Deep sea multichannel corrosion electrochemical in-situ test device and test method

An in-situ test and multi-channel technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, scientific instruments, etc., can solve the problems of lack of, inability to display or characterize the corrosion kinetic process and aging state of materials in deep sea in real time , to achieve the effect of low power consumption, small size, simple deployment and recovery operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

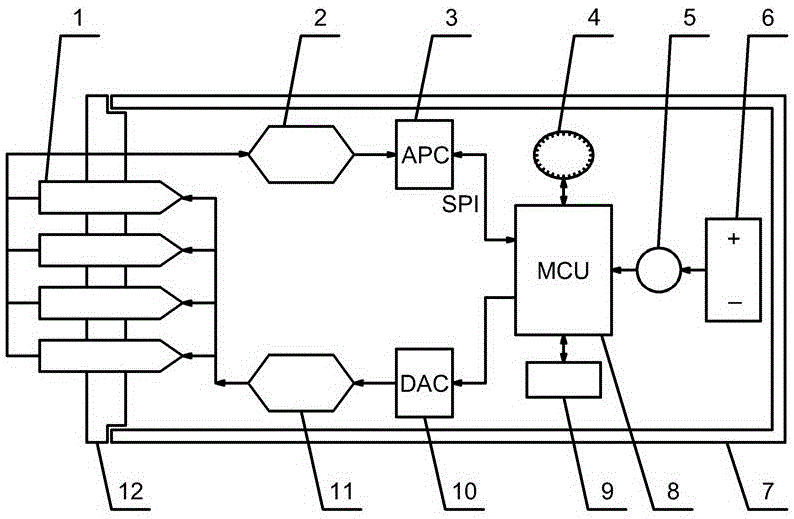

[0039] Attached below figure 1A deep-sea multi-channel corrosion electrochemical in-situ test device and its test method of the present invention will be described in detail below.

[0040] Example:

[0041] as attached figure 1 As shown, a deep-sea multi-channel corrosion electrochemical in-situ test device of the present invention, its main structure mainly includes a pressure-resistant casing 7 and a top cover 12, and the pressure-resistant casing 7 and the top cover 12 form a closed test space, and Install multi-channel measuring electrode system in its internal space 1, operational amplifier proportional operation circuit and filter / compensation circuit 2, analog-to-digital converter (APC) 3, timing clock 4, integrated switching tube DC-DC converter 5, 12 V Lithium-ion battery pack 6, single-chip microcontroller (MCU) 8, SD card data storage 9, digital-to-analog converter (DAC) 10 and channel selection relay 11.

[0042] Among them, the 12 V lithium-ion battery pack 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com