Forming method of nitrogen-doped silicon carbide thin film

A silicon carbide and thin film technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of unstable interconnect structure properties, large differences in reflectivity, and large differences in film properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

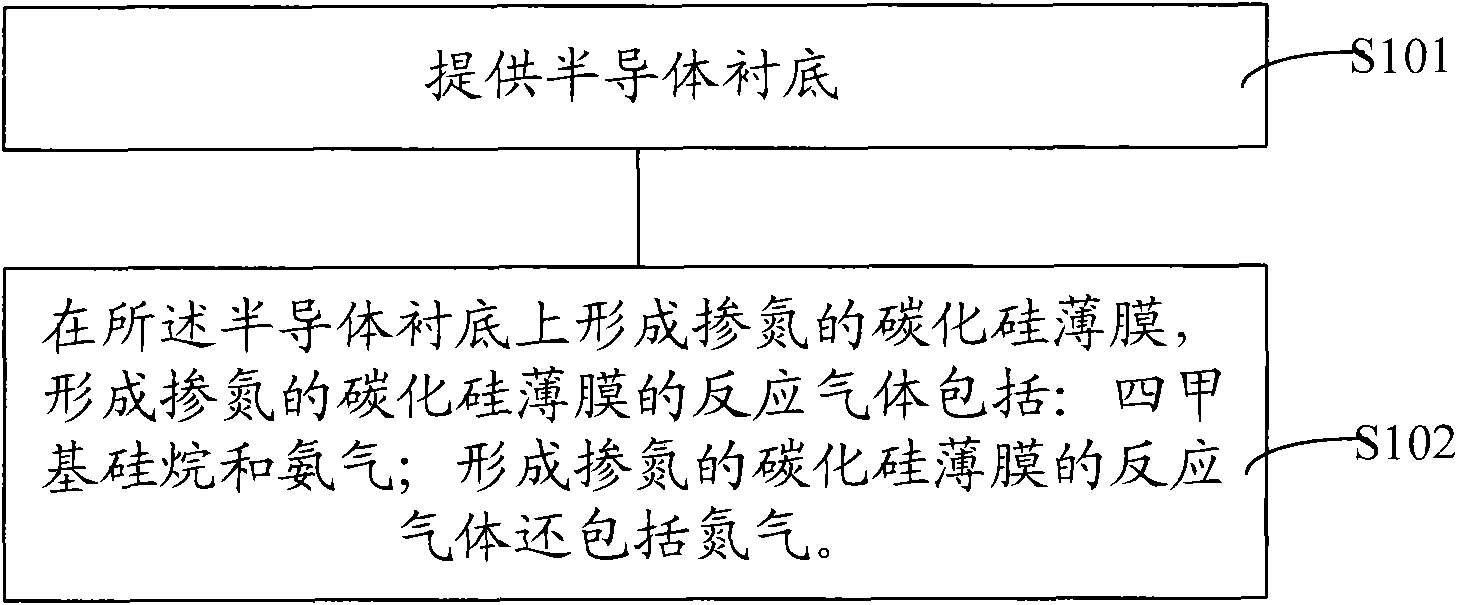

Method used

Image

Examples

Embodiment Construction

[0015] With the rapid development of semiconductor technology, dielectric thin films have become a research hotspot in the field of semiconductor manufacturing. Dielectric thin films with a k value lower than 3.0 are called low dielectric constant materials by the semiconductor manufacturing industry, and the k value is a measure of the dielectric constant of the material. Dielectric films are used to insulate metal conductors, and low-k dielectric films can reduce RC delay, thereby increasing signal transmission speed.

[0016] It can be seen from the background technology that the size of the RC delay depends on the semiconductor manufacturing process. As the semiconductor process enters the node of 130 nanometers and below, in addition to using metal copper as the semiconductor conductive material to reduce the resistance R, it will also use low dielectric constant Materials are used to reduce the capacitance C, thereby reducing the parasitic effects generated by the resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com