Patents

Literature

44results about How to "High synthesis cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyester polyol

The invention discloses polyester polyol, which is characterized in that the residual liquid that is generated from the production of oxalic acid, trimethylol propane and neopentyl glycol is selected as the raw material, thus recycling the waste liquid, reducing the environmental pollution and reducing the production cost of the polyester polyol by 15 to 25 percent. The prepared polyester polyol is used in polyurethane hard foam plastics.

Owner:张鹏飞

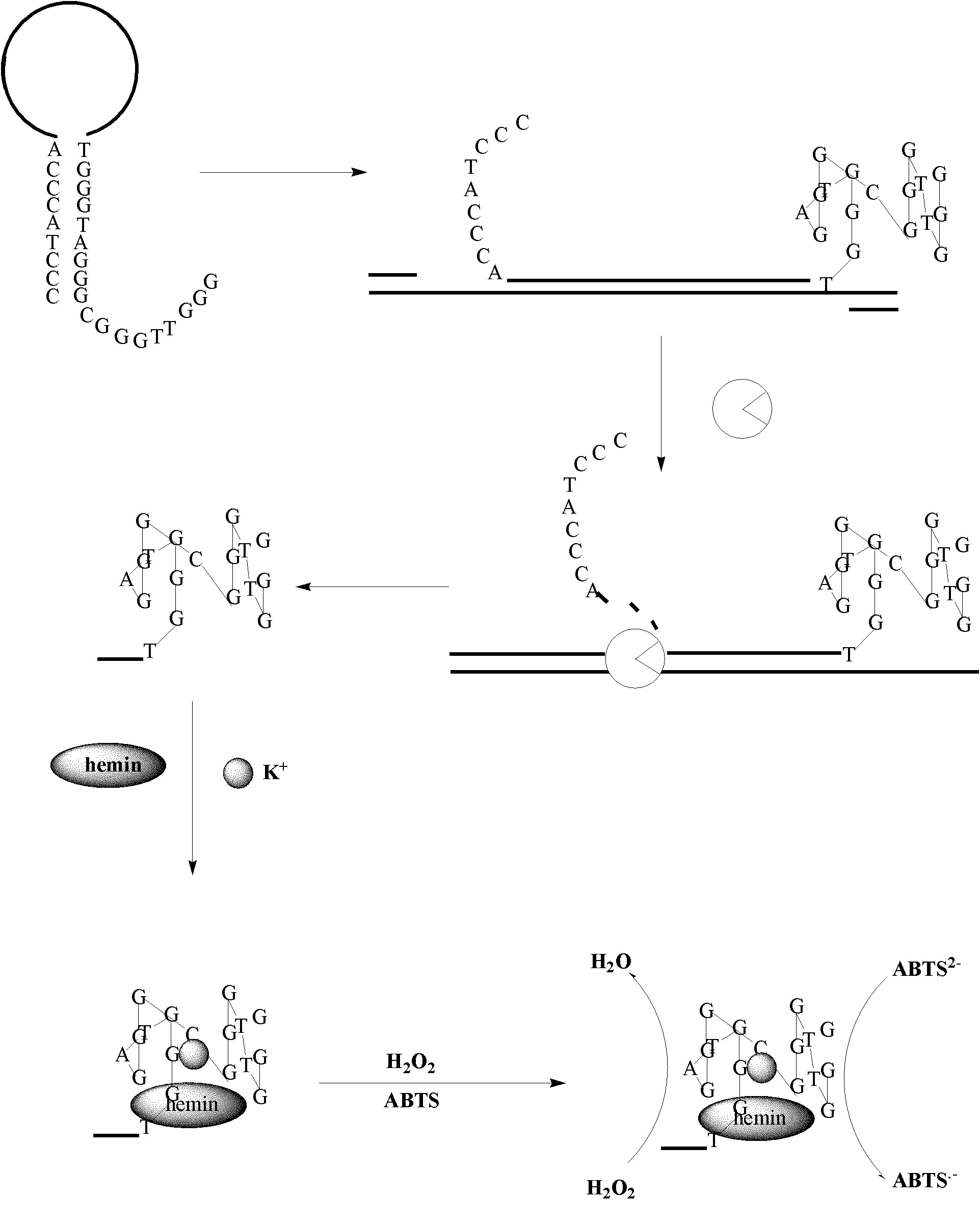

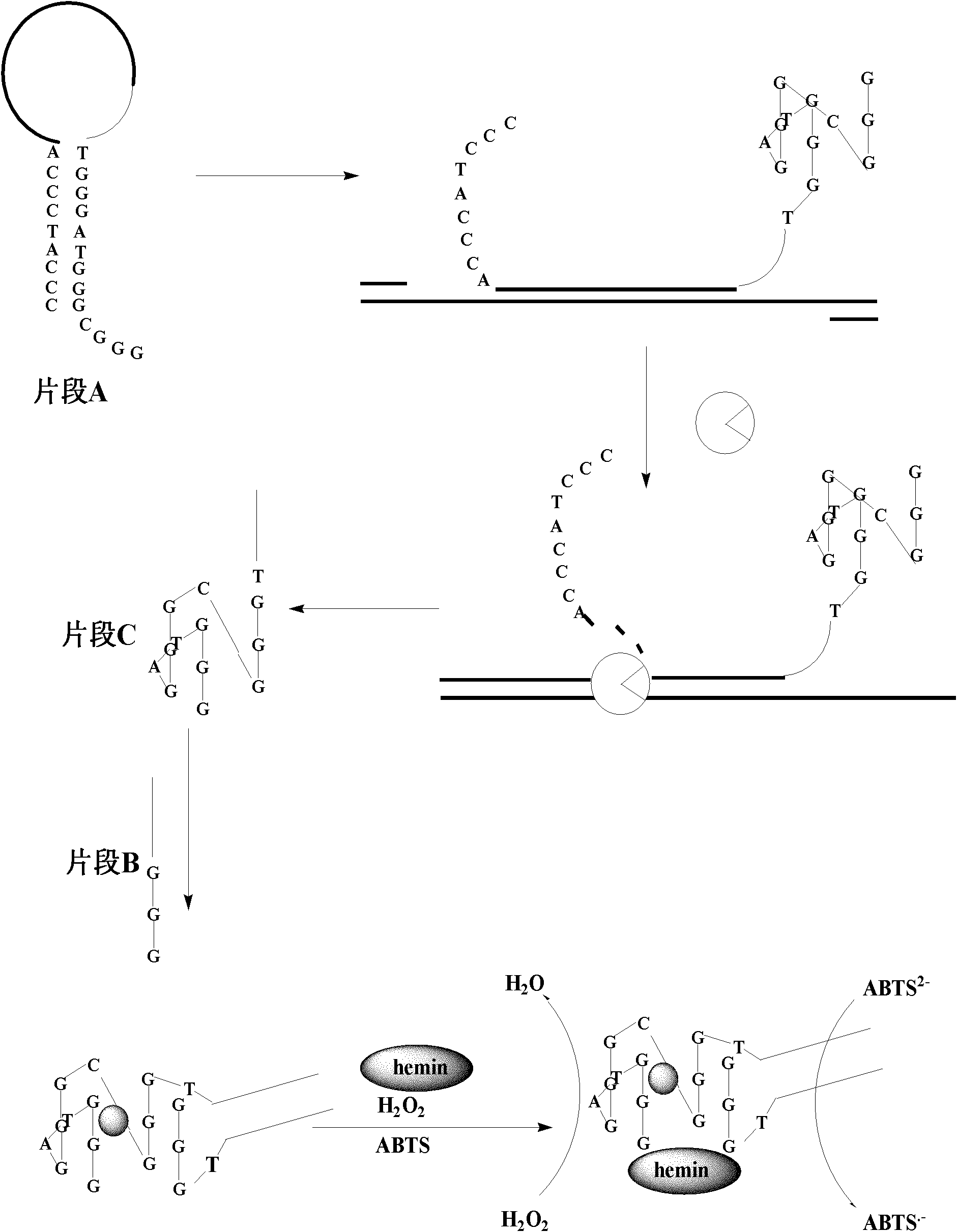

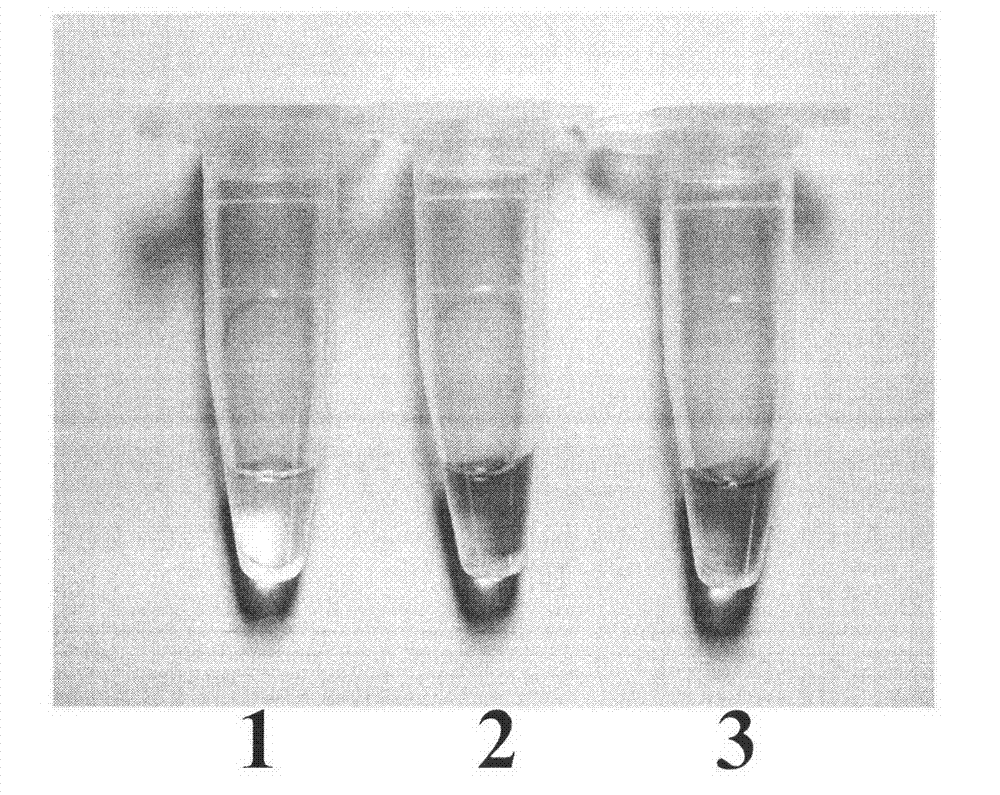

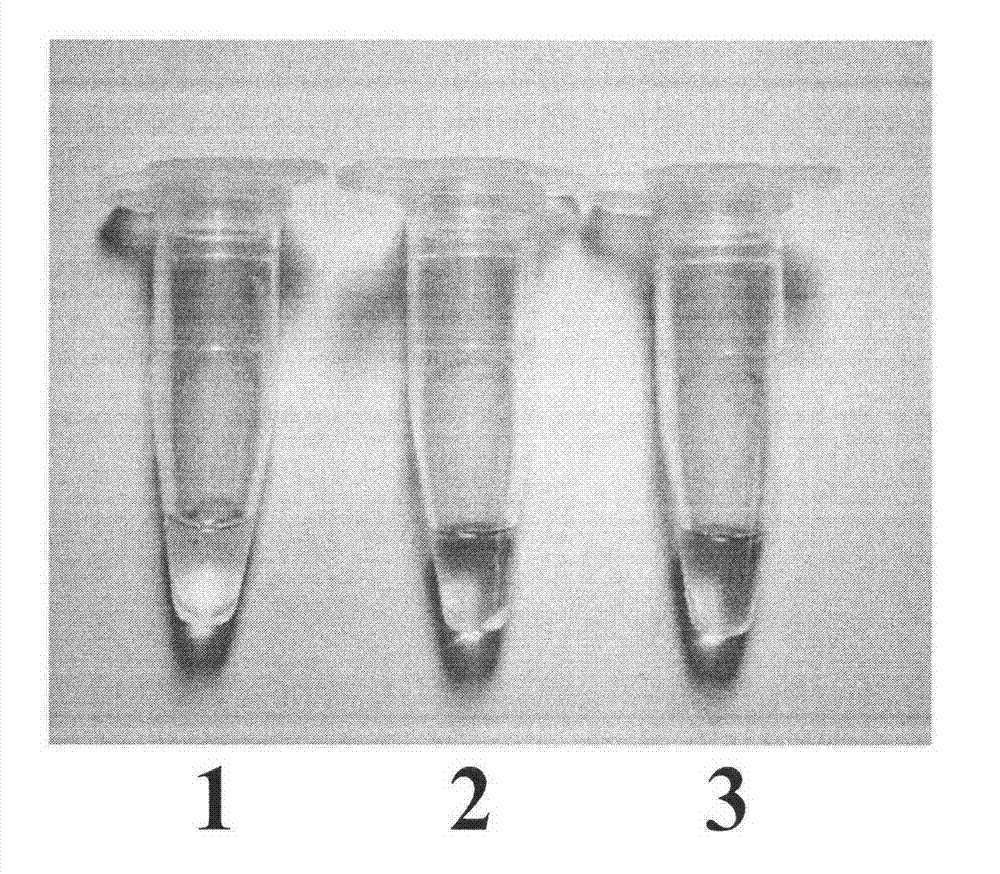

PCR (polymerase chain reaction) nucleic acid detection method

ActiveCN102071251AExtensive testingEasy to detectMicrobiological testing/measurementGenetic analysisReal-time polymerase chain reaction

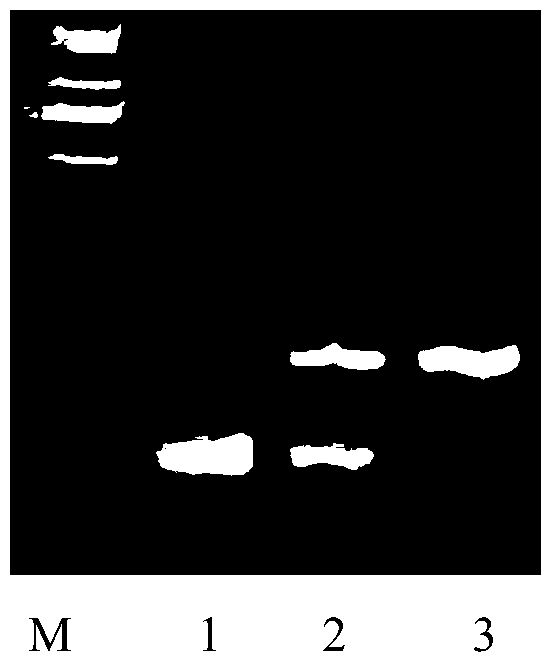

The invention belongs to the technical field of molecular biology and relates to the analysis and detection of nucleic acids, particularly to a PCR (polymerase chain reaction) detection method which is universal and utilizes 5'-3' excisionenzyme activity of nucleic acid polymerase for releasing DNAzyme. The nucleic acid detection method comprises the following steps: adding an oligonucleotide probe labeled by the DNAzyme or partial DNAzyme in the PCR system, amplifying nucleic acids to be detected by a forward primer and a reverse primer, releasing the DNAzyme label or the partial DNAzyme label in the probe by the 5'-3' excisionenzyme activity of the nucleic acid polymerase, and carrying out qualitative analysis or quantitative analysis of nucleic acids by detecting labels released from PCR products. The method achieves sensitivity, accuracy, fastness and cheapness; and the method can be applied in various gene detection systems and is highly applicable to the early detection and genetic analysis of some diseases, and the like.

