A kind of simultaneous denitrification and dephosphorization adsorbent and its preparation method and application

A technology for simultaneous denitrification and dephosphorization, and adsorbents. It is applied in chemical instruments and methods, adsorbed water/sewage treatment, and other chemical processes to achieve the effects of no secondary pollution, low price, and a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

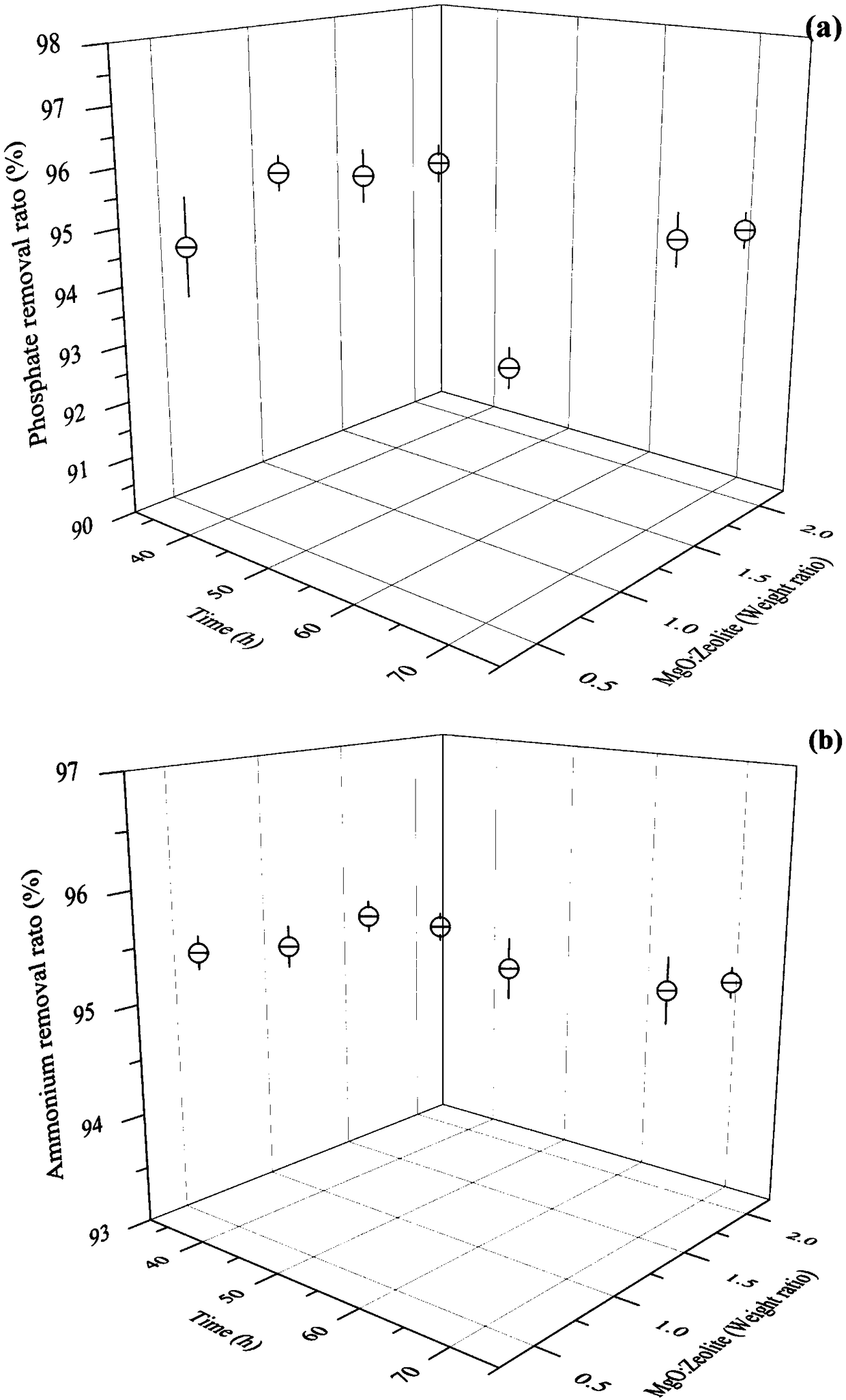

[0040] Take simulated wastewater with a phosphate concentration of 50mg / L.

