Method for preparing NaY molecular sieve by recycling NaY mother liquor

A technology of molecular sieve and mother liquor, applied in the direction of octahedral crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve problems such as unsatisfactory, low silicon content, and non-reusable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

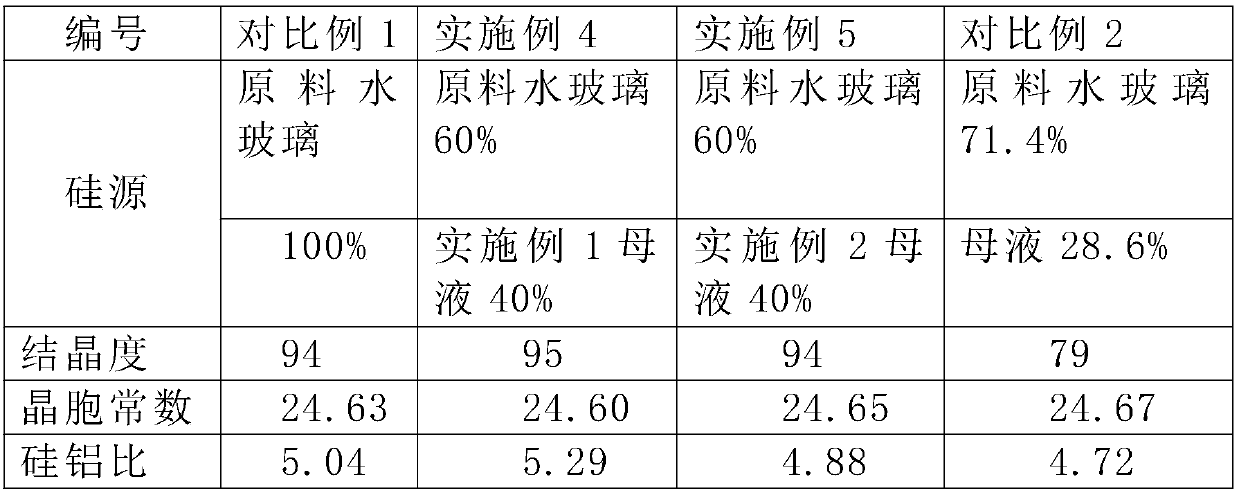

Examples

Embodiment 1

[0020] The present embodiment prepares the water glass of modulus 3.0 by utilizing NaY mother liquor.

[0021] Get 8 liters of industrial NaY mother liquor (Hubei Saiyin Chemical Co., Ltd., specific gravity 1.113, SiO 2 Content 56.1 g / L, Na 2 O content 27.2 grams / liter, modulus 2.13), stir, slowly add precipitated hydrated silica (Zhuzhou Xinglong New Material Co., Ltd., specific surface 170m 2 / g, SiO 2 97.6, PH value 6.8) 182.8 grams, spare.

Embodiment 2

[0023] Present embodiment is to prepare the water glass of modulus 3.2 with mother liquor.

[0024] Get industrial NaY mother liquor 8 liters (same as embodiment 1), stir, slowly add precipitation hydrated silicon dioxide (same as embodiment 1) 225.2 grams, for subsequent use.

Embodiment 3

[0026] This example is the synthesis of the directing agent, which provides the directing agent for the subsequent NaY synthesis. The molar ratio is Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=16:1:15:320. The directing agent can be prepared by the method disclosed in US3639099.

[0027] Water glass 2098ml (produced by Hubei Saiyin Chemical Co., Ltd., SiO 2 274.51 grams per liter, modulus 3.04), stir, add chemical water 280ml, slowly add high alkali sodium metaaluminate solution 1466ml (produced by Hubei Saiyin Chemical Co., Ltd., Na 2 O301 g / l, Al 2 o 3 44.53 g / L, Na 2 O / Al 2 o 3 =6.76), stirred for 30 minutes, and aged statically. Stop forming until the directing agent becomes turbid, and the aging time is 20 hours. The specific gravity of the directing agent is 1.267g / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com