Dry chemical test paper for quantitatively determining human alanine aminotransferase

A technology for the quantitative determination of alanine amino groups, which is applied in the field of in vitro clinical diagnostic reagents, can solve problems such as function and speed limitations, and achieve the effects of good uniformity, simple manufacturing process, and high color intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

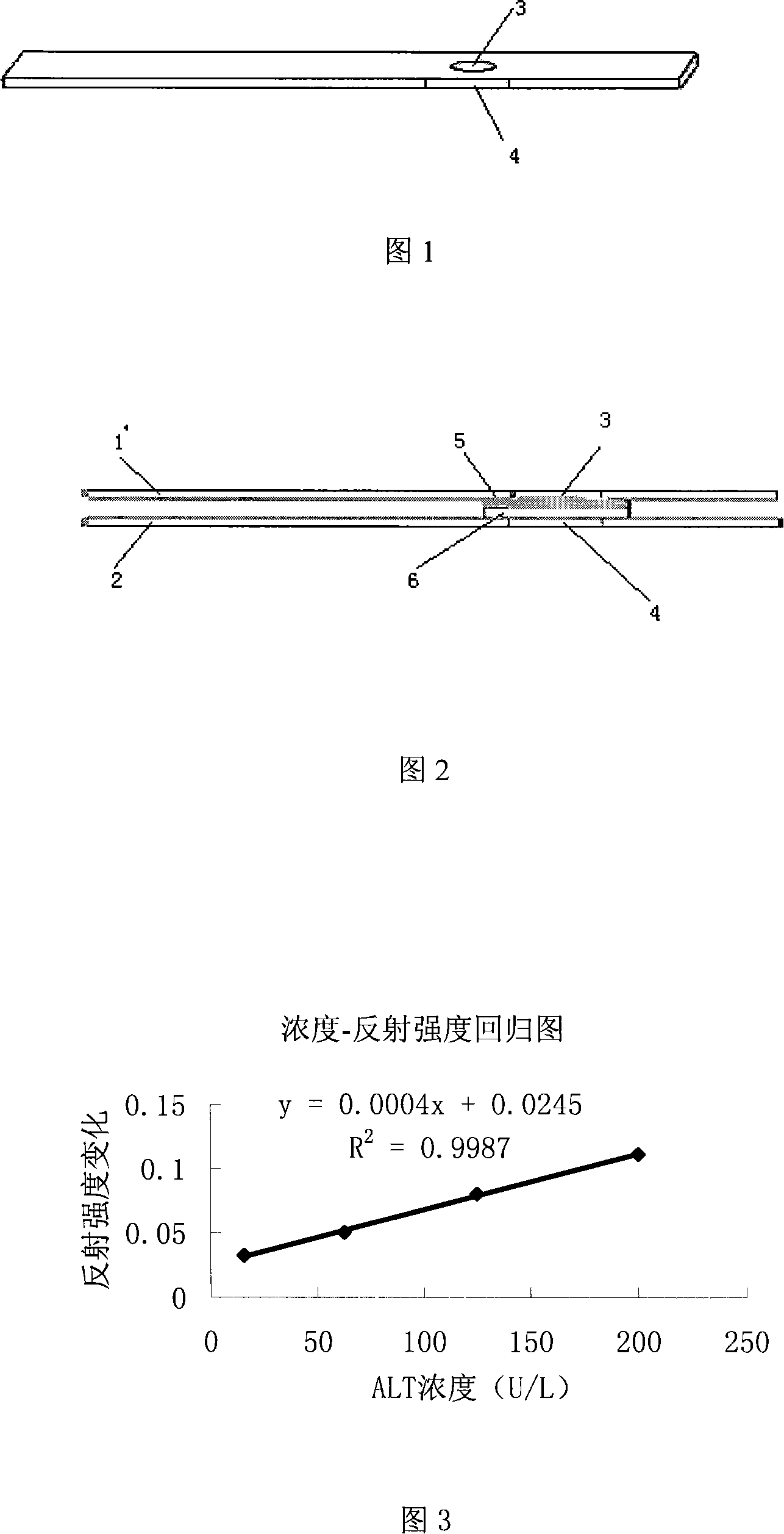

[0019] Embodiment 1: The upper and lower support layers are made of PVC sheets, and the sample hole 3 and the test hole 4 are punched out with a punching machine. The diameter of the holes is 4mm, and the hole distance is 8mm. The substrate layer 5 adopts glass fiber and is pasted on the upper supporting layer. The color-developing layer 6 adopts a nylon film, which is pasted on the lower support layer. The prepared substrate solution and chromogenic solution were spotted on the substrate layer 5 and the chromogenic layer 6 respectively with a BIO-DOT dot sprayer, 6 μl per well. Put the sprayed test paper into a vacuum drying oven at 30-50°C, and take it out after drying. The upper and lower support layers are pasted together, and the sample hole 3 is aligned with the test hole 4. Cut the test paper into 8mm wide test strips with a hob machine.

[0020] The reagent composition is as follows:

[0021] Phosphate buffer: 50mM

[0022] L-alanine: 500mM

[0023] Sodium α-keto...

Embodiment 2

[0036]Embodiment 2: The upper and lower support layers are made of PET sheets, and the sample hole 3 and the test hole 4 are punched out with a punching machine. The diameter of the holes is 4 mm, and the hole distance is 8 mm. The substrate layer 5 is made of glass fiber, and the color-developing layer 6 is made of PES film with a width of 8 mm. Soak the substrate layer 5 and the color developing layer 6 in the substrate solution and the color developing solution respectively, take them out after completely soaking, and scrape them flat. Put the soaked test paper into a vacuum drying oven at 30-50°C, and take it out after drying. The substrate layer 5 is pasted on the upper supporting layer, and the color-developing layer 6 is pasted on the lower supporting layer. The upper and lower support layers are pasted together, and the sample hole 3 is aligned with the test hole 4. Cut the test paper into 8mm wide test strips with a hob machine.

[0037] The reagent composition is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com