Device and method for synthesizing silver-copper alloy nanofluid

A nanofluid, silver-copper alloy technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of high risk factor of reducing agent, difficulty in large-scale production, difficulty in dispersing particles, etc. , to achieve the effect of solving the shortcomings of easy oxidation, excellent optics, and uniform particle distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

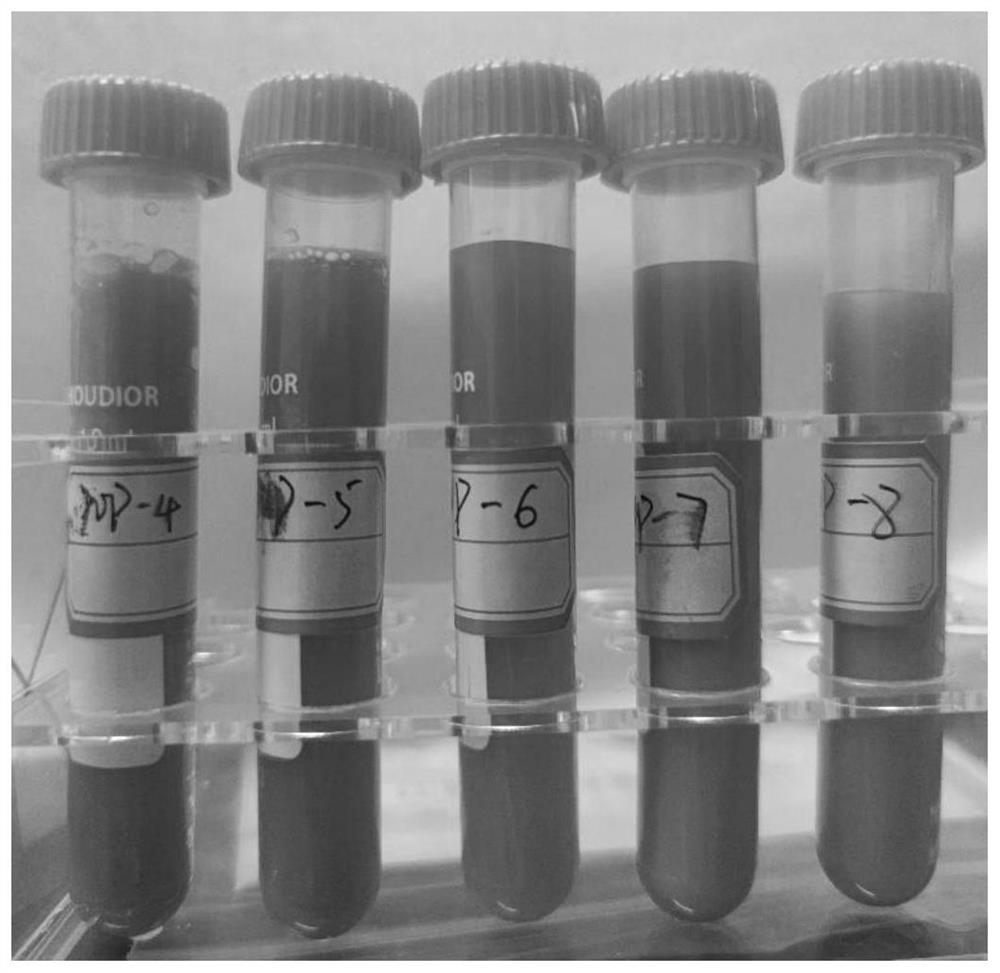

[0034]Embodiment 1 (total concentration of copper and silver is 12mmol / L)

[0035] (1) weigh silver acetate and 0.075g copper sulfate, 0.333g polyvinylpyrrolidone (the quality of PVP is calculated by monomer molecular weight) with precision balance (according to Ag + and Cu 2+ The ratio of the concentration of the substance to PVP is 1:5), 0.528g and 0.1056g of ascorbic acid, pour the PVP powder into 50ml of deionized water and stir to make a PVP aqueous solution, and then put the copper acetate particles and copper sulfate particles in turn. into the PVP aqueous solution, stirred and ultrasonically oscillated for 20 minutes, respectively dissolved ascorbic acid in 50 ml of deionized water as a reducing agent solution, and stirred for 15 minutes.