Owner:湖州申科生物技术股份有限公司

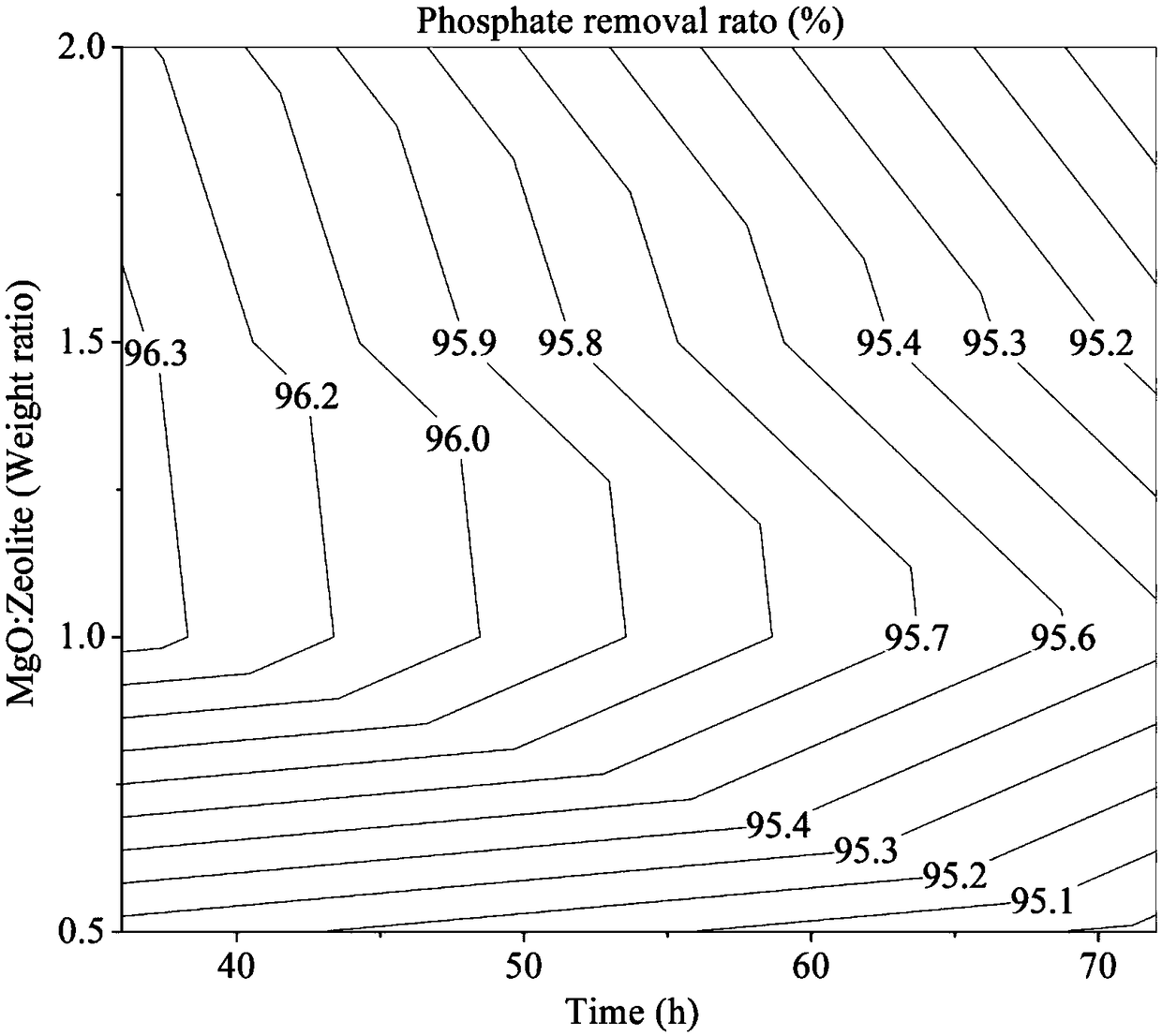

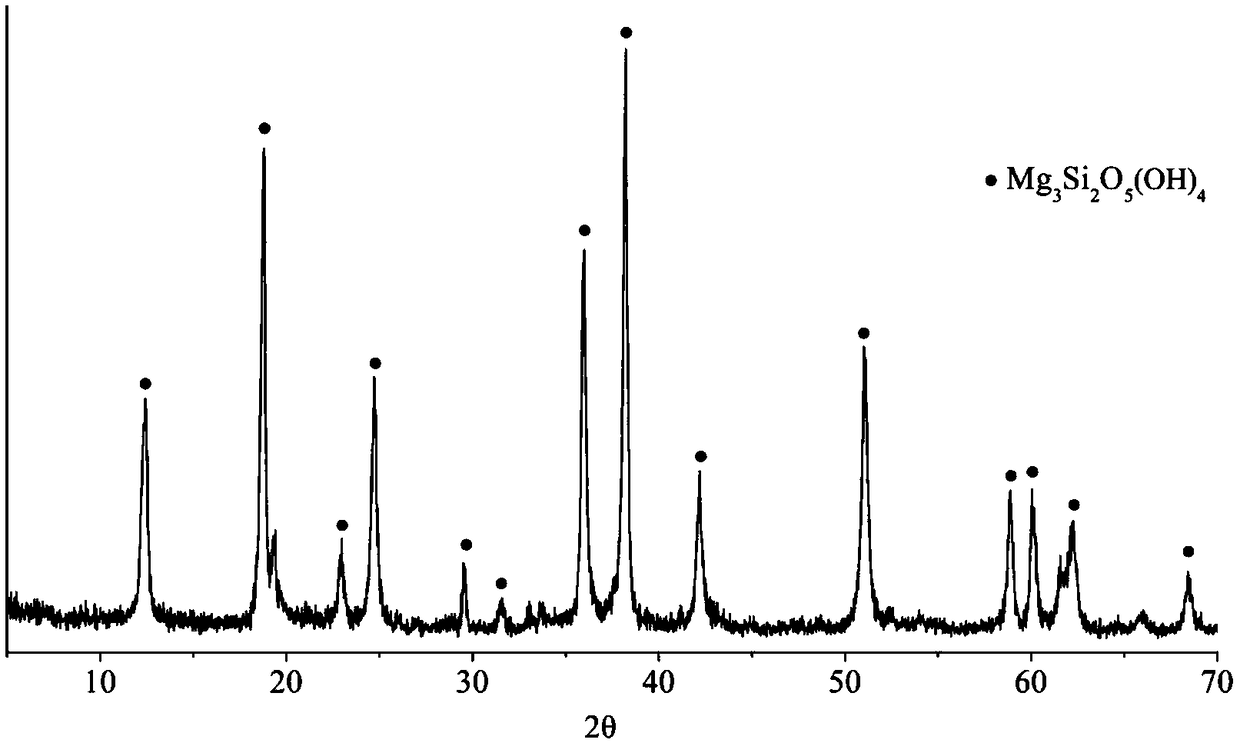

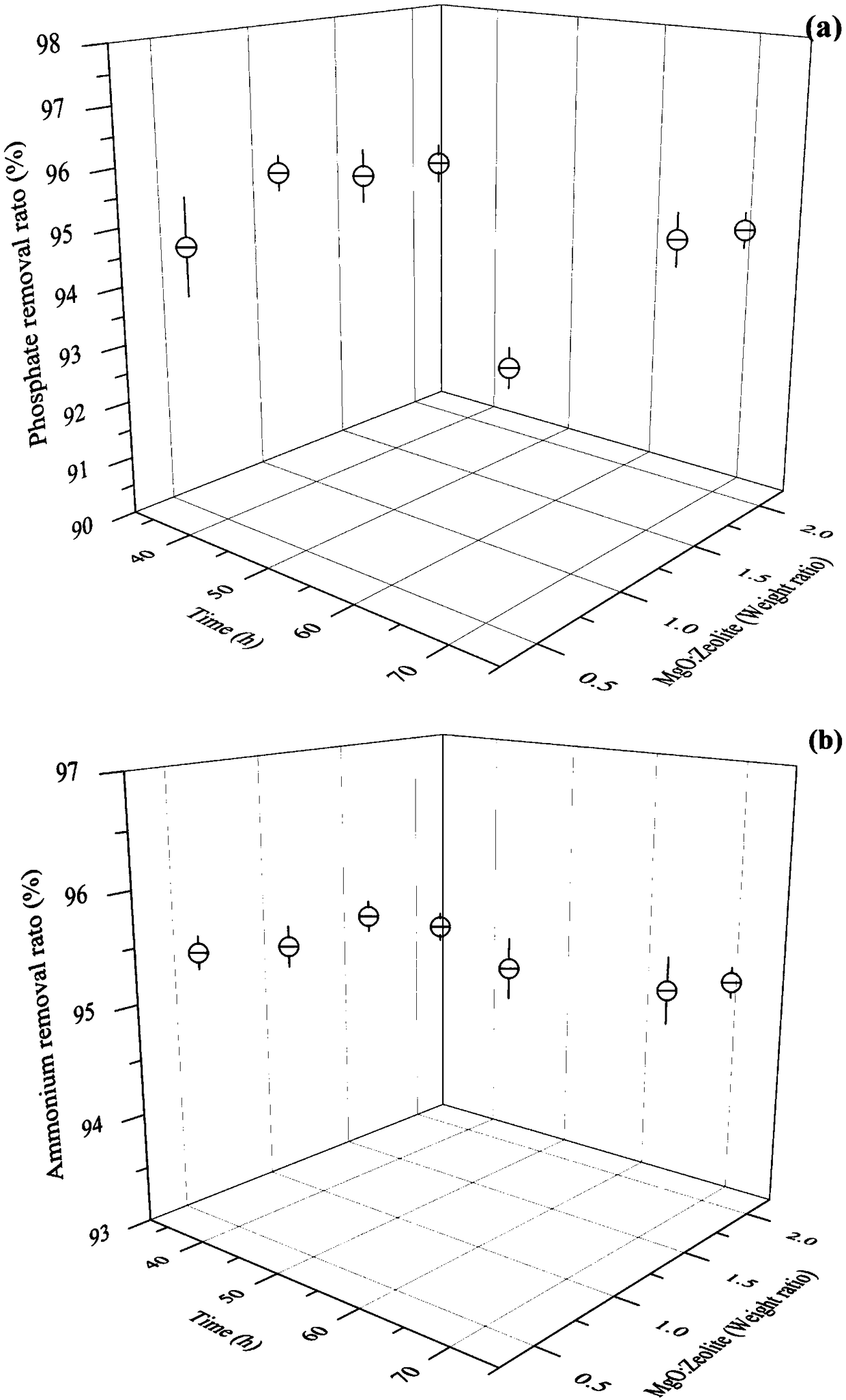

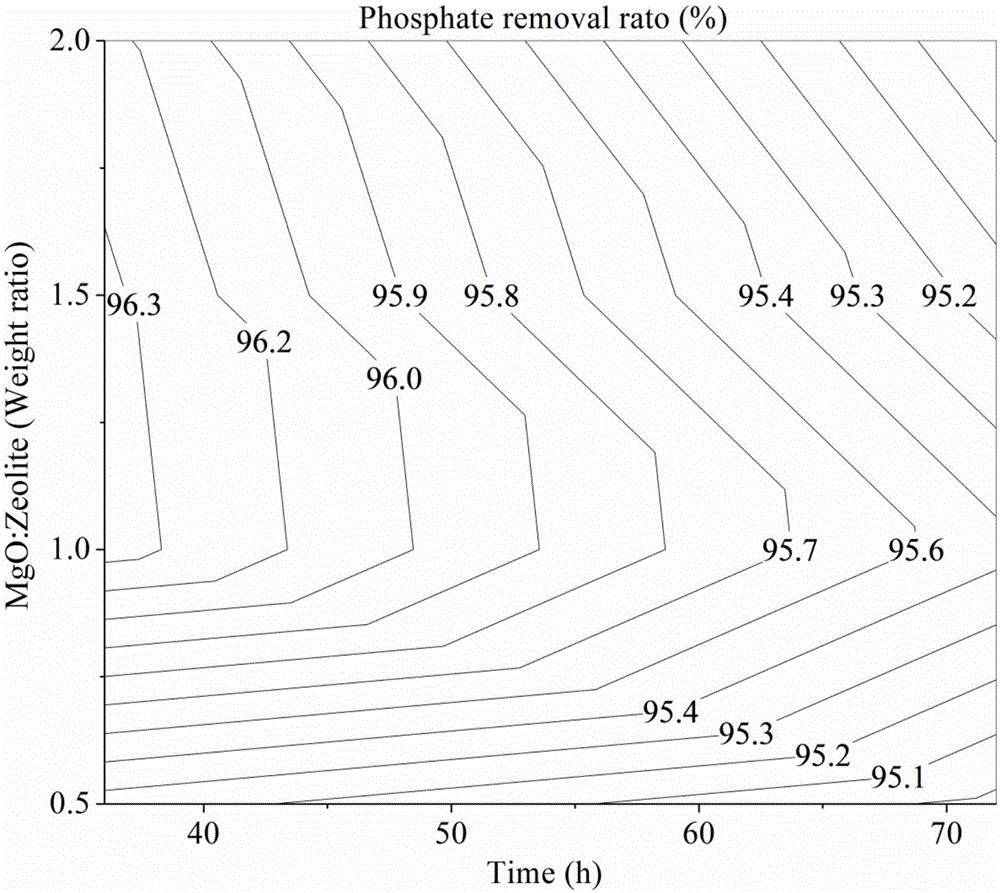

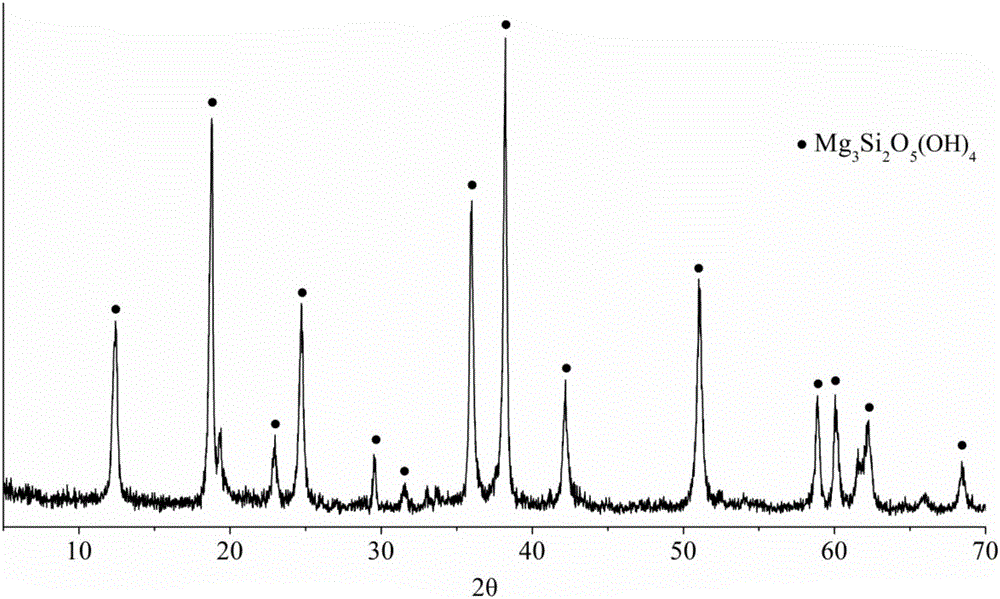

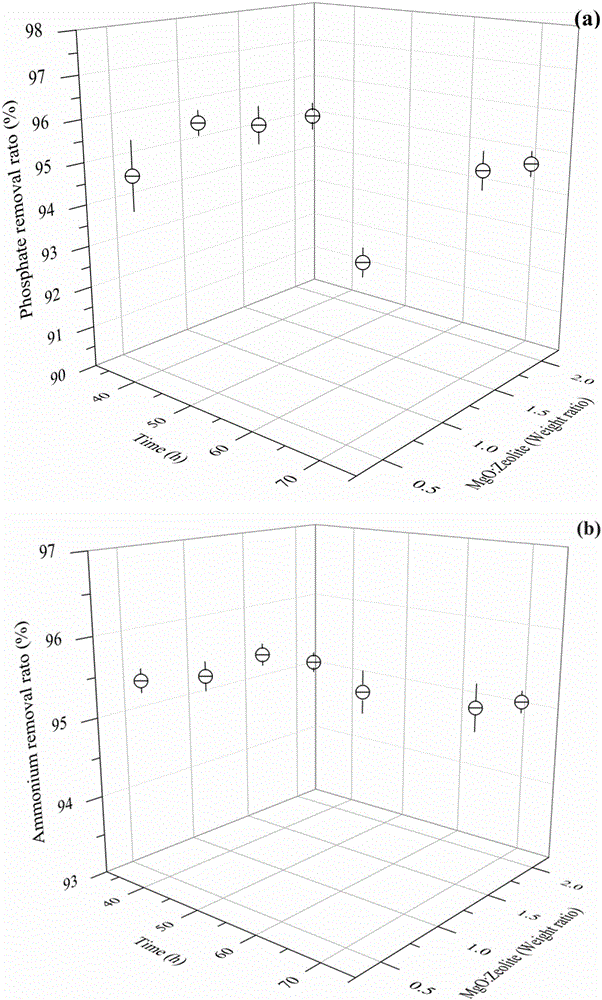

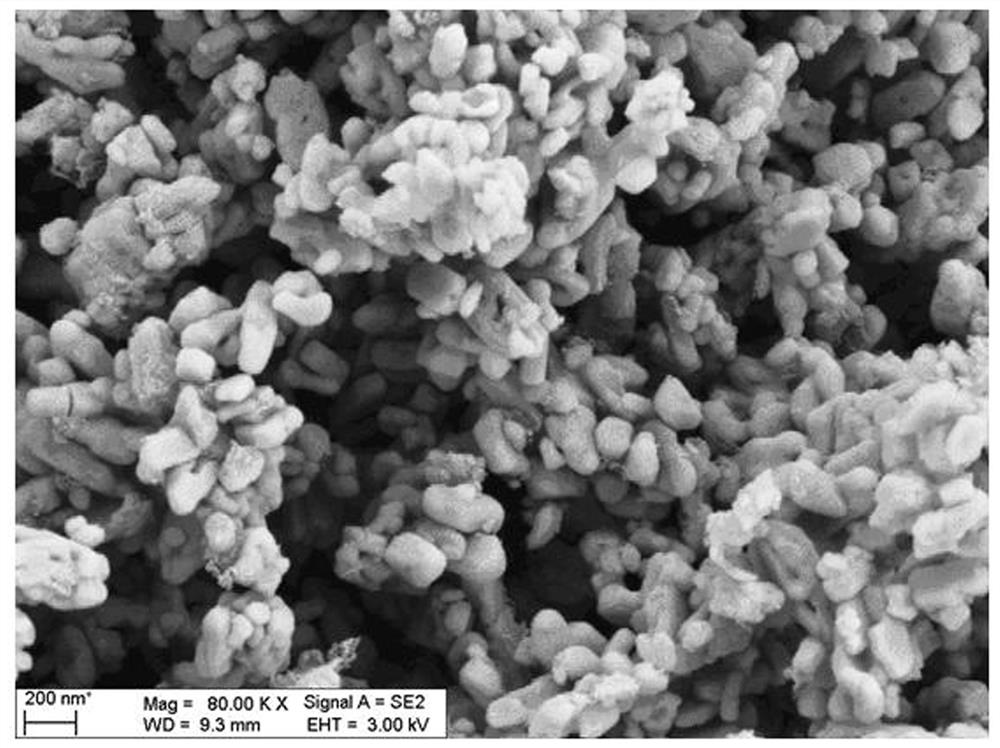

Synchronous denitrification and dephosphorization adsorbent as well as preparation method and application thereof

ActiveCN106111055ASolve the problem of nitrogen and phosphorus removalWide variety of sourcesOther chemical processesAluminium silicatesChemical industryEutrophication

The invention discloses a synchronous denitrification and dephosphorization adsorbent as well as a preparation method and application thereof, and belongs to the field of waste water treatment. The synchronous denitrification and dephosphorization adsorbent disclosed by the invention relates to in-situ treatment of domestic sewage and eutrophication water bodies, and comprises a calcined product of magnesite stone powder and zeolite powder. The synchronous denitrification and dephosphorization adsorbent is made through the following steps of (1) crushing magnesite stone ore, performing screening, and performing high temperature calcination so as to obtain the calcined product; and crushing zeolite, grinding the crushed zeolite, and screening the ground zeolite with a 100-mesh sieve so as to obtain the zeolite powder; and (2) mixing the calcined product with the zeolite powder, performing synthesis by a hydrothermal method, then performing cooling, and performing centrifugal filtration so as to obtain a synthetic product namely the synchronous denitrification and dephosphorization adsorbent. The synchronous denitrification and dephosphorization adsorbent and the preparation method thereof disclosed by the invention can be applied to the in-situ treatment of waste water containing ammonia nitrogen and phosphate, such as the domestic sewage, chemical industry waste water and eutrophication watercourse water bodies.

Owner:JINGDEZHEN CERAMIC INSTITUTE

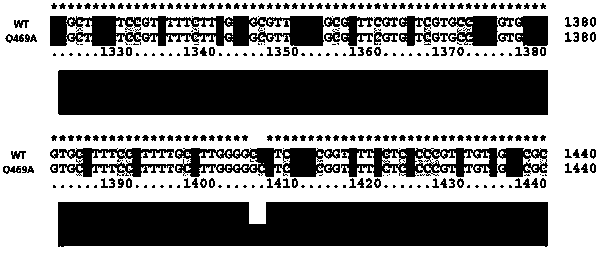

ApNGT gene of actinobacillus pleuropneumoniae and application of ApNGT gene

InactiveCN105505959ABasement efficiency improvementHigh stereoselectivityTransferasesPeptide preparation methodsEscherichia coliActinobacillus pleuropneumoniae

The invention relates to specificity mutation and application of nucleotide at the 1405th bit and the 1406th bit of the ApNGT gene (NCBI:ACCESSION A3N2T3) of actinobacillus pleuropneumoniae. The nucleotide is the nucleotide shown in SEQ ID NO:1 or the nucleotide shown in SEQ ID NO:2. ApNGT is glycosylation transferase coming from actinobacillus pleuropneumoniae, can recognize the N-X-S / T sequence in polypeptide or protein, and can transfer Glucose (Glc) to an Asn residue from an activated donor UDP-Glc. After mutated ApNGT is expressed in actinobacillus pleuropneumoniae, the glycosylation efficiency at the polypeptide level is improved by 160 or more times compared with wild ApNGT, great convenience is provided for galactosylated modification of polypeptide and protein type biological products. Stability of mutated ApNGT is good, and ApNGT can be used as a tool enzyme, can be easily produced in a commercialized mode and has wide application prospects.

