Method for preparing dimethyl dichlorosilane

A technology for dimethyldichlorosilane and trimethylchlorosilane, which is applied in the field of preparing dimethyldichlorosilane, can solve the problems of strict equipment requirements, difficult separation of impurities, low safety performance, etc., and achieves convenient distillation and purification. , easy industrialization, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

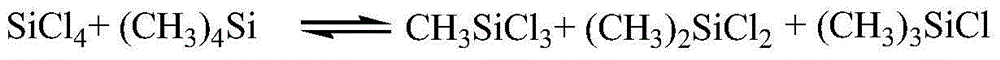

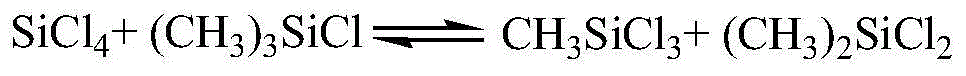

Problems solved by technology

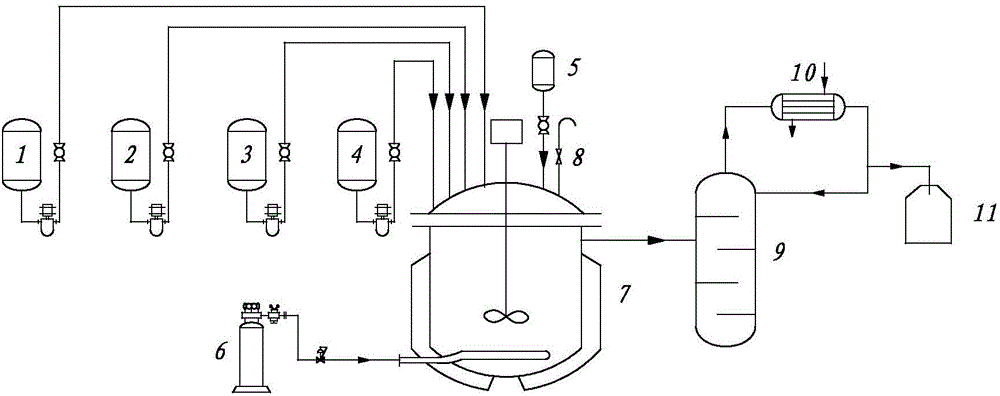

Method used

Image

Examples

Embodiment 1

[0040] Add 100kg of methyltrichlorosilane, 40kg of trimethylchlorosilane, 60kg of azeotrope, 40kg of tetramethylsilane and 1.8kg of aluminum trichloride into the disproportionation reactor, start stirring, raise the temperature to 120°C, react for 8h, and react After the completion, the crude product of dimethyldichlorosilane was obtained by rectification, and the content of the crude product detected by gas chromatography was 85.1%, and the yield of the crude product was about 75.2%.

Embodiment 2

[0042] Add 100kg of methyltrichlorosilane, 50kg of trimethylchlorosilane, 70kg of azeotrope, 50kg of tetramethylsilane and 3.0kg of aluminum trichloride into the disproportionation reactor, start stirring, raise the temperature to 170°C, and react for 12 hours. After the completion, the crude product of dimethyldichlorosilane was obtained by rectification. The content of the crude product detected by gas chromatography was 86.8%, and the yield of the crude product was about 82.7%.

Embodiment 3

[0044] Add 100kg of methyltrichlorosilane, 50kg of trimethylchlorosilane, 60kg of azeotrope, 40kg of tetramethylsilane and 2.9kg of aluminum trichloride into the disproportionation reactor, start stirring, raise the temperature to 150°C, and react for 12 hours. After the completion, the crude product of dimethyldichlorosilane was obtained by rectification, and the content of the crude product detected by gas chromatography was 91.8%, and the yield of the crude product was about 86.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com