Powertrain with torque converter and axially compact seven speed dual clutch transmission

By combining the hydraulic torque converter and dual friction shift clutch with synchronizer, the compact seven-speed transmission is designed to solve the high heat and axial length limitation problems of dual-clutch transmission, achieving efficient fuel economy and operating efficiency, and simplifying Improved cooling circuit and structural adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

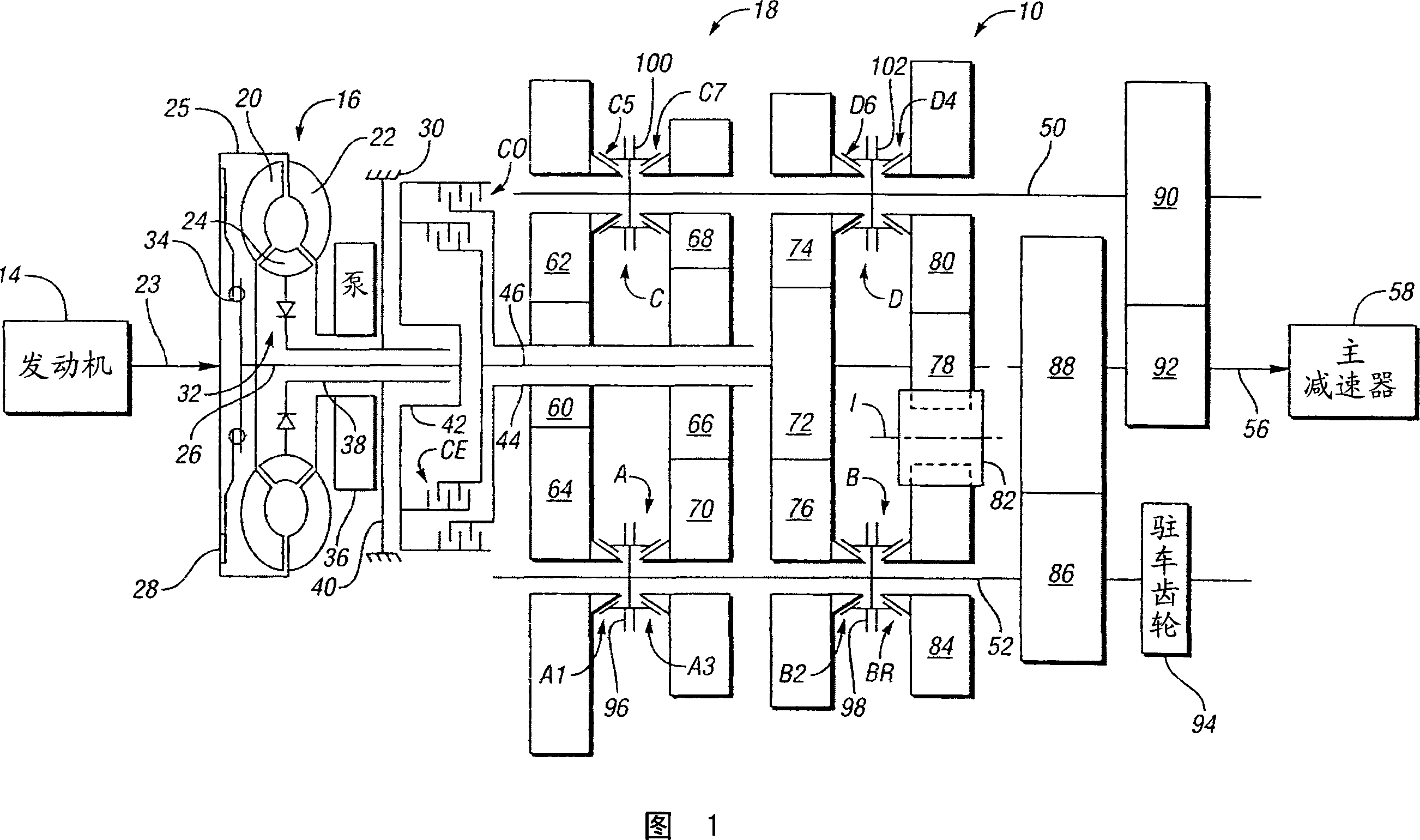

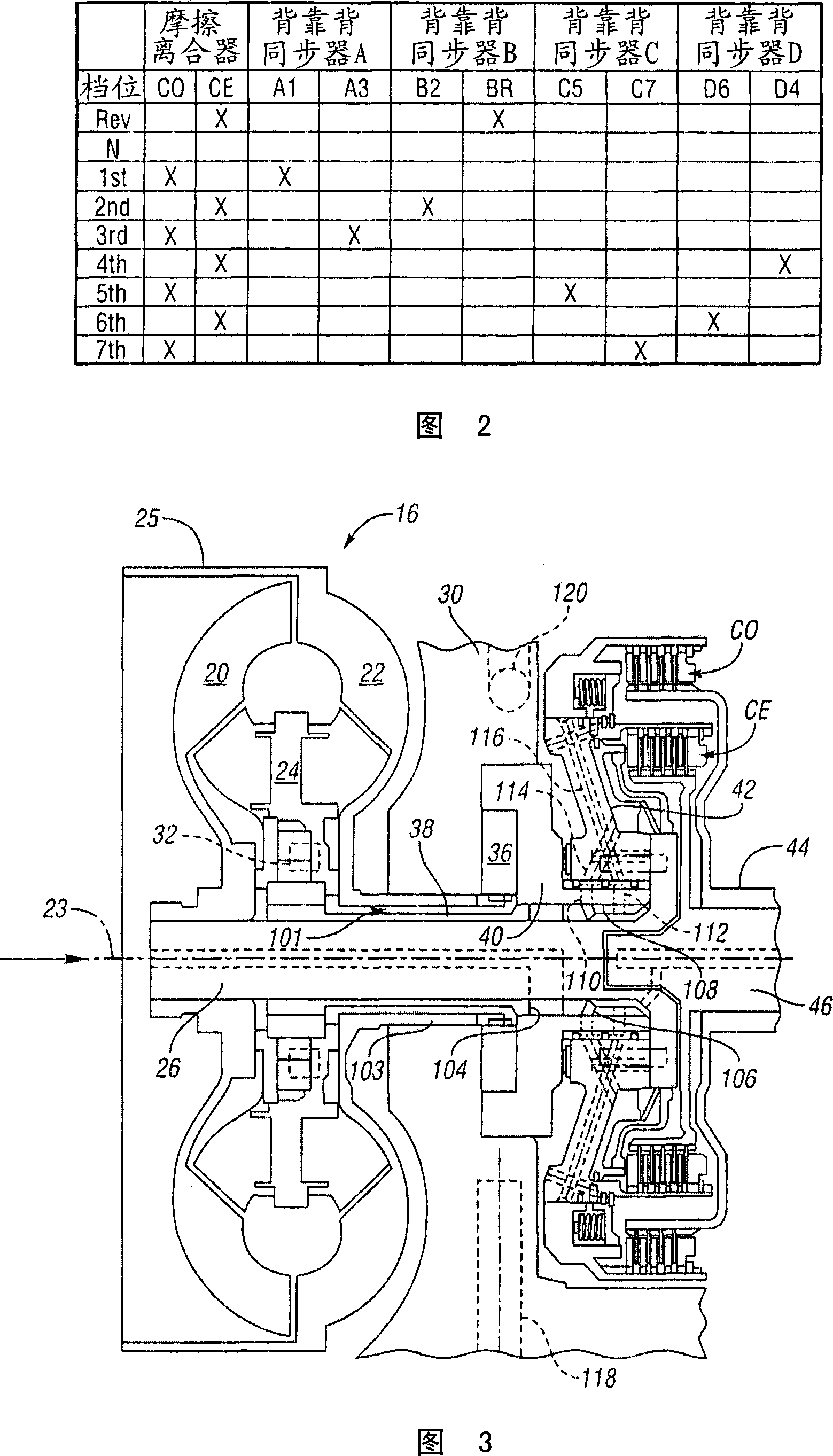

[0010] Referring to the drawings, wherein like reference numerals indicate like or corresponding parts throughout the several views, there is shown in FIG. 1 a powertrain 10 for a vehicle (not shown). The powertrain 10 includes a power source or engine 14 , a torque converter 16 and a transmission 18 . The torque converter 16 includes a turbine section 20 , a pump section 22 and an stator section 24 . The engine output shaft 23 is connected for rotation with a hub member 25 which is connected to the pump portion 22 . Turbine section 20 is coupled with a transmission input member 26 . Thus, a hydraulic coupling between the pump portion 22 and the turbine portion 20 operably connects the engine 14 with the transmission input member 26 . The transmission input member 26 is preferably in the nature of a shaft. Selective engagement of torque converter clutch 28 allows engine 14 to be coupled directly to input member 26 , bypassing torque converter 16 . Preferably, the torque co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com