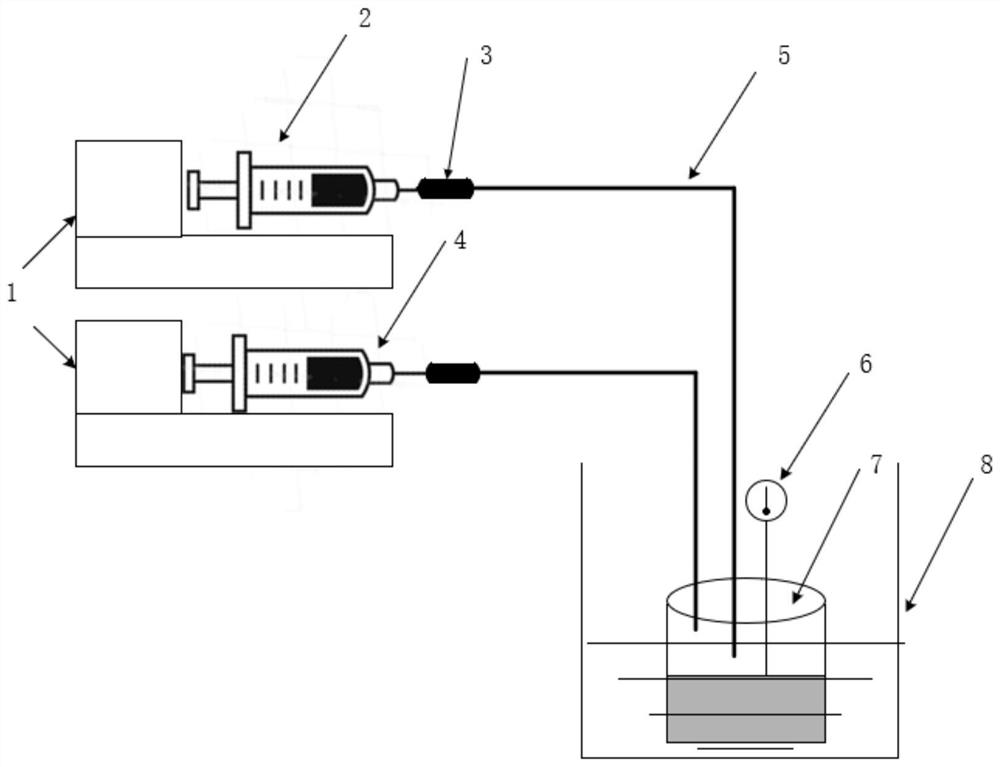

[0036] (2) Take 20ml of precursor solution and reductant replenishment solution and load them on two micro-syringes respectively and fix them on the syringe pump with clips, place the beaker containing 20ml of reductant solution in...

Embodiment 2

[0038] Embodiment 2 (total concentration of copper and silver is 10mmol / L)

[0039] (1) weigh silver acetate and 0.0625g copper sulfate, 0.2775g polyvinylpyrrolidone (the quality of PVP is calculated by monomer molecular weight) with precision balance (according to Ag + and Cu 2+ The ratio of the concentration of the substance to PVP is 1:5), 0.44g and 0.088g ascorbic acid, pour the PVP powder into 50ml of deionized water and stir to make a PVP aqueous solution, and then put the copper acetate particles and copper sulfate particles in turn. into PVP aqueous solution, stirred and ultrasonically oscillated for 20 minutes, dissolved ascorbic acid in 50 ml of deionized water as reducing agent solution and reducing agent replenishing solution, and stirred for 15 minutes.

