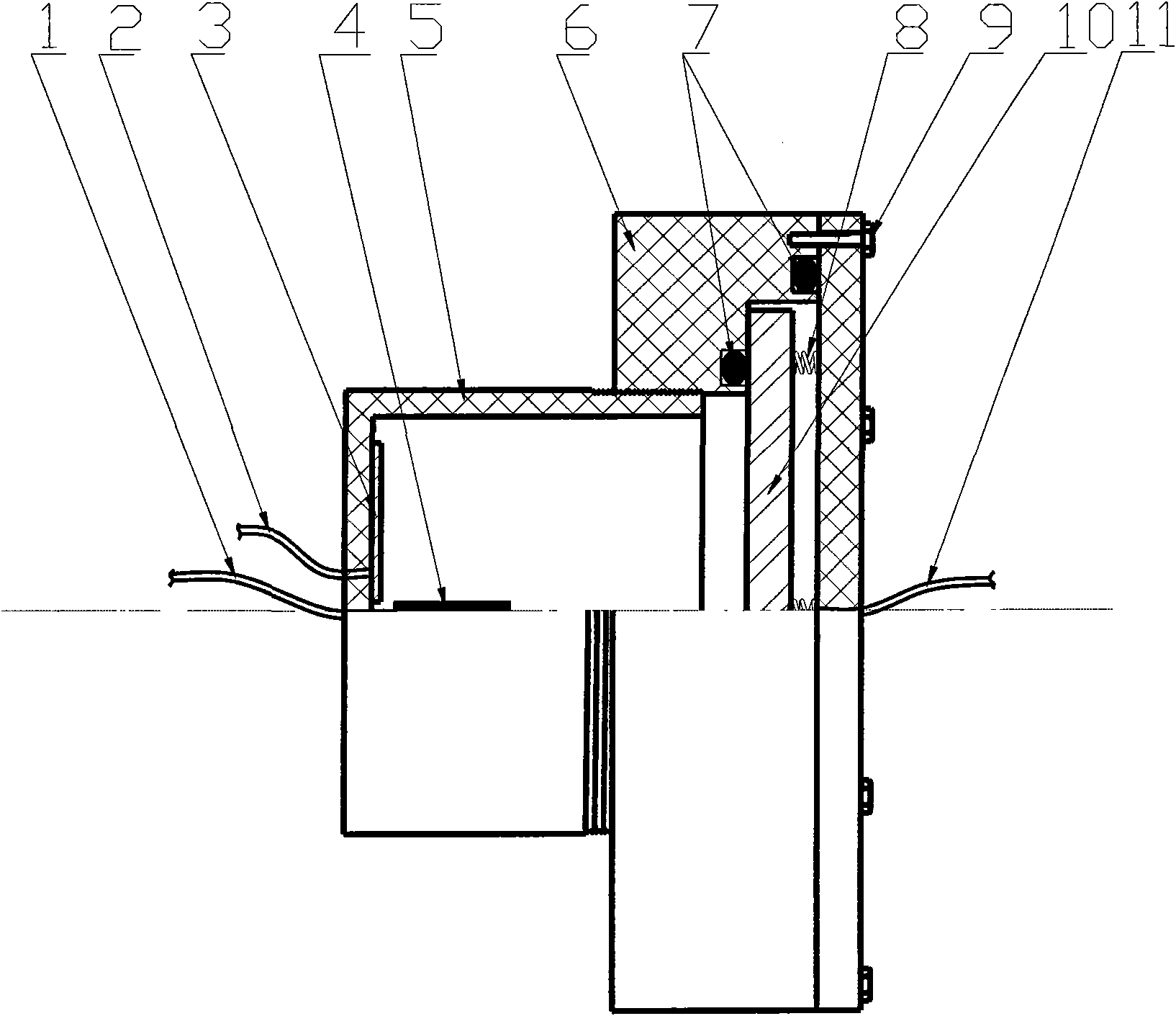

[0012] The main structure of the on-site corrosion test device involved in this embodiment includes a reference electrode lead wire 1, an auxiliary electrode lead wire 2, an auxiliary electrode 3, a reference electrode 4, a probe housing 5, a sample sealing structure housing 6, a sealing ring 7, a pressing Spring 8, fastening bolt 9, sample 10 and sample lead 11, the overall structure is made of plastic, nylon or other non-metallic materials, split structure design, including two parts of electrochemical test probe and sample sealing structure; The electrochemical test probe is rotated to the sample sealing structure shell through the screw thread at the front of the probe shell 5. The electrochemical test probe is electrically connected by the reference electrode lead 1, the auxiliary electrode lead 2, the auxiliary electrode 3, the reference electrode 4 and the probe shell 5. Connected composition; the reference electrode 4 and the auxiliary electrode 3 are respectively fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com