Normal-temperature and normal-pressure synthesizing method of Zr-Si-C ceramic precursor

A ceramic precursor and atmospheric pressure synthesis technology, which is applied in the field of normal temperature and pressure synthesis of Zr-Si-C ceramic precursors, can solve the problems of poor designability, low zirconium content of ceramic products, complex process, etc., and achieve less control conditions , simple equipment and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment includes the following steps:

[0036](1) Under normal temperature, normal pressure, and nitrogen protection, place 10.0g (39.8mmol) dimethyl zirconocene in a three-necked flask, stir and add 90mL of anhydrous and oxygen-free tetrahydrofuran to dissolve, drop in 8.8mL of TMEDA and 96.0mmol n-butyllithium (commercially available 2.4mol / L n-butyllithium n-hexane solution 40.0mL), reacted for 11 hours, and vacuum dried to obtain active zirconocene lithium salt;

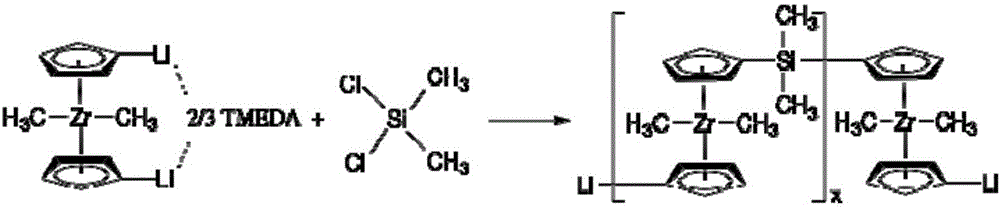

[0037] (2) Dissolve 5 g (14.7 mmol) of the active lithium zirconocene salt prepared in step (1) in 50.0 mL of anhydrous and oxygen-free tetrahydrofuran under normal temperature, normal pressure, and nitrogen protection. Dilute 2.1ml (17.4mmol) of dimethyldichlorosilane in 45.0mL of anhydrous and oxygen-free tetrahydrofuran, and drop into the solution of active zirconocene lithium salt, and stir for 13 hours to generate figure 1 Shown polymerization, drop 2.0mL of methanol to terminate the reaction...

Embodiment 2

[0042] This embodiment includes the following steps:

[0043] (1) At normal temperature, normal pressure, under the protection of argon, put 10.0g (39.8mmol) dimethyl zirconocene in a Schlenk bottle, stir and add 80mL of anhydrous and oxygen-free tetrahydrofuran to dissolve, drop in 8.8mL of TMEDA and 96.0mmol n-butyllithium (commercially available 2.4mol / L n-butyllithium n-hexane solution 40.0mL), reacted for 12 hours, and vacuum dried to obtain active zirconocene lithium salt;

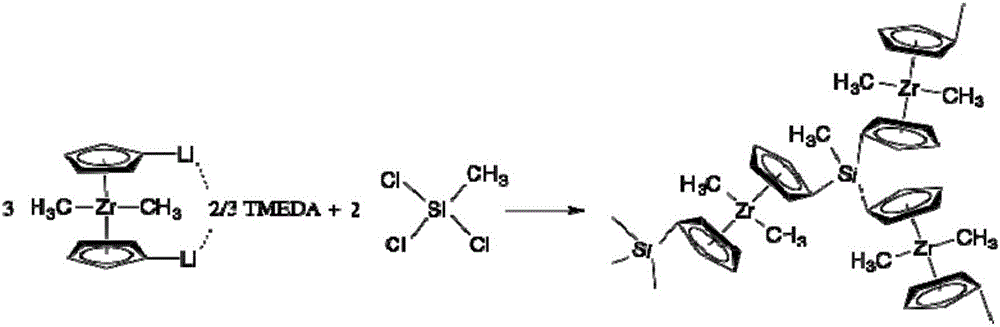

[0044] (2) Dissolve 5 g (14.7 mmol) of the active lithium zirconocene salt prepared in step (1) in 40.0 mL of anhydrous and oxygen-free tetrahydrofuran at normal temperature, normal pressure, and under the protection of argon. Dilute 1.4ml (11.9mmol) of methyltrichlorosilane in 40mL of anhydrous and oxygen-free tetrahydrofuran, and drop into the solution of active zirconocene lithium salt, and stir for 11 hours to generate figure 2 For the indicated polymerization, 1.5 mL of absolute ethanol was ad...

Embodiment 3

[0047] This embodiment includes the following steps:

[0048] (1) At normal temperature, normal pressure, and under the protection of argon, put 10.0g (39.8mmol) dimethyl zirconocene in a three-necked flask, stir and add 90mL of anhydrous and oxygen-free tetrahydrofuran to dissolve, and drop into 8.8mL of TMEDA And 96.0mmol n-butyllithium (commercially available 2.4mol / L n-butyllithium n-hexane solution 40.0mL), reacted for 10 hours, and vacuum dried to obtain active zirconocene lithium salt;

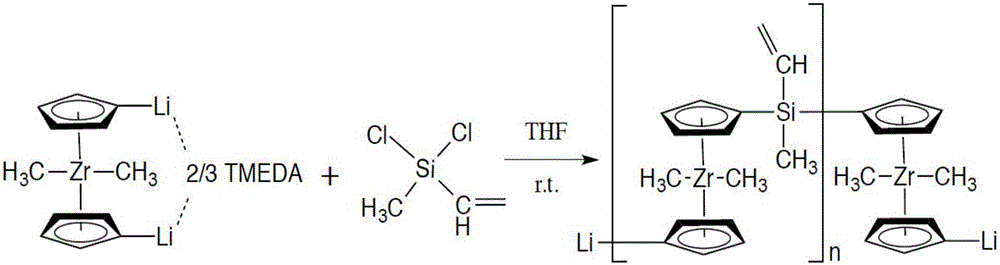

[0049] (2) Dissolve 5 g (14.7 mmol) of the active lithium zirconocene salt prepared in step (1) in 50.0 mL of anhydrous and oxygen-free tetrahydrofuran under normal temperature, normal pressure, and nitrogen protection. Dilute 2.3ml (17.6mmol) of methyl vinyl dichlorosilane in 30.0mL of anhydrous anoxygen-free tetrahydrofuran, and drop into the solution of active lithium zirconocene salt, stir for 12 hours to generate image 3 Shown polymerization, drop 1.0mL of methanol to terminate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com