[0040] (2) As in step (2) of Example 1, the reaction system was assembled.

[0041] (3) The silver-copper alloy nanofluid was synthesized as in step (3) of Example 1.

Embodiment 3

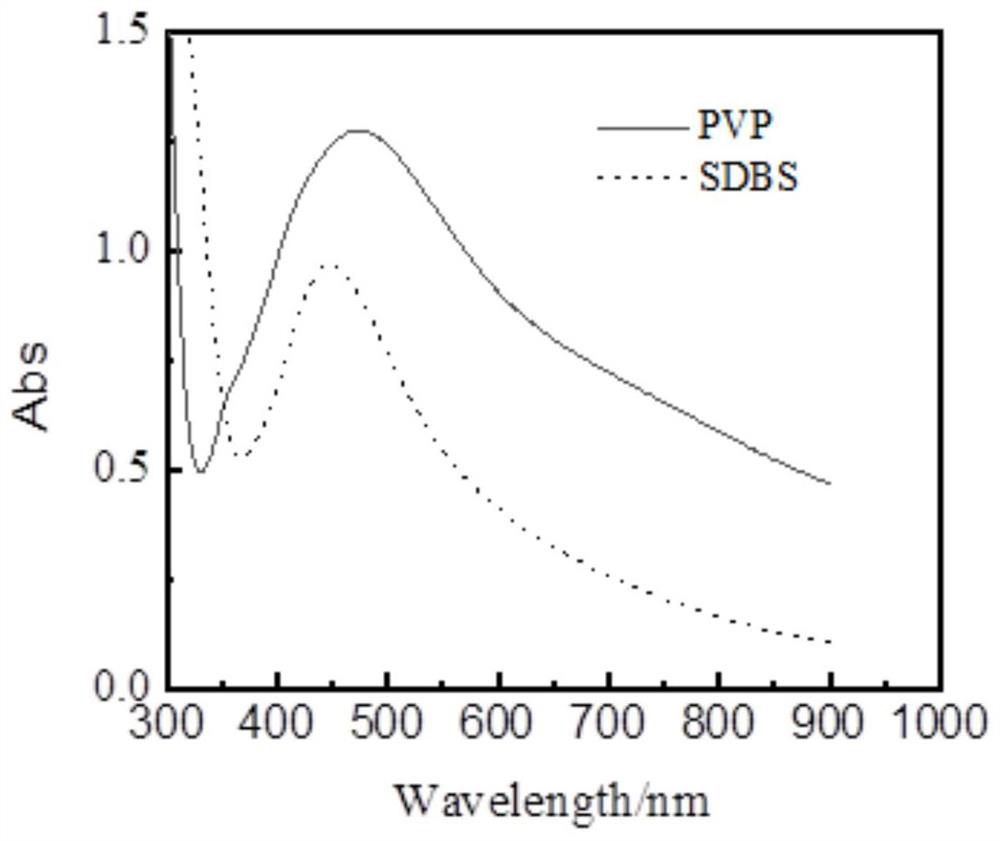

[0042] Embodiment 3 (total concentration of copper and silver is 12mmol / L, and surfactant is SDBS)

[0043] (1) Use a precision balance to weigh silver acetate and 0.075g copper sulfate, 0.2091g SDBS (according to Ag + and Cu 2+ The ratio of the concentration of the substance to SDBS is 1:3), 0.528g and 0.1056g ascorbic acid, the SDBS powder is poured into 50ml of deionized water and stirred to make an SDBS aqueous solution, and then the copper acetate particles and the copper sulfate particles are placed in turn into SDBS aqueous solution, stirred and ultrasonically oscillated for 20 min, and ascorbic acid was dissolved in 50 ml of deionized water respectively as reducing agent solution and reducing agent replenishing solution, and stirred for 15 min.

[0044] (2) As in step (2) of Example 1, the reaction system was assembled.

[0045] (3) The silver-copper alloy nanofluid was synthesized as in step (3) of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com