Electro-hydraulic driver of control valve

A technology for controlling valves and actuators, applied to valve details, valve devices, engine components, etc., can solve problems such as response lag and slow dynamic response time, and achieve fast response speed, improved reliability, and large thrust or torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

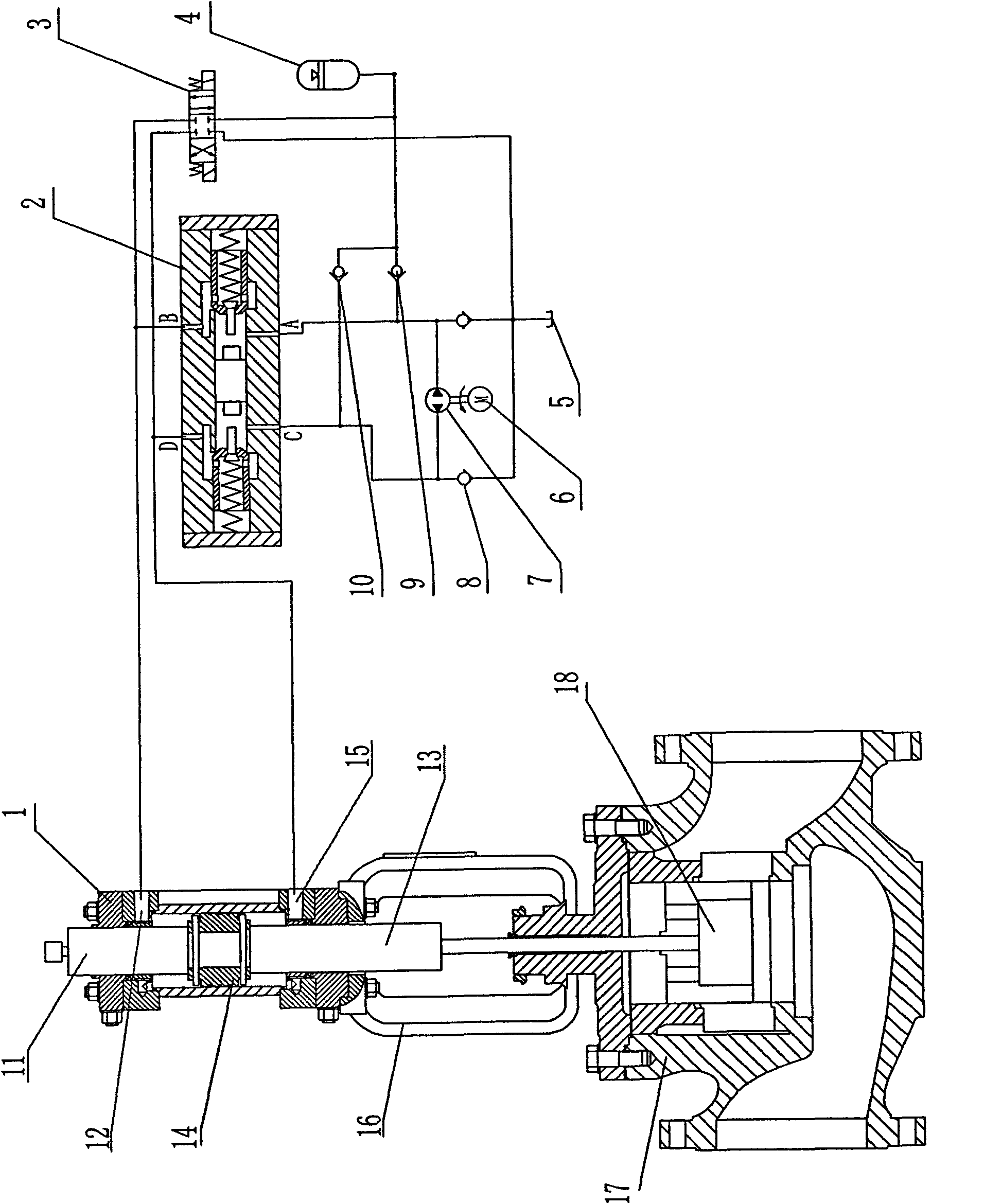

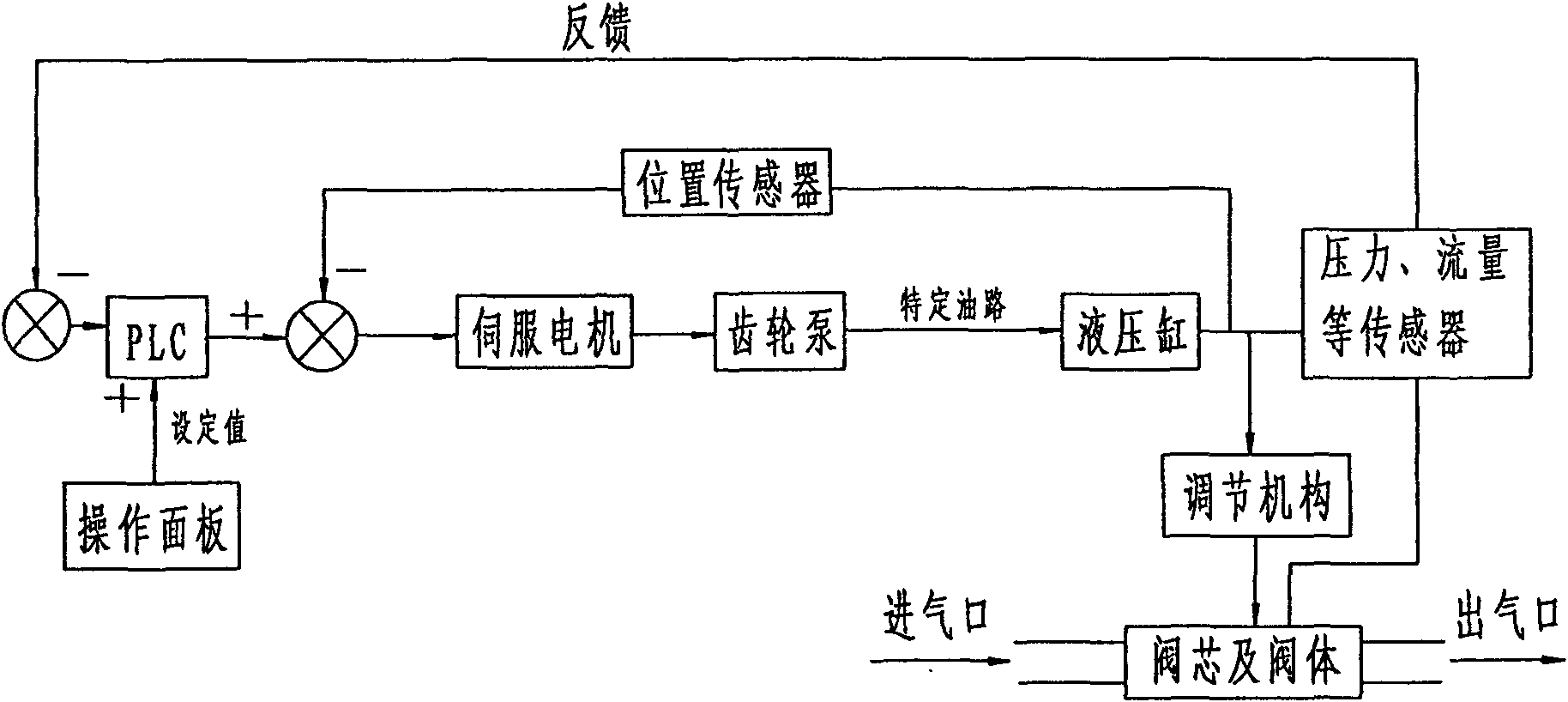

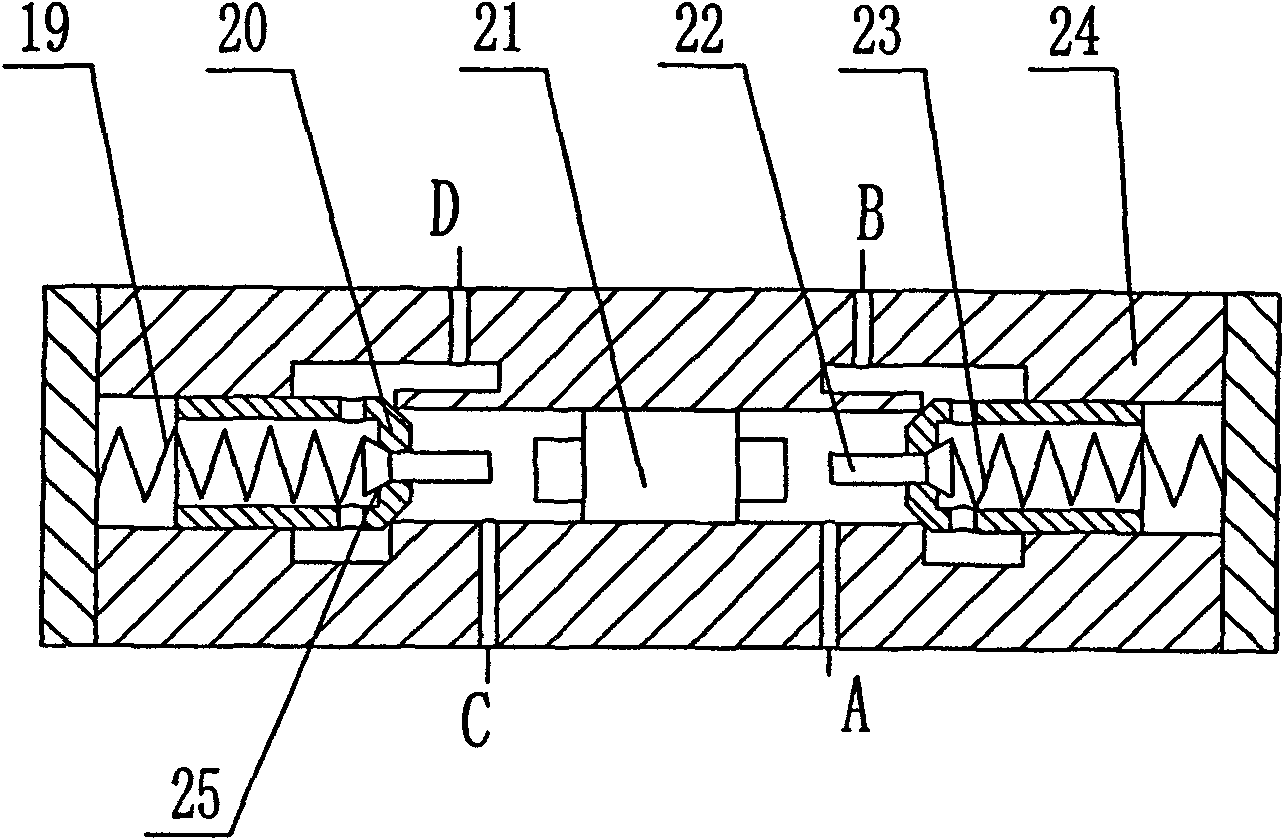

[0016] The control valve electro-hydraulic actuator of the present invention comprises a hydraulic drive system, a pressure sensor, a flow sensor, a position sensor and a control unit, and the hydraulic drive part, the pressure sensor, the flow sensor and the position sensor are all connected with the control unit (see figure 2 ).

[0017] Such as figure 1 As shown, the hydraulic drive system mainly includes a double-acting drive cylinder 1, a directional control valve 2, a three-position four-way reversing valve 3, an accumulator 4, a servo motor 6, and a two-way gear pump 7, and the two-way gear pump 7 and the servo motor 6 connected, the operation is controlled by the servo motor 6, and the servo motor 6 is connected with the control unit (PLC). On the one hand, the oil inlet and the oil outlet of the bidirectional gear pump 7 are respectively connected to the accumulator 4 through the one-way valve 9 and the one-way valve 10, and the accumulator 4 is driven by the three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com