Owner:NANKAI UNIV

Visualized detection method of BAR transgenic crops

InactiveCN102787175ASimple detectionEasy to synthesizeMicrobiological testing/measurementGenetic engineeringReal-time polymerase chain reaction

The invention belongs to the technical field of genetic engineering and relates to a detection technology of transgenic crops, in particular to a visualized detection method of BAR transgenic crops. The method comprises steps as follows: adding DNAzyme-marked specific probes for detecting the BAR gene into a PCR (polymerase chain reaction) system, amplifying the BAR gene by forward and reverse primers, releasing the DNAzyme markers from the probes by exonuclease activity of nucleic acid polymerase 5'-3', and detecting the markers released from the PCR product to judge whether the sample is a transgenic sample or not. The method provided by the invention has the characteristics of being efficient and convenient and low in cost and the like.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

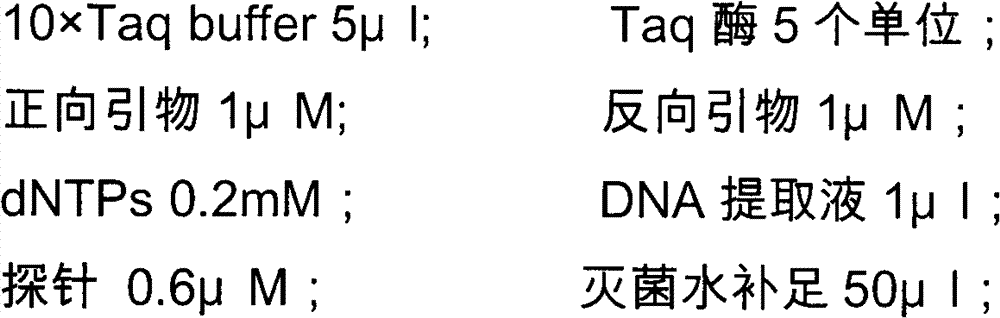

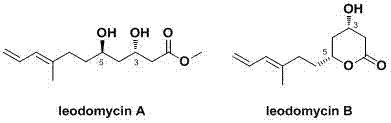

Method for stereoselective synthesis of IeodomycinA and B

InactiveCN103755568AHigh synthesis costInnovative design ideasOrganic compound preparationCarboxylic acid esters preparationWittig reaction3-chloroperbenzoic acid

The invention relates to a method for asymmetric synthesis of chain nonsaturated ester IeodomycinA and B. The method utilizes geraniol as a raw material and through Swern oxidation, 3-chloroperbenzoic acid epoxidation reaction, Wittig reaction and periodic acid oxidation cutting-off reaction, an intermediate 5 is prepared. Through a two-step reaction with trimethylchlorosilane, methyl acetoacetate as an intermediate 2 is prepared. Silyl enol ether 8 and aldehyde 5 are synthesized into a key intermediate 9 in the presence of a titanium tetraisopropanolate / (S)-BINOL as a catalyst. Through hydroxyl-induced reduction reactions, the end product IeodomycinA and B are synthesized. The method comprises the eight steps, has a simple and reasonable design, utilizes cheap raw materials and has a high product yield. The IeodomycinA and B have high optical purity.

Owner:JIANGXI SCI & TECH NORMAL UNIV

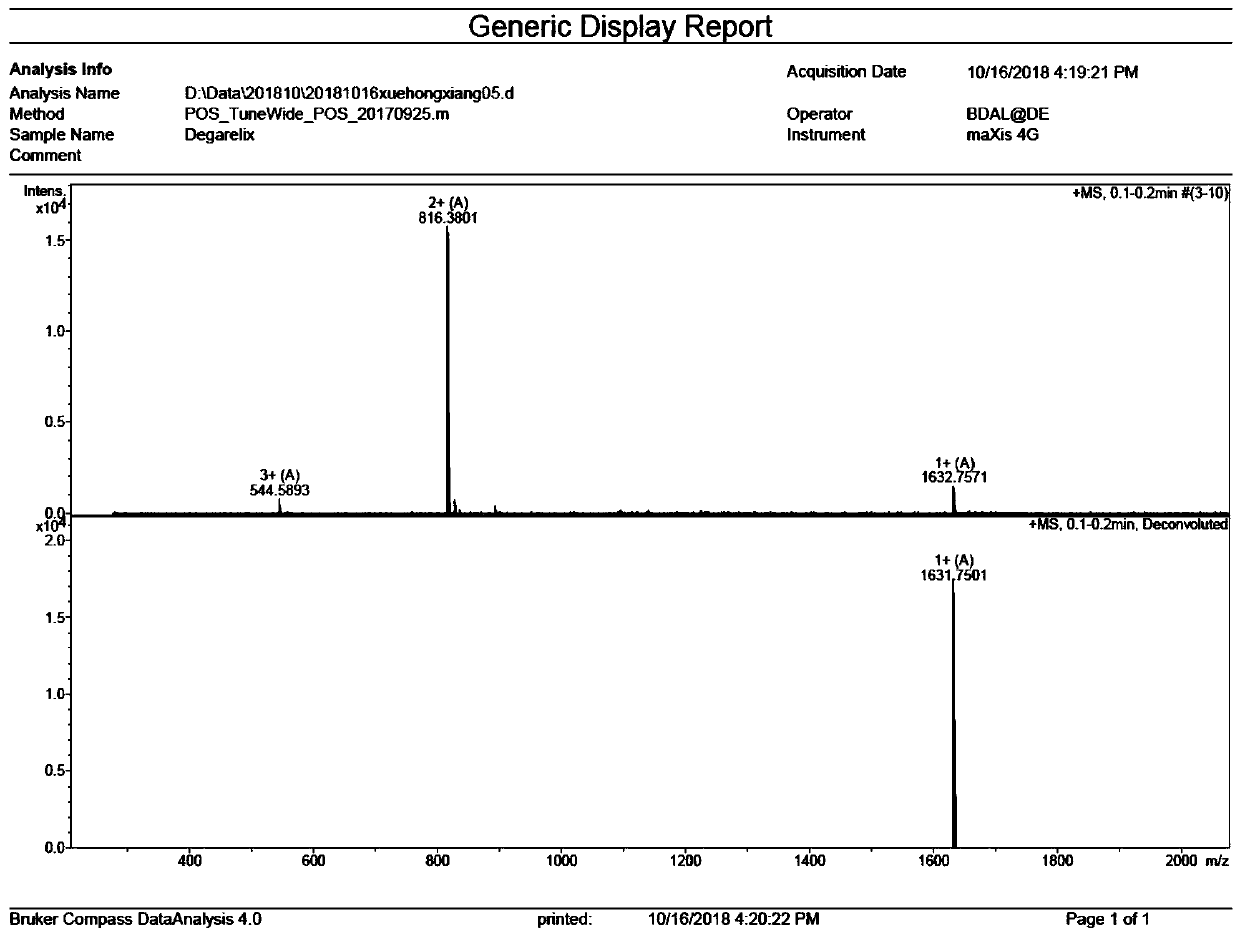

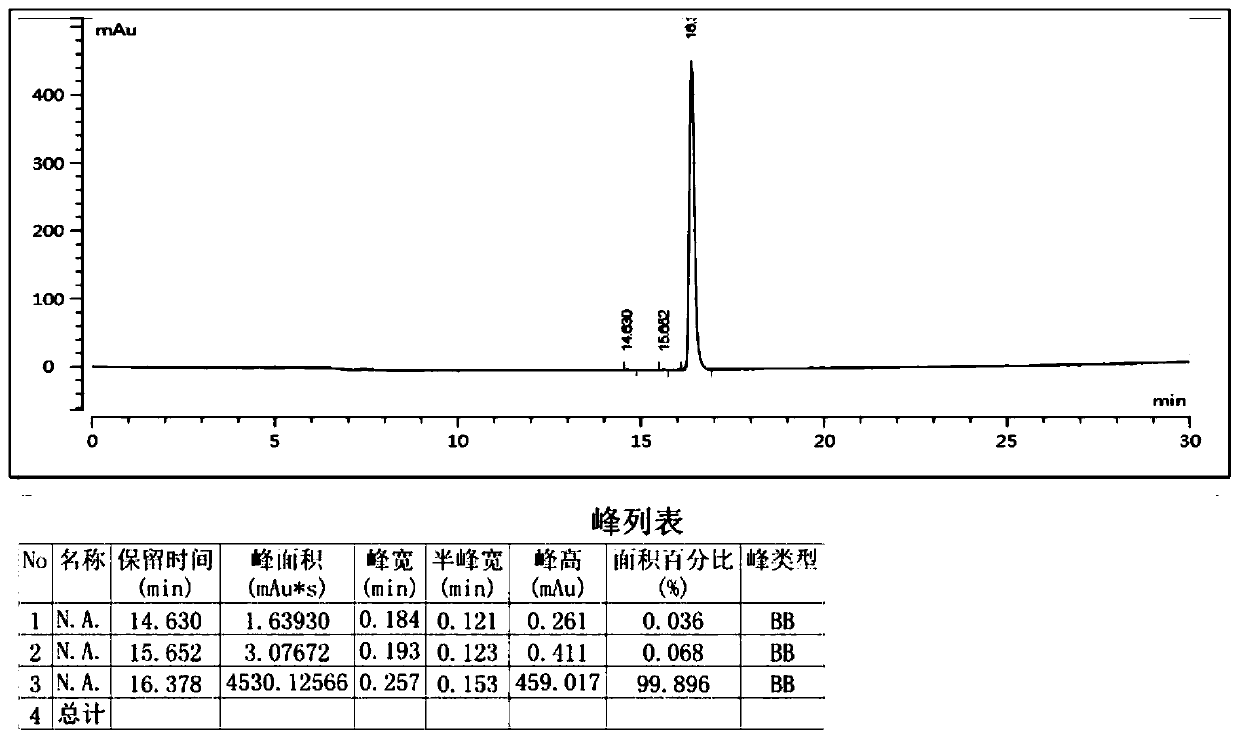

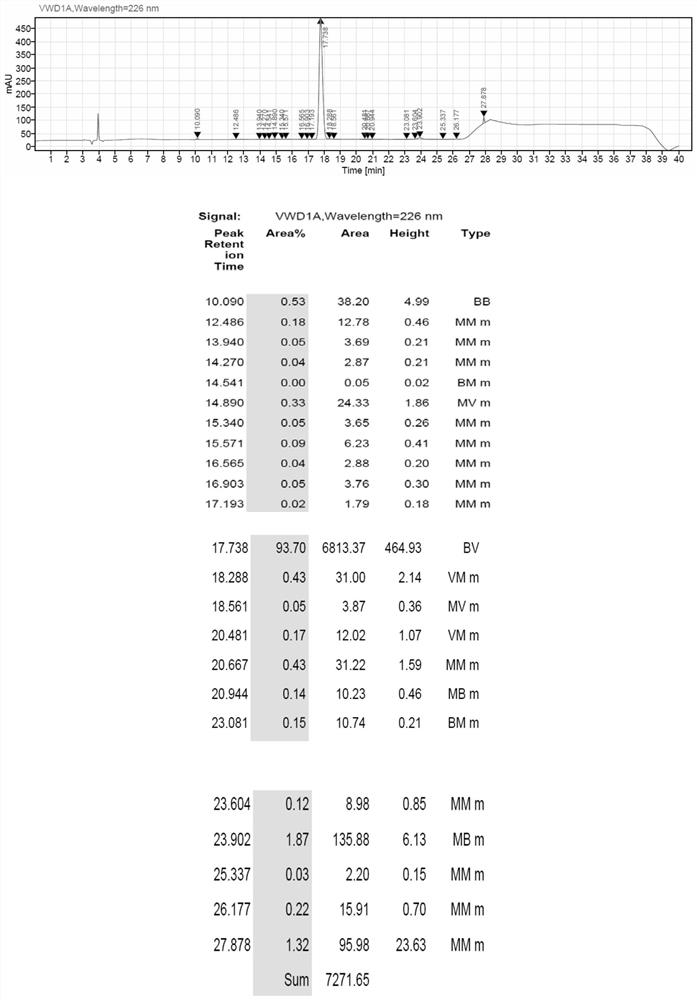

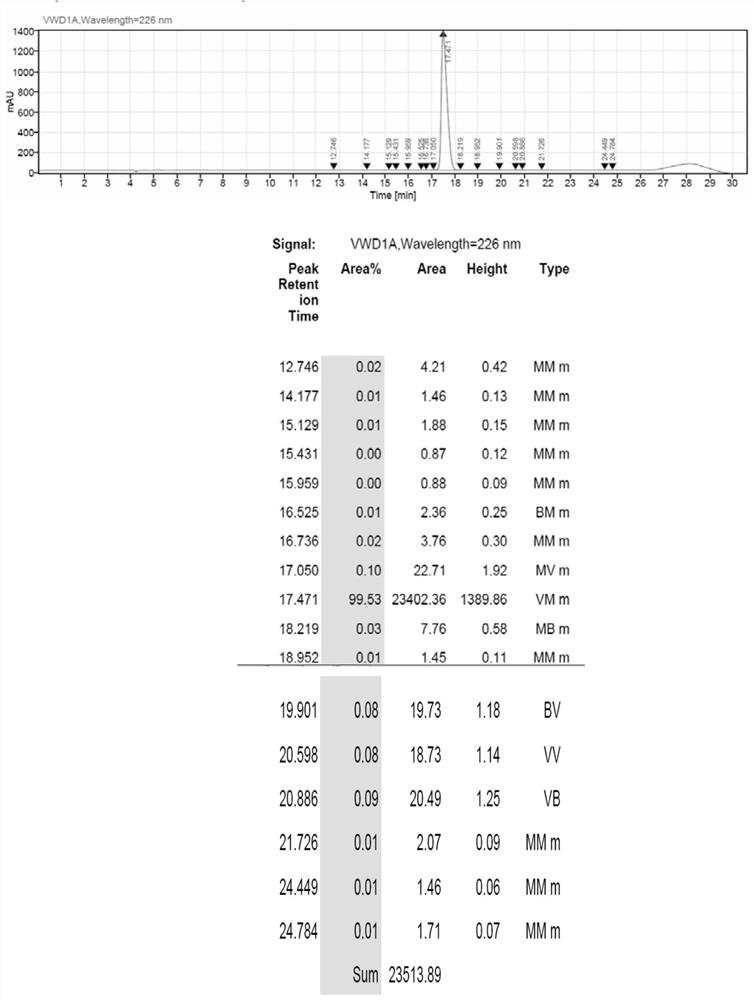

Method for preparing degarelix through fragment condensation

ActiveCN109575109AHigh purityHigh yieldLuteinising hormone-releasing hormonePeptide preparation methodsSide chainProtecting group

The invention discloses a method for preparing degarelix through fragment condensation. Three side chain protection peptide fragment sequences are respectively synthesized; each peptide fragment is gradually coupled to obtain whole protection degarelix ; then, protecting groups are removed through cracking so as to obtain degarelix crude peptides; purification and salt replacement are performed toobtain the degarelix, wherein the three peptide fragment sequences are as follows, the first peptide fragment sequence is 1st to 4th site amino acids in the degarelix sequence; the second peptide fragment sequence is 5th to 8th site amino acids in the degarelix sequence; the third peptide fragment sequence is 9th to 10th site amino acids in the degarelix sequence. The method provided by the invention has the advantages that the impurities are removed; the yield is improved; the synthesis cost is greatly reduced; the large-scale industrialized production is facilitated.

