Self-powered ultrasonic scale removal tube cleaner

A pig and ultrasonic technology, used in cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problem of huge signal acquisition workload in long-distance pipelines, affecting low-frequency magnetic field signal acquisition, and insignificant effects, etc. problems, to achieve the effect of good pigging effect, reduced mechanical damage, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

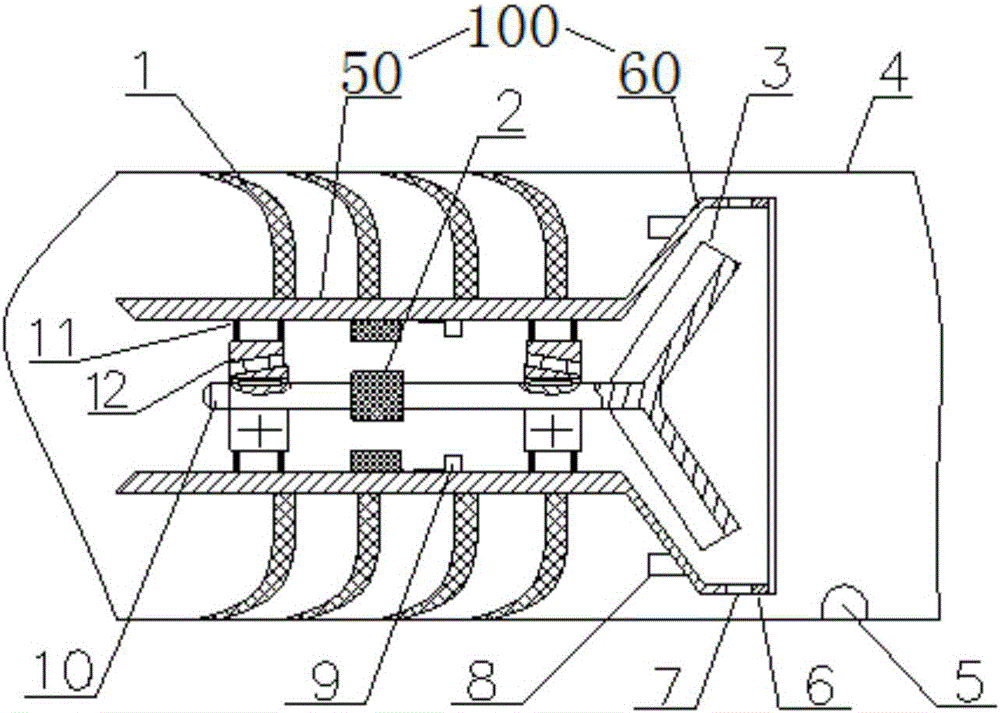

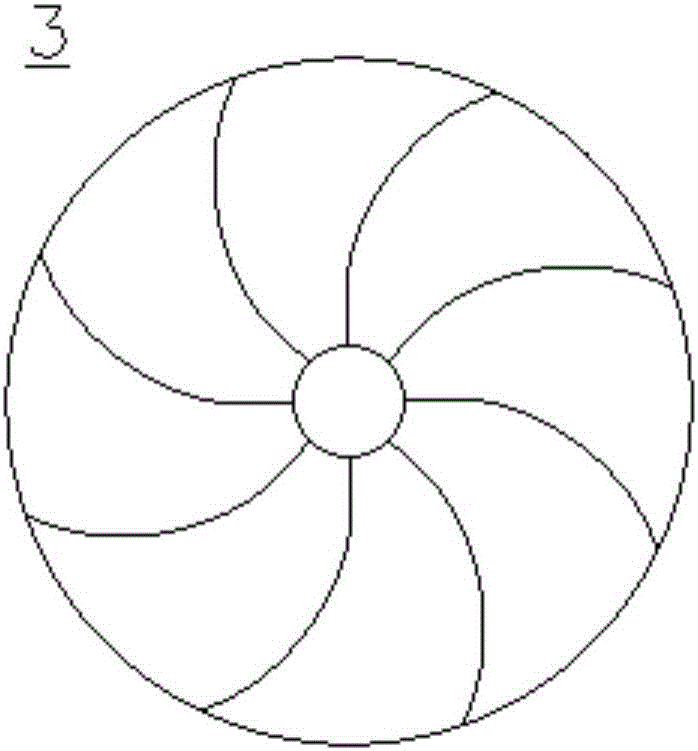

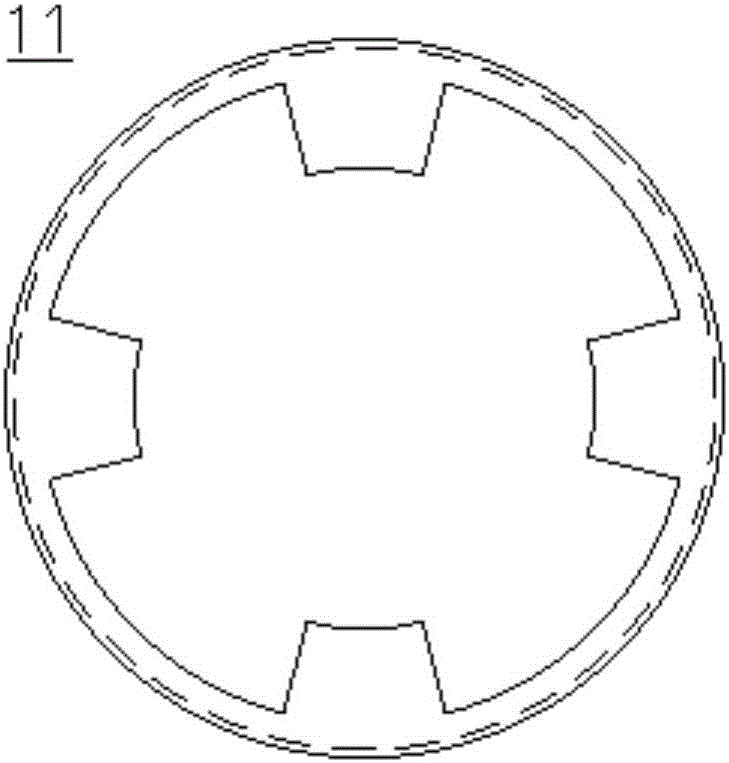

[0027] like Figure 1-4 As shown, a self-service ultrasonic descaling pig includes a body 100 and an ultrasonic generator set on the body 100, an electromagnetic induction power generation device, a power supply device and a protection device; wherein the body 100 includes a cylinder 50 and a cone 60. The ultrasonic generating device includes an ultrasonic generator 8; the electromagnetic induction generating device includes a transmission connecting rod 10, an inductance coil 2 and a converter 9; the power supply device includes a leather cup 1 and an impeller 3 with a flow channel; the protective device is a metal protection Cover 6, the metal protective cover 6 is provided with a discharge hole 7, the diameter of the metal protective cover 6 is slightly smaller than the pipe diameter; and the two ends of the transmission connecting rod 10 are support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com