Efficient heat exchanger device

A technology of heat exchangers and shell-and-tube heat exchangers, which is applied in the field of high-efficiency heat exchanger devices, can solve problems such as adhering impurities and affecting heat transfer effects, and achieve high-efficiency heat transfer, improve heat transfer effects, and improve heat transfer efficiency. The effect of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

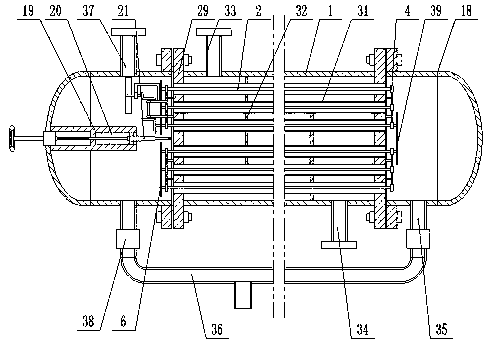

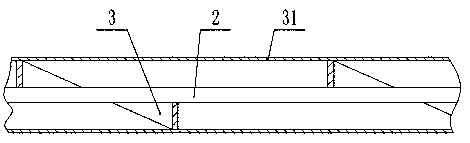

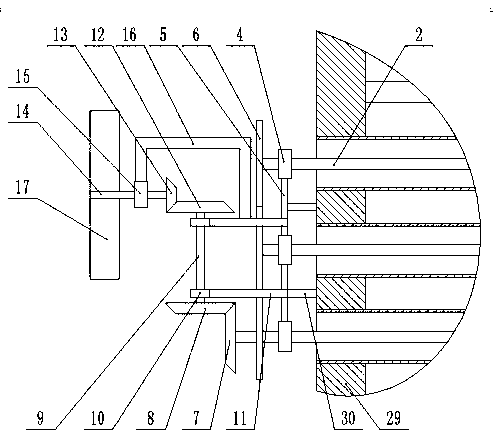

[0024] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, in this implementation:

[0025] The invention of this application lies in the structural design of the hydraulic heat exchange tube cleaning device, combined with the attached figure 1 , attached figure 2 And attached image 3 , the hydraulic heat exchange tube cleaning device includes a number of rotating shafts 2, spiral scrapers 3 are installed on the rotating shaft 2, rotating bearings 4 are installed at both ends of the rotating shaft 2, and between the adjacent rotating bearings 4 on each group of rotating shafts 2 Connected by the connecting rod 5, one end of the rotating shaft 2 is equipped with a rotating gear 6, and the rotating gears 6 on two adjacent rotating shafts 2 are engaged with each other, and one end of one of the rotating shafts 2 is equipped with a transmission bevel gear 7, the transmission bevel gear The transmission bevel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com