Method for preparing white carbon black by combusting tetramethylsilane and preparation device thereof

A tetramethylsilane and preparation device technology, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of high cost, high energy consumption, and high equipment requirements, and achieve the effects of reduced equipment requirements, energy saving costs, and excellent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

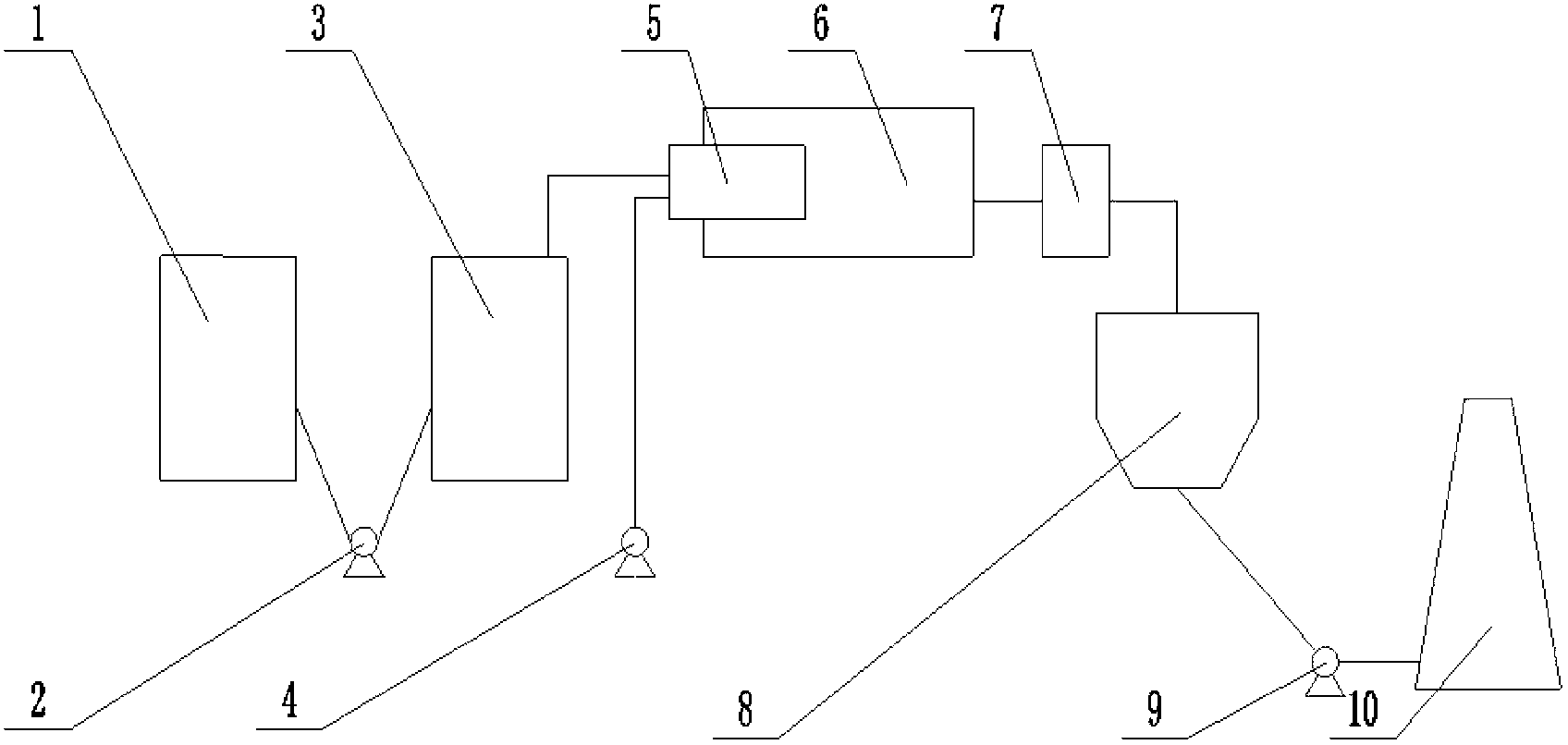

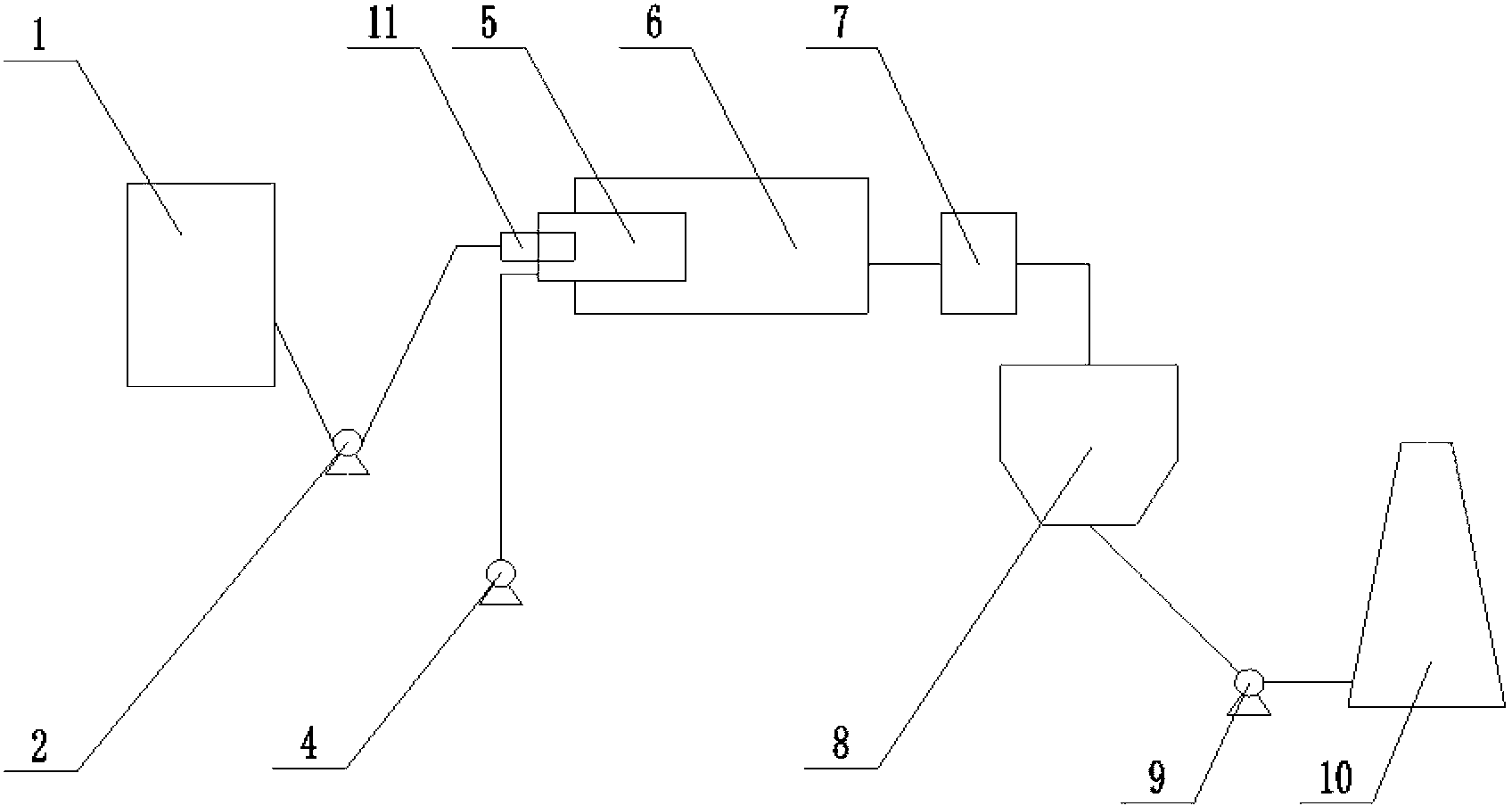

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0027] A method for preparing white carbon black by burning tetramethylsilane, the specific steps comprising:

[0028] A. Tetramethylsilane enters the atomization device from the storage tank 1 through the delivery pump 2, and after being gasified in the atomization device, it is sent to the burner 5 as gaseous tetramethylsilane;

[0029] B. The blower 4 sends air to the burner 5, and the air volume is an excess air coefficient of 1.0 to 1.5;

[0030] C. Tetramethylsilane and air are injected into the burner 5 to fully burn in the furnace 6. The combustion temperature is 800-1400°C. According to the chemical reaction formula: C 4 h 12 Si+8O 2 ==4CO 2 +6H 2 O+SiO 2 , generating white carbon black, water and carbon dioxide;

[0031] D. The high-temperature flue gas flow produced by combustion passes through the flue gas cooler 7 and then en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com