Owner:LANZHOU UNIVERSITY

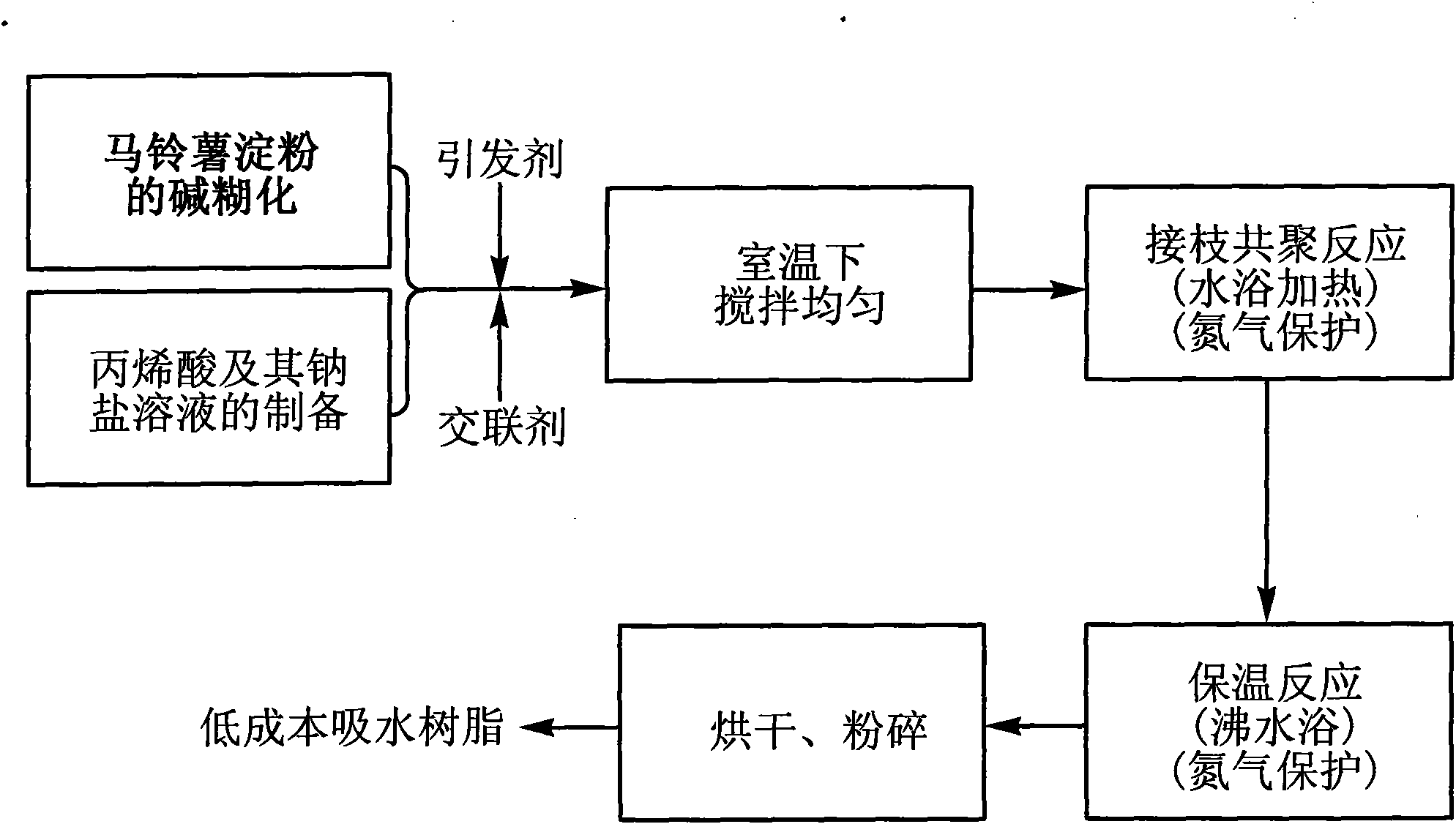

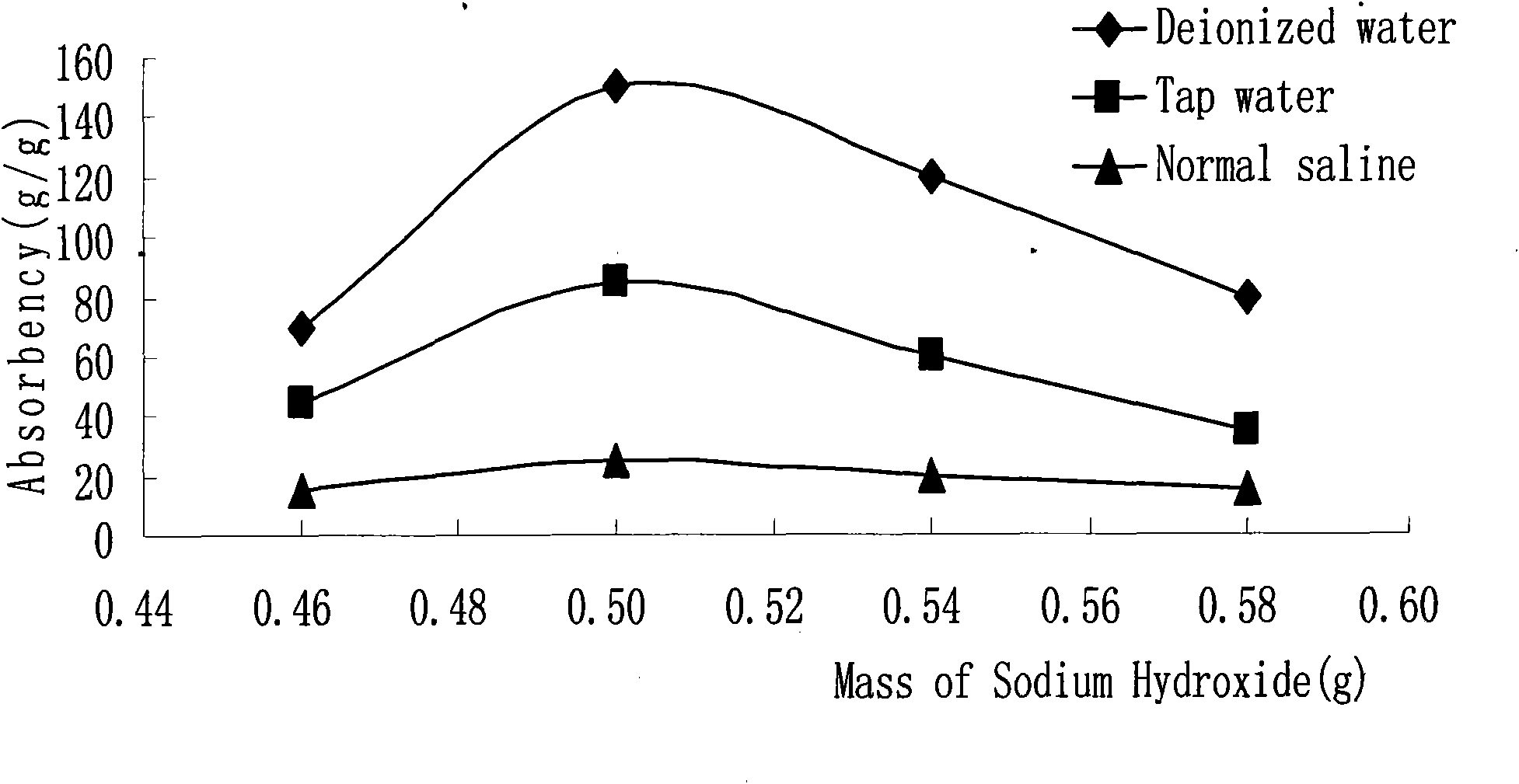

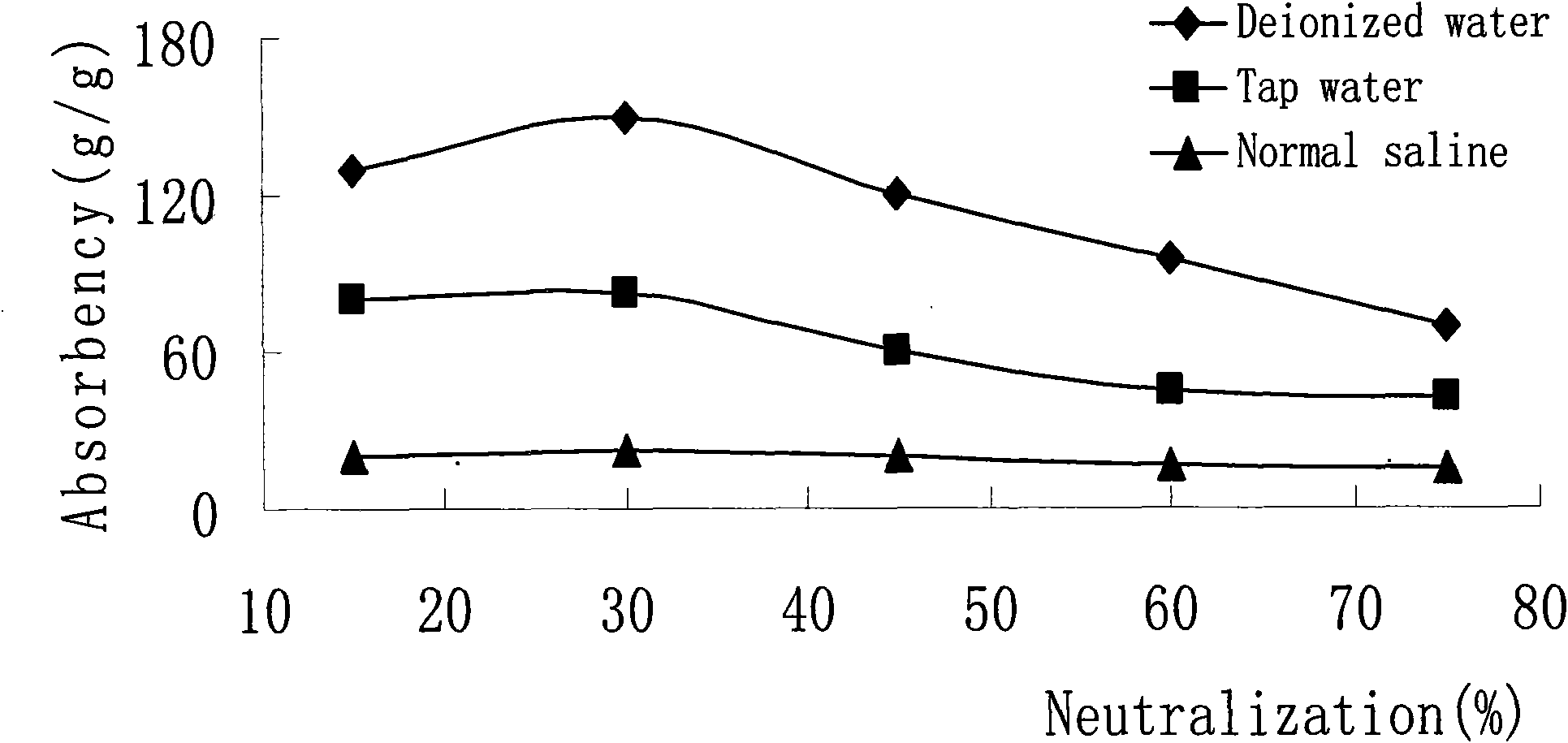

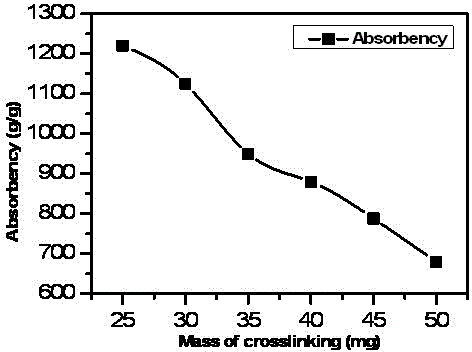

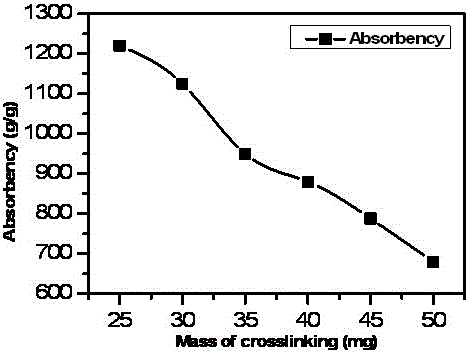

Method for synthesizing low-cost and super-absorbent resin from potato starch serving as raw material

The invention discloses a new process for synthesizing a low-cost super-absorbent resin. The process mainly comprises the following steps of: preparing strong caustic solution with a certain concentration, dropwise adding the strong caustic solution into a potato starch milk at a room temperature to obtain alkali pasted potato starch, heating the alkali pasted potato starch in water bath under the protection of nitrogen, performing graft copolymerization on the alkali pasted potato starch, crylic acid and sodium salt of the crylic acid to obtain the low-cost super-absorbent resin, wherein the low-cost super-absorbent resin has good liquid absorption ability; the highest deionized water absorptivity is 150-450g / g; the highest water absorptivity is 80-200g / g; the highest normal saline absorptivity is 25-40g / g; and the gel state is good and the water holding ability is strong after absorbing water. In the invention, the strong caustic solution is totally used to paste the potato starch milk; and the alkali pasted potato starch prepared by the method is used to synthesize the low-cost super-absorbent resin for the first time. Compared with other preparation methods of the super-absorbent resin, the method of the invention has the advantages of novel proportioning of raw materials, low cost, simple process, low energy consumption, is easy to operate and control, and develops a new path to large-scale production of the super-absorbent resin in the future.

Owner:INNER MONGOLIA UNIVERSITY

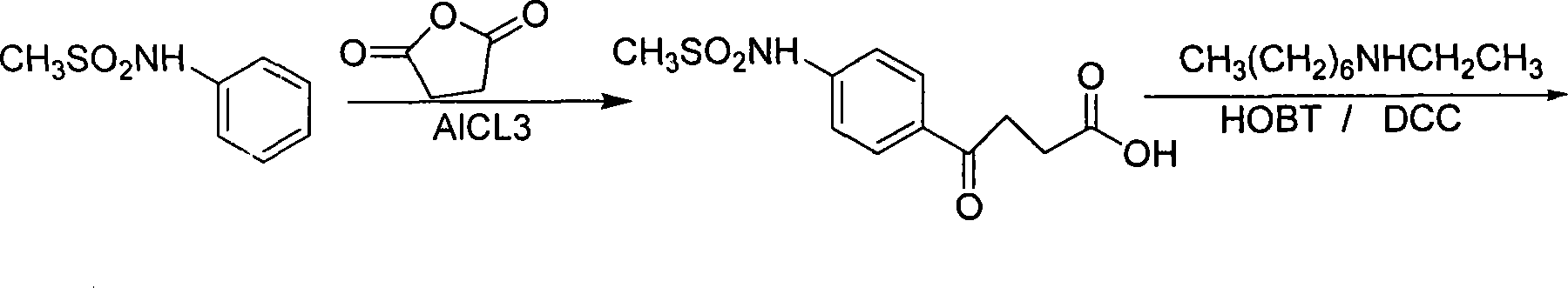

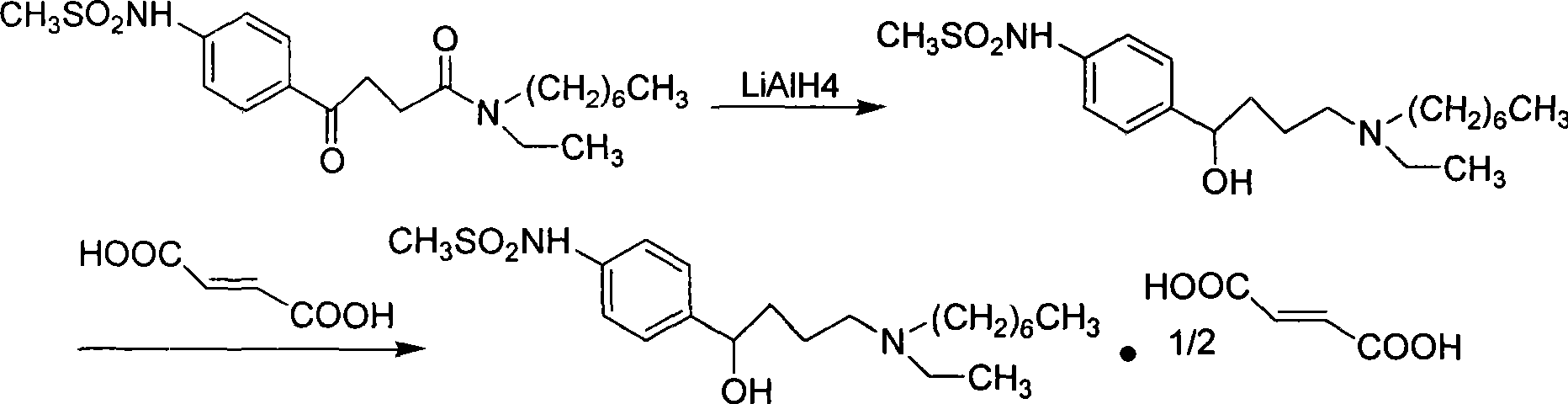

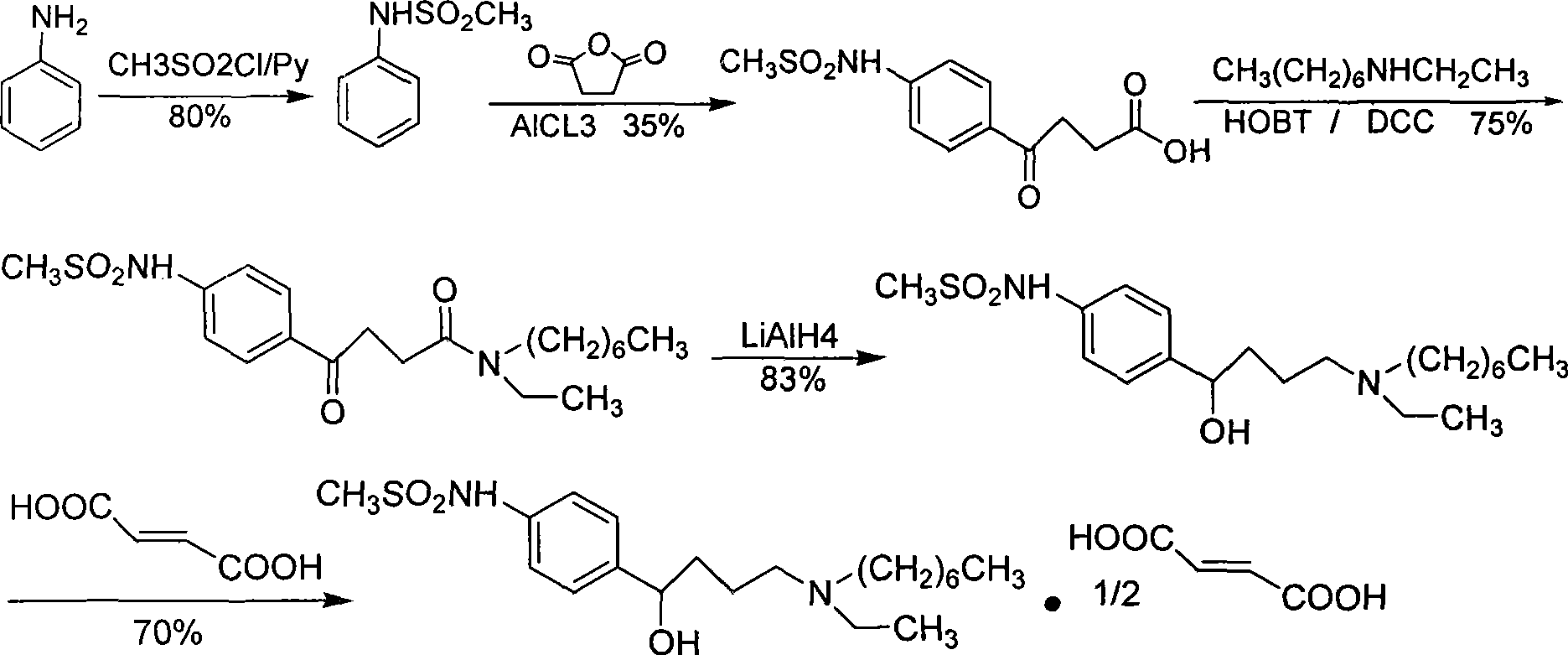

Ibutilide fumarate synthetic process

InactiveCN101381332AHigh synthesis costHigh yieldSulfonic acid amide preparationCardiovascular disorderAluminateFumaric acid

The invention relates to a process for synthesizing ibutilide fumarate. 2-pyrrolidone is taken as an initial raw material, DMF is taken as a solvent, and the 2-pyrrolidone and the DMF are N-alkylated with halogen ethane to obtain N-ethyl-butyrolactam under the catalysis; then 4-ethylamino-ethyl acetic acid is obtained through acid hydrolysis; the 4-ethylamino-ethyl acetic acid reacts with chloroheptane under the catalysis to obtain 4-ethylheptylamino-ethyl acetic acid; 4-ethylheptylamino-n-butyryl chloride is obtained through the acidylation; and the 4-ethylheptylamino-n-butyryl chloride is subjected to friedel-crafts reaction with N-phenylmethanesulfonamide to obtain (+ / -)-N-[4-[4-(ethylheptylamino)-1-ketonebutyl]phenyl] methanesulfonamide, (+ / -)-N-[4-[4-(ethylheptylamino)-1-hydroxybutyl]phenyl] methanesulfonamide is obtained by reducing sodium borohydride and / or tetrahydro-aluminate lithium, and then a target compound, namely the tetrahydro-aluminate lithium is obtained by salifying with fumaric acid. The process is more reasonable and is more convenient for industrialized production.