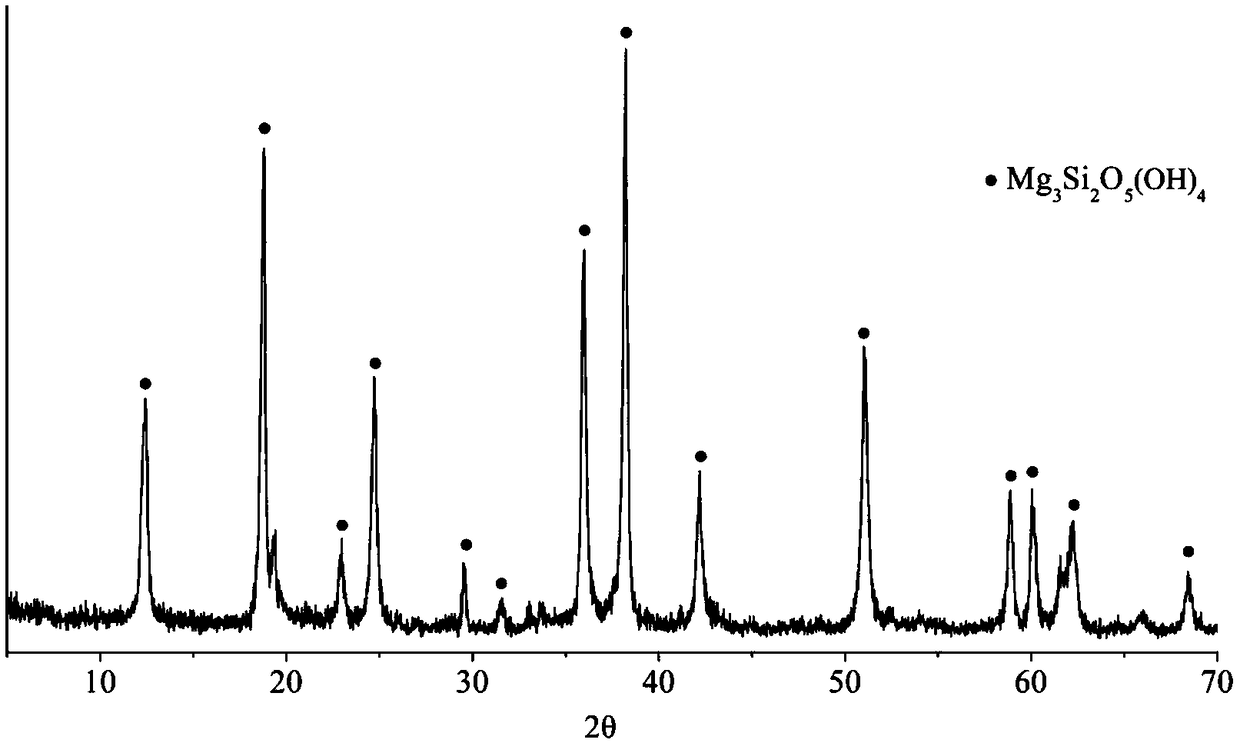

[0041] A kind of simultaneous denitrification and dephosphorization adsorbent of this embodiment comprises the calcined product of magnesite powder and zeolite powder, and its preparation steps are:

[0042] (1) Crushing the magnesite ore and passing through a 100-mesh sieve, taking the under-sieve and calcining at 600°C for 4 hours to obtain a calcined product of magnesite powder; crushing and grinding the zeolite, and passing through a 100-mesh sieve to obtain zeolite powder;

