Spiral-spring wire brush type tube cleaner

A helical spring and wire brush technology is applied in the field of pipe cleaners to achieve uniform wear, less wear and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

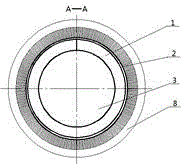

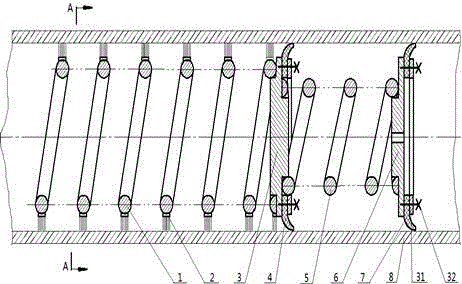

[0013] A helical spring wire brush type pipe cleaning device, which consists of spring I (1), helical spring wire brush (2), spring cup seat I (3), cup I (4), spring II (5), spring leather The bowl base II (6) and the leather bowl II (7) are composed; it is characterized in that: the spiral spring wire brush (2) is installed on the outer edge of the spring I (1), and the spring leather bowl base I (3) is installed on the spring I ( 1) At one end, the cup I (4) is installed on the spring cup seat I (3), one end of the spring II (5) is connected to the spring cup seat I (3), and the other end is connected to the spring cup seat II (6) Connection, the leather cup II (7) is installed on the spring cup seat II (6), and the center of the spring cup seat II (6) has a pressure balance hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com