Owner:重庆医科大学医药研究所

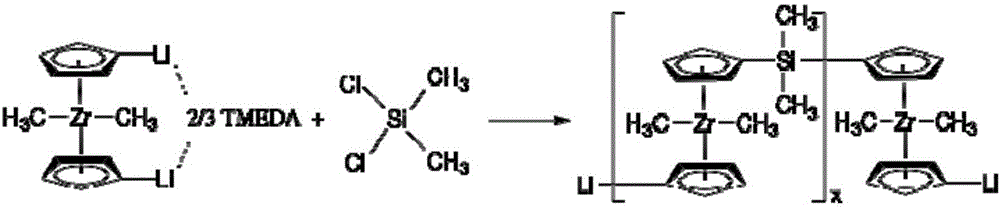

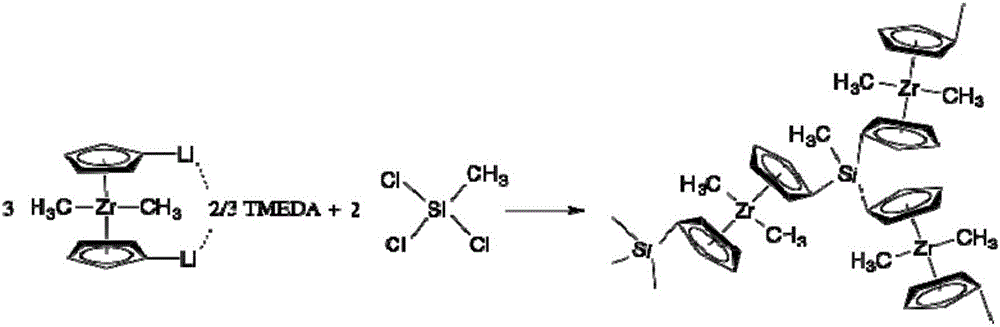

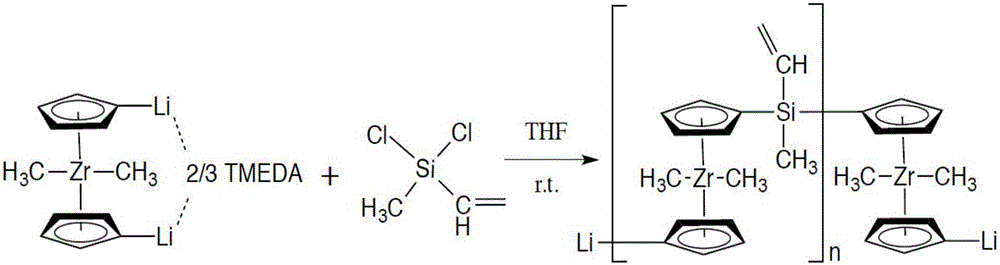

Normal-temperature and normal-pressure synthesizing method of Zr-Si-C ceramic precursor

The invention relates to a normal-temperature and normal-pressure synthesizing method of a Zr-Si-C ceramic precursor. The normal-temperature and normal-pressure synthesizing method includes the steps of firstly, dissolving dimethyl zirconium dicyclopentadiene in an organic solvent under inert gas atmosphere protection, stirring, adding an organic lithium compound and a ligand compound, and drying to obtain active zirconium dicyclopentadiene lithium salt; secondly, dissolving the active zirconium dicyclopentadiene lithium salt with an organic solvent under inert gas atmosphere protection, stirring, adding halogenated silane monomer, performing polymerization reaction, dropwise adding a terminating agent to terminate the reaction, filtering, concentrating, purifying, and drying to obtain the Zr-Si-C ceramic precursor. The normal-temperature and normal-pressure synthesizing method has the advantages that conditions such as high temperature, low temperature, high pressure and energizing are not needed, the reaction can be performed under normal temperature and normal pressure, the dimethyl zirconium dicyclopentadiene high in activity and cheap and safe n-butyl lithium are used to have reaction with the halogenated silane monomer so as to prepare the Zr-Si-C ceramic precursor through a two-step method, and the preparation method is simple, scientific and reasonable; the Zr-Si-C ceramic precursor synthesized by the method is diversified and can be used for prepared various kinds of Zr-Si-C ceramics.

Owner:NAT UNIV OF DEFENSE TECH

New method for solid-phase synthesis of side-chain-protected peptide chain

InactiveCN101628929AImprove efficiencyHigh synthesis costPeptide preparation methodsBulk chemical productionSolid phasesSide chain

The invention relates to a new method for solid-phase synthesis of side-chain-protected peptide chain, which belongs to the technical fields of solid synthesis and preparation of organic compounds and polypeptides. During the peptide chain synthesis, in order to obtain large peptide chain segments, the peptide chain segments protected by the side chains are spliced in liquid phase. When the common polypeptide solid phase synthesis resin is subjected to peptide chain synthesis, the peptide chains are cut off from the resin by acid cracking reagent, side chain protecting groups of the peptide chains are simultaneously released, and then unprotected peptide chains are obtained. A handle is connected with the resin to improve the resin, the peptide chain synthesis is carried out on the 'handle', the peptide chains are cut off from the 'handle' under weak alkaline condition, and the side chain protecting groups can not be released, therefore, the invention can be used for the solid synthesis of side-chain-protected peptide chain.

Owner:中国人民解放军防化学院

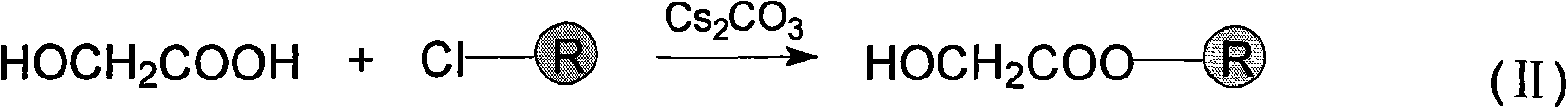

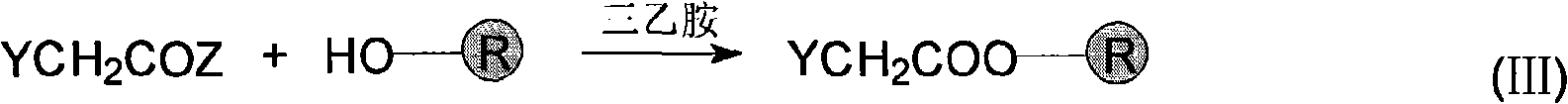

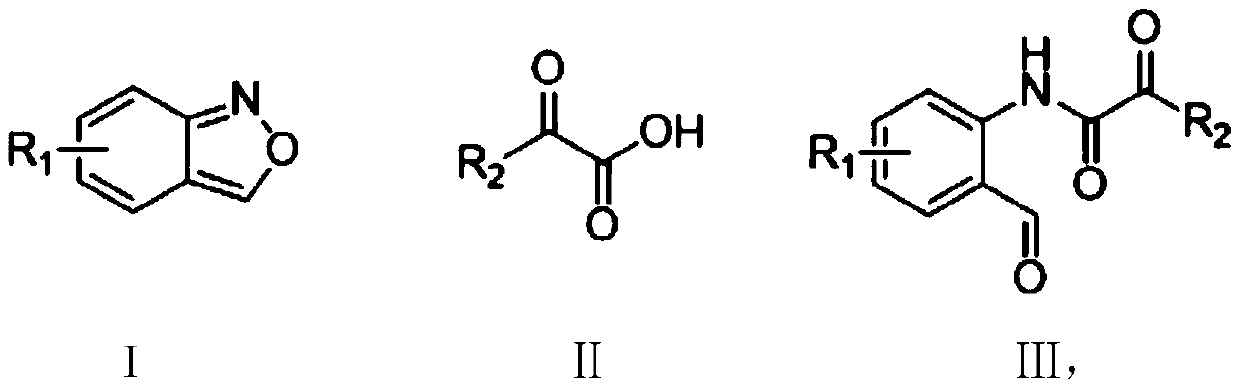

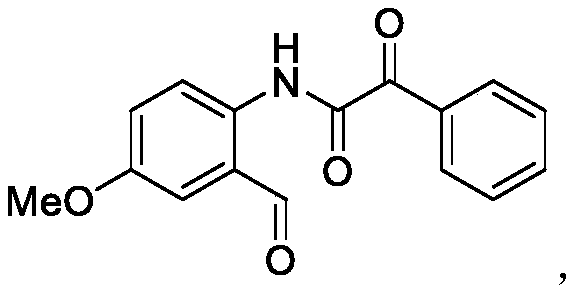

Method for synthesizing ortho-aldehyde group-containing alpha-ketoamide compound

ActiveCN109776488ALow priceReduce dosageOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzeneOrganic solvent

The invention discloses a method for synthesizing an ortho-aldehyde group-containing alpha-ketoamide compound. Benzo[c]isoxazole shown in formula I and benzoyl formic acid shown in formula II are dissolved in an organic solvent and react in an inert atmosphere under the function of a catalyst, and an obtained reaction liquid is purified to obtain the ortho-aldehyde group-containing alpha-ketoamidecompound shown in formula III. The method has the advantages that the adopted raw materials are low in cost, the method is environmentally friendly, the use quantity of the catalyst is small, the catalytic efficiency is high, and the application range of substrates is wide. The formulas are show in the description.

Owner:JIANGNAN UNIV

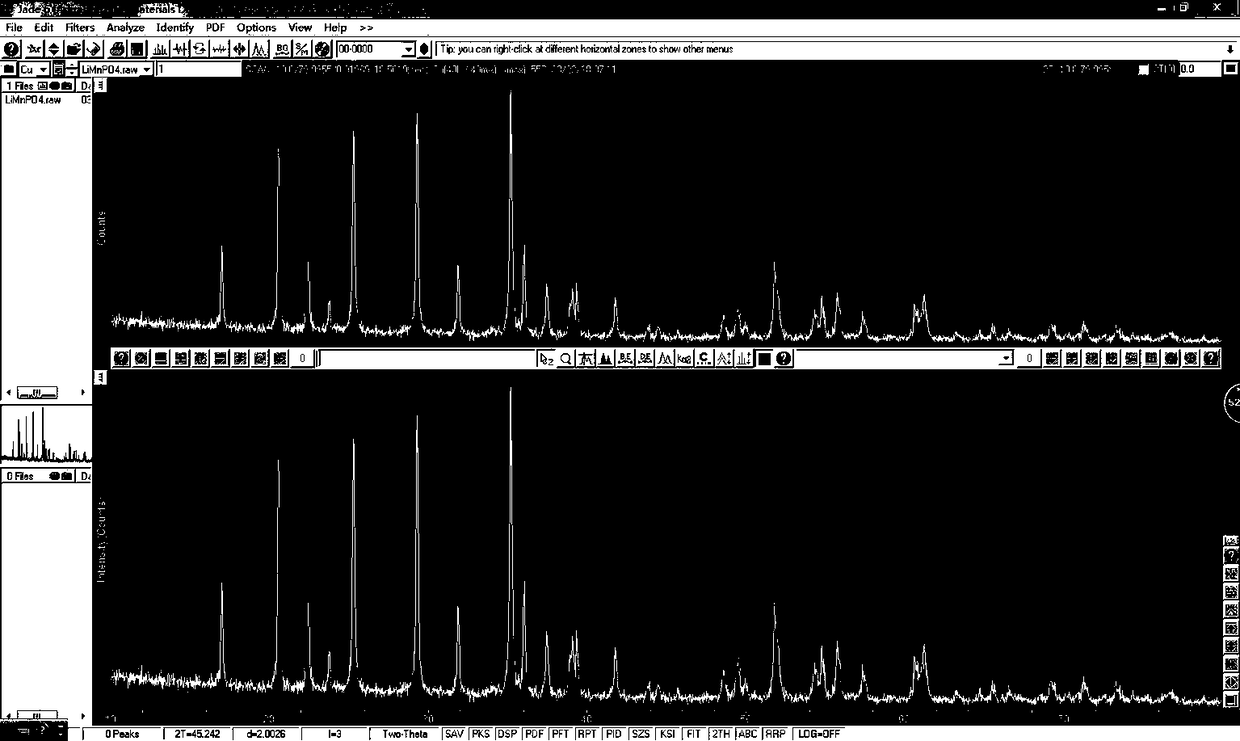

Preparation method of EU-1/MOR (mordenite) co-crystallized molecular sieve

ActiveCN103803574AAvoid it happening againHigh synthesis costCrystalline aluminosilicate zeolitesMolecular sieveHazardous substance

The invention discloses a preparation method of an EU-1 / MOR (mordenite) co-crystallized molecular sieve. The method is as follows: according to the mol ratio of 9-13Na2O:40-65SiO2:A12O3:2200-4000H2O, mixing an inorganic alkali, a silicon source, an aluminum source and water to make an initial silicon aluminum gel, then adding EU-1 molecular sieve, wherein the mass ratio of the added EU-1 molecular sieve and the added silicon source by SiO2 is 0.05-0.20, after even mixing, crystallizing at 180-240 DEG C for 15-70h, then separating, washing and drying to obtain the EU-1 / MOR (mordenite) co-crystallized molecular sieve. According to the method, the EU-1 / MOR (mordenite) co-crystallized molecular sieve can be synthesized without use of an organic template agent, and raw materials for the synthesis are conventional inorganic materials, and do not contain toxic and harmful substances, so that the whole preparation process is green and environmental-friendly, and the operation process is simple and easy.

Owner:CHINA PETROLEUM & CHEM CORP +1

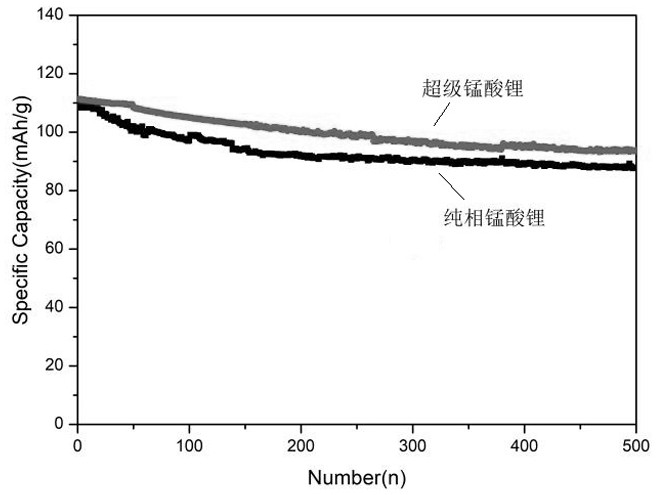

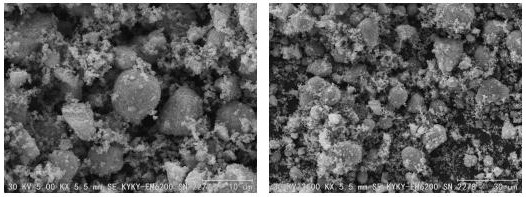

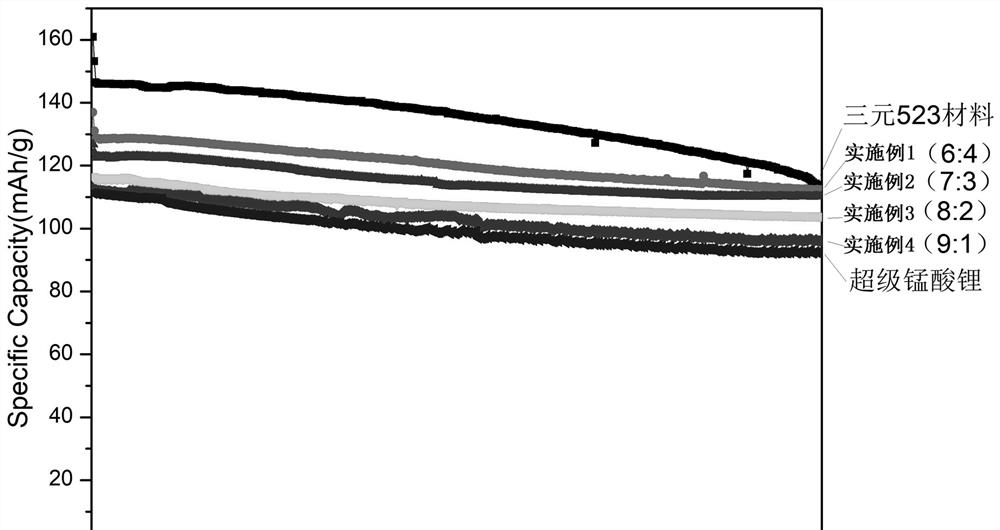

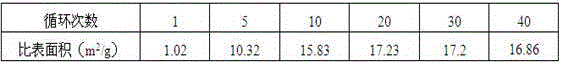

Composite positive electrode material of aluminum-titanium double-doped lithium manganate and 523-type ternary material and preparation method of composite positive electrode material

InactiveCN111816875AImprove long-cycle performanceHigh synthesis costSecondary cellsPositive electrodesManganateManganese

The invention discloses a composite positive electrode material of an aluminum-titanium double-doped lithium manganate and 523-type ternary material. The composite positive electrode material is mainly characterized in that an aluminum-titanium double-doped method is adopted to modify a lithium manganate material to obtain an aluminum-titanium double-doped lithium manganate material with stable cycle performance; and then the 523-type ternary spherical material with good sphericity and high specific capacity is prepared, the two materials are subjected to wet ball milling and mixing to obtainthe composite positive electrode material of the aluminum-titanium double-doped lithium manganate and 523-type ternary material, and the composite positive electrode material is uniform in mixing, relatively high in specific capacity and excellent in cycle performance. According to the composite positive electrode material, the aluminum-titanium double-doped lithium manganate is mixed with the 523-type ternary spherical material, so that the specific capacity and the cycle performance of the composite positive electrode material can be effectively improved, the material cost can be reduced, the high-oxidation-state deterioration condition of the ternary material can be effectively slowed down, and meanwhile, the formation of lithium dendrites is avoided, so that the safety performance of the composite positive electrode material is improved.

Owner:淮安新能源材料技术研究院

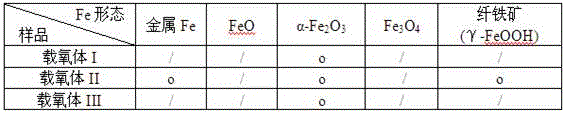

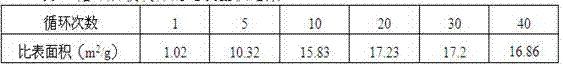

Chemical looping combustion oxygen carrier and application method thereof

ActiveCN106367156AHigh reactivityImprove mechanical propertiesIndirect carbon-dioxide mitigationFuel additivesCombustion systemResource recovery

The invention discloses a chemical looping combustion oxygen carrier, which is characterized in that the chemical looping combustion oxygen carrier is sintering return mine comprising an active component being alpha-Fe2O3 with the mass percent of 60 to 80 percent, and inert components comprising the following ingredients in mass percent: 10 to 15 percent of CaO, 0 to 2 percent of Al2O3, 5 to 15 percent of SiO2, and the balance of impurities. The oxygen carrier (sintering return mine) in the invention has favorable reactivity and mechanical property, is sintered ore which is not sinter molded at a sintering workshop section in the metallurgical industry, and can be applied in a chemical looping combustion system for realizing resource recovery and recycle; according to a method, the sintering return mine in the metallurgical industry is used as the oxygen carrier in the chemical looping combustion system, has favorable reactivity and mechanical property, and is low in cost, rich in inventory, and beneficial to be applied in actual industrial production.

