Full hydraulic electric forklift hydraulic system

A technology of electric forklifts and hydraulic systems, applied in the direction of lifting devices, etc., can solve the problems of damaged hydraulic motors, poor stability performance, high oil temperature, etc., and achieve stable hydraulic control of braking maneuverability, improved working stability, and improved reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

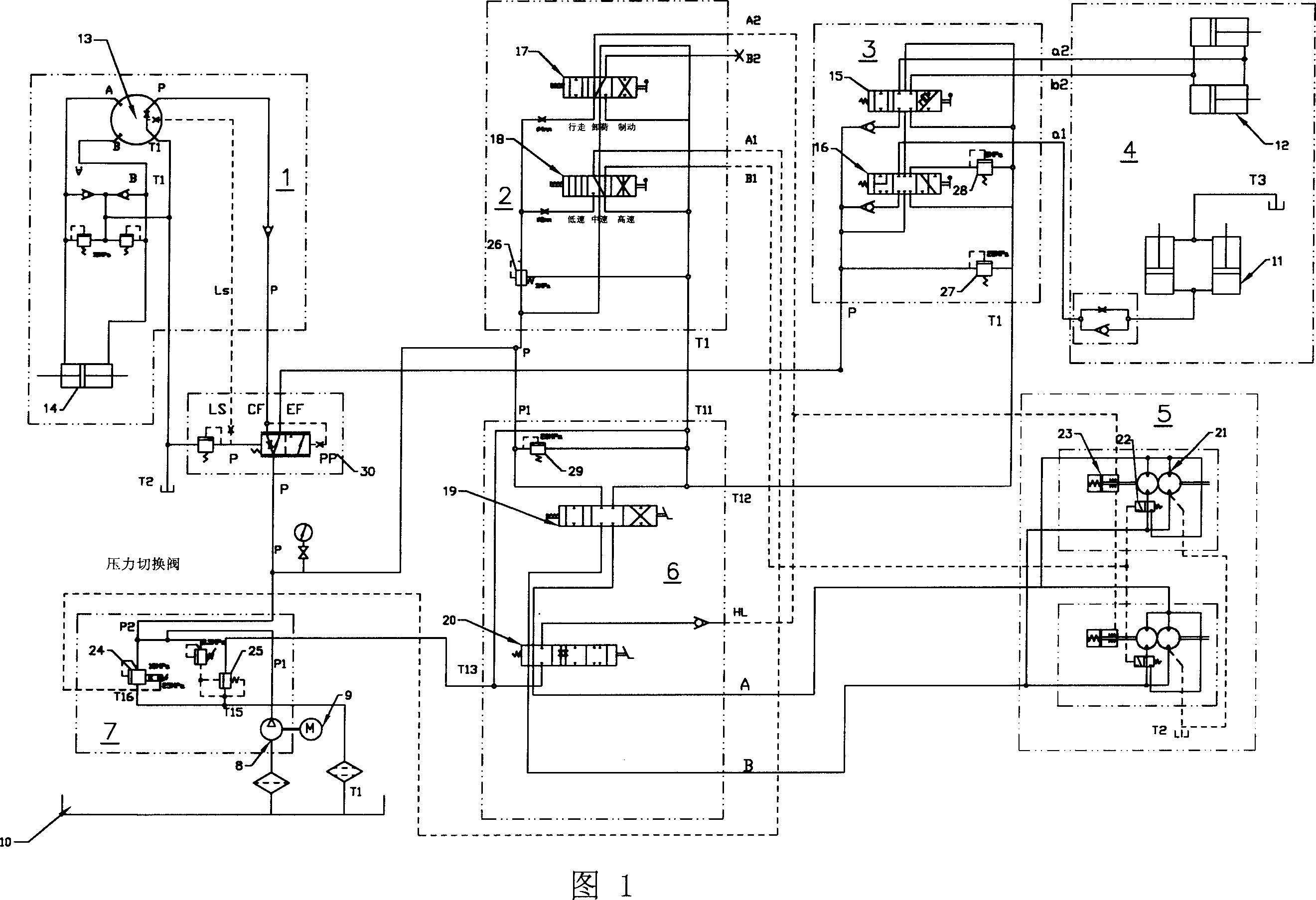

[0019] As shown in Figure 1, the hydraulic system of a full-hydraulic electric forklift is composed of a single motor 9 and a gear pump 8 connected by transmission to form a power plant; a lifting cylinder 11 and a tilting cylinder 12 form a tilting lifting device 4; The steering device 1 is composed of the device 13 and the steering cylinder 14; the traveling drive device 5 is composed of a two-speed hydraulic motor 21, a hydraulic brake 23 arranged on the motor and a hydraulic speed regulating valve 22; Valve 17 is controlled. The multi-way valve 3 is composed of a tilting valve 15, a lifting valve 16, etc.; the main oil circuit of the oil inlet valve of the multi-way valve 3 is provided with a relief valve 27 to control the system pressure of the tilting lifting device 4, and the main oil circuit and the tilting valve 15 It communicates with the cavity of the lift valve 16, wherein the lift valve 16 is provided with a relief valve 28 to control the lift pressure; the tilt v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com