Process for preparing diamond-like coating doped with silicon element

A technology of diamond coating and preparation process, which is applied in metal material coating process, coating, superimposed layer plating, etc., which can solve the problem of poor bonding between coating and substrate, large internal stress of coating, and failure to meet industrial needs and other issues to achieve good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

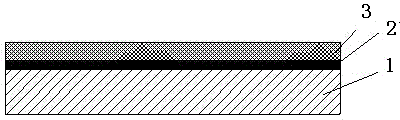

[0028] The structure of the diamond-like coating prepared by the preparation process of the silicon-doped diamond-like coating of the present invention, such as figure 1 As shown, it includes a transition layer 2 and a top layer 3. The transition layer 2 is CrN to improve the bonding force between the coating and the substrate and reduce the stress inside the coating. The top layer 3 is a silicon-doped diamond-like coating, and its Vickers hardness More than HV2800, the friction coefficient is less than 0.05.

[0029] The preparation process of the silicon-doped diamond-like coating of the present invention: the equipment used is a physical vapor deposition equipment (model ICS-04 ARC PRO) plus a glow discharge device. The coating structure of the workpiece 1 consists of a transition layer 2 and a top layer 3 . For the surface pretreatment of the workpiece 1, argon gas is introduced into the vacuum furnace to perform plasma cleaning on the workpiece; nitrogen gas is introduce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com