Owner:GUIZHOU INST OF TECH

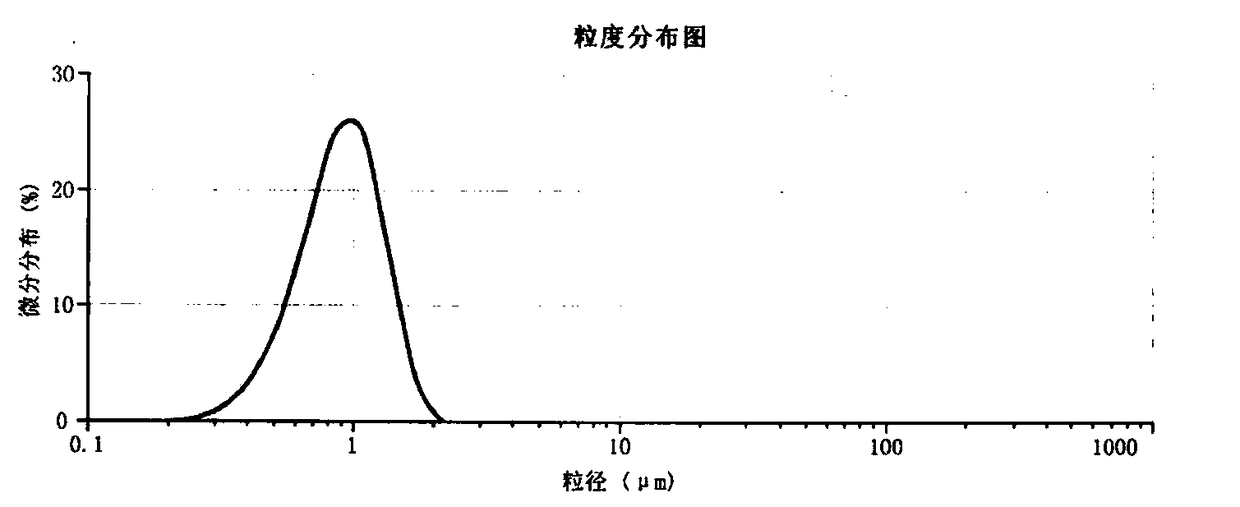

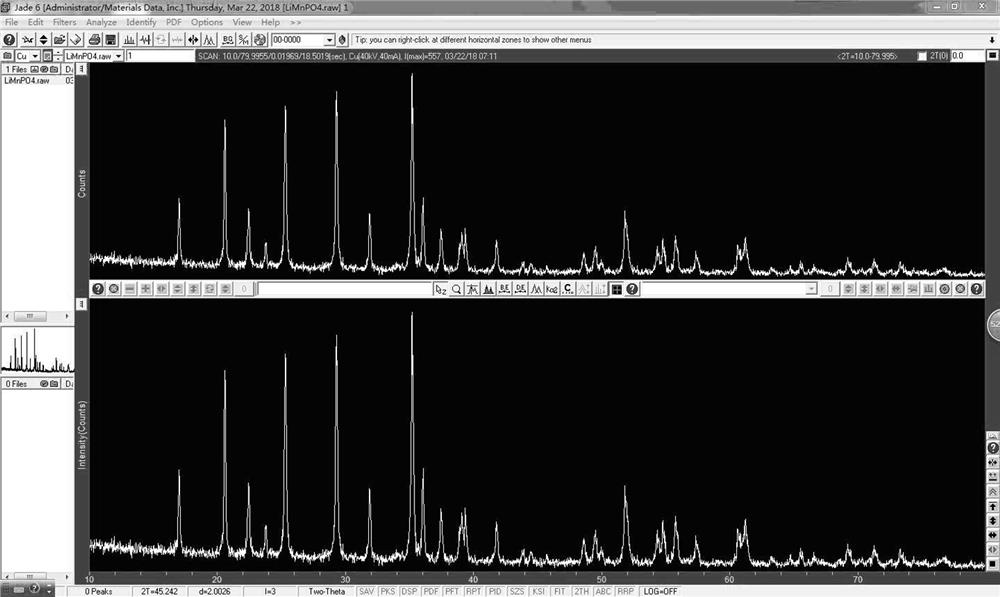

Preparation method of pollution-free low-cost lithium manganese ferric phosphate crystal material

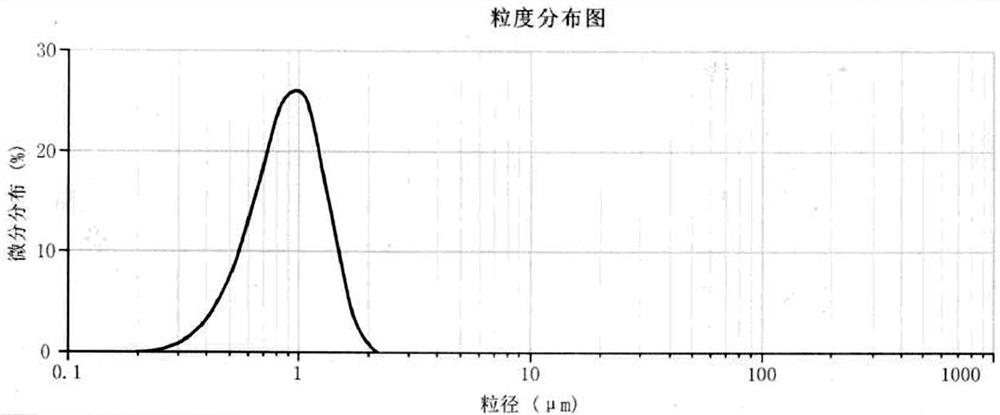

ActiveCN108408709AImprove the level ofWidely sourced, non-toxic and cheapCell electrodesPhosphorus compoundsEnvironmental resistanceLithium hydroxide

The invention discloses a preparation method of a pollution-free low-cost lithium manganese ferric phosphate crystal material. The preparation method includes following steps: selecting iron powder and manganese powder high in purity, wherein granularity is selected from 20-20000 meshes; taking the manganese powder, the iron powder, phosphoric acid and a lithium source solution according to a certain mass ratio, diluting, putting them into an acid-resistant reactor, and stirring to enable the iron powder, the manganese powder and the phosphoric acid to be in sufficient reaction; adding the lithium source solution into obtained reaction precursor size, and sufficiently stirring, wherein the lithium source solution is soluble lithium source lithium hydroxide or lithium acetate; transferringobtained size into a reaction kettle, and starting hydrothermal reaction; performing solid-liquid separation on size obtained after reaction, and subjecting solid lithium manganese ferric phosphate which is separated out to clathration carbonization annealing treatment to obtain the lithium manganese ferric phosphate crystal material. Compared with the prior art, the preparation method has the advantages that cost is low, process operation is convenient, the material is high in commercial value, the preparation process is free of pollution, and current requirements on environment protection are met.

Owner:南阳逢源新能源科技有限公司

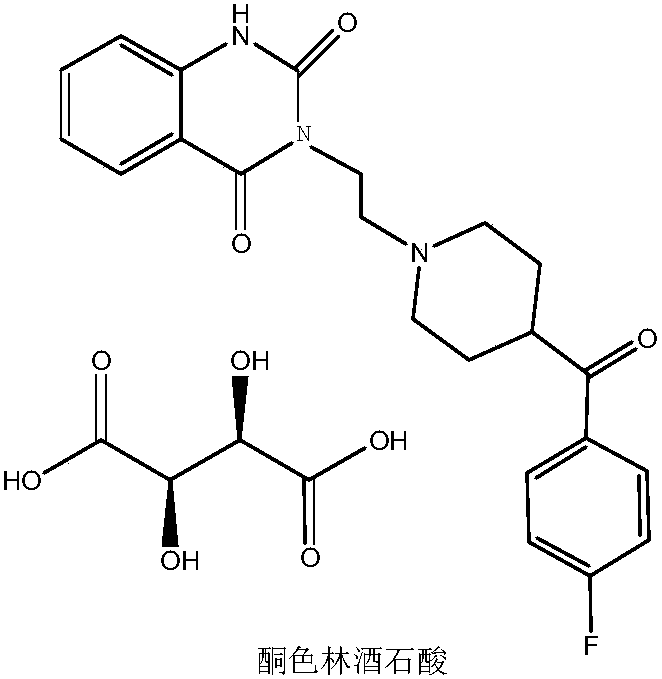

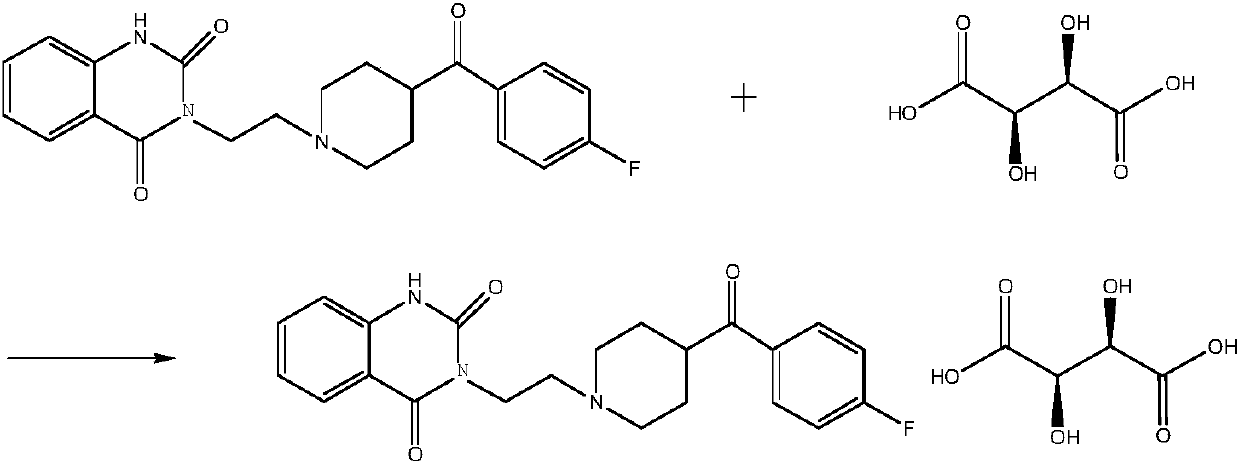

Preparation method of cardiovascular drug ketanserin tartrate

InactiveCN109836411AReduce pollutionProcess synthesis steps are simpleCarboxylic acid salt preparationCardiovascular drugKETANSERIN TARTRATE

The invention belongs to the field of drug synthesis, and provides a ketanserin tartrate preparation method, wherein ketanserin and DL-tartaric acid are used as raw materials, ethanol is used as a solvent, heating dissolving is performed, and the target product is directly obtained through crystallization. According to the present invention, with the method, the total yield can reach 80%, and theproduct purity exceeds 99.0%; and the method has advantages of simple process synthesis steps, substantially reduced production cost and low environment pollution, and substantially alleviates the environmental problem caused by the production of ketanserin tartrate.

Owner:辽宁博美医药科技有限公司

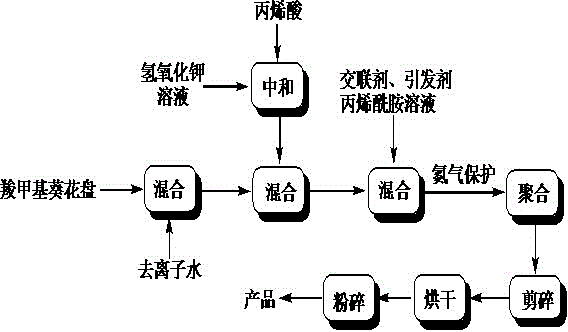

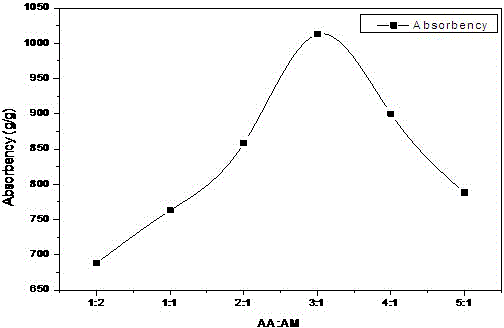

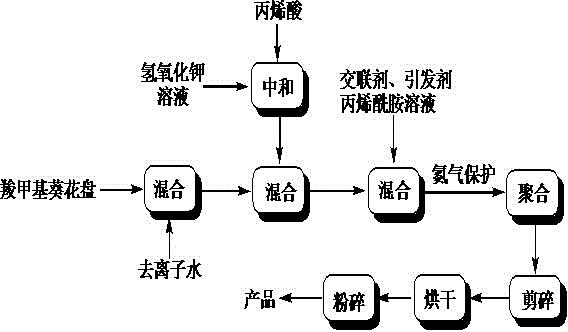

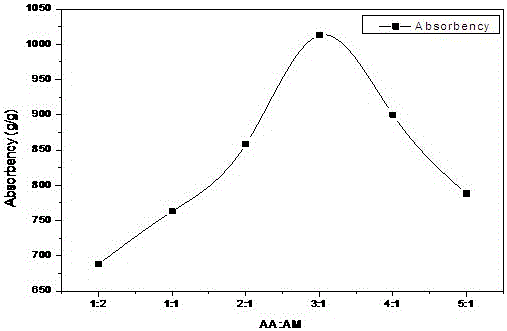

Method for preparing nitrogen and potassium containing super absorbent resin by utilizing carboxymethyl sunflower disc

The invention discloses a method for preparing nitrogen and potassium containing super absorbent resin by utilizing a carboxymethyl sunflower disc. The method for preparing the nitrogen and potassium containing super absorbent resin by utilizing the carboxymethyl sunflower disc is characterized by comprising the following steps: mixing a certain amount of sodium hydroxide solution with sunflower disc powder in a three-opening bottle, soaking, so that the sunflower disc is fully swelled; dropwise adding the sodium hydroxide solution into the mixture, stirring for 1 hour in a water bath kettle at the temperature of 30 DEG C, then dropwise adding a sodium monochloroacetate solution in reaction mixture, carrying out reaction for 2 hours, then pouring the mixture after reaction is finished into a stainless steel disc, carrying out reaction in a drying oven, washing with 70% ethyl alcohol after drying is finished, then drying, and smashing, so that the carboxymethyl sunflower disc is obtained; uniformly mixing acrylic acid and potassium acrylate, acrylamide, the carboxymethyl sunflower disc, potassium persulphate, N,N'-methylene bisacrylamide and deionized water, protecting by adopting nitrogen, heating in water bath and stirring, stopping stirring at a polymerization temperature, continuously heating, insulating and carrying out reaction for 2 hours in boiling water bath, stopping introduction of nitrogen, taking out reactants, placing the reactants into a blast drying oven at the temperature of 40-60 DEG C to be dried to constant weight, and smashing, so that the nitrogen and potassium containing super absorbent resin product is obtained.

Owner:INNER MONGOLIA UNIVERSITY

A chemical looping combustion oxygen carrier and its application method

ActiveCN106367156BHigh reactivityImprove mechanical propertiesFluidized bed combustionIndirect carbon-dioxide mitigationResource recoveryActive component

The invention discloses a chemical looping combustion oxygen carrier, which is characterized in that the chemical looping combustion oxygen carrier is sintering return mine comprising an active component being alpha-Fe2O3 with the mass percent of 60 to 80 percent, and inert components comprising the following ingredients in mass percent: 10 to 15 percent of CaO, 0 to 2 percent of Al2O3, 5 to 15 percent of SiO2, and the balance of impurities. The oxygen carrier (sintering return mine) in the invention has favorable reactivity and mechanical property, is sintered ore which is not sinter molded at a sintering workshop section in the metallurgical industry, and can be applied in a chemical looping combustion system for realizing resource recovery and recycle; according to a method, the sintering return mine in the metallurgical industry is used as the oxygen carrier in the chemical looping combustion system, has favorable reactivity and mechanical property, and is low in cost, rich in inventory, and beneficial to be applied in actual industrial production.

Owner:GUIZHOU INST OF TECH

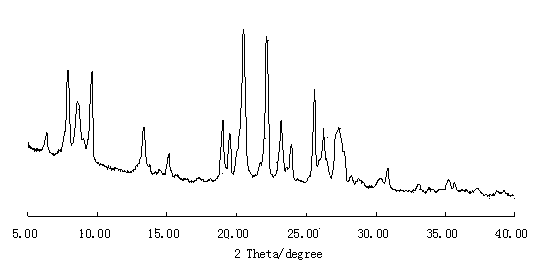

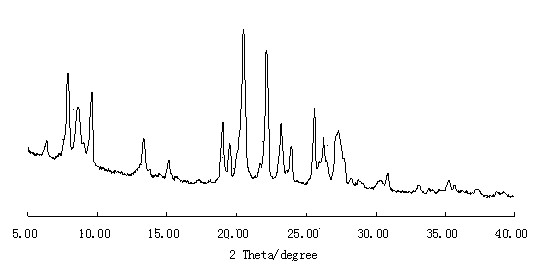

Synthesis method of furan [3, 2-b] pyridine derivative

ActiveCN114213424AGenerally low yieldLow yieldOrganic chemistryBulk chemical productionFuranWittig reaction

The invention discloses a synthesis method of a furan [3, 2-b] pyridine derivative, which comprises the following steps: refluxing a substance as shown in a formula (I) and triphenylphosphine in a solvent, cooling and filtering to obtain a compound as shown in a formula (II); carrying out Wittig reaction on the compound shown in the formula (II) and formate under the action of alkali to obtain a compound shown in a formula (III); and performing cyclization reaction on the compound represented by the formula (III) under an acidic condition to obtain a compound represented by a formula (IV). The method disclosed by the invention is convenient to operate, simple in process, simple and easily available in raw materials and low in cost, and is suitable for small-scale preparation in a laboratory and industrial production.

Owner:GUANGZHOU GAOLING PHARMA CO LTD

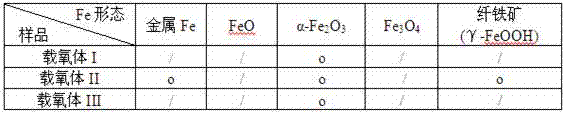

Preparation method of gabapentin acetate

PendingCN113929751AHigh synthesis costPromote decompositionLuteinising hormone-releasing hormonePeptide preparation methodsGabapentinEthylic acid

The invention discloses a preparation method of gabapentin acetate. The preparation method comprises the following steps of: 1) coupling amino resin with amino acid to obtain linear peptide resin; 2) performing acetylation reaction on the linear peptide resin obtained in the step 1); 3) cracking the linear peptide resin obtained after the acetylation reaction in the step 2) to obtain linear peptide; 4) modifying the linear peptide in the step 3) with ethylamino-1H-pyrazole under an alkaline condition to obtain crude gabapentin acetate peptide; and 5) purifying the crude gabapentin acetate peptide. According to the preparation method, the use of Fmoc-HArg (Et) 2-OH and Fmoc-D-HArg (Et) 2-OH which are high in synthesis cost and easy to decompose as raw materials is avoided, and the defects that the reaction time is long, the operation is complicated and the purity of the obtained crude peptide is not high due to the fact that alkali needs to be continuously added to adjust the pH to 7.5-10.5 for reaction in the reaction process are overcome.

Owner:HYBIO PHARMA

Method for preparing nitrogen- and potassium-containing superabsorbent resin from carboxymethyl sunflower disc

The invention discloses a method for preparing a nitrogen- and potassium-containing superabsorbent resin from carboxymethyl sunflower discs, which is characterized in that: a certain amount of sodium hydroxide solution and sunflower disc powder are mixed in a three-necked bottle, soaked to fully swell the sunflower discs; Add sodium hydroxide solution dropwise to the mixture, stir in a water bath at 30°C for 1 hour, then add sodium chloroacetate solution dropwise to the reaction mixture, react for 2 hours, then pour it into a stainless steel plate and react in an oven, dry it with 70 % ethanol, then dried and crushed to obtain carboxymethyl sunflower discs. Mix acrylic acid and its potassium salt, acrylamide, carboxymethyl sunflower disc, potassium persulfate, N,N′-methylene bisacrylamide and deionized water evenly, protect with nitrogen, heat and stir in a water bath, when the polymerization temperature is reached Stop stirring, continue heating, keep the reaction in a boiling water bath for 2 hours, stop nitrogen flow, take out the reactant, put it in a blast oven at 40°C-60°C and dry it to constant weight, crush it to get the product.