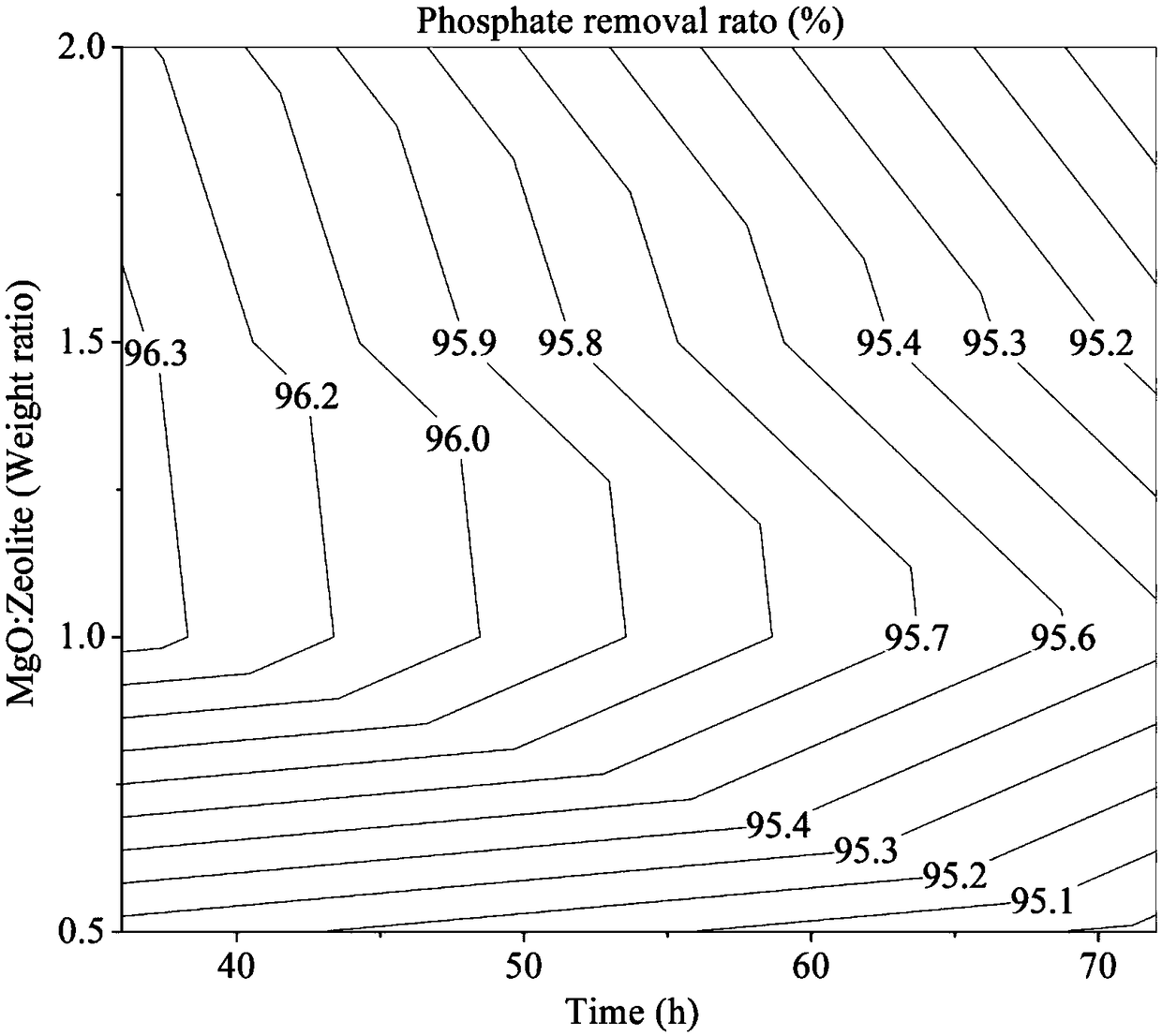

[0043] (2) Step (1) The weight ratio of the calcined product to the zeolite powder is 0.5-2:1. After mixing in water, the hydrothermal method is synthesized at 200°C for 36-72 hours, then cooled, and centrifuged to obtain the synthesized product. Simultaneous nitrogen and phosphorus removal adsorbent.

[0044] The application of a kind of simultaneous denitrification and dephosphorization adsorbent in this embodiment, the st...

Embodiment 2

[0049] Application of a simultaneous denitrification and phosphorus removal adsorbent in this embodiment in domestic sewage treatment:

[0050] Take simulated domestic sewage, the concentration of phosphate is 50mg / L, and the concentration of ammonia nitrogen is 20mg / L.

[0051] A kind of simultaneous denitrification and dephosphorization adsorbent of this embodiment and its preparation method and application, its steps are:

[0052] (1) crush the magnesite ore and pass through a 100-mesh sieve, take the under-sieve and calcinate at 1000°C for 1 hour to obtain a calcined product; crush and grind the zeolite, and pass through a 100-mesh sieve to obtain zeolite powder;

[0053] (2) Step (1) The weight ratio of the calcined product to the zeolite powder is 0.5 to 2:1. After mixing, ball milling is carried out first. The ball milling time is 30min, and the speed is 300r / min; , synthesized by hydrothermal method for 36-72 hours, then cooled, centrifuged and filtered to obtain the ...

Embodiment 3

[0060] The application of a simultaneous denitrification and phosphorus removal adsorbent in this embodiment in the treatment of chemical wastewater:

[0061] Take the simulated chemical wastewater, the concentration of phosphate is 50mg / L, and the concentration of ammonia nitrogen is 20mg / L.

[0062] A kind of simultaneous denitrification and dephosphorization adsorbent of this embodiment and its preparation method and application, its steps are:

[0063] (1) crush the magnesite ore and pass through a 100-mesh sieve, take the under-sieve and calcinate at 800°C for 3 hours to obtain a calcined product; crush and grind the zeolite, and pass through a 100-mesh sieve to obtain zeolite powder;

[0064] (2) Step (1) The weight ratio of the calcined product to the zeolite powder is 1:1, and ball milling is carried out after mixing, the ball milling time is 90min, and the rotating speed is 100r / min; Synthesize by thermal method for 50h, then cool down, and centrifuge to filter to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com