Owner:INNER MONGOLIA UNIVERSITY

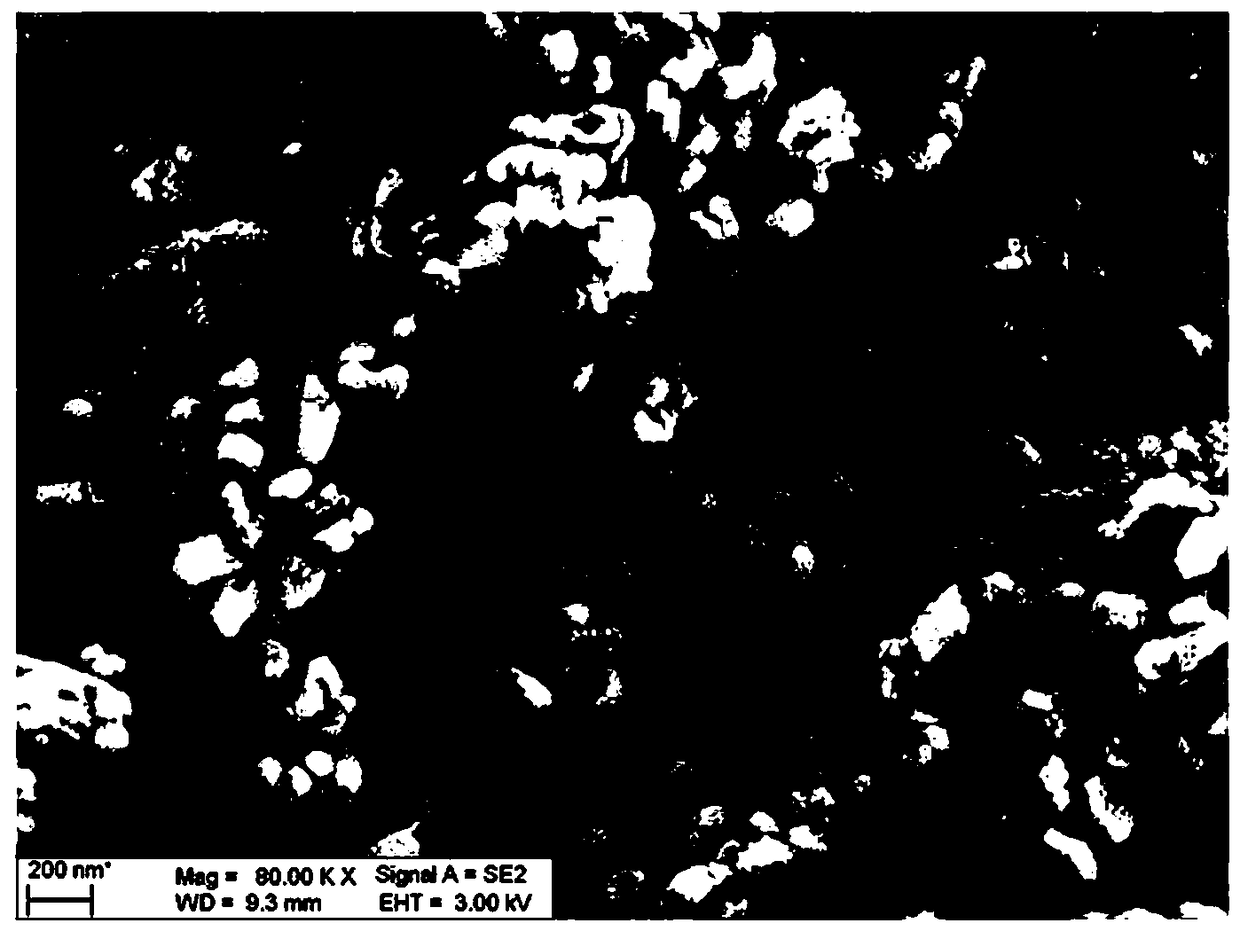

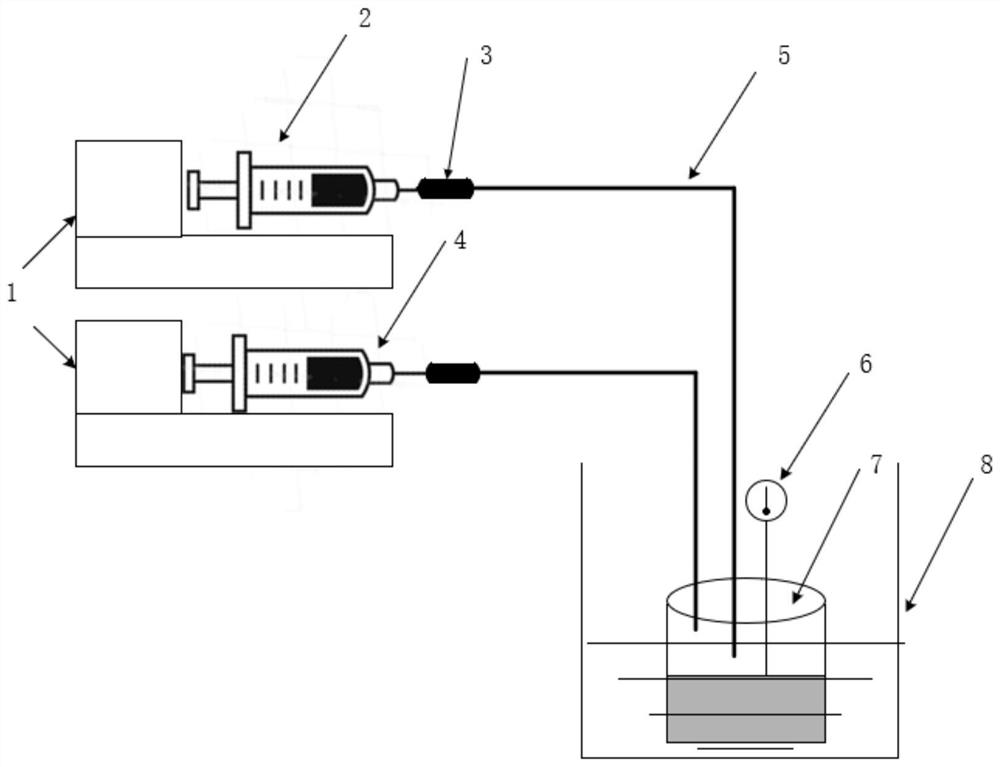

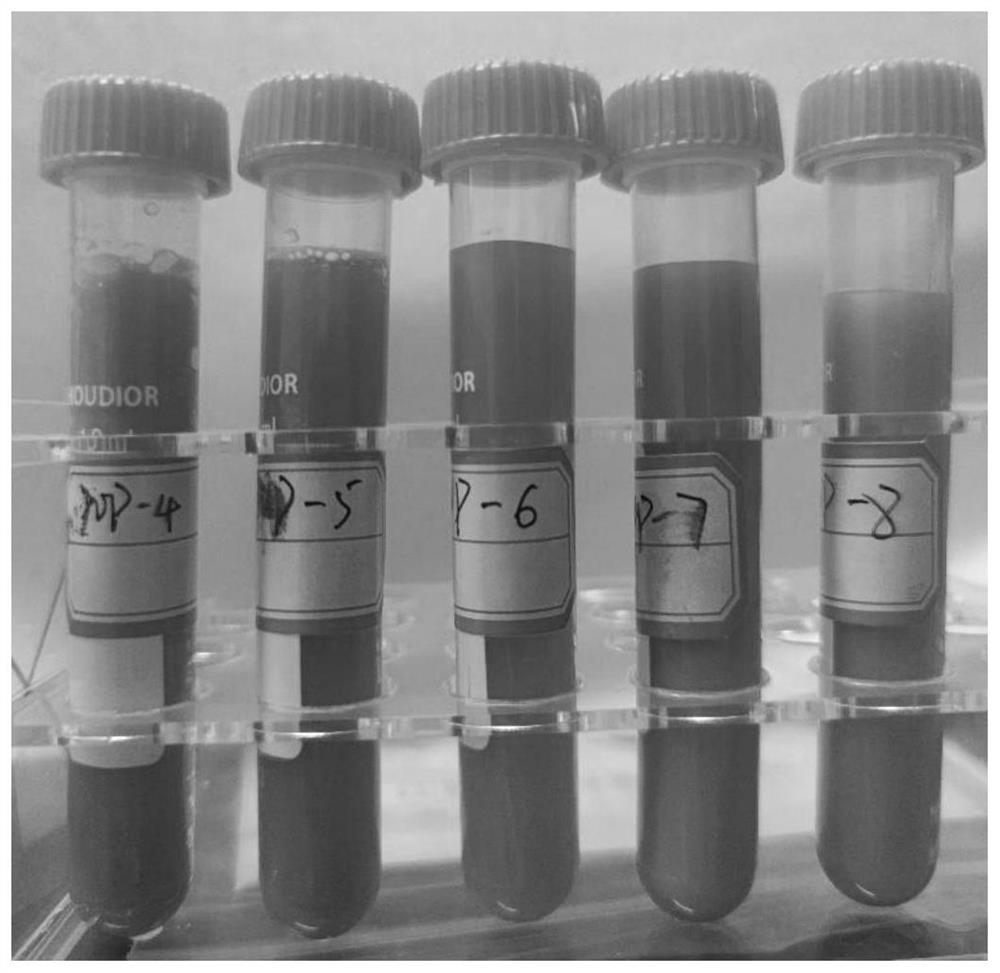

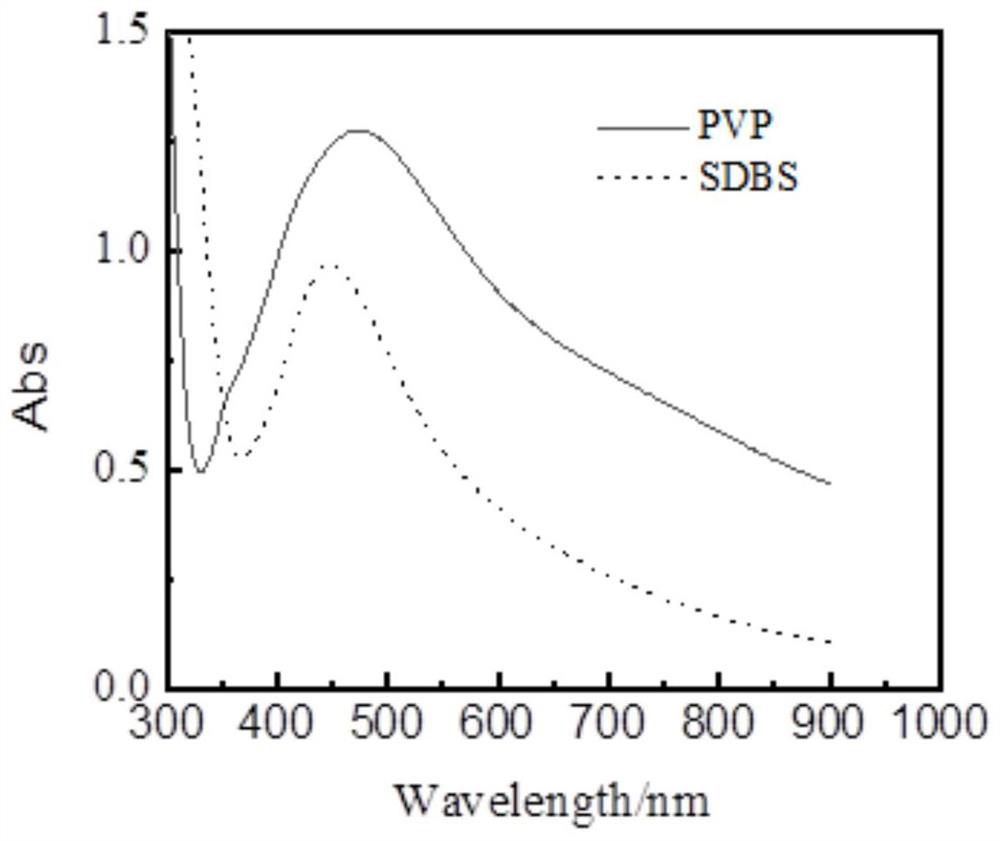

Device and method for synthesizing silver-copper alloy nanofluid

ActiveCN113828789ALow costSolve the shortcomings of easy oxidationMaterial nanotechnologyCooling/ventilation/heating modificationsNanofluidCopper metal

The invention discloses a device and a method for synthesizing a silver-copper alloy nanofluid, and belongs to the technical field of nanofluid preparation. The device and the method for synthesizing the silver-copper alloy nanofluid solves the problems that a traditional heat exchange working medium cannot meet the heat exchange requirement of extremely high heat, a nanofluid preparation method basically requires a high-temperature and high-pressure environment and a toxic reducing agent, and common metal nanoparticles are prone to oxidation. The preparation process is simple to operate, ascorbic acid is used as a reducing agent, and the method is safe to operate and environment-friendly; and in the aspect of particle selection, silver and copper metals with high heat conductivity coefficients are selected, so that the heat conductivity of the base solution can be improved to the maximum extent, the problem that the metals are easy to oxidize can be better solved by dispersing the silver and copper metals in the base solution in an alloy form, and the nano-fluid particles prepared by the preparation method are uniform in particle distribution, have the particle size of 60-90 nm and are good in heat-conducting property.

Owner:BEIJING UNIV OF TECH

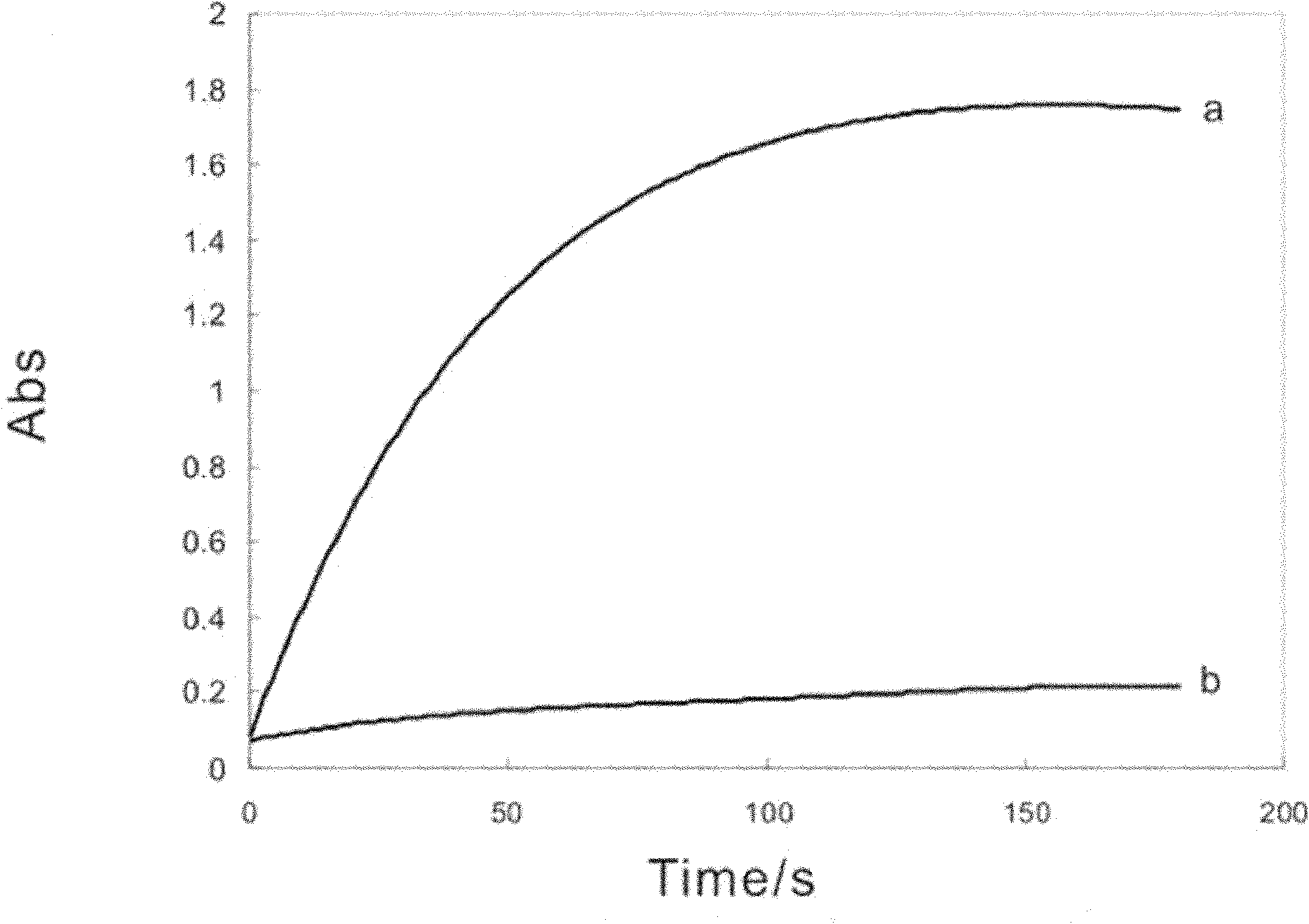

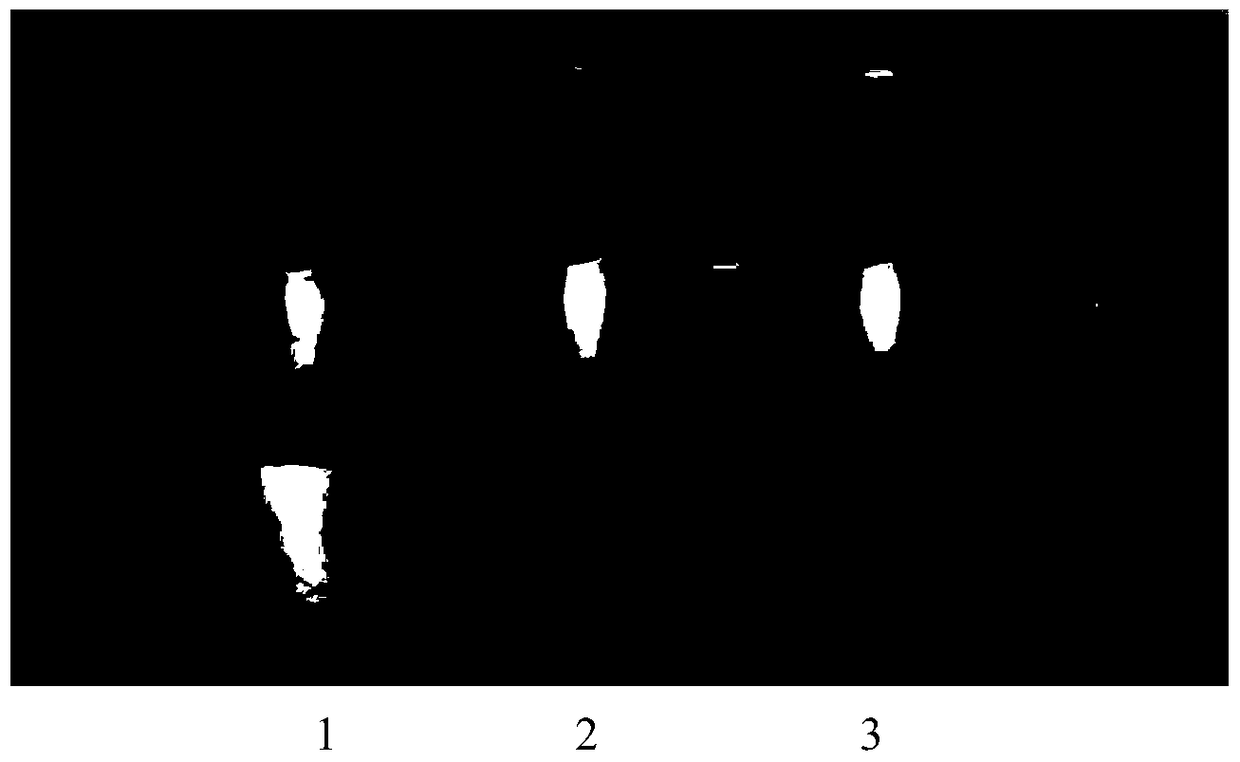

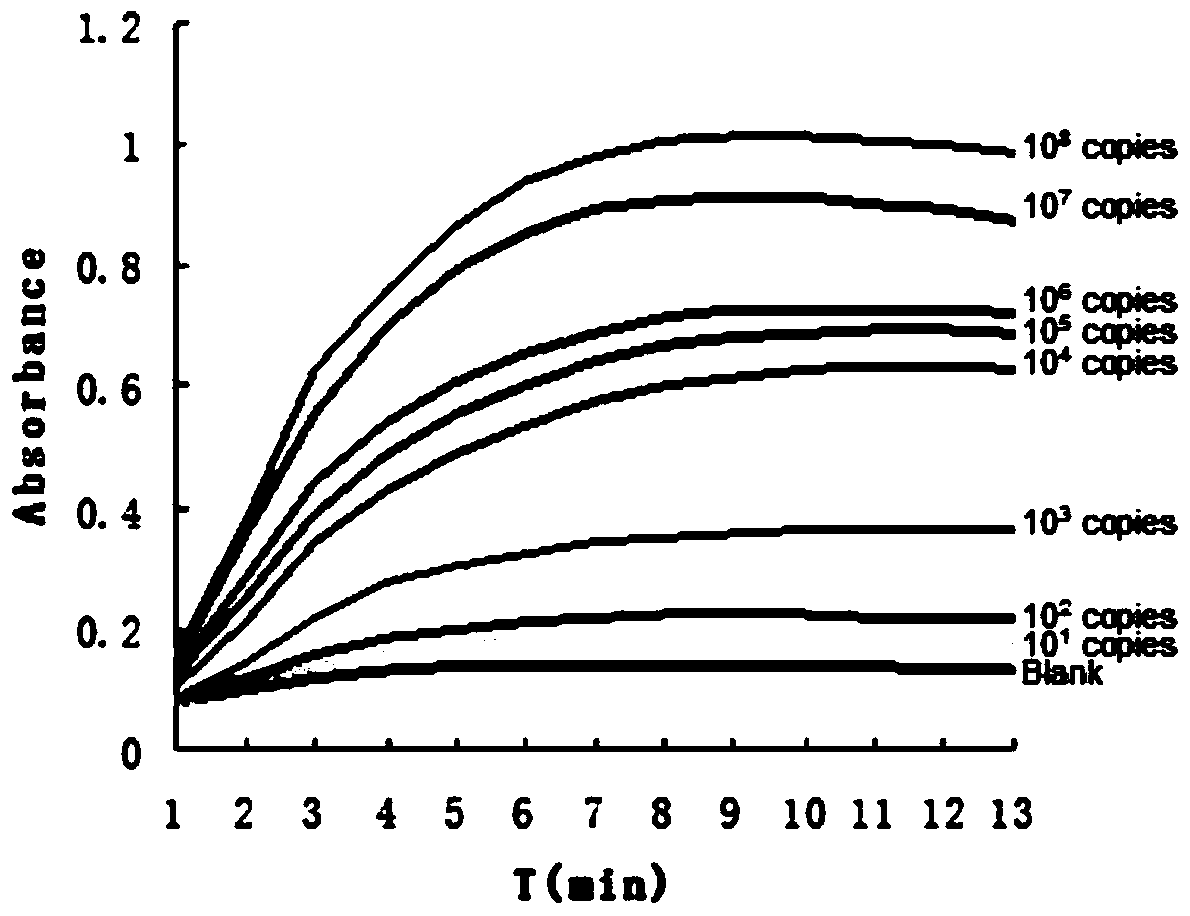

A detection method for hepatitis B virus based on dnazyme probe

ActiveCN103952497BAvoid pollutionGood heartbeatMicrobiological testing/measurementMicroorganism based processesHepatitis B virus DNAHepatitis B virus

The invention belongs to the technical field of molecular biology and discloses a method for qualitatively and quantitatively detecting hepatitis B virus DNA by using a DNAzyme probe. Aiming at the limitations of the prior art, the present invention uses PCR amplification as a detection platform, and realizes one-step qualitative and quantitative detection of hepatitis B virus by introducing a 3'-amino-modified DNAzyme probe. The technology has the advantages of high sensitivity, strong specificity, wide detection linear range, low cost, high accuracy, and convenient operation, and provides a simple, fast, accurate, efficient, economical and practical detection method for hepatitis B virus.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

Preparation process of a pollution-free and low-cost lithium manganese iron phosphate crystal material

ActiveCN108408709BImprove the level ofWidely sourced, non-toxic and cheapCell electrodesPhosphorus compoundsO-Phosphoric AcidLithium hydroxide

The invention discloses a process for preparing a pollution-free and low-cost lithium manganese iron phosphate crystal material, which is completed through the following steps: select iron powder and manganese powder with high purity, and the particle size is selected between 20 mesh and 20000 mesh; according to a certain quality Select manganese powder, iron powder, phosphoric acid and lithium source solution, after dilution, put them in an acid-resistant reactor and stir to fully react iron powder, manganese powder and phosphoric acid; add lithium source solution to the obtained reaction precursor slurry and stir well , the selected lithium source solution is a soluble lithium source lithium hydroxide or lithium acetate; the obtained slurry is transferred into the reactor to start the hydrothermal reaction; the obtained slurry after the reaction is subjected to solid-liquid separation, and the separated solid lithium manganese iron phosphate Carry out clathrate carbonization annealing treatment, prepare lithium manganese iron phosphate crystal material. Compared with the prior art, the invention has lower cost and convenient process operation, and not only the manufactured lithium manganese iron phosphate crystal material has higher commercial value, but also has no pollution in the manufacturing process and meets the current environmental protection requirements.

Owner:南阳逢源新能源科技有限公司

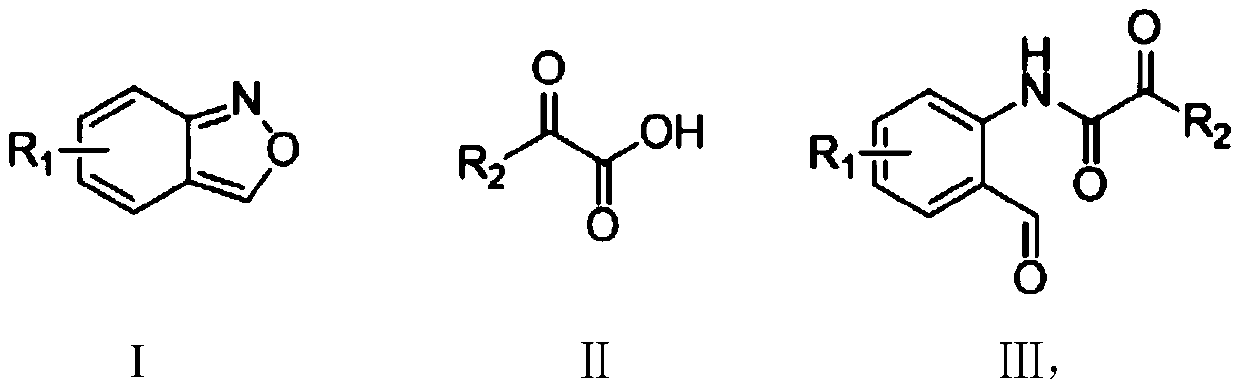

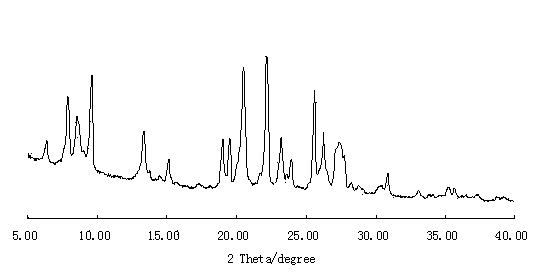

A kind of preparation method of aromatic cyclo[b]thiophene-3(2h)-one-1,1-dioxide

ActiveCN109293626BHigh reaction yieldHigh synthesis costOrganic chemistryBiochemical engineeringReaction rate

The invention provides a method for preparing aromatic ring[b]thiophene-3(2H)-one-1,1-dioxide, the method is: reacting the compound shown in formula I with an oxidizing agent to obtain the aromatic compound Cyclo[b]thiophene-3(2H)-ketone-1,1-dioxide; the present invention also provides the preparation method of the compound shown in formula I; the preparation method provided by the present invention has high reaction yield and fast reaction speed Fast, easy to obtain raw materials, low cost, mild reaction, easy to control, simple post-processing, very little waste generated, and low pollution. Large and low yield, the method provided by the invention provides a feasible synthetic route for green chemical industry, and has high production and application value.

Owner:JINAN SHAOYUAN MEDICAL TECH +1

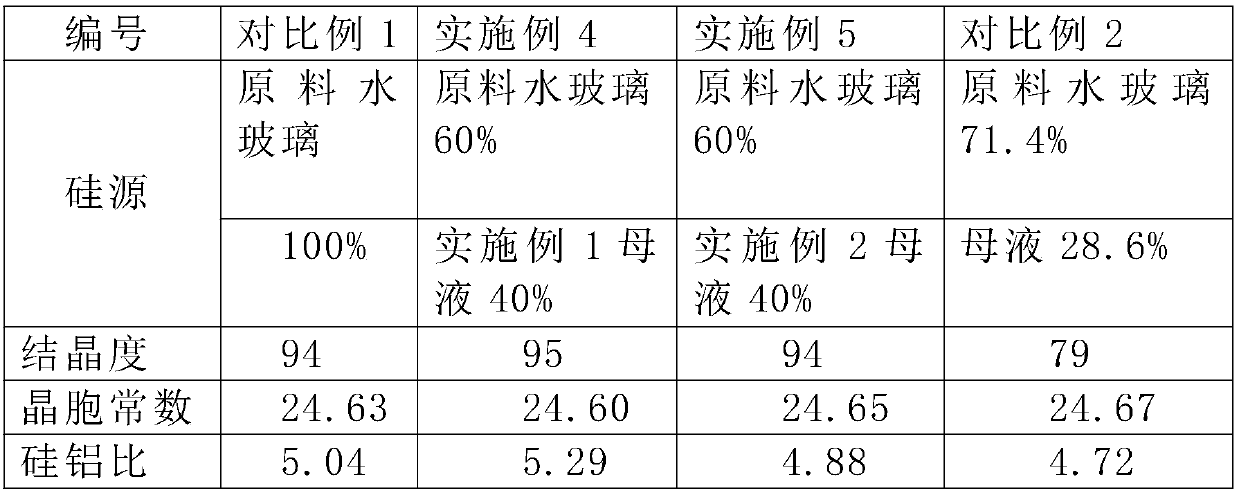

Method for preparing NaY molecular sieve by recycling NaY mother liquor

PendingCN111320184AHigh synthesis costReduce utilizationFaujasite aluminosilicate zeoliteMolecular sieveInorganic Syntheses

The invention provides a method for preparing a NaY molecular sieve by recycling a NaY mother liquor, and belongs to the technical field of inorganic synthesis. The method solves the technical problems of low NaY mother liquor recycling rate, large pollution, high utilization cost and the like in the prior art. The synthesis method comprises the following steps: (1) stirring NaY mother liquor until the NaY mother liquor is uniform; (2) slowly adding a metered supplementary silicon source into the mother liquor according to the modulus of 3.0-3.4 until the supplementary silicon source is completely dissolved in the pulped NaY mother liquor, and controlling the temperature of the mixture of the NaY mother liquor and the supplementary silicon source to be 30-80 DEG C in the dissolving processto obtain high-modulus recycled water glass; and (3) synthesizing the NaY molecular sieve by utilizing the recycled water glass obtained in the step (2) according to a gel method. According to the method, the NaY mother liquor can be completely recycled, and the pollution of waste liquor and waste residues to the environment is reduced.

Owner:湖北赛因斯科技开发有限公司

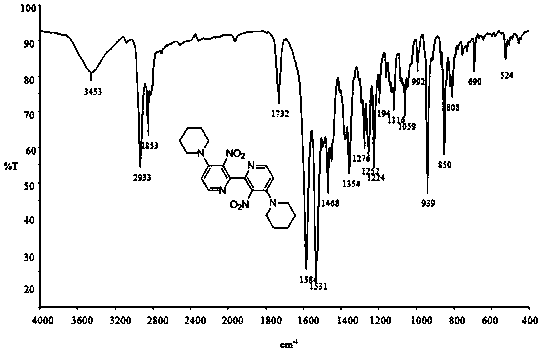

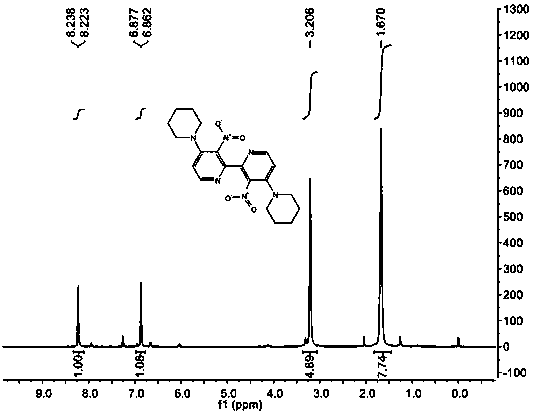

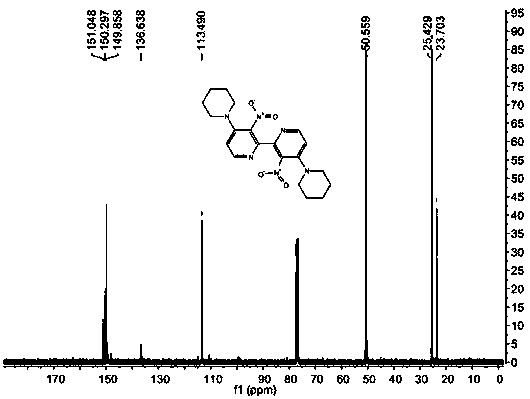

Bipyridine derivative with substituted multiple functional groups and method for preparing bipyridine derivative

The invention belongs to the field of organic chemistry, and particularly relates to a method for preparing a bipyridine derivative with substituted multiple functional groups. The method includes mixing halogenated pyridine derivatives and activated copper powder with one another to obtain first mixtures, carrying out reflux cooling, adding ammonia water into the first mixtures to obtain second mixtures, filtering, abstracting and extracting the second mixtures, combining organic phases with one another, drying the organic phases, and carrying out chromatographic purification by the aid of silica columns to obtain the bipyridine derivative (shown as a formula I) with the substituted multiple functional groups; dissolving products shown as the formula I in methanol, sequentially adding ferric trichloride and activated carbon into the methanol to obtain third mixtures and carrying out heating reflux for 10 minutes; adding hydrazine hydrate into the third mixtures to obtain fourth mixtures, carrying out reflux, filtering the fourth mixtures while the fourth mixtures are hot, washing the fourth mixtures, combining organic phases with one another, drying the organic phases and carrying out chromatographic purification by the aid of silica columns to obtain products shown as a formula II. The method has the advantages that coupling reaction is carried out under the catalytic effect of copper, and accordingly the bipyridine derivative with the substituted multiple functional groups can be efficiently synthesized; the method is simple and is important supplement to existing pyridine coupling reaction, and the obtained bipyridine derivative with substituted electron withdrawing groups further can be converted into a bipyridine derivative with substituted electron donating group amino.

Owner:FUZHOU UNIVERSITY

A kind of simultaneous denitrification and dephosphorization adsorbent and its preparation method and application

ActiveCN106111055BSolve the problem of nitrogen and phosphorus removalWide variety of sourcesOther chemical processesAluminium silicatesPhosphateSorbent

Owner:JINGDEZHEN CERAMIC UNIV

A kind of method for preparing porous cerium oxide catalytic material

ActiveCN108355639BEfficient conversionImprove conversion efficiencyPreparation by oxidation reactionsOrganic compound preparationPorosityCerium

The present invention relates to catalytic material preparation technology, and aims to provide a method for preparing porous cerium oxide catalytic materials. It includes: using cerium salts, cerium salt hydrates or cerium salt aqueous solutions as precursors, using lipid polymers generated in situ from organic acids and alcohols as foaming agents, and performing foaming treatment: using the precursor, water, as The ethanol of the solvent, the organic acid and the alcohol used for the esterification reaction with the acid are mixed and stirred evenly, and then heated and stirred at 50 to 170°C until it is gel-like and foaming; the foamed viscosity is The thick colloidal material is dried and roasted to obtain porous cerium oxide catalytic material. The volume of the porous cerium oxide aerogel with high porosity prepared by the present invention can reach more than 20 times the volume of commercially purchased cerium oxide. Using it to activate the C–H bonds of alkanes has excellent oxidation effects and can achieve solvent-free and efficient conversion of toluene. The synthesis process of the material is simple and low-cost.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesis method of furan [3, 2-b] pyridine derivative Synthesis method of furan [3, 2-b] pyridine derivative](https://images-eureka.patsnap.com/patent_img/920ca166-a3c7-4292-83cb-8fa61251c415/HDA0003446451950000011.png)

![Synthesis method of furan [3, 2-b] pyridine derivative Synthesis method of furan [3, 2-b] pyridine derivative](https://images-eureka.patsnap.com/patent_img/920ca166-a3c7-4292-83cb-8fa61251c415/HDA0003446451950000012.png)

![Synthesis method of furan [3, 2-b] pyridine derivative Synthesis method of furan [3, 2-b] pyridine derivative](https://images-eureka.patsnap.com/patent_img/920ca166-a3c7-4292-83cb-8fa61251c415/HDA0003446451950000021.png)

![A kind of preparation method of aromatic cyclo[b]thiophene-3(2h)-one-1,1-dioxide A kind of preparation method of aromatic cyclo[b]thiophene-3(2h)-one-1,1-dioxide](https://images-eureka.patsnap.com/patent_img/451efade-c1b8-4604-8c1c-1e65302b7e70/BDA0001836754040000021.png)

![A kind of preparation method of aromatic cyclo[b]thiophene-3(2h)-one-1,1-dioxide A kind of preparation method of aromatic cyclo[b]thiophene-3(2h)-one-1,1-dioxide](https://images-eureka.patsnap.com/patent_img/451efade-c1b8-4604-8c1c-1e65302b7e70/BDA0001836754040000031.png)

![A kind of preparation method of aromatic cyclo[b]thiophene-3(2h)-one-1,1-dioxide A kind of preparation method of aromatic cyclo[b]thiophene-3(2h)-one-1,1-dioxide](https://images-eureka.patsnap.com/patent_img/451efade-c1b8-4604-8c1c-1e65302b7e70/BDA0001836